Features waterproof and moisture resistant laminate

In the Soviet years, with massive construction of prefabricated houses, linoleum was laid on the floor almost everywhere in the country. Installation of linoleum floor took less time than laying a Christmas tree parquet. For the price, it was also cheaper than its competitors, and it did not require care. But today, when repairing apartments, this outdated building material is immediately replaced with laminate. What is the reason? We will try to figure it out.

Structure

Laminate as a building material appeared relatively recently. Only at the end of the last century it was presented in one of the European countries. But it very quickly became popular around the world, and the domestic market is no exception. It is laid in the hallways, living rooms, kitchens and bathrooms.He is in demand in a commercial environment.

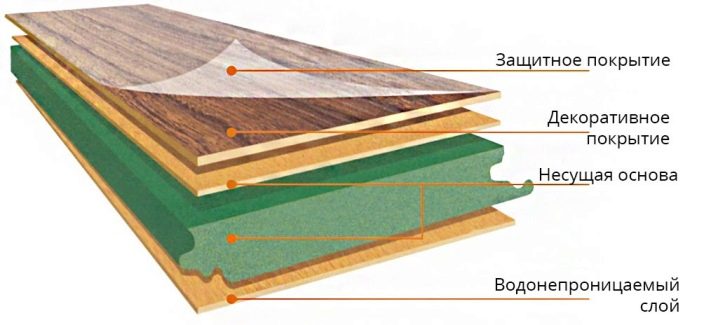

The structure of the laminate consists of four zones, the visible of which is the front. This outer layer itself may consist of several components, the main of which are polyurethane and acrylate. In addition to the protective function - moisture resistance and wear resistance - the film of the outer layer protects against ultraviolet radiation. The decorative layer is responsible for the color and pattern. Usually it is paper with a certain pattern - wood, metal or rocky rocks.

With an individual approach and photo printing is possible.

The next layer is directly the basis of the laminate. Since the base must withstand high loads and constantly be under the "pressure", MDF or high density fibreboard is most often used as a base, less often - glued wood flour, because synthetic resins act as an adhesive, which can release formaldehyde, and this is fraught with at least allergy . Experts do not advise laying cheap laminate in rooms where there are small children. By the way, at first glance, laminate from high-density fibreboard can not be distinguished from solid boards; negligent sales consultants use it, overestimating the cost of such products.

The bottom layer protects the laminate from the concrete slab, so it must be resistant to temperature changes. It is no secret that in summer the concrete heats up, and in the winter it cools down. The fourth layer should also be moisture resistant. Rarely, but other additional layers are used. In some cases, their task is noise absorption, and in some - the ability to take a punch. This is especially important in production, where dropping a heavy device is very easy.

The substrate under the laminate is made of the following materials:

- Styrofoam. It copes well with its task - sound insulation, but over the years it is deformed and sags. Allows you to hide the unevenness of the floor.

- PE foam. Differs democratic value, which implies a short period of operation. But at the same time it is moisture resistant and is not damaged by microorganisms.

- Bung. Expensive material that hides the unevenness of the floor. Undesirable use in rooms with high humidity.

Specifications

The width and length of the laminate depends on the manufacturer. For domestic needs, as a rule, a board is about 130 cm long. This laminate is very convenient to lay, unlike a board of great length, especiallythat under the long laminate need to carefully align the surface. Laminate with a length of 185 cm is different from the usual weight. When buying it, you may have to use the services of loaders. With regards to the width of the laminate, the standard is 19.5 cm. For parquet lovers, laminate of the same size is still being produced, and to imitate tiles there are instances about 30 cm wide. In terms of convenience, it is easier to stack laminate.

But the key parameter of the laminate is its thickness. If it is 6 or 8 mm, then this is the thinnest option. For premises with a high load - if there is heavy furniture or high traffic is present - it is better to use this building material with a thickness of 12 or 14 mm and the main thing is that it is non-slip. Laminate, in which this parameter is equal to 10 mm, is moderately resistant to stress. Older "brothers" wear resistance is higher, there are no traces and dents on them.

Everything else, "thick" laminate practically does not let the noise and retains heat.

Classification

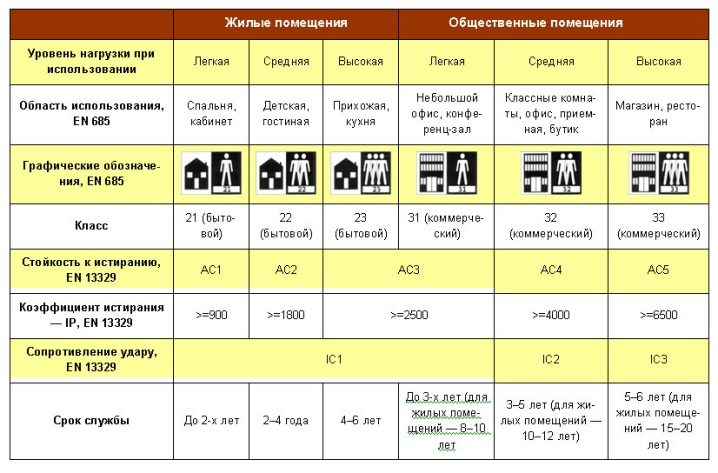

When there is a choice of laminate is very important, it is important to know and be able to read specialized terms printed on its packaging, otherwise there is a high probability of buying unsuitable building materials.Classification for durability implies a guaranteed service life, the density of the board and its ability not to deform under the action of gravity. In the countries of the former Soviet Union, the word “class” has become widespread, in contrast to the countries of the European Union, in which the alphabetic and numeric designations have been introduced. Chinese manufacturers have their own idea about the class of durability, so their labeling only misleads buyers.

In previous times, the life of the most durable laminate was only five years, it was unprofitable for consumers, because they had to change the floor every five years. Now this period is about fifteen years, and with proper care it can be higher.

- Classes from 21 to 23 (in another interpretation - from AC1 to AC3) are intended for rooms with minimum permeability (in storage rooms, bedrooms and children's rooms) or in residential premises in apartments or houses where the number of families does not exceed four people. Lifetime, due to the fact that this laminate was developed at the beginning of the century - from two to six years.

- Laminates of classes 32, 33, 34, 35 and 36 (or from AC3 to AC6) are intended for city apartments and country houses. The higher the class, the durability, respectively, is also higher. By the way, the higher the class - the more expensive the product. In some cases it is more expedient to buy laminate at a lower class, since any new items always have an unreasonably high price tag. With the commercial use of laminate life is significantly reduced.

- Laminate 43 class - This is one of the latest developments in this area. The base is covered with vinyl film, which has a high rate of moisture resistance, impact resistance and wear resistance. Correspondence of building materials to this class is indicated by a picture in which three people are depicted.

The Russified badges on the package also testify to the resistance of the laminate to fire, resistance to ash and ultraviolet radiation, and demanding care.

Kinds

Laminate can be different in design. By the way, this building material was created, as a cheap replacement of a wooden floor, so the key pattern has always been under a woody structure - oak, birch or maple. But, like any industry, this segment has been improving every year.The first experiment in the design was an imitation of the skin. Most of all liked by the representatives of large business laminate "crocodile skin." In the tone of the laminate even carried out the appropriate decoration of the walls. Few can afford to buy laminate from European manufacturers.

For the economy segment work domestic plants.

- For rooms designed in the style of hi-tech, classic laminate is not suitable, so a special metal design. Most often it is placed in kitchens, where there is a huge amount of metal and gray plastic.

- Vinyl The laminate is suitable for rooms with high humidity. It fits not only in the kitchen, but also in the bathroom.

- For fans of ceramic tiles, too, their own alternative solutions were invented. It is worth noting that the artistic version can be with a tile pattern. And this not only saves money, but also significantly reduces repair time. The complete drying of the solution can take up to several days, and the laminate in the same bathroom can be laid in a few hours.

- Art stone pattern imitates paving stones - and this, in turn, is an alternative solution for owners of country houses. This laminate looks good in technical areas and in the hallways.

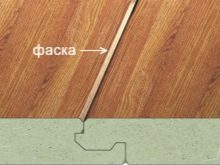

- Designed for uneven surfaces laminate with chamfer. Chamfer - a recess around the perimeter of building material. Finds its application and double-sided chamfer (grooves along the entire length). Thanks to her hiding the seams between the laminate, from a design point of view - laminate with a chamfer visually expands the room. It imitates the roughness inherent in the wooden floor.

- Designer Laminate has no artistic limitations. For children's rooms, drawing can be with cartoon characters or funny pictures, for a wooden house - aged wood. It all depends on the preferences of the consumer and his financial situation.

- Glossy laminate is a bit like a wooden floor, painted with several layers of varnish. It never looks dirty and, coupled with a glossy ceiling, reflects daylight, making it always light in the room.

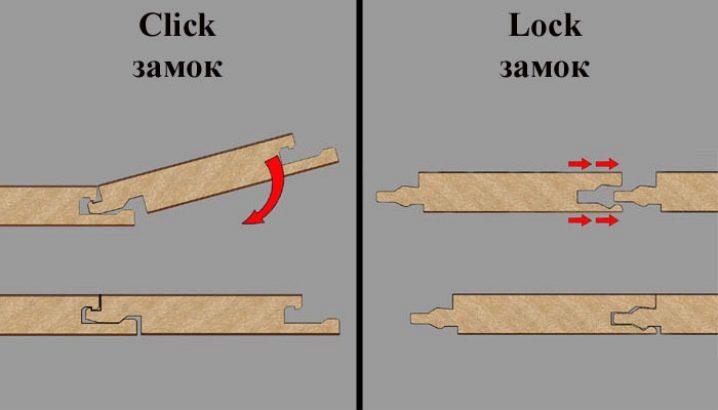

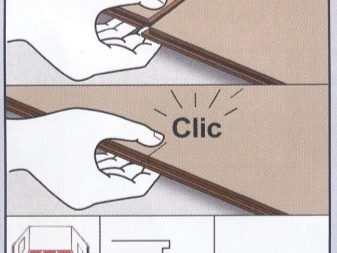

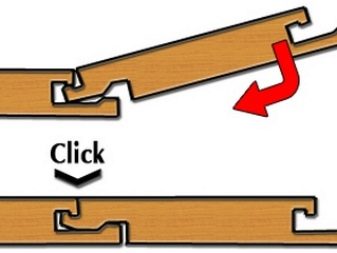

Laminate differs in connection elements (locks). At the dawn of its appearance, this building material was combined with a special glue. A lock method was later invented.

- Padlock lock was coined before anyone else. On the left side there was a ledge, and on the right side - the “entrance”. When laying laminate one board was connected to another. A mallet was used to enhance the effect. The peculiarity of the protrusion is that it is figured, thanks to this the connection is fixed tightly. Such laminate is still popular, because at a price it is cheaper than its competitors. But there are also disadvantages.

- Experience is required for laying such a laminate. If this is done by a person without certain skills, then a good result is not guaranteed.

- Locks due to gravity may break over time. At a minimum, this will lead to an ugly appearance of the floor, and as a maximum - to replace it.

- If an error is made during installation and the floor is laid unevenly, the lock will break.

- One of the latest types of compounds is lock click. Among experienced handlers, this type of connection is popular because less time is spent on floor installation, which means you can earn more by the end of the month, and in the public environment, laminate flooring with a Click lock is widespread due to the ease of the procedure: bring the board and snap it at a certain angle - 45 degrees. No extras needed.A woman can handle this job. During the period of operation such a lock does not break. Laminate can be easily disassembled, and from this it follows that if a move is to be made, then it is easy to remove and take it to a new apartment. Like any new product, this laminate is more expensive than its predecessors.

Materials

Today, laminate is not only made from wood-based materials (an option known by the joint system as a click, tongue-and-groove and glue), but also presented in the building stores such varieties as PVC laminate and flexible vinyl lamellae. By the way, the tongue-and-groove laminate of chipboard is intended not only for laying on the floor. Thanks to the castle system, it is easy to mount on the walls and even on the ceiling. The main thing - do not forget to fix the connection furniture nails.

Separately worth staying on the plastic version. The plastic laminate consists of a top layer - a pattern, a base of PVC and a substrate that separates the concrete floor from the central layer. If necessary, added sound insulation and resistance to ultraviolet radiation. For resistance to sliding, the top layer is made with rough edges.Plastic laminate, made of quality materials, can be a full replacement for conventional laminate, especially since PVC has strength and hardness, unlike other varieties. This option is also distinguished by its democratic value.

Everything else, plastic laminate has several advantages:

- Moistureproof. It can be laid in the bathroom, in the kitchen and in private pools.

- Heat resistant. It can withstand temperature drops from deep frost to scorching heat.

- Easy to install. Thanks to the rubberized joints, it is not only easy to assemble and disassemble, but it does not even let in or absorb moisture in the joints.

- It has an aesthetic look. Even the cheapest plastic can have a pattern of expensive wood, tile or natural stone.

- Easy to maintain. Wet cleaning can be done at least every day; dust and dirt can be removed with any cleaning agent.

Matte laminate slowly gives way to glossy. In terms of production, the differences are minimal. The HDF plate is taken as a basis, the upper layer also imitates a certain pattern, and the lower one is designed for noise reduction.Mirror panels are impregnated with special resins that make the laminate resistant to damage and wear.

Glossy lacquered floor requires close attention. If liquid is spilled on its surface, it should be removed immediately, traces may remain on cheap plastic.

Expensive options for glossy plastic include corundum and silver ions.

The first material provides resistance to damage, and silver ions cover plastic with an antibacterial layer.

Manufacturers Rating

Not only laminate manufacturers in economy class, but also the best brands are represented on the domestic construction market. Among them are local representatives, and representatives of European countries.

Sweden is the birthplace of laminate. It is not surprising that in the ranking the first line is occupied by the Swiss Pergo company with a score of 10/10. It was this manufacturer in the already distant 1979 that began the production of laminate and is rightfully considered the leader in this segment not only in the European part of the world, but also on the remaining continents. A key feature of this manufacturer is that it relies on the quality of its products.Pergo manufactures both high-quality durability and vinyl laminate. The service life declared by the manufacturer is more than twenty years.

In the second place in the ranking is the joint production of Belgium and Norway. Berry Alloc received a score of 9.9. The Belgian plant Berry Floor and the Norwegian Alloc once united in an association, thanks to which they were able to combine their know-how and technology and presented the HPL-based laminate to the world. Laminate, made by high-pressure technology, differs from the laminate made by direct pressure - highly resistant to the environment. Laminate Berry Alloc (Belgium-Norway) is designed for thirty years of use, environmentally safe, presented in twenty collections, equipped with a unique patented lock system.

In third place is the Austrian kaindl company. The German manufacturer has been working with wood for more than a century. In addition to production, the company with its efforts sells finished products. In 2009, this particular manufacturer was recognized as the best in the European Union.

The top five are completed by two German manufacturers - this is Haro and Kronotex. Both of these companies have been operating for about thirty years in the building materials market.Their products are delivered to almost a hundred countries of the world. Haro has its own developments and entire research and production departments, Kronotex is the only supplier of laminate, in the catalog of which there are about two hundred items.

Germany occupies the next place in the ranking, but from 9 to 14 places are occupied either by domestic producers, or joint ventures with Russia. Their rating ranges from 6 to 8 points on a ten-point scale. Joint production, created on the territory of the Russian Federation to reduce the cost of the final product, because there is savings in logistics. The enterprises have European technologies and standards, so we can safely say - this is a quality building material at an affordable price.

It is necessary to be careful of the Chinese laminate made on doubtful manufacture.

Such products have a specific smell, there are no special marking tips on its packaging.

Where can I put?

Due to the characteristics of the laminate - resistance to temperature changes, it can be safely laid on the loggia.

It is desirable that the following conditions be met:

- The balcony was glazed with plastic windows.A big plus, if a three-chamber profile was used, it retains more heat.

- Loggia was thoroughly insulated. Even in the bitter cold in this territory there should not be any indicators of temperature below fifteen degrees. Especially unacceptable icing, because at high temperatures on the laminate will remain moisture.

- On the balcony or loggia was microairing - this is a kind of prevention of condensation on the windows.

If all conditions are met and nothing abnormal has been detected during all seasons, it means that you can safely proceed to laying laminate at least 32 or 33 classes.

For a bathroom, ordinary laminate is not suitable, it does not tolerate high humidity. Conventional laminate, laid in a room with high humidity, quickly becomes useless. Plastic laminate tolerates moisture on its surface, does not deform from high humidity. In addition, plastic is always warm, unlike ceramic tiles. You can also lay moisture-resistant laminate from fiberboard to the bathroom. The fact is that it has an extra wax-silicone coating that can repel water.In addition, such a laminate is resistant to high temperatures, microorganisms and has a long service life.

For a hallway, sales assistants advise laying any laminate flooring. This room has no temperature changes, exposure to ultraviolet radiation. The only thing worth paying attention to is the number of guests and household members. If one person lives in the apartment, then the wear resistance of the laminate may be 21 classes. If the owner has a big family and guests often come, then it is better to buy laminate at least 32 strength classes.

With the same approach, it is worth buying laminate flooring in the living room and bedroom. In a bedroom, as a rule, a person spends the least amount of time at all, so laying expensive laminate does not make much sense.

In the kitchen, as in the bathroom, it is best to lay moisture-resistant laminate of high grade strength. It will be heavy household appliances, kitchen furniture, it will constantly move.

Therefore, saving will not work, otherwise in five years you will have to buy a new one.

How to choose?

By buying laminate for the house should be approached responsibly, with proper maintenance of high-quality building material will serve for ten and twenty years.

In the store should pay attention to the following points:

- The name of the manufacturer and its location. The best manufacturers are Sweden, Belgium and Germany.

- The cost of the product. Quality laminate can not be cheap. Too low cost says only one thing: the product was made in an artisanal way, it can be dangerous to health.

- Material resistance to mechanical damage and ingress of moisture. Waterproof laminate should be laid, including, and in living rooms. If one of the guests at a tea party accidentally spills liquid, it will be enough to wipe it with a napkin.

- Lifetime. He points to the durability of the laminate. Best of all, if the class of the laminate AC6 (or grade 34).

- Design. It should take the laminate that will match the interior.

It is desirable that the laminate had a click lock, such a laminate is connected for centuries. This compound will not break from heavy objects. This laminate is easy to install. Opening the box with laminate, the buyer should not feel a strange smell, whether it be glue or paint. This building material should smell like sawdust. There should not be chips, cracks or bumps.The quality of processing angles and connections should be high.

You should know that only a moisture-resistant laminate is suitable for underfloor heating. Laminate, which is produced by the old technology, dries and deforms due to temperature changes. Moisture resistant laminate is marked with the English word aqua, depicted as an umbrella or a dripping crane.

It is best to buy building materials in specialized hypermarkets, where there are always sales consultants and certificates of conformity for products.

Care rules

The top layer of the laminate with time comes into disrepair, proper maintenance helps to prolong its performance.

- If the laminate is installed in the hallway, then in the corridor it is desirable to put a rug at the entrance. Due to this, dirt, moisture and dust will not fall on the laminate, but the mat must be periodically shaken out.

- Wet cleaning should be done at least once a week. On all other days it’s enough to go on the surface with a vacuum cleaner with a special brush. The larger the brush pile, the better.

- Wash the laminate with the use of special equipment. No powders should be, dry substances with chaotic movements leave scratches.Substances with a high content of acids or alkalis can completely destroy the protective layer.

- Special household chemicals consist of a soap base, antimicrobial and antibacterial substances, glycerin and fragrances. For allergy sufferers, a careful study of the composition remains, unfortunately, in cheap household chemicals, fragrances can be of poor quality.

- Special means can be used only once a month. The bottle lasts for a long period, since a small amount of the concentrate is diluted in a ten-liter bucket of water.

- Waterproof laminate is not afraid of water. For almost six hours nothing will happen to him, unlike his predecessor. Therefore, it is necessary to take care of the predecessor more carefully, not to use rags and a washing vacuum cleaner, otherwise the water will fall on the main layer and eventually spoil the product.

For the first wet cleaning, do the following:

- Check household chemicals in a small area. If after applying the substance the laminate has changed color or there are scratches, the further use of this substance is fraught with negative consequences.

- To part a concentrate according to the instruction.There is also an alternative folk method - a spoonful of vinegar in a half-bucket of water. It was such a tool in the Soviet years that wiped windows and mirrors.

- Starting from the window and the corners, gradually moving to the exit. Otherwise, you will at least walk on the wet floor.

- Use a damp rather than a wet cloth.

- Cotton cloth to secure the result.

It will be useful to know a few tricks that will facilitate the care of the laminate:

- Under office chairs should be placed under the rug. Thus, the roller base will not scratch the floor.

- The spots left by alcohol, coffee or chocolate are easily removed with special household chemicals.

- Chewing gum or wax from a candle can be removed in a dried form with an ordinary scraper made of wood.

- Traces of markers, lipstick, shoe polish should be removed with acetone diluted in water.

If there are already scratches on the laminate, do not despair and rush to the hardware store. Manufacturers have provided and produced special wax pastes, crayons and varnishes. By the way, in the sets you can also find a spatula. Wax pastes come in a variety of colors, so you should buy a tube that matches the color of the laminate.

- First of all, it is necessary to clean the surface and allow it to dry. In the future, you should take a piece of chalk or paste and walk on the scratch. It should "overgrow". After a certain time, when the wax is completely dry, you just have to walk with a cloth or a napkin.

- If the chip is large, then applying the heated paste. For safety reasons, it should be applied with a spatula. Surpluses are cleaned with a wet rag. After drying, the polishing of this area of the laminate is necessary.

What to process?

Manufacturers around the world, trying to make money, offer special sealants, pastes, putties and gels for laminate. These special products are odorless, colorless, and adhesive. By applying them during installation, you can ensure a long service life.

- Sealant prevents the passage of moisture, does not incorporate harmful components and dries instantly. Due to its properties, it is possible to install used laminate at low and high temperatures. Its application leaves no visible marks, and sealing the seams leads to noise reduction.

- Acrylic putty for water resistance eliminates the appearance of raids yellow, used with various types of wood. Using color putty, you can decorate unsightly areas.

- Silicone gel - this is a novelty in this segment. Silicone not only performs the task of waterproofing, but also is durable to use. Installers around the world appreciate it for resistance to temperature extremes and for reliable fixation.

- Impregnation for laminate can be wax based. Wax does not pass moisture, therefore it is used also when laying a floor, as alternative to sealant. It is recommended to apply the impregnation on both sides of the fixing compound, and for greater moisture resistance, the edges are also processed. Apply impregnation should be a conventional brush.

- Wax crayons make laminate impact resistant and protected from the action of ultraviolet radiation.

There is also a special mastic for laminate. It prevents the entry of dust, dirt and moisture, and reliably connects the lamella with each other. If the factory protection layer already exists, it is not recommended to use mastic.

By the way, solid and liquid mastic helps to eliminate scratches.

Beautiful interiors

In white or light rooms should be laid in the appropriate color laminate. In addition to the combination, this solution visually increases the space, since the light is reflected from all the interior objects.

For the kitchen is suitable laminate of any color and design. The main thing is that it is moisture resistant, wear resistant and shock resistant.

In the rooms equipped in the style of country, designers recommend laying the floor with an imitation of aged board. Choosing natural wood is expensive, and besides, wood needs care.

Moisture resistant laminate for the bathroom can be made in the variation of ceramic tiles. It takes less time to install, and it is cheaper in cost.

Laminate for children's room is made in a special color. This material is environmentally safe, so you can not worry about children.

To extend the operational life of the laminate, it is recommended to make a combined floor in the hall: the entrance area is made of tiles, and then the laminate is laid.

Glossy floor is suitable for any situation. Due to its reflective properties, it visually expands any small apartment.

Laminate can be laid not only on the floor, but also on the walls and ceiling. This solution in the same style can be implemented by owners of country cottages.

Laminate commercial class can be laid in areas with high attendance. The latest models guarantee a ten-year lifespan.

In conclusion, I would like to note that the laminate over the past forty years has come a long way. Starting its history as a cheap replacement for wooden parquet, today it is one of the most popular building materials. Thanks to its moisture resistance and water resistance, it is possible to lay this building material in bathrooms and kitchens, while there are no restrictive barriers in the decorative part. It can imitate not only wood, but also ceramic tiles, natural stone, and photo printing is possible.

You will learn more about the features of waterproof and moisture-resistant laminate from the following video.