Where is the staircase with winding steps 90 degrees used?

Modern urban and country house construction has undergone significant changes. Instead of single-storey houses are built buildings in two or three floors.

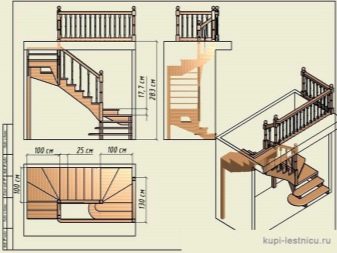

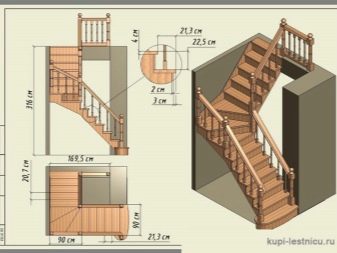

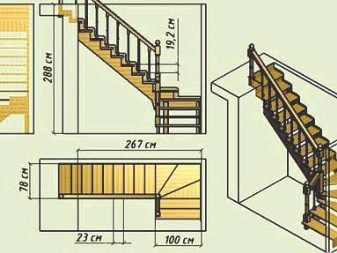

To get to the second or third level of your mansion you can, using the stairs. To save usable space, builders recommend installing L-shaped corner staircases with zabezhnymi steps.

What it is?

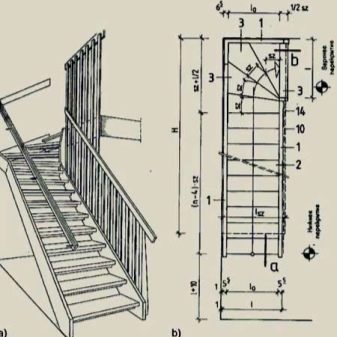

The L-shaped corner staircase to the second floor with treads steps and a 90 degree turn angle is a structure in which, unlike the ordinary ladder, turntables are replaced by steps.

The treads are not installed parallel to the others, they are mown at an angle to the overall structure. This effect is achieved by changing the width of the step itself. Its inner part is narrower than the outer. Only in the central gap does it coincide in width with other stair steps. As a result of mounting such a system, a turn is formed.

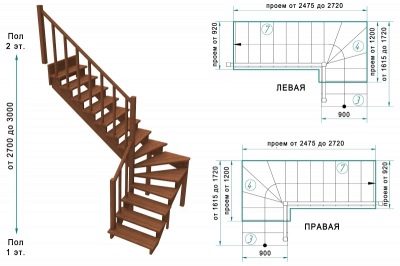

When the installation of a conventional staircase is impossible, pivot stairs are used. If necessary, between the gaps mount sites. The appearance of the corner stairs to the second floor can have several variations. There are L-shaped (L-shaped) and U-shaped design. Also, the stairs are made with two or three turns.

Kinds

There are three main types of staircases with zabezhnymi steps.

- When the bowstrings and kosouri ladders adjoin one wall of the room, it is called a single-arm model.

- If two walls are used for the construction of the staircase, and its marches are angled to these walls, then it can be said that this is a double-mart design.

- The three-march ladder is more complicated to install and requires the correct calculation of all the constituent elements.

For easy operation of the staircase, it is recommended to install 8-10 steps in one flight. If it is necessary to mount more than 10 steps, then it is best to make a staircase in two marches.

Very often, in order to free up space in a room, a two-flight ladder is installed with one or two turns. With respect to the wall, the rotation can be at an angle of 90 degrees and 180 degrees. There are no platforms for double-mast ladders, but there are only pivotal steps. It is better to mount the march as a curvilinear construction. In this case, the stairs will be turning parts. The turns of the two-frame structure are interconnected by a platform located perpendicular to the entire staircase cascade.

The L-shaped staircase can be performed at any angle, however, homeowners prefer stairs that are installed at an angle of 90 or 180 degrees.

In private houses and cottages, the one-man-operated staircase is most often mounted, that is, a model with a single span.

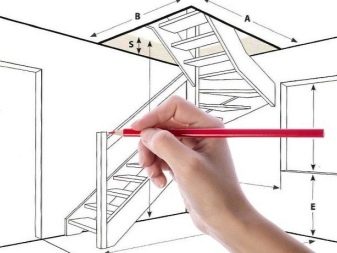

For the correct choice of the ladder design, you need to make a series of measurements and perform a drawing. The main parameters for the design and installation of the stairs will be:

- step height and depth;

- span width (railings and steps);

- the march and length of the stairs;

- tilt angle;

- upper and lower threshold.

The choice of stairs should be made taking into account its location in the house. It is necessary to determine from which material it will be made and what appearance it will take as a result.

Then you can go to the calculations themselves.

How to calculate everything?

The calculation of the staircase with treads with a turn of 90 degrees is performed using several methods: mathematical and graphic. The latter method is more accessible for understanding and does not require in-depth knowledge of geometry.

At the beginning of the calculations it is necessary to determine the dimensions of the main constituent elements. These include:

- average marching line of at least 80 cm;

- the angle of rotation of the steps (90 or 180 degrees) and the angle of inclination of the stairs (from 23 to 37 degrees);

- the width of each step (at least 120 mm in the narrowest part and 200 mm in the middle);

- the length of the flight of stairs in the gap between the height of the angle of rotation and the last step;

- the radius of the structure itself and the width of the treads (the narrow part of the tread must be at least 100 mm, and the widest - 400 mm);

- step height not more than 180 mm;

- height of passage from 1900 to 2700 mm;

- number of steps in transit (14–18 pcs.).

It is also necessary to calculate the number of bearing beams (rail), railings, handrails, balusters.

Drawings and diagrams should be made on paper in order to display the staircase in a horizontal view. Throughout the march, you should draw a center line and determine where the boundary of the last straight steps will be (below and above). Next, you need to put on the diagram or drawing of the central reference point. From it distribute zabezhnye steps. The depth of the tread is calculated from the central marching line.

For example, you need to calculate the number of steps along the length of the flight of stairs. The height between the floors is 2500 mm. Then the height of the steps (risers) - 150 mm.

The depth of the steps will be calculated by the formula: LH - 2 x B = HS, where B is the height of the step, LH is the average statistical length of a person’s step, equal to 620 mm. Thus, the calculated depth of the steps is calculated as follows: 620 - 2 x 150 = 300 (mm).

Then count the number of steps. For this, the size of the height of the opening must be divided by the height of the steps 2500/150 = 16.67 (pcs.). After rounding to integer values, 17 steps are obtained.

The length of the entire flight of stairs is calculated by multiplying the depth index of the steps by their number 17 x 300 = 5100 (mm). Accordingly, the length of each march will be: 5100/2 = 2550 (mm).

Pros and cons of design

The advantages of the rotary L-shaped stairs include a number of indicators.

- This design looks quite original;

- it can be made from different materials;

- This staircase is mounted with a turning angle, which allows it to occupy a minimum of usable space.

The following indicators can be attributed to the drawbacks of the stairs with the run-in steps:

- the runners are unusual for walking along them and there is a risk of loss of coordination when moving;

- to design and make an exact fit of each step to the desired size is quite difficult;

- errors in the calculations of indicators are not welcome, because from this the strength of the whole structure decreases.

Material used

The manufacture of stairs can be of several types of material. They can be wooden, metal, concrete and glass cascades.

The design of the tree is the most common and easy to install. Zabezhnye steps, no matter how accurate they were made according to the drawings, often have to be customized on site during work. Concrete or metal parts cannot be adjusted after installation. Unlike these materials, steps made of wood can be adjusted on any part of the work without disassembling the entire structure.

Elements of the ladder can be made of wood such as oak, pine or ash. Perhaps the use of pine or maple in the work.

The tree must be dried well to prevent the parts from deforming, the creaks of the steps, and, as a result, the structure will soon be repaired.

Attach the ladder using a beam or skewers.

To do this, use the materials:

- boards at least 40–50 mm wide;

- not less than 30–40 mm thick bars;

- metal corners for mounting;

- mounting glue, screws and screws of different lengths, screws.

For the ladder of metal need sheet metal profiles. Also need channels and pipes. Zabezhnye steps made of metal in two ways.

In the first case, the frame is performed. For it, use profiles that are interconnected by welding.In the second case, the models of the treads are made with bowstrings and fillies.

Concrete stairs with zabezhnye steps performed by pouring concrete solution in the form of a future stair design. For strength, a reinforcement mesh is placed in the solution. The solution is prepared from crushed stone, sand and cement in appropriate proportions. Pour it in the upward direction. After pouring, the solution is allowed to dry a little and is adjusted using the rule. After leaving until the final drying.

Glass constructions design and install construction companies. It will be very difficult to make such a ladder on your own.

Perform stairs of triplex, multiplex and metal. Also, their installation includes the presence of a large number of additional fastening and supporting elements: fences, railings, handrails.

Recommended Specifications

In private homes, the staircase should be located in such a way that fire safety requirements are not violated. The house where such a ladder is installed should not be subject to constructive changes.In the event of a fire, zabezhnye steps should not be an obstacle to the descent of people from the second floor of the house. They should not be on the march segments for which evacuation is provided.

Steps should not slide. Elements of the ladder should be fixed to each other very carefully, with exact observance of the dimensions and sections indicated on the drawings. It will be safe to move up the stairs only if the depth of the step, its height, and the width of the march are correctly installed.

Great attention is paid to the railing. They must be continuous throughout the flight of stairs and not interrupted. Also should not be low railing.

Platform between marches can not be done by narrow design. Self-made ladder will be safe if all technical requirements are met.

Independent production

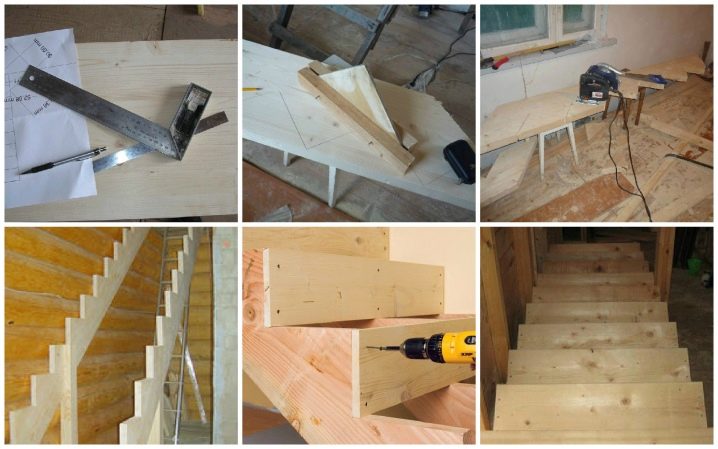

The most time-consuming part of the work with the independent production will be in the preparatory part. First, it takes time to make the details of the stairs. Begin work with the manufacture of steps and risers.

According to the drawings make smooth and rotary steps. In the narrowest part of the turning stage cut corners.For the installation of each step, you will need four corners for fastening and two support bars for each of them.

After a piece is made. With it, on a bowstring or ladder kosoure produce markup. In conclusion, make the supporting pillars. They act as a support for kosour or bowstring.

Installation of the turntable is made on the frame with the frame method. In the case of kosourov use it put on kosoura. Depending on the design of the stairs, the kosour is possible only in the central part of the stairs. They can also be two, if they are installed on the sides, or three: two side and one central element.

Bowstring is a beam holding the steps. Steps are inserted into the grooves pre-sawn on the sides of the board. A kosour differs from a bowstring in that the supporting part for the step is cut in the upper layer of the board, and the steps are laid over the support.

Installation begins with the mounting wall kosoura. It is fixed to the wall with screws. The supporting pillars set the second stage. It is best to concreted. On them external kosour is mounted.

Steps as a continuous canvas are made similar to each other.Installation begins with the installation of standard parts, and then install the tambour elements.

Their narrowest part is fixed on a support.

All steps are mounted horizontally. The bowstring (kosour) and steps are connected by means of a metal angle (4 pieces) and a support bar (2 pieces). During installation, all errors are corrected, which subsequently will affect the reliability and durability of the structure.

After mounting the horizontal make angular steps. To the support they should fit very tightly. If it is not possible to fix the stage very tightly, then it is better to replace it by making a new element.

The installation of the steps is the installation of the risers. They are mounted outside or inside the stage. The next step is the installation of treads. They are mounted similarly to the risers.

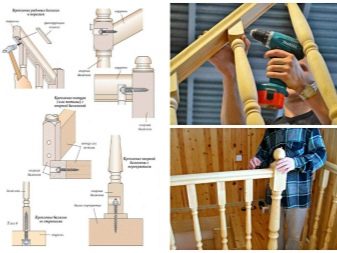

In the final part of the mounting stairs make railings (balusters) and the railings themselves.

Fix them with support pillars and steel studs. Then make balusters. For their installation use dowels. In tread drill holes and pour glue.

Next, using the tool (mallet), hammer the dowels into the holes. In the lower part of the baluster a similar hole is drilled and it is fitted to the shkant.Thus, the railing is formed. After the whole staircase is painted and varnished. At this installation work ends.

Useful tips

Masters involved in the installation of rotary stairs with treads, give a lot of advice.

When designing the stairs recommend installing an odd number of steps. When climbing up the stairs, it is advisable to step on the last step with the same foot as on the first. It is very comfortable in the psychological aspect.

The height between the march and the ceiling base should not be made less than 190 cm. A person should not bend over the stairs.

In the installation of the most simple are single-march structures. It is better to erect two-mid-flight ladder lifts with the same number of steps in each march and do the railing on the right side.

Independently manufacture and install the ladder design, you can clearly know the whole installation algorithm and having reliable calculations and drawings.

If you have doubts as to whether you can make a solid and safe staircase, it is better not to waste material, time and effort, purchase a ready-made structure or consult professionals.

For information on how to make a template for an in-turn pivotal step for a ladder, see the next video.