Spiral staircases: designs, assembly and installation features

In houses and apartments more than one floor can not do without the stairs. But it happens that there is very little free space, and it is very necessary to climb up. In this case, a simple but steady spiral staircase can help. Some models are played up by modern designers so that they become not only a convenient lift, but also an excellent addition to the interior and a roomy storehouse for useful and important trifles.

Types and elements

Spiral staircases are so named because of their external resemblance to the screw.Starting on the top floor, such a staircase descends with a light streamer ribbon. Decoration, functional addition and lightweight design that can be assembled by yourself.

Screw-type ladders have four basic types depending on the method of fastening the steps.

- Axis + walls. For this construction, a central axis is first established - a pillar, a pipe, or simply even the connecting elements of the steps. The walls of the room, located near the opening for the stairs, are the most common method of fastening. Thus, the main load of the structure falls on the central pillar and walls of the room.

- Console mount. The main actor is still the central axis - a wide pipe. Stairs are attached to it with the help of consoles. The walls of the room are not involved in this, the staircase can be placed in the middle of the room, but the design is quite stable, tough and durable due to the console mounting.

- Bent bowstring + fencing. One of the most original and easy options. Such designs, as a rule, create the illusion of floating in the air.In fact, the ladder with this type of attachment has an increased complexity of installation, while remaining quite strong and safe. There is no central axis on which the steps could rest. The main link of the whole structure is spiral bowstrings - kosouri tape form. Balusters with railing fasten upwards from these flowery strips. Alternatively, monolithic broad lanes can also be attached to the string of the ladder, also serving as a support-fence for a person.

- This view is very similar to the second - cantilever mount, but not so. This is a kind of prefabricated structure, the steps of which are strung on the casing support pipe with its narrow end. It also does not use walls or any other additional support.

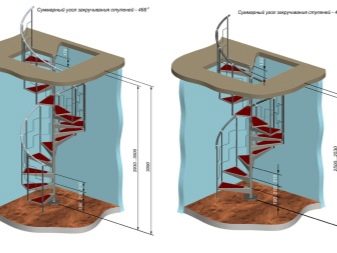

The circular staircase is a complete launch-and-lift structure, which by its shape provides a convenient and practical operation. If you look at it ready from the height of the second floor, you can see the drawing of the stairs. The cascade chain of steps usually descends on a flat circle with a minimum diameter. Sometimes you can contemplate the shape of a polygon, when the ladder rests on the center axis and the walls of the room.

The original modular ladder is the same screw design, with only a small turn. This design, which is based on the installation of steps-modules on each other. And also there is one central support, which is placed strictly in the middle of the screw march and gives the structure strength. However, such ladders are most often used where one has to climb upward infrequently.

It can be traumatic and uncomfortable.

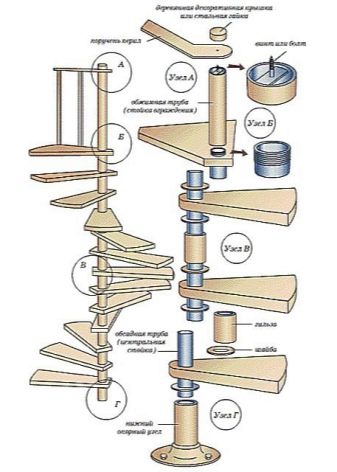

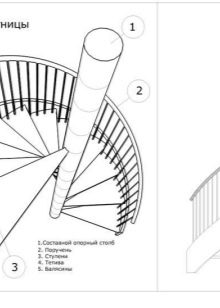

Ready-made spiral staircase structures include the following main components:

- steps;

- top platform;

- railing post;

- directly railing;

- center pole - the axis of the structure;

- racks balusters that connect the turns of the stairs in a single structure;

- the fence of the second floor.

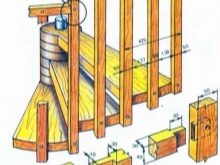

The main points of the assembly are four nodes.

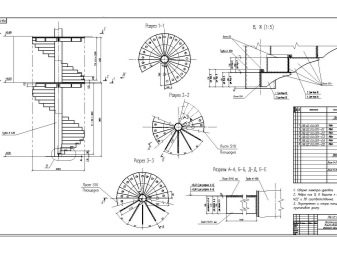

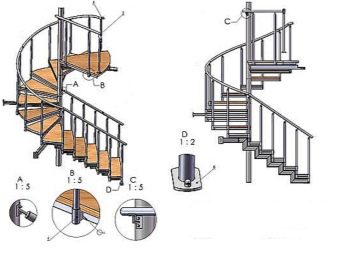

The mini-scheme for a dial-up configuration of spiral staircases looks like this:

- node A - fastening the axial pipe to the railing of the second floor;

- node B - the center tube is connected to the stage console;

- node B - washers and sleeves are installed on the axis, which serve as a lock for consoles, as well as serve for decorative design of the structure;

- node G - the union of the lower support center with the main pipe.

Advantages and disadvantages

Possessing originality, the spiral staircase has several undeniable advantages, which, however, deftly parry tangible drawbacks.

Positive statements in favor of a florid design on the second floor:

- spiral staircases take up very little space, the most cumbersome design has a diameter of 2 meters, while savings in usable space are also evident on the second floor;

- Ornate constructions can play the role of service ladders, when you don’t need to climb up very often, but you don’t want to buy and install bulky or folding models;

- low cost relative to standard marching structures;

- It is often used as an additional place for storage and as a decor for a room, its main highlight.

Private house - a private area where everything should be perfect for the owner, individually and tastefully chosen. But there are moments when something went wrong and all the advantages of spiral staircases suddenly faded against the background of their minuses.

- According to them it is impossible to lift large items to the upper floor.Despite even the largest diameter, turning around on a serpentine staircase with a piece of furniture is a big problem.

- Discomfort with constant use. Some may even feel dizzy in the process of descending or ascending a structure that is too curved. For others, the steps in the form of petals do not seem to be very comfortable for the foot: the foot may slide off, leading to unforeseen injuries.

In any case, all the pros and cons of spiral staircases - personal experience of each individual owner, therefore, it is not worth to fully affirm and ensure that this option is the best or the worst.

Let's try to understand the materials from which spiral staircases are made.

Materials

Everything is rather prosaic here, as in most staircase structures. These can be models made entirely from one raw material, as well as combined ones. In some cases, there are combinations of several different materials. But consider now the main ones.

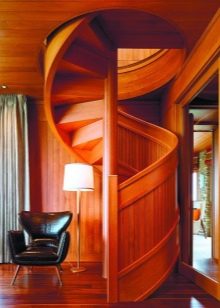

- Wooden spiral staircase - a classic of the genre. Just because before all lifting structures were made of this material.Despite the large number of curved lines, wood harmoniously fit into the image as a whole.

- Stairs from metal also cozily settled in modern dwellings. Its essential disadvantage is the cold of the metal, transmitted to bare feet at the time of operation. But such structures show a high level of strength and durability. In addition, the metal spiral staircase has an excellent opportunity to become a bestseller, equipped with original forging.

- Glass the design is quite rare, but it creates the illusion of a ladder floating in the air. Most often glass is present in the combined models, acting as steps or fencing.

- Concrete - around the head in modern buildings. Typically, concrete solid spiral staircases are laid at the design stage of the future home. As a rule, such models have the most cumbersome structure compared to the same, but made of wood.

- A rock both natural and artificial, along with wood, is the most conservative material for the manufacture of spiral staircases. The design is quite heavy, so it is also often used in combined models.

Spiral staircases, in which two or more metals are connected, are not uncommon today. Such designs allow you to save a little and achieve the desired result. But you need to select them wisely and in accordance with the design of the dwelling in which the stairs will be installed.

For example, iron support, wrought iron railing and wooden steps are perfect for classic and retro style interior. Fully metal constructions will appeal to lovers of the loft. Hi-tech harmoniously merges into a single unit with a glass-metal ladder.

For pompous grotesque rooms, bulky structures made of concrete or stone will be a unique solution.

Shape selection

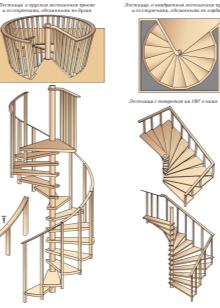

Another way to divide spiral staircases into subgroups is depending on the shape.

Despite the fact that the form is already predetermined, it may have different variations:

- spiral or circular - uniform coils are formed around the pillar, the base has the same radius on each revolution;

- rectangular - when relying on an axis and on a wall, this form of ladder is often formed, while, as a rule, it has no more than one span;

- curved - spiral with changeable inner and outer radii of the ladder, which has several subspecies: G, P and S-shaped.

To understand which ladder you need, decide on the place where it will be installed and calculate all possible options for its placement.

If you have not yet cut a ceiling opening for a screw design, consider whether it will be convenient for all family members to climb to the second floor, in which a round hole of relatively small diameter will be cut.

Design

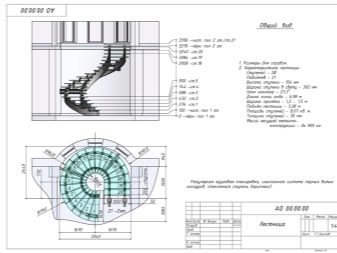

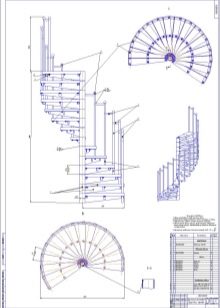

At the stage of creating a project, the main difficulty arises with the calculation of all the necessary parameters and dimensions. You can contact the special architectural or design office, which during the day will provide you with all the necessary drawings. And you can try your own happiness and develop a plan for the manufacture and installation of a spiral staircase.

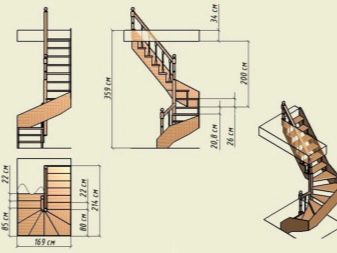

The dimensions of the serpentine-type lifting structure have the following starting points:

- steps - width, length and distance between them;

- axis - wall thickness and pillar diameter;

- risers - the presence or absence, the first option is revised item number 1;

- coil - a height that is comfortable not only for lifting or lowering a person (steep or flat), it must also correspond to the height of the tallest person in the family, so as not to beat your head against the next turn of the staircase screw.

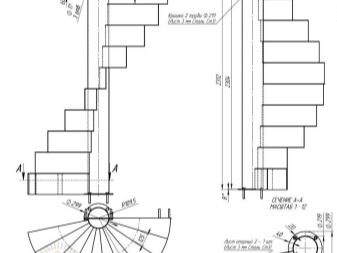

First of all, we accept the calculation of the dimensions of the main parts and the project drawing itself. To calculate all the necessary parameters, there is a special building formula, which is not easy to figure out the first time. We suggest you to do all the calculations on the example of specific numbers. So it will be clearer.

For example, the average data of a virtual spiral staircase will be taken. The width of the march is 90 cm, the height of the structure is 2 m 70 cm, the diameter of the center pillar is 30 cm.

First we need the overall diameter of the spiral staircase. Find this value will help the formula in which you want to multiply the width of the march by 2, and the result of the result to add the diameter of the column. At the output we get the following example: 90 cm x 2 + 30 cm = 210 cm or 2 m 10 cm.

The next element to measure will be the trajectory of a person moving along this ladder. Here the formula dictates us to add the radius of the main pipe with the width of the march. Then all this is divided in half: (150 mm + 900 mm): 2 = 525 mm is the radius of the circle of the human trajectory.

Now we calculate the number of steps to a given height of the stairs. First, we determine the circumference of a person’s walking trajectory using the formula 2xPxR. It turns out the figure of 3,297.Next, we take the width of the middle part of the stage of the screw structure (usually it is 20-25 cm), we divide the circumference obtained by it. We get 3 297: 250 mm = 13,188. That is, the steps in the design should be 13 pieces. Most often, professionals round up the result in a big way.

It is necessary to determine at what distance from each other steps will be located, that is, their height. First we calculate the height from the upper step to the lower. The approximate thickness of the standard stage is 30 mm. The maximum height of a member of your family (1900 mm) with an allowance of 100 mm, it must be folded with the previous parameter. Total we get - 2030 mm.

The height between the steps is equal to the ratio of the height of the coil (2030 mm) to the number of steps (13-14). We get the figures of 156.15 mm and 145 mm, respectively.

When all measurements have been made, the diagrams have been drawn, and the material and form have been chosen, you can proceed directly to the manufacture of a spiral staircase.

Manufacturing

Once again, I would like to clarify the importance of observing all the nuances and proportions in order for this compact and lightweight design to be a truly practical acquisition.

As the main core of the spiral staircase can be used:

- metal pipes;

- concrete and brick pillars;

- wooden supports.

Attach steps to a metal, concrete or brick base using special couplings and bolts.

They are attached to the tree in much easier and more diverse ways.

The main axis of the ladder should be fixed as firmly as possible both at the top of the structure and at the bottom. The metal rod may have a minimum diameter of 50 mm. As for the other materials, then the scope should be wider - from 150 to 500 mm. Depending on the size of the room, you can increase the final figure.

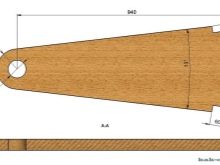

The next step is the creation of steps. Consider this process on the example of wood products and the main recommendations for it:

- usually the thickness of the finished stage is not more than 50 mm, although there are exceptions;

- wooden boards should be perfectly flat, dry and treated;

- use glued bars as a starting material.

To make the steps by the method indicated in the last paragraph, it is necessary to assemble the wooden components into a single panel. Pay attention to the direction of the fibers in all the bars was in different directions. So the drawing of the product will be more original and pleasing to the eyes.Glue each butt joint with glue and fix the total web in clamps or vice until it is completely dry.

While the material is drying, make a pattern for your steps. On thick cardboard, draw the shape of your future step with all the preliminary dimensions and cut out the template. The first upper stage will serve as a launching pad on the second floor, so do it almost twice as many others.

We transfer the step scheme to each glued wooden plane and cut it out with a jigsaw or saw. Next, perform all the necessary work on the processing of wooden products by hand or with the help of special tools.

After that, you can begin to make balusters - support racks for the railing of the structure - and directly the handrails themselves. Before proceeding with the production of the latter, it is necessary to consider that their particular curved appearance is not always subject to simple physical impact. For the manufacture of railings and balusters, it is better to contact a specialist if you do not have special education or experience.

It is worth noting that the balusters and railings - this is the last stage in the manufacture and installation of a spiral staircase with your own hands.

Learn more about how to make a spiral staircase, you will learn from the following video.

Installation: order and nuances

Measurements, drawings, stages of manufacture and the acquisition of the main components and fasteners behind. Now you can begin to complete the installation of a spiral staircase. And if you decide to do it yourself, pay attention to the procedure and basic installation tips.

- Determine the location of the stairs in the house. Consider it in conjunction with the shape of the design. If you chose a spiral staircase with a support on the walls of the room, then they should be somewhere near the place of your choice.

- The marking of the floor and ceiling is made symmetrically. It is necessary to determine the center of the structure in which the main rod of the spiral staircase will be installed.

- Having decided on the overall diameter of the structure, cut a circular hole in the ceiling and process it with the necessary materials.

- If this is not a modular ladder, then the next step is to install the axis of the structure. Further work with the support stand depends on the type of ladder selected.

- The lower level can be laid directly on the floor of the first floor or on a wooden backing for better fixation. The upper platform is installed directly on the floor of the second floor.

- The next step is the installation of balusters and railings.

The installation of a spiral staircase in the house is complete. It remains only the final processing, decoration and filling with additional features if necessary.

You can paint the steps or railings in the desired color, place shelves on the back side of the steps, hanging structures for flowers and trifles. With any decorative finish, pay attention to the fact that the safety of lifting by this design does not suffer. Since the steps in it often have a slightly smaller width than in standard stairs, it is necessary to leave the risers through so that the foot can stand on the step as firmly and confidently as possible.

So that your spiral staircase becomes not only a beautiful property of the interior, but also an indispensable safe assistant, pay attention to the most common tips and recommendations of experts.

You will learn more about installing a spiral staircase in the following video.

Recommendations

A compact and cozy spiral staircase is not at all an advertisement on the cover of a magazine or a fantasy of an expensive designer.Experts keep several effective secrets that help to bring all this to life with minimal material costs. The only thing that is required to the maximum extent is the desire, diligence and meticulous execution of instructions. And to make it easier to cope with this task yourself, re-read the main recommendations for this process.

- The length of one turn of the ladder must be at least two meters so that it is comfortable for the movement of a person of any height along it.

- During the final processing of wooden structures, pay special attention to the process of painting. If the natural design of the material is more than satisfactory for you, then you can do with a two- or three-layer coating with yacht or parquet lacquer.

- Before proceeding with painting or varnishing the surface, be sure to clean it from debris, dust and other types of contamination. Then you get a durable quality coating.

- Pay attention to the angle of the steps. Ideally, they should be parallel to the floor so that there is no risk of leg slipping and injury.

- Materials for the manufacture of stairs should be of high quality, durable and durable. When selecting closely look closely to all components and components.

- Fire safety is paramount. All materials must be heat-resistant impregnation and processing.

- Moisture is also a poor companion for spiral staircases of various materials. Therefore, you should immediately clarify the question at the stage of choosing whether the structure has been treated with a special moisture-resistant coating.

- Fastening tools must all be in place and be securely screwed in, driven in, fixed. The plane of the steps should be perfectly smooth without any unpleasant protruding additions.

- In the process of marking and creating drawings of the future design, be sure to take all the measurements several times, recheck yourself. Incorrectly specified dimensions can lead to uncomfortable operation: skew, creak, rapid wear of components.

- If it is necessary to replace the step, fastener, railing, baluster and other things, do it immediately. Otherwise, the entire structure as a whole, as well as the person himself, who climbs or descends, may suffer.

- Constantly take care of your spiral staircase: clean, tint, repair if necessary.

Constant care and supervision of the serpentine home design will ensure its durable operation at the highest level.

Beautiful examples

Simple wooden spiral staircase economy class, fully created by the hands of the owner. The classic rectangular design with one span. Used to descend into the basement.

Another simple inexpensive design that has a spiral shape. The main materials used in the production of components: wood and metal. The spiral staircase rests on the central axis, made in the form of a curled tube, has a metal railing-rod. This design is very safe and easy to install.

The interfloor spiral staircase is made of S-shaped wood, has no railing, but is equipped with a high baseboard along the entire length. The lower and upper stages differ in shape from the rest. They are slightly wider and more stable. Unsafe for use by small children.

Spiral metal spiral staircase for small openings.Painted in bright red color, the style is combined with the interior space. The main support is a metal pole and corner walls. Also one of the variations of the economy class.

Compact screw structures made of wood and metal are suitable for use not only in small multi-level apartments. Such a model is also an ideal option for summer cottage, for rooms that do not have a large and constant flow of people.

The original space spiral staircase with metal steps-petals. The support is only the central tube, on which the steps are strung. Not recommended for use by small children and the elderly.

Classic modular screw design. It consists of wooden steps and a metal base. And also very convenient for use in narrow ceiling openings. Suitable only for moving a person up or down.

Openwork spiral staircase, made using forging. Vintage design will be not only functional, but also a very beautiful acquisition. Will add its charm to the decoration of the room in a classic or retrostyle.

Pig-iron spiral staircases are quite rare.They are usually used in loft style interiors. This original black construction with steps similar to those on a train creates a pleasant atmosphere when everything is in place. Despite its cumbersome construction, the cast-iron staircase looks pretty easy and at ease.

Another original option for small openings in the loft style. The fence has a monolithic construction and is made in the form of perforated steel.

Constructions of the new style underground direction are made not only from metal. There are also variations with wooden steps of dark color, as well as with stone components.

Lightweight futuristic models in high-tech style will not leave indifferent lovers of original and practical interiors. Often, these structures have a fairly large diameter, side by side with panoramic windows and spacious rooms.

The main materials used for the manufacture of spiral staircases in the high-tech style are metal, glass and plastic. All those basic raw material combinations that are so firmly rooted in the modern construction world.

Simple concrete structures today can also be found everywhere in the interiors of loft, hi-tech and modern. They are very bulky and heavy, but a spiral staircase made of such material will last as long as the platforms at the standard entrances of apartment buildings.

Delicate spiral staircase in the Japanese style. Mounting method - on the string. Production material - plastic and wood. High monolithic railings allow you to confidently hold on to it. White color and original Japanese pattern will not leave you indifferent.

Spiral staircase as a central piece of furniture. Massive wooden marches arranged in a spiral. Transparent glass handrails. And the lower steps as a pedestal for the pedestal. Everything points to the breadth of scope and the modernist slope of the room.

Another design comes from the future. Glass steps floating in the air, framed by a practically invisible support of the same material, abut the perimeter walls of the room. Despite the seeming fragility of the whole structure, this spiral staircase is very strong and resistant to mechanical damage.One of the nuances is the possibility of sliding the legs along the steps, which can be easily removed with the help of special silicone or rubber linings.

You will learn more about spiral staircases in the following video.