Ladder steps: what is it made of and how is it installed?

Steps - face stairs. For them, using materials that emphasize the appearance of the structure. The choice of raw materials for finishing in the modern market is huge, but it is necessary to acquire the finishing of stairs taking into account standards and existing norms. It is important to understand the differences between the types and features of the stairs themselves.

Types and features

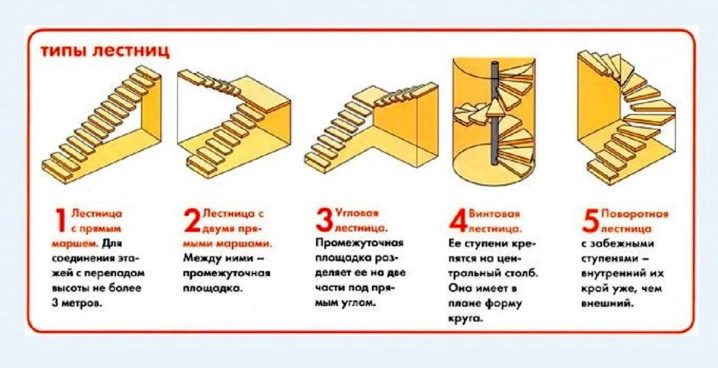

Criteria for the separation of stairs and stairs according to the types and features are diverse. For example, subgroups can be differentiated by the form of treads. This is the upper horizontal part of the step, which happens:

- zabezhna;

- arcuate;

- straight;

- swivel.

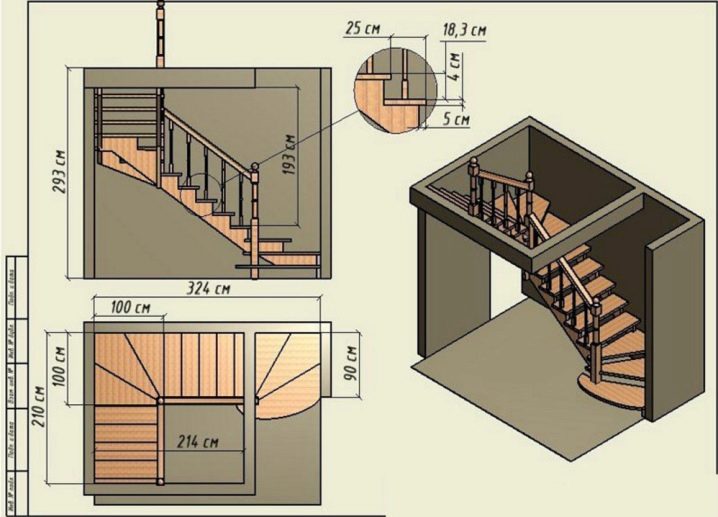

The use of rotary steps is important in homes where a small portion of the area is reserved for the stairs. Street stairs are rarely equipped with turntables.To save space, they often equip the staircase with steps. These steps are peculiar in design, but the norms and standards are observed here. It is difficult to calculate the parameters of this design, since the steps have different widths.

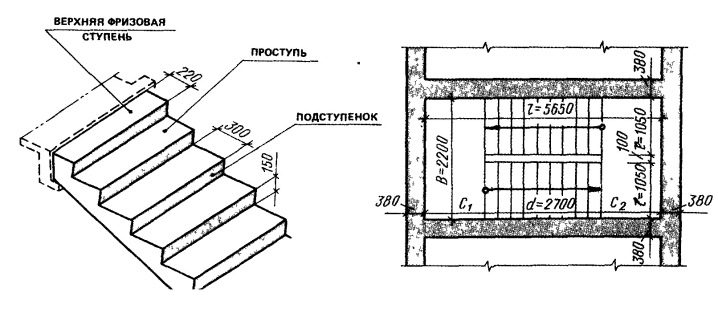

Any staircase includes one or more marches. At the beginning of the march this, the starting step, ends with the construction of the exit stage. Steps located between them are called intermediate. The height between the two steps is called the riser. It can be open or closed. The height of this part is calculated according to GOST.

Work is not easy, it will take more time for installation. In addition, the steps differ in the way they fit together. Connections are rectangular or roller-shaped. Specialists classify the risers depending on the design parameters. They can be:

- wedge-shaped;

- rectangular;

- triangular;

- round.

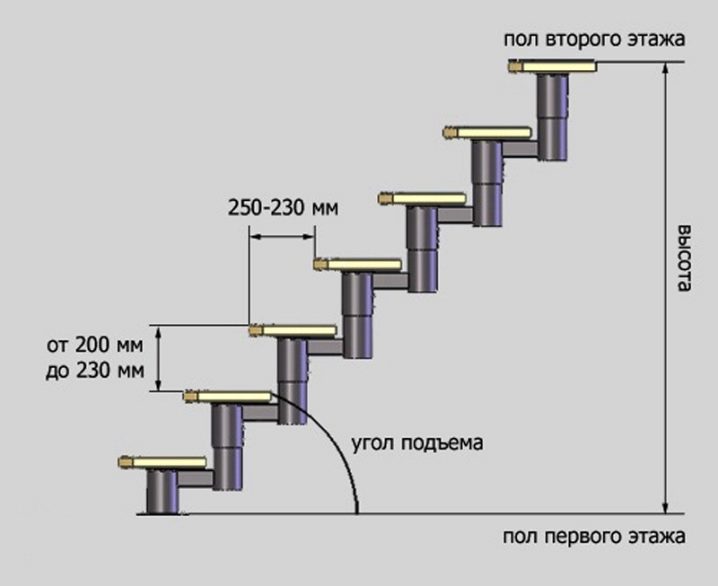

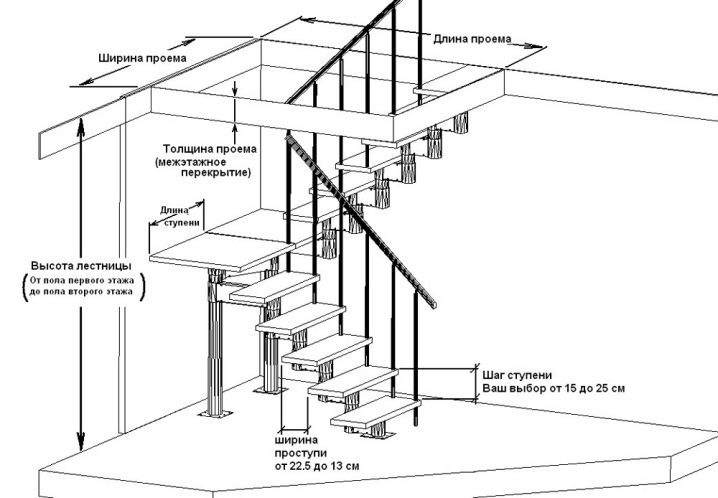

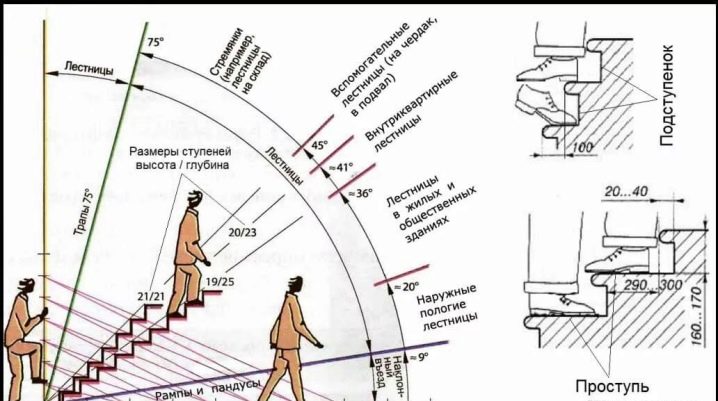

Stair steps must also comply with strict standards, as moving along stairs should be safe. For example, for internal stairs, the height of the riser varies from 15 to 22 cm.The width of the horizontal part of the step is from 25 to 40 cm. If the stairs are round (spiral), it is allowed to change the depth of the tread. In this embodiment, the design on the outer edge is wider, to the inner side is usually already.

The width of the ladder can leave at least 90-100 cm. This value can be changed if a massive decorative porch is erected near the house. It is unreasonable to make wider internal stairs, as they will occupy a lot of usable space. These standard data are needed in order to calculate the optimal angle of inclination of the finished staircase. The total number of steps in the march must meet certain standards. Standards relate to the characteristics of materials selected for the construction of the stairs.

The total number of steps in the march must meet certain standards. Standards relate to the characteristics of materials selected for the construction of the stairs.

Materials

Different materials can be used to finish the steps. For this fit:

- a rock;

- tree;

- brick;

- tile;

- glass.

Wood is considered a short-lived material, the details of a wooden staircase are usually treated with protective agents.This prolongs the life. Antiseptic impregnation eliminates the formation of mold fungi on the surface.

Glass steps seem fragile, but the reliability of modern types of this material is not inferior to other types. For the steps is usually used laminated (reinforced) glass. The construction of the staircase itself is usually metal, consisting of grating.

Tiles are often used for cladding concrete or stone stairs. The industry offers this material in a wide variety of options, including imitations for different textures. For example, collections with the texture of a tree are popular. Many companies offer the attention of the buyer such tiles. Among them, the ceramic tree from the Kerama Marazzi collection is particularly popular.

The structure and color of porcelain tiles in this series are similar to natural wood. Kerama Marazzi is an excellent imitation of natural stone. This is a finishing material that has been known for its qualities for a long time. Ceramic granite brand is actively used for interior decoration.

The ceramic concrete collection is even more popular.Special series appreciated by designers and architects.

The “carpets” collection bears a special aesthetics. This element of decor can be seen in private interiors with staircases, administrative buildings, restaurants and cafes.

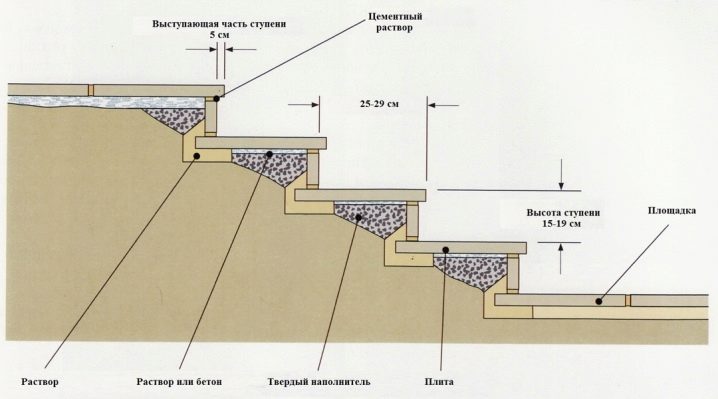

Porcelain stoneware is durable and durable. This material can be washed, its surface is cold, unpleasant by tactile sensations. The device of steps from a brick in the house is unprofitable. Such structures are usually external, they are needed for lifting into the house (they are used for the porch). For brick steps you need:

- a foundation for which sand and rubble are usually taken;

- bricks that are laid in a specific order;

- facing (ceramics or paving slabs).

The last stage can be excluded if clinker bricks are selected for the steps. The clinker brick is an elite finishing material, it is distinguished by an affordable price in comparison with ceramic granite. This brick is used for indoor and outdoor stairs. This coating is extremely durable.

The clinker steps and porcelain stoneware are produced in collections, which include sets with details of certain sizes to create a stair structure.

Selecting a suitable material for finishing steps is half the battle. It is more important to make calculations correctly. They will allow you to purchase the exact amount of material, build a proper and safe construction.

Parameters: calculation

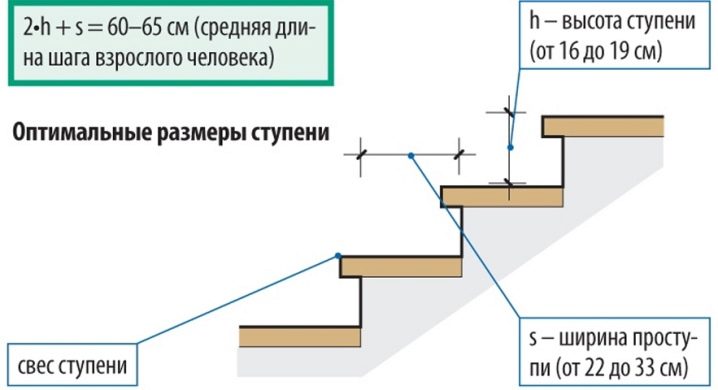

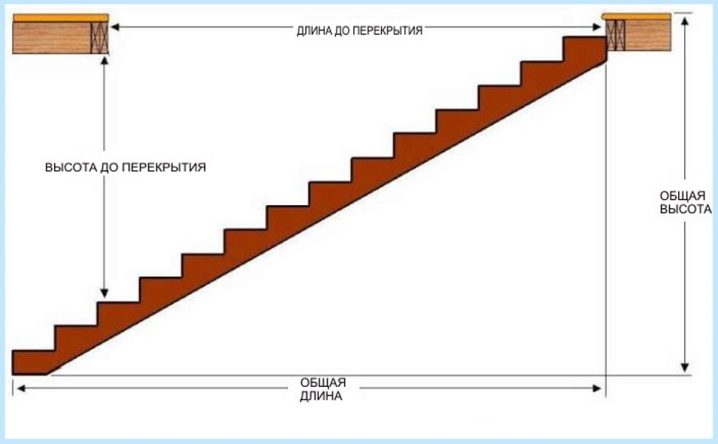

In the calculations will help draw up a plan or project. At this stage, you need to correctly determine the size of the structure, architectural features. All ideas are best displayed on paper. A good tool in the work will be the ability to use special computer programs. Consider the standard height and width of one step (from 15, 30 cm). Comfortable slope is the angle of the staircase at 30 degrees. If it is smaller or larger, it is better to provide zabezhnye or rotary steps.

The generally accepted angle of inclination of a classic staircase for a dwelling can reach 45 degrees. Constructions in public places are mounted at an angle from 20 to 30 degrees, street - at an angle from 5 to 20 degrees. The lifting step is determined by the height and width of one step. To calculate it, the height of the ladder should be divided into equal parts. According to the norms, this size should be within the range of 15 to 25 cm. Deviations up or down will make climbing steps uncomfortable.

When taking into account the height of the step, it should be understood that the riser can have a decorative and functional duty. If the staircase is wooden, this part will be bearing in the structure. If it is concrete, it will become an ornament. The depth of the stage of the step, on which a person’s foot steps, is determined by standards. It should not be less than the size of the foot.

The depth of the tread is increased by mounting the overhanging element, but it is not necessary to release the tread by more than 4-5 cm. The ladder design will turn out inconvenient, and brittle materials (for example, a board) will break off when walking.

The last statement is not suitable if the treads are made of porcelain stoneware or concrete.

Consider an example calculation for a small staircase that will provide a climb to the second floor in a private house. To calculate the required number of stages, you must use the graphical method. Determine the values of one element, according to safety standards. You can take the parameters of the finished (purchased in the store) parts. Transfer the overall design view to a millimeter sheet of paper, applying scaling.

In the drawing, the parameters are useful:

- step heights;

- number of steps;

- risers height.

For example, take the height of the risers - 15 cm, platforms - 150 cm. 150: 15 = 10 steps. The length of the entire march can be calculated by multiplying the number of steps by their width. The recommended tread width is 25-30 cm. 25 multiplied by 10, we get a march of 2.5 meters in length. When rounding values, it should be borne in mind that the intermediate steps of the ladder should be the same. To distribute the error of calculations can be on one of the steps (lower or upper).

Manufacturing

Steps for stairs made of porcelain stoneware are the most popular today, let's take a closer look at them. They are monolithic and teams. The one-piece steps made of porcelain stoneware are sheets of standard size 30x30 cm, and the dimensions of the risers are 30x9.6 cm. If the one-piece steps are made, they will be especially strong and stable.

A ladder can be assembled into modular (prefabricated) elements using the method of forming a seam butt joint using decorative elements. Designer decoration is achieved by selecting items from the collection or by combining various types of porcelain stoneware.

It happens:

- polished;

- unpolished;

- glazed.

Standard equipment for prefabricated stairs is a set that includes tread, risers and baseboard. If the stage is monolithic, all these parts are connected in one piece. Ceramogranitny steps make by a pressing method at factories. Installation of steps on the staircase is possible only by special technology.

The second most popular type of stairs is wooden. For this option, choose different varieties of material (oak, beech, ash, maple). In the absence of experience with the plane, it is better to choose already processed raw materials. The undoubted favorite in the production of finished wooden steps is oak.

Wood has a special beauty and long life. Beech is inferior to the first variant in strength, but the steps made from it are cheaper, because the variant is no less popular. Ash and maple are notable for their attractive exterior characteristics, rich texture and unusual shades of the base. The templates of the processed material must meet certain parameters.

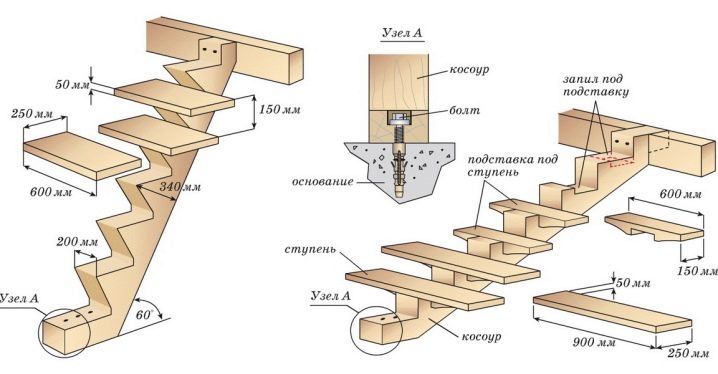

Standard treads and risers made of planks are plain rectangular sheets. Non-standard forms are only rotary steps.But these parts are easy to make yourself, having the relevant drawings.

If untreated wood is used for work, it is better to immediately protect the surface of the parts obtained with appropriate mixtures or primers.

Installation

There are several known ways of mounting steps. Some methods are complex and require skills. Others are convenient for self-assembly designs. Installation of wooden steps can be carried out using:

- kosoura;

- bowstrings;

- boltsov.

The last option refers to a complex method, the first two can be done independently. If it is decided to mount the steps to the kosoura, it is possible to join the tread and the risers with screws or a joint into the groove, as well as by means of an additional rail. In any case, the riser and tread must first be interconnected. Then they can be fixed over the teeth.

For fixing the steps on the string you can use:

- additional bar;

- metal corners;

- mount into the groove.

The last option is important to do deep. Connection for reliability you need to glue with glue.When installing the steps on the bolts, it is important to provide special components, in the role of which use bolts. These fasteners will hold the steps on the stairs. Fixing the steps on the Bolzah allows you to build structures of unusual shape, as it is permissible to fasten the steps to the wall.

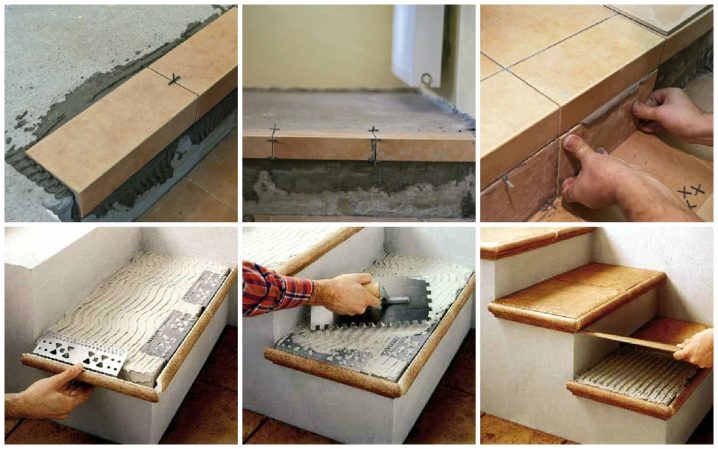

The technology of finishing steps with porcelain stoneware consists of several step-by-step points.

- Start at the top of the ladder. Apply the solution on the surface and lay the individual parts will be more convenient.

- Prepare the right amount of adhesive in the container that fits on the steps.

- Choose a spatula size that is not more than the tread width and riser height.

- Observe the priority of installation of parts: first tread, then risers.

- Be sure to clean the seams.

- To increase the decorative and durability of their need to fill a special grout.

The ideal joints are those that are flush with the steps. Allowed to make the joints a little wider. Strongly protruding elements should be cut off at once, otherwise they will be unstable on the stairs, and may later break.

Finishing and design: examples

Decorative qualities of porcelain stoneware are widely used by designers to create a general view of the interior and exterior.

- As a rule, risers are involved in the design, which play the role of decorative components. Installation of the risers with patterns and drawings allows you to create original and skillful design of stairs.

- An alternative can serve as a single-colored porcelain stoneware details that can be decorated. For example, contrasting with the base color of the baseboard steps.

- For bright and unusual interiors, a combination of plain ceramic granite and mosaic will be suitable.

- Wooden steps with metal railings will look great.

- Designed staircase with wooden steps, hovering in zero gravity. This is a bolt version of mounting steps to the wall without the use of additional elements of the stairs.

How to make a staircase with your own hands, see the next video.