The details of the selection of components for the railing

Railings are designed not only to ensure safe movement on the stairs, but also serve as an excellent additional stroke in the decoration of the decor.

Railings are widely used both indoors and outdoors, so many factors are taken into account when selecting them and related components.

Special features

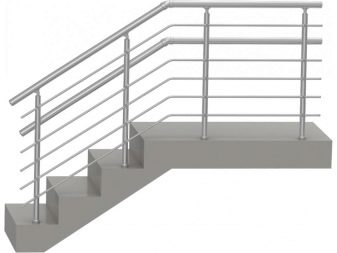

Steel has a high resistance to temperature and high humidity, does not need special care, it is not afraid of mechanical effects. In addition, it combines exquisite appearance and affordable price.

These qualities explain the widespread use of this material for the manufacture of railings and related components, such as hinges, plugs, clips and various fasteners.

When choosing a railing should take into account the combination of materials from which they are made, and the conditions of their operation.

For the manufacture of railings using cast iron, steel, aluminum, iron, bronze and brass.

- Cast iron more suitable for the street, because he is not afraid of moist air. This material allows you to create beautiful and complex patterns, but has a cumbersome look. It is for this reason that it is rarely used in home interiors, but it looks perfect on embankments and in parks.

- Steel - the most practical material. Its resistance to temperature and weather conditions allows it to be used almost everywhere. Stainless steel has resistance to the formation of corrosion, which allows its use in places with high humidity. Grinded steel is practical in application, unpretentious in operation and has a high level of wear resistance.

- Aluminum is more popular in the manufacture of various designs, including railings. The flexibility and plasticity of this material allows to embody a wide variety of shapes and colors. Aluminum railings are usually used indoors.

- Iron - A problematic option, because it has many difficulties in processing and assembly, besides it requires a certain care: periodic tinting and coating with anti-corrosion compounds. It is used more for mass production.

- Bronze and Brass they are used very rarely because of their impracticality - they darken too quickly and need thorough care.

High-quality components - this is a direct path to a successful and durable fence, which will certainly adorn any interior.

Components for stair railings to assemble with your own hands is not difficult if you follow our recommendations. The package bundle can be the most diverse, the set is selected individually. Side decoration can be made from nickel-plated elements or wooden pillars.

Device

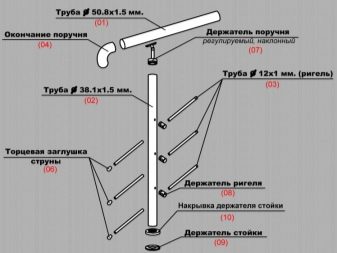

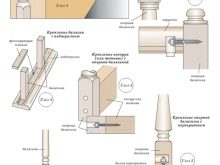

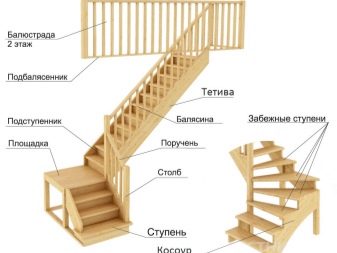

Railings consist of a baluster, a handrail and fill the fence.

Baluster is called support, which is attached to the stairs. It can have both a usual, and a decorative appearance.

Handrails are mounted on balusters and are designed for comfortable operation of the structure.

Filling fencing is applied between balusters to close empty space.

It is used not only for additional security, but also as an additional element of decor.

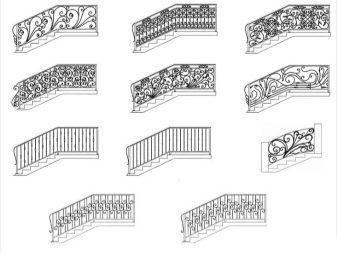

Railings differ not only in the production of materials, but also in the method of production and are divided into 6 types:

- national teams;

- welded;

- stamped;

- forged;

- cast;

- combined.

Prefabricated units consist of individual parts, for the collection of which special fittings are used.

Welded, or reinforced profile railings are made primarily of steel and ferrous metals. Any of these materials allows you to create intricate patterns and shapes in various styles.

Stamped - their original and stylish design is produced by stamping in mass production.

Forged are created by individual forging each element.

This is quite time-consuming and complex manufacturing process. Such railings are created only by special projects and acquire additional charm due to wooden elements and the original color for gold or copper.

Cast are made from molten metals. The liquid alloy is poured into molds, after solidification is removed and subjected to additional processing. This option is more durable railings.

Combined railings have, as a rule, a metal frame that is filled with other materials. Glass or plastic can be used as a fill.

It is the method of making railings that affects their operating conditions and installation site.

Species

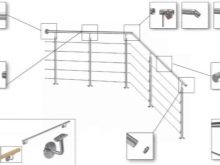

The wide range of components used for fencing is divided into three main categories: fasteners, fittings and decorative elements.

Fasteners

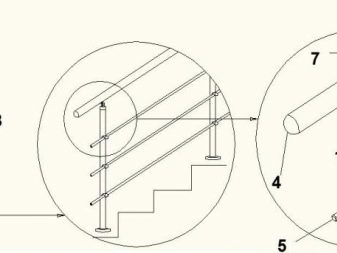

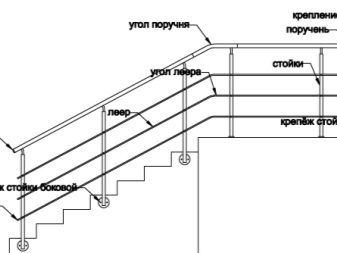

When assembling the supporting elements, they install racks of round or rectangular cross section on the floor and are fixed on the walls or ceiling. These include various flanges, plates or inserts, connected with anchors.

Glass holders are necessary for the installation of transparent fill fences. There are two designs:

- requiring holes in the glass for fixing;

- firmly attached to the support and fixing the glass through a plastic gasket with a screw clamp.

The tie holders or bolt holders are designed for a guide located near a wall or column, as well as for securing the longitudinal filling of the railing with pipes of small diameter.

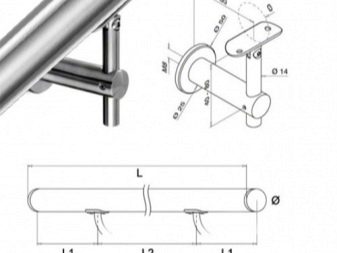

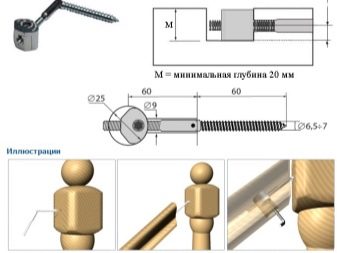

The bracket is intended for fastening the railing and has a whole specific row in accordance with the location of the place of attachment.

Fitting

These are the accessories intended to put hand-rail. They differ in diameter, section and angle of rotation. These include connectors, elbows, twins, corners, turns, which allow you to connect the parts of the handrail into a single unit so that for several spans on it there are no obstacles and joints.

In addition, adjustable connectors allow you to dock handrails at the required angle.

Elements for decoration

Decorative items include:

- Stubs spherical or flat - are necessary to improve the appearance, so their size must necessarily correspond to the railing, otherwise it will give the impression of a foreign element.

- Cups close the ends of racks and railings, preventing ingress of moisture and dirt inside the structure.

- Balls mounted on racks to create an attractive look.

- Heels attached in places of junction racks to the stairs, serve as an additional decoration.

- Decorative twist for the handrail serves to fix it at an angle and differs according to the diameter of the pipe.

Decorative twists for a bowstring are used to create aesthetics to the joints of pipes, marking is carried out in accordance with the section of the pipe.

Connecting elements include:

- the string is a guide tube, it can be of different diameter;

- retraction is designed to connect the parts of the guide, located at an angle;

- connecting elements have different diameter and shape of the section.

Installation

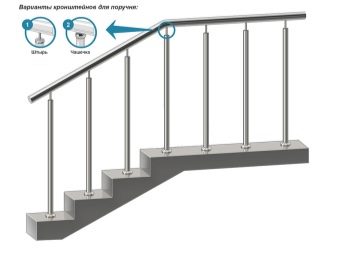

Installation of stainless steel railing starts with the installation of two racks.

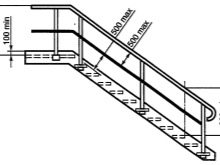

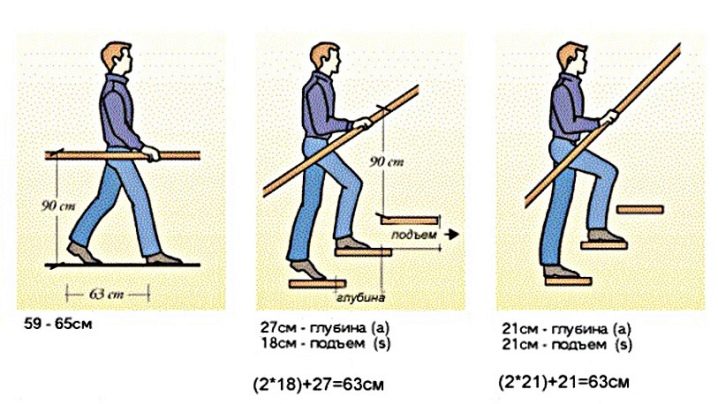

The standard height of the fence corresponds to 90-95 cm, from which the size of the adjustable tip is cut off by the grinder. The burrs formed are scraped off with a wire nozzle or an emery wheel outside and inside the pipe. Those places on which the raid was formed are treated with a felt wheel and polishing paste.

Then, on the prepared racks, lugs are attached, the design of which includes adjustable legs, cradles, handrails and caps. The latter are designed to hide the cut-off position at the front.

Behind the caps are put on washers, between which are located rings of rubber.

During installation, they are squeezed out in order to peck the tip and ensure a secure fit.

After this stand set on the edge of the lowest steps, departing from the edge of 5 cm, mark the place for the holes. This indent is necessary to avoid damage.

At the marks obtained, holes are drilled into which anchor bolts are placed. On top of them, embedded parts are put on and fastened with nuts.

After it is worth making sure that all racks are installed correctly and straight upright. After that on them ready steel railing are established.

After the end of the collection of the straight section of the stairs is completed, its turn is assembled. To do this, take components for removal and inserted into the ends of the pipe, fixed with glue or welding. After using the welding machine, all seams should be carefully cleaned and polished.

Then the fastening of strings (crossbars) is carried out with the help of special holders. For this, a pipe of small diameter is cut off and fixed with a deadbolt. After installed plugs, pre-missed glue.

Properly assembled stainless steel railings have great strength and practicality.

Wooden railings consist of handrails and balusters. Balusters are fastened with handrails, this ensures reliability and durability of the structure.

Installation begins with the installation of extreme bollards with a height of 80-90 cm. To check the convenience of the selected height of the uprights, a rope is stretched between them, holding onto which one should climb and descend the steps. If the height suits, you can move on, if not - it is corrected.

Then, the installation frequency of balusters is calculated (at least 20 cm to ensure the safety of movement of small children) and a hole is made in the handrail with a drill. The lower edges are mounted on the steps, and the upper edges are sawn off at an angle of the taut bowstring.

Fixing the whole structure is best done on the screws, additionally securing them with glue.

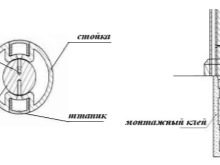

Installation of aluminum railings is also carried out in several stages and takes a little time.

- Pre-marking of the stairs in the places of installation of balusters. Then holes are made with a diameter of about 2 cm and a depth of about 10 cm.A two-component adhesive is poured into the holes and anchors are inserted. After they put on the rack.

- Then put on the hinges and handrail. Having adjusted the height of the tilt of the handrail, it is attached to the anchors.

- The flange is fixed to the floor with glue, and the handrail to the hinges - with screws. In case the staircase has several marches, then they are interconnected by turning elements. They are of two types - 90 and 135 degrees.

Metal railings can be combined with stairs made of any material.

The railings are bolted or welded to metal structures. Metal flanges are fastened to wooden stairs with bolts or screws, and the railings are welded to them.

If necessary, mounting the railing on the wall will need brackets. Their size is chosen in such a way that the distance between the wall and the handrail is 10 cm. The fasteners can be used both cast and folding. If necessary, such a structure can be easily dismantled and moved to another place. The use of hinged fasteners makes it possible to adjust the level of the railing of the railing.

Tips and tricks

When choosing components for railings, special attention should be paid to the surface and shape of the product.

The surface should be smooth and even without burrs, cracks, rust, scale, mechanical damage, bending and other deformations. Otherwise, the protection of the part against corrosion will be violated, which will lead to a complete replacement of the fencing section.

High-quality components correspond to the operating conditions not only indoors, but also outside, which allows them to be used in ordinary street conditions.

To increase the service life and protection from weather conditions, metal elements are subjected to galvanic treatment, i.e. nickel-plating or chrome plating. After this treatment, metal parts are contraindicated in contact with welding, since the galvanic coating breaks down when heated.

The process of installing stainless steel railings, see the video below.