Cast-iron spiral staircases: design features

Extraordinary products always attract attention. Cast-iron stairs are no exception, they are often used to give a special charm to the room. Such structures will immediately transform any home, make it much more interesting. Ladders from cast iron are so unique that they seem made of complex openwork weaving.

Specifications

Products from cast iron amaze with their grace and magnificence. Among them, it is worth noting the stairs, such products contribute to the creation of a majestic atmosphere both inside and outside the room.

It should be said that the first mention of the use of cast iron for casting was recorded in the VI century BC. er in China.In Russia, the iron craft began to be used during the reign of Vasily III. Cast iron was more seriously used in the time of Peter the Great, when the first mining enterprises appeared.

Ladders from cast iron were for a long time popular in houses at the nobility. Currently, products made of cast iron also remain a very expensive pleasure, which not everyone can afford. Many would like to install a molded staircase in their house, it’s worth saying that such cast-iron products are premium-class products. After installing the cast-iron staircase, the house will immediately become more convenient, such designs will introduce extraordinary sophistication into the atmosphere of the home.

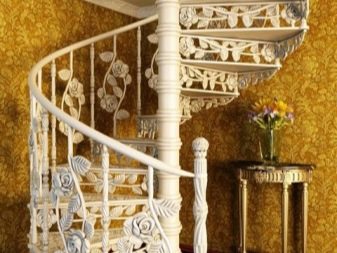

The main feature of the staircase cast-iron structures is the presence of a complex openwork pattern, which cannot be made using other materials. Products made of cast iron are really made for ages, they can stand for dozens of years without any changes, please with their quality and surprise with aesthetic perfection. Many unusual and elegant objects can be made from this material, and cast iron structures are used to decorate rooms both indoors and outside the building.

The main characteristics of stairs made of cast iron, can be called their resistance to:

- weather conditions;

- mechanical damage;

- corrosion process;

- low temperatures.

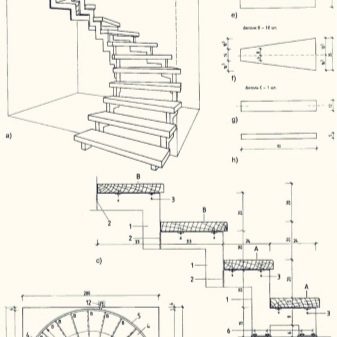

They make stairs in two versions: marching or screw. Cast-iron marching structures are durable and reliable, they are very convenient for movement, for carrying objects.

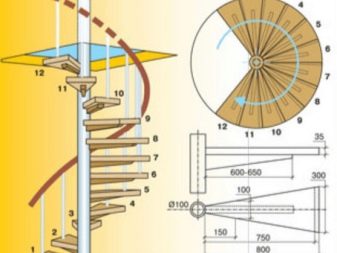

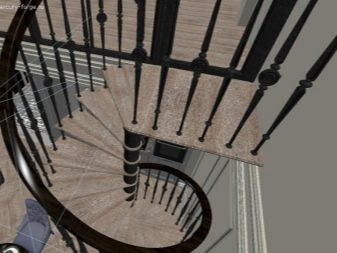

If we talk about spiral staircases made of cast iron, it is worth mentioning that, in addition to its aesthetic qualities, these products are very compact. Such a neat product can be installed even in the smallest rooms, even if you had never planned to do it before. The slope of the product directly depends on how many steps it has and their distances from each other. Steep steps should not be done in places where children or elderly people will climb. For them, not steep, but flat constructions, which require more space, are more suitable.

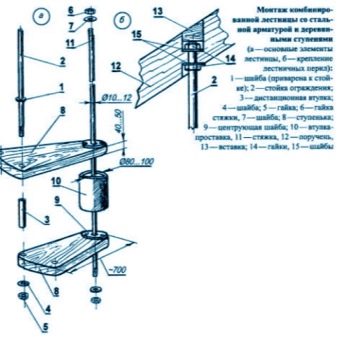

To install the ladder, on the column, which will be the reference, string the steps. Subsequently, they are opened as a fan around the central part and fastened by the method of mechanical assembly.Between themselves, they are fixed with metal bolts, which will ensure the immobility of the steps, while the load will be transferred to the central part of the column. With a fan-shaped arrangement of steps, the ladder can be turned in any direction that is convenient for each specific room.

Cast iron can be called a noble material, any product made from it will look very beautiful and elegant.

Cast iron stairs have many advantages:

- these designs are very light and elegant, but surprisingly durable;

- products have an unusual design;

- spiral staircases are striking in their compactness, in comparison with marching;

- cast iron stairs are easy to install;

- products can be used both indoors and outdoors, often stairs installed on the street;

- products easily tolerate changes in temperature, have resistance to ultraviolet rays;

- cast iron products are reliable, durable, have increased wear resistance.

Pig-iron stairs amaze with their originality and variety of designer finishes.

Manufacturing

The process of making stairs of cast iron is quite expensive, besides, such work may take a lot of time.Often the process takes from several weeks to six months, which is directly related to the scope of work.

At the first stage of manufacturing a ladder of cast iron, it is necessary to determine its design and make a project.

First of all, should:

- determine the type of construction;

- make the necessary measurements;

- calculate the size of all parts;

- determine the style and artistic image of the design;

- create a complete technical project;

- determine the casting method.

After all the preliminary stages of work completed, proceed to the basic process of creating models. Drawings and documentation are transferred to the workshop for the manufacture of these products. At the final stage, everything is transferred to the foundry.

Types of casting

In the manufacture of cast iron stairs use three methods of casting, Let us dwell on each of them:

- pattern casting;

- in hardening solutions;

- in earthen forms.

If for the creation of products choose the second and third option, then they are made of plastic models. To do this, use a special milling machine and using 3D technologies make the necessary elements.

These include:

- march area;

- post;

- baluster;

- small items.

If the work is carried out with the use of an earthen form, then the models are covered with a mixture of sand, clay and pressed. When the plastic sample is removed, hot metal is poured into the remaining mold in the mold. This method of casting is more suitable in the manufacture of steps, balusters and staircases, that is, in the manufacture of simple, in terms of design performance, products. When casting in hardening solutions, sand and cold-hardening resin are used as the composition.

Casting on a pattern is a rather difficult process, which takes place in several stages.

- At the initial stage, models are made using clay or gypsum. When working with them, you should make sure that there are no defects on the surface, it should be perfectly flat.

- The sample is covered with a rubber sheath, which contains quick-hardening rubber. When the rubber hardens, the shell is cut and the workpiece is pulled out. The wax is then poured into the mold to create a wax cast.

- Next, it is applied silicate powder. When the casting is completely hardened, it is heated and the wax is removed. The shell is fired in a furnace, it becomes durable and is suitable for the manufacture of parts of the stairs. This method helps to cast interesting patterns and curls, intricate details.

How the casting will be done is determined by the technologist. For casting can be used as one of the methods, and their combination. Each element of the cast-iron stairs is made separately, and the installation of the finished structure is made on site.

Species

If you describe the types of stairs, they can be divided into several types.

- Marching This type can be attributed to the most used.

- Screw Such stairs with their shape and structure resemble a screw.

- Spiral. These products have a different mount than the previous version and a larger radius inside the structure.

Marching structure is often installed in public buildings, it can move a large number of people.

Direct marching constructions consist of:

- steps with one peak;

- steps with two peaks;

- steps-tiles;

- risers

Screw option, in turn, will give an advantage when installed in a small room. The pillar in the spiral staircase will be the pillar in the center, on which the steps are fixed. This option is often used in country houses, cast iron products create an unusual atmosphere.Spiral staircases can perfectly fit into the interior of an office or administrative building, these designs only emphasize the status and significance of the company.

The cast iron spiral staircase consists of:

- steps;

- glasses;

- steps are rectangular with a ring, with risers;

- steps-platform.

If the spiral version is used, this will require a more complex type of fastening, since the load will go to the beams. Spiral models are often combined with other structures, their different types can be used simultaneously.

When choosing a staircase design, pay attention to balusters.that will provide security and maintain the railing. Baluster is a vertical support column, the main element of the railing. Installation of balusters is strictly vertically, they are attached to the steps or the bowstrings of the ladder. Supporting columns are often an element of decor, so the production of balusters made of cast iron or other materials will give the product an unusual shape.

Cast iron balusters are resistant to heavy loads and external influences in the form of precipitation, so these metal elements are installed outdoors, for example, on the porch.The sizes of the balusters can be different, many masters recommend using the rack thickness from 4 to 8 cm and installing them with an interval of 12-15 cm.

Decor

Often, for decorating stairs made of cast iron, designers use floral motifs in the form of intricate curlicues and leaves or geometric shapes.

To give the product a special form, apply additional materials, such as:

- tree;

- plastic;

- glass.

Stairs fences with wood details look very nice.

The advantage of casting from cast iron before forging is that when choosing any form from steps to baluster, you can not limit your choice. Quite often you can find such an option, where wood is used for balusters, and cast iron is used for steps, or vice versa.

Modern masters often use technology where glass is used with cast iron, which makes the structure more airy, open and weightless.

To make the product more unusual color is used. You can use paints that are sold in a specialty store. They are very durable, after their application does not need to use an extra layer of varnish.The cast forged products covered with a patina look very interesting, which gives the structures a special charm.

Beautiful examples

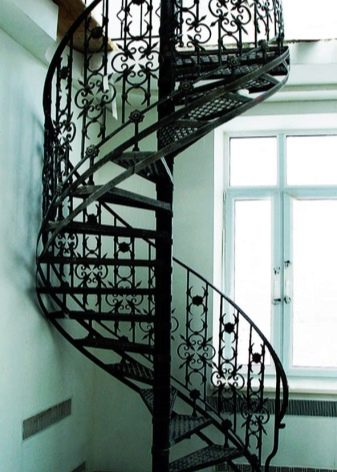

Spiral openwork staircase will decorate any room.

Cast iron spiral staircase.

Ladder from cast iron for external use.

Beautiful and original cast iron product.

Marching staircase of great beauty.

Such a snow-white airy product will not leave anyone indifferent.

How to make a spiral staircase with your own hands, see the next video.