The choice of balusters for stairs in the house: features and varieties

People who faced the construction of a two-story house or apartment with access to the loggia, often thought about the stairs that could give the interior refinement and a sense of a real fairy tale. Often, for this purpose, railings are made, which can be decorated with balusters, thus making the stairs both beautiful and safe.

What it is?

Balusters are additional architectural details that decorate the interior. They also serve as an additional support for the railing. Such elements have been used for a long time both to create a support function under the railing, and for decorating an architectural structure. Over time, these structures began to be used to decorate the facades of houses.

Standards

If it is assumed that the balusters will perform a support function for the stairs, then it is necessary to observe certain norms in their manufacture. For example, the distance between adjacent balusters should not exceed 150 mm, which is especially important in those parts of the room where children will play, because the elements of the decor so arranged will protect children from falling and sticking their heads between supports. The height of balusters should be selected under the railing - according to the norms they should not be less than 90 cm.

However, individual data must be taken into account - if tall people live in a house, then it is worth doing as it will be convenient for them. In a house with children it is possible to install intermediate rails for the growth of children.

Regardless of the material of manufacture, all balusters have the following components:

- Base. This includes the part of the rack that attaches to a step or a special beam, called an underbelly. Often this part of the baluster does not have a standard size, so that during installation it was possible to choose the height suitable for the railing.

- Central part. Performs as a supporting function, and decorative.

- Rail support - This is part of the baluster, which is attached directly to the railings. It is made with a stock for fitting in size.

Types and forms

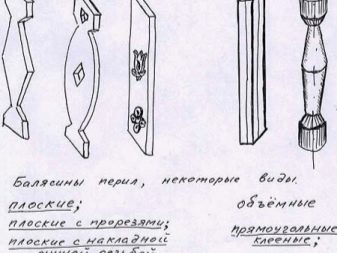

Balusters can be classified according to different parameters. In form, they are different - it all depends on the design ideas and the overall interior design of the room.

The most common on the market are round balusters, but, in addition to these options, there are other interesting solutions:

- Flat balusters. In the cross section they have the shape of a narrow rectangle or ellipse. They are installed quite close to each other, forming a certain ornament, thereby realizing the design idea.

- Square balusters.

- Balusters in the form of a spiral, Roman twisted and many other unusual forms: twigs, animals, statues.

If you have to choose the form of balusters, then you should pay attention to the overall style of the room and the preferences of the owner of the house.

Depending on the material from which the balusters are made, there are the following options:

- plastic;

- concrete;

- glass;

- stainless steel;

- from an artificial or natural stone;

- gypsum;

- wooden.

It is also possible a combination of some materials that are in harmony with each other.

Materials

Each material can show its positive aspects only when certain operating conditions are met. Sometimes the price of the product and the purpose of using the baluster play one of the main roles in the choice of material - it can be used both outdoors and in the house.

Polyurethane

Plastic balusters appeared on the market recently. They are considered the most convenient and practical solution to complete the interior. If you compare with other species, then this option is most versatile in terms of price, strength and service life.

In addition, such structures are not susceptible to corrosion in comparison with metal versions or rotting, for example, wooden elements. Polyurethane columns are often used as decorative parts, since they are rather weak to perform the support function. This design is used both inside and outside the house.

Some features of this product can be highlighted:

- low weight does not burden the overall structure, as a result of which you can not worry about repairs for a long time;

- the strength of the material provides safety in use, so you can apply them in those homes where young children live;

- beautiful exterior design perfectly complement the interior;

- wear resistance both in open buildings (resistance to weather conditions: dampness, direct sunlight, cold air) and inside the house, as well as resistance to mechanical damage;

- care for such material is quite simple and does not require additional costs.

Concrete options

They are a massive, but very attractive solution for outdoor use.

Main advantages:

- the material does not require additional processing, that is, after the purchase there is the possibility of their installation;

- long service - it is worth spending a small amount once, then to forget about the cost of additional care;

- impressive resistance to mechanical loads;

- material is safe to use;

- Concrete balusters are resistant to moisture and various weather conditions.

From the negative sides, the following positions can be noted:

- when compared with other materials, the concrete is stable, but not as much as granite;

- installation will require additional equipment and outside assistance due to its weight and massiveness;

- The appearance of a natural stone is much more attractive than that of concrete balusters.

Glass

This is a sophisticated solution that creates a wonderful feeling of being in an ice castle. Balusters can be made from both solid glass and with the addition of air bubbles. The glass itself can be clarified or colored (bronze, gray). More often buyers prefer products made of transparent glass, which can be installed together with glass railing or any other options. Fasteners are made of "stainless steel" or chrome-plated brass.

One of the important drawbacks of glass is that it can not withstand the load and mechanical stress, leading to scratches.

From an artificial or natural stone

More often, granite or marble is used as a material for the production of this option. More resistant granite. Marble and granite balusters will add splendor to the room and decorate any staircase. They can be used both for support and as an independent part of the interior.If the choice is on the balusters made of natural stone, then you should think about individual design and find an experienced master who will realize the dream of the owner of the property.

Granite balusters perfectly tolerate temperature fluctuations in the external environment and are extremely durable, and it is these facts that are decisive in the choice of material.

Important advantages are the following indicators:

- ease of care;

- non-clogging;

- color fastness even when exposed to direct sunlight.

The disadvantages include a significant price and sensitivity to chemicals (detergents are not intended for natural stone).

You can also choose the railing of artificial stone - they are resistant to aggressive substances, which distinguishes them from the natural option.

The budget option is artificial stone.

This material has much more palettes of colors, shades and patterns.

The advantages of this material:

- imitation of any natural stone is possible;

- affordable price;

- a rich choice of texture and color;

- excellent performance.

Minuses:

- artificial stone is quite easily scratched, which is especially noticeable on dark shades;

- some species are not inferior in price to natural stone (for example, agglomerate).

Gypsum products

They not only support the railing, but are also a good design solution that creates a mysterious atmosphere of elegant elegance. Many options for forms opens up a big world of fantasy in the style of stair railing and balcony railings. Such balusters can be made independently, which can not but rejoice, or use special forms purchased in the store. However, such constructions require special care, since moisture penetrates well into the plaster, damaging it.

Acrylic options

They can be made to order with any sizes and shapes. Despite their low weight, they perform their function quite well as supports for the railing. Acrylic is stronger several times than the glass itself at the same thickness, but due to transparency it can completely replace it. At the same time, acrylic has a longer service life. Due to new technologies, it is possible to make acrylic balusters using LED backlighting,which will add uniqueness and will perfectly replace conventional lighting, which will ensure safe descent along the stairs at night.

Easy installation and maintenance, as well as pricing will delight the consumer. However, this material has drawbacks: acrylic is more prone to scratches, which will lead to damage to the appearance, but this is easily corrected by polishing.

In addition to the above, acrylic balusters are perfectly combined with other materials and complement each other. They will perfectly fit into the room and give elegance to the most ordinary design.

Wood

You can definitely say that this option is the most common material for the manufacture of balusters. Great for wooden stairs in country style. The material is quite easy to process, as a result of which you can get any shape with a beautiful thread. It must be remembered that the tree requires care and does not very well withstand temperature extremes.

Depending on the material used wooden balusters are:

- From larch. This conifer is resistant to temperature change and decay.It is a fairly durable material and is second only to oak.

- From beechwood. When exposed to wood, steam bends well - this makes it possible to create the necessary shape. In the open air such material is short-lived, therefore it is used only indoors.

- From oak. Practicality, strength and durability - these are the main advantages of such a material. Wood is characterized by high wear resistance, resistance to decay. The material has a dark or light brown color, looks great in the treatment of varnish on wood. The dense structure of oak allows you to perform the smallest details on the material.

- Ash tree balusters. Wood is similar in appearance to oak, but ash is less hard compared to it. The material has a beautiful texture, resistant to moisture and rotting, it can be used in open places. It has a yellowish color with dark light stripes. Due to its flexibility, it can be used to form rounded balusters.

- From birch. This option is rarely used compared to previous materials due to susceptibility to rotting, cracking and strong shrinkage.But at the same time, birch perfectly amenable to processing and coloring. Due to special coloring agents, you can give the birch any color format.

- Pine. This material belongs to soft wood, which allows it to be processed. The wood is immune to temperature fluctuations in the external environment and is quite resistant to fungal infections. The color of wood in a yellowish range. Because of its uneven porosity, it is stained differently, which can create the impression that the structure is uneven. You can use any kind of wood, but preference should be given to hardwood.

Wooden balusters are made according to three main technologies:

- Point balusters - performed on a lathe;

- milled - on such racks there are cuts in the form of screws, braids and other elements;

- carved - there are elements of the thread.

Design features are in constant care for the material, if it is installed on the street. It is necessary to constantly tint and tap it to strengthen the contact between the parts.

Of metal

The material is universal with respect to mechanical damage.Constructions made of this material perfectly perform their support function. According to the method of manufacturing balusters there are several types:

- Cylindrical or square rods. Such manufacturing options can often be found in the old high-rise buildings. To date, many homeowners refuse this type of construction.

- Forged balusters. Great for rooms in the Baroque, Gothic and other styles. Can be combined with some materials.

- Cast balusters are durable and versatile. This option is cheaper than the previous one.

Compared to wooden versions, these structures have several advantages: durability, ease of maintenance (they are well restored), a wide range of applications can be used both outdoors and in the house.

Metal balusters, as well as railings, can be used not only on the stairs, but also on the terrace, balconies and other parts of the building. Depending on the metal used, the balusters can be made of various materials.

Stainless steel

Used as a stand-alone structure, surrounded by glass or wood.Such material gives the chance on realization of the most courageous design decisions. The durability of such a construction depends on the railing device itself. Currently, there are many varieties of beautiful and stylish balusters.

The advantages of such material include the following items:

- High anti-corrosion performance. Chrome balusters are suitable for those rooms where the temperature is variable and the humidity is high.

- Strength. Due to its strength, you can make quite aesthetic details that will look quite easy, giving a feeling of lightness.

- Ease of manufacture.

Of the minuses can distinguish the high price of the product.

Cast iron

The advantages of the material include the following items:

- Functionality. Cast iron balusters are perfectly combined with ladders of any material, such as wood or metal.

- Durability. Due to this quality, the metal does not lose its physical and aesthetic properties for a very long time. Selecting this material once, you can forget about changing it for a long time.

Not all ladders will be able to withstand balusters made of this material, since cast iron is a very heavy metal.

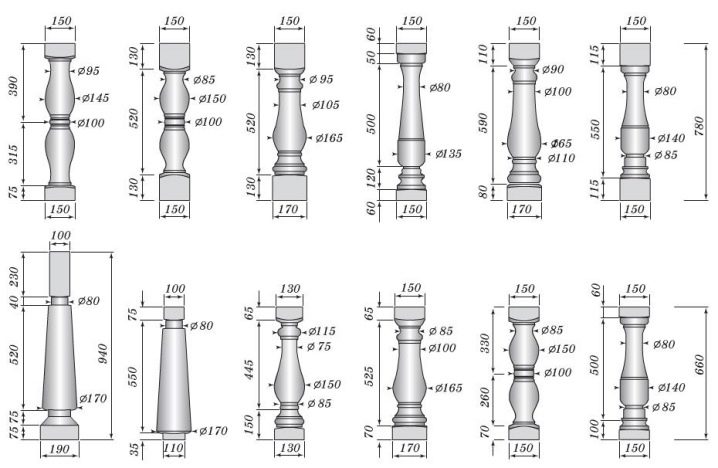

Dimensions

Balusters do not perform the carrier function, so their thickness, area and size do not matter, as the distance between the elements plays the most important role. Most manufacturers produce balusters with a height of 900 mm, often with the ability to adjust the height. When building stairs in a private house, the size can be as high as 120 cm - this will protect children from falling.

For small fidget, additional handrails can be installed. Each baluster needs to be fixed both above and below. The upper and lower supports of the balusters incur the greatest load, so they must be installed correctly. The elements are usually mounted on a straight base, to which they are attached with various clamps.

Making your own hands

The process of creating balusters with their own hands is not easy and requires certain knowledge and compliance with the rules. In order to make racks for the stairs, you need to initially decide on the material. Then you should think about the shape of the future design and make its drawing.

However, if there is no confidence in the fantasy or you need to find exactly what is suitable for a particular design, you should look at the beautiful options on the Internet - there certainly will be an option for the soul.Well, if there is no desire to make a model of the house, then you should buy in the store a special device into which you can pour concrete or plaster for balusters. After designing the product and choosing a material, you can begin work.

If the choice is on wood, then it is worth choosing solid varieties, since they are more resistant to moisture, thereby serving for a long time. You also need to pay attention to the wood was not cracks, knots and other defects. Of course, if previously there was no experience in working with wood, then it is better to take a more economical option: pine or birch.

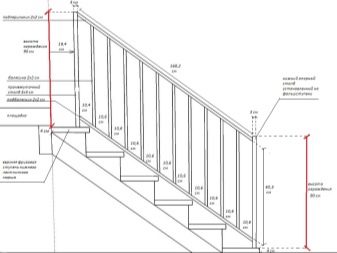

Calculation and installation

Before making balusters, it is worth making measurements of the height of future railings - the recommended height varies from 0.7 to 1 m. If tall people live in the house, then the dimensions can be changed.

Then you need to determine the distance between the racks - do not put the cost of materials at the forefront, because safety is more important. In this case, a distance of no more than 150 mm is recommended - the number of racks depends on it. The height of the balusters can be calculated as the difference between the total height of the railing and the thickness of the handrail.Basically, their height ranges from 65 cm to 100 cm.

Below are two options for making balusters: wood and plaster.

Tree

To create figures, wood cutters are needed, each of which has its own purpose. For example, reyer is used to grind vaults, Meissel creates spherical parts, and shtichel - cone-shaped. A machine is also needed on which the baluster will be machined.

To work on it is worth following a certain sequence:

- Fixing a wooden blank on the machine is strictly in the center.

- To give the workpiece a rounded shape, it is pre-grinded with a semicircular chisel with further cleaning with a reyer.

- The most interesting part is the production of shaped parts. Here you should rely only on your preferences and follow the drawing. The turning of parts is possible with a reyer, but here it is necessary to understand that the pressure force should be the same, because the depth depends on it. If there is a desire to simplify your work, then you can make the figures a frezer - so they will be more even and equal. But the router is less flexible in movements and, as a result, more straight lines are obtained.

- After that, you can start grinding and polishing.

- The final stage of the work is the processing of the column with special means: varnish, paint, stain, and other substances.

Often wooden balusters can be flat. To make them at home, you need to prepare a template of the desired size with the desired ornament and perform a sketch. The drawing is applied to the workpiece and cut out with a jigsaw along the contour. After that, an ornament should be cut out, all the patterns are ground, made more symmetrical and smooth.

Gypsum

Gypsum elements can be made in two main ways:

- Using special forms for casting, which are sold in specialized stores. They need to look in the department of landscape design.

- Using templatesmade by yourself. To do this, you need a certain set of necessary tools. These include profile tubes, which act as a metal container for casting, silicone (rubber), wood and a lathe.

The easiest option is to buy a template in the store, but it may not correspond to the wishes of the owner of the house.After the template is selected, you need to prepare a plaster composition to a creamy consistency. The two halves of the template are interconnected and fastened in such a way that there are no gaps.

In order to fill the mixture, in the upper part of the template make a hole. In the resulting channel is poured ready plaster fill. The cast form is aged for two hours, and then the finished product is removed, which is left for a day until it is completely dry. After that, it can be refined if there are inaccuracies in appearance.

Installation

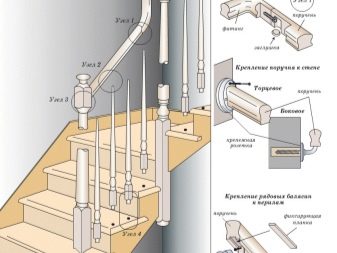

One of the main stages is the installation of balusters, because the safety of operation of the stairs depends on how they are installed. It is worth remembering that the handrails can lean around, so you need to fix the stairs firmly.

Installation of wooden balusters can be performed to the following elements of the stairs:

- to the landing - for this you need to make the holes strictly in the center;

- on the step;

- on string or on kosour.

The easiest way is to install the balusters independently on the platform of the stairs or steps. If you take the mount in the first embodiment, then it is carried out on the bottom strap with the help of studs.

Installation on the stage can be done in the following ways:

- on steel studs - choose galvanized products with a length of about 10 cm with a thickness of 8 mm;

- on self-tapping screws - quite reliable and durable material;

- the dowels are rounded wooden spikes.

It is not recommended to mount on nails - this is due to the fact that parts may diverge and thus will not provide the structure with sufficient strength. Due to the discrepancy of details there will be a creak that will cause discomfort and discomfort from walking up the stairs. For fastening of wooden balusters it is necessary to observe some rules that will make the construction safe. Some of them have already been described above. One has only to add that at the very beginning and at the end of the stairs, as well as at the corners of the site, it is necessary to install pillars.

If wooden balusters are flat, before installation they can be glued together to create a conceived pattern. After their connection the handrail is mounted.

Painting

To increase the service life of the product it is necessary to treat all surfaces. This stage must begin from the board for the railing, gradually lowering to the lower elements.

All wooden elements can be varnished. After that, paint the structure. The most common color is white, but you can use any other color that is suitable for interior design.

To protect plaster balusters from damage and give them a decorative look, products should be treated with a protective layer of lacquer or a waterproof agent.

Beautiful examples

Carved wooden pillars will emphasize the status of residents of the house and harmoniously fit into any interior.

Balusters made of marble and granite make it clear to any guest that a person who knows a lot about construction lives in this house.

How to make a Roman baluster, you will learn in the next video.