Granite steps: material features and design options

The use of natural materials has always been a winning option for interior decoration, as well as internal and external structures in the building. The bright and durable representative of natural raw materials used for construction, repair, restoration and cladding is granite. Therefore, most of the staircases in private houses and general-purpose buildings are equipped with steps of granite.

Material Specifications

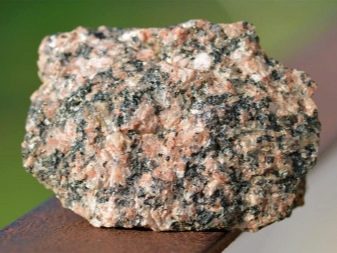

Granite owes its attractive, distinctive beauty to its complex composition, which includes polymeric rock.

In the role of components of mining raw materials are the following elements:

- feldspar;

- quartz;

- minerals.

In addition to the main components forming the structure of the material, granite may contain other impurities responsible for the quality characteristics of the stone. It is worth noting that a high level of quartz content causes good strength indicators of granite., and biotite, the presence of which will exceed 10% of the total mass of the components, on the contrary, will lead to the fact that products made of granite will eventually crumble.

Based on the specificity of the composition, when choosing steps from this material it is very important to familiarize yourself with the information about the raw materials that should be attached to the product.

Granite is widely used for exterior and interior decoration, so cladding or buying ready-made steps is a very common choice when it comes to staircases of any kind and purpose.

Granite is an ancient igneous rock, but producers under this name of raw materials in the manufacture of products imply not only a igneous mineral, but also metaphorical rocks, which have a similar density and structure.

The characteristics of the raw materials are represented by several qualities.

- Resistance to temperature changes - granite retains its attractiveness and properties in the temperature range from +50 to -60C.

- Strength mineral - it has indicators of 3.17 g / cm3, which are twice as high as the similar qualities of marble and other rocks used in construction.Due to this feature, grinding and cutting of plates from this material is carried out using diamond nozzles for tools.

- Water absorption level is 0.2%, so that products made of granite are recommended for use in rooms with high levels of moisture. In addition, the stone is less prone to the formation and development of fungus and mold on the surface in comparison with marble.

- Hardness of raw materials ranges from 6 to 7 on the Mohs scale, which allows the breed to be used for various construction works.

Types of granite

The name of the stone is obliged to the Latin word "granum", in translation - grain.

A distinctive feature of the material is a huge selection of colors and textures, in the light of which it is more popular than marble.

But this characteristic requires careful selection of one or another product for facing the steps, since the color scheme must be combined with the rest of the interior.

Such parameter as granularity, allows to classify a stone, dividing it into typeswhich, in turn, are recommended for a specific area of use.

- Coarse-grained stone - grain size may be more than 10 mm. Such granite is used very rarely in construction.

- Medium grained mineral - grains have sizes from 2 mm. Raw materials have good strength.

- Low grained - the densest material, the grain size is less than 2 mm. The optimal view, which perfectly manifests itself in the course of the stair steps and the base of the floor. This is explained by the resistance to mechanical stress and abrasion resistance.

Steps from fine-grained material are intended for installation on the street, since the stone of a large fraction is unstable to aggressive mechanical impact and erosion. For cladding internal stairs, you can buy granite slabs with an average grain size, but this type of product is also preferred as a material for decorating facades of buildings.

It is worth noting that the stone has an impressive weight, the weight of one meter of the overlap tread may be about 50 kilograms, which is why even at the design stage of a porch with degrees or an internal staircase, where granite steps are assumed, it is necessary to carefully calculate the load that the structure is able to withstand.

Based on the figure, granite is:

- monophonic a mineral with a smooth base - most often such raw materials are used for cladding public buildings;

- layered raw materials - where the solid layers form a very clear pattern;

- streaky material - such granite is composed of not brightly pronounced layers, resembling ordinary strips in a section, moreover, there are no large expressive spots on the stone.

Among the vast variety of shades of natural mineral are the main colors of the breed, based on which companies specializing in the production of products from granite, offer a classification of the material.

- Whites rocks - this group includes materials with a white or gray background, with grains of black or dark gray. Products from such granite are the most expensive, since such minerals are very rare. Laying white stone granite will turn any staircase into a work of art.

- Yellow rocks - include a stone, the shades of which can be light or bright and rich yellow. The steps of this group of material look more attractive when the products are polished and get a glossy mirror surface.

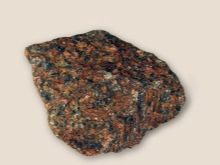

- Brown granite - in its structure, the mineral can be homogeneous or can have visually distinguishable layers on the base. Such material is distinguished by durability, therefore it is in demand for lining floors and stairs.

- Red stone - presented in different shades of color. It is mainly used for interior decoration with small elements.

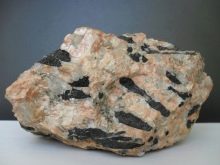

- Pink granite - it occurs most often, which is why it has a low cost.

- Purple granite is a rare species of rock, it has pink and lilac crystals. Lilac without additional shades and inclusions is a very rare mineral.

- Multicolor materials - are bluish or red-brown granite.

- Green the mineral is almost never found.

- Blue breeds - have many variations of shades. It is recommended for finishing steps.

- The black mineral - it contains black and light gray crystals. In addition, there are stones that are completely monochrome black.

- Gray granite - a very common form, which has a low cost.

Advantages and disadvantages

Granite steps are products that have individual positive and negative qualities.

The advantages of the products include the following characteristics:

- the material does not lose color and is not subject to deformation from mechanical loads;

- does not require specific care;

- raw materials are completely safe for human health;

- high aesthetic appeal due to a wide choice of colors and textures;

- the material makes it possible to decorate products with various edges and patterns;

- fire safety of granite - the rock melts only at a temperature that will exceed +700 C;

- the lowest level of abrasion - due to this feature, granite steps and stairs are recommended for use in places with a large flow of people.

Steps of granite - ideal for arranging the outer porch, ceremonial or intra-house staircases, since it is this stone that has combined in itself high strength indicators, providing a long operational life, as well as visual appeal and luxury.

However, reliable and beautiful natural material has some drawbacks:

- consumers note a small minus of steps from granite, which is connected with the fact that it is quite difficult to visually hide the joints of stone slabs;

- work on the installation of components of the stairs and steps can only be performed by highly qualified specialists;

- The large weight of the stone is also a minus when it comes to the staircase structure of monolithic granite steps.

Design features

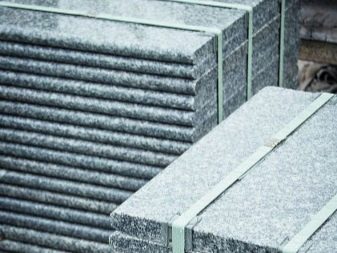

Steps for granite stairs correspond to SNiP and there are several types.

- Solid products that are cut out of stone, based on the specified parameters - length, width, thickness. A tread in such a case can be straight or curvilinear.

- Overhead models - they represent a composite structure, which consists of a tread and a small thickness of the riser - about 140 mm. Some steps go without it. This type is used to finish the stairs, made of concrete and metal.

- Multifurture - such steps have an anti-slip strip on the base. This detail increases the level of safety in the operation of staircases, but does not affect the attractiveness of the whole structure.

Based on the options for processing surfaces of steps from granite, the following types of products are distinguished:

- products with ground base - the use of such processing makes it possible to emphasize the natural structure of the material;

- polished products - the base of the steps is brought to a glossy shiny state with the help of abrasive wheels, while treads with such a surface must have a strip that will eliminate the risk of slipping;

- steps from heat-treated granite they are distinguished by a rough base, due to which they do not require a safety strip, its function is performed by a special coating consisting of a liquid substance;

- sliced products - in this case, the product is not subjected to any processing after cutting.

Granite steps have standard sizes:

- length 600, 1000, 1200 mm;

- width 300 mm;

- thickness is 20, 30, 40 mm.

In addition, most manufacturers offer consumers products that are made according to individual customer sketches.

For outdoor stairs and the arrangement of the porch is better to use heat-treated platesbecause the risk of traumatic situations, especially in winter, is significantly higher on the outside than inside buildings. Some experts propose to perform the porch and steps with heating, using the "warm floor" system, which will increase the practicality and reliability of the design.

Typically, the width of the tape deposited on the surface is 5 cm, the number of required strips is selected individually in each case.

In addition, in order to protect the flight of stairs, in some cases, for example, when arranging steps with linings of a granite-quartz composite, you can use an abrasive belt, which is represented in a large color variety. Therefore, it is possible to choose the material under the light of the stone, so as not to spoil the appearance of the whole structure.

Street steps can be secured using anti-slip rubber.However, such products, as a rule, have a short lifetime, and therefore will require frequent replacement. Especially with a high mechanical load on the steps, for example, in general-purpose buildings.

Beautiful examples

Black color is able to emphasize the luxury of the situation, as well as to correctly place accents in the interior. A spiral inner staircase with steps of black glossy granite is a masterpiece that will turn any decoration of the room into an original and unique stylistic solution.

The porch of the house, equipped with dark granite steps and carved white balusters on the railing, will decorate a country cottage and the entire backyard.

For information on how slabs are made of granite for the steps, see the following video.