The details of the process of making railings for the stairs

Railings are designed to ensure the safety of movement on the stairs. They can be of various forms - both simple and skillful. For the manufacture of such fences are used almost any materials: metal, concrete, wood plastic. To make them yourself, you need to take into account a lot of factors. How to understand all this and avoid mistakes is described in detail below.

Special features

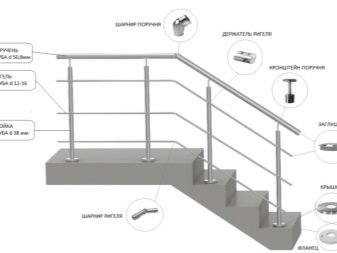

In glass enclosures, fasteners are made in this order: to begin with, they are fastened to racks, and then handrails are attached from above. Such barriers are safe, provided that all the fixings are made correctly.

Handrails should be on all fences, they fix the entire structure. To more securely fasten parts, use metal rods. The shape of the handrails should ideally match the stair covering.

All the flaws will be visible if the design is twisted from high humidity, and then all the flaws can be seen with the naked eye.

It is necessary to take into account the fact that the simpler the shape of the handrails, the less chance of improper bending of the handrails.

Materials

You can buy fences in finished form, it can be chrome fences. It is important during this choice to calculate and take into account all the elements that may be needed. But we must remember that this type of railing has some drawbacks. For example, they quickly erased coating. The most susceptible to such damage to the railing, installed in areas of high people.

Aluminum

Making the railings out of aluminum is not so easy. In most cases, all the details can be bought in finished form. You can assemble fences from ready-made parts, you just need to correctly calculate the necessary fasteners and additional elements. The aluminum railings also have a number of drawbacks: they bend upon impact, prone to corrosion, tarnish and scratch.

Forged fencing

They can be cold and hot forged. Hot forging is hard to perform at home, so most of the time such work is ordered at special factories. At home, it is easier to perform cold forging. But to create this type of railing you will need highly specialized devices, equipment and skills.

Of the minuses we can note the high cost of such railings, the complexity of manufacturing and the availability of special tools. But they also have pluses - this is a great variety in the design of the railing.

Stainless steel

Very often there are stainless steel railings. This metal does not fade over the years, has a beautiful luster. The railing of it is very strong, durable and safe. But to build them yourself, we need the minimum skills of a welder and metal cutter.

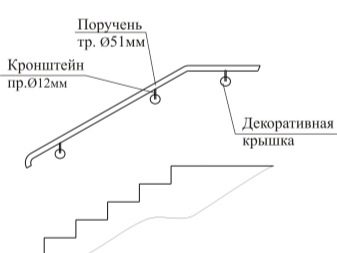

Drawings and sketches

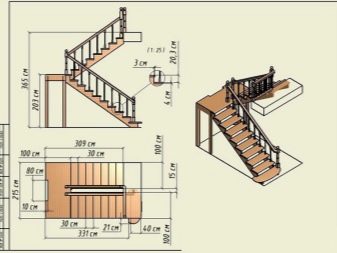

Before you start work, you need to determine what kind of fencing will have. After that, draw what you represent on paper. You can use a variety of ready-made drawings.

If you decide to create your own drawings and sketches, you should understand that you cannot do without accurate calculations. In this matter, special attention should be paid to safety and ease of movement. That plans meet this important criterion, Consider factors such as the width and height of the stairs, the size of the steps and other parameters.

It is clear that the straight and wide staircase is very convenient. But it is not always possible to make it the way you want. When building a drawing, consider such important factors as the angle of elevation of the stairs. It should not go beyond 24-36 degrees.

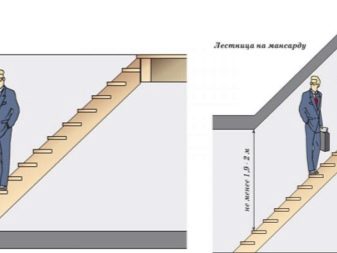

The clearance is the distance between the step and the ceiling. Its minimum allowable value is 2 m. It is necessary to take into account the width of the march, because the convenience of the stairs largely depends on this parameter. In a house or apartment, this figure should not be less than 0.9–1 m.

Requirements

The main function of the railing is to ensure safe ascent and descent of the stairs. In addition, it is a decorative element and can contribute to the interior. Parapets must be made with all the rules and regulations in accordance with SNiP.

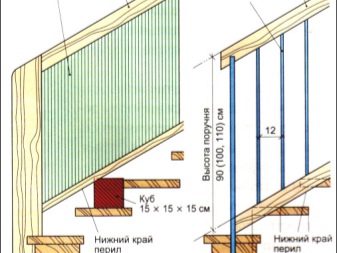

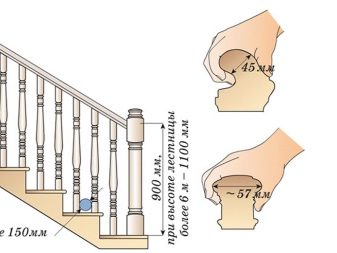

The height of the railing in residential premises should be from 90 cm and higher, and for high structures, the desired height is 100-110 cm. In places where children live, the railing should not be less than 120 cm, for the safety of movement of the child.

The handrails themselves should not be very wide, the ideal width is 6–9 cm. With such a width it is convenient to grab them by hand. If the staircase is narrow, you can install one parapet.But when planning a wide model, we need two parapets. If children live in the house, for their convenience, you need to make a second, lower handhold.

How to do it yourself?

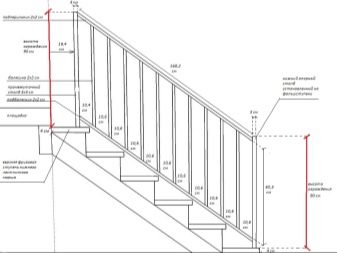

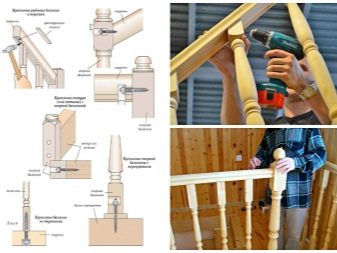

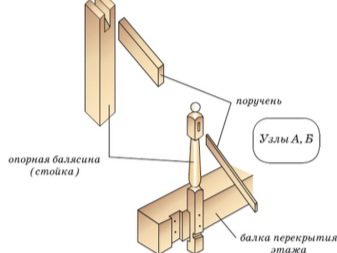

The first thing you need to decide what height of the fence you want and what will be the gap between the balusters. On the lower and upper steps set the so-called pedestals. They are necessary to fix the entire structure.

When choosing the curbstones, please note that the diameter of the baluster should be less than their girth.

The standard height of the railing is 95 cm, but the frame must be raised 10 cm from the ladder itself. Still need to consider 5 cm on the rail. Then subtract 15 cm from the total height and get 80 cm. This is the size in which you need to cut out balusters and pedestals.

After all the work and preparation, you can start welding. We lay out the frame of the prepared profile, and quite a bit we grab by welding. You do not need to tightly weld all the elements right away, because if you have a marriage or a bias, then you can’t avoid unnecessary work. After you have finished welding with the frame, balusters are welded to it. It should be noted that the bollards must be two times larger in diameter than internal metal lintels.

After you have completed all the previous work and did not see the marriage or distortions, you can begin to finish welding. The seams need to be welded on both sides, this maximizes the strength of the structure.

When you have finished all the work on the frame, columns with square or round plates should be welded to the underside, the columns should be 10 cm high. Make holes in the plates, they are needed to attach them to the steps. To give the railing a finished look, you need to polish the entire structure and remove the remnants of welding.

You can give your design a beautiful look with the help of various forged elements. They can be bought ready-made in specialized stores, where they will offer you many similar accessories, various flowers, ornaments, or other decorative items. You can weld them to the frame and thus give the fence an exclusivity. Do not forget about the handrails themselves. Most often they are made of wood. Handrail blanks are carefully polished and rounded.

Wood options

For fencing of wood suitable materials such as pine, oak, birch or beech.

- One of the most affordable materials is Pine. It is soft, has an uneven structure. Because of this feature, the paint is absorbed at different rates during dyeing. Pine is not bad for various treatments and responds well to changes in humidity and temperature.

- Very strong and durable material, is oak. It is not deformed after processing, is not subject to rotting and does not crack. It does not start parasites. But there is one drawback - a considerable price.

- Birch tree is a durable material. It is well served by polishing and various treatments. Unfortunately, this type of wood is very susceptible to rotting and cracking with changes in temperature and humidity.

Another type of wood that is suitable for railings is beech. He is not inferior to oak. However, it is very sensitive to dry air. Due to the very dry air, beech, breaks through the fibers and deforms.

Components of wooden fences

In wooden structures, as in metal structures, they are distinguished: cabinets, balusters and handrails. In wooden structures, balusters also perform a decorative function, and not just the supporting one.Most often they are made of glued timber and give them various forms.

A true work of art is hand cutting. Masters carve various patterns, designs and patterns, and some even carve animal figures. The easiest way to decorate the stairs yourself is flat balusters. You can cut patterns in them.

Flat Baluster Fencing

Above it was already written about what height the railing should be. The total height of the balusters we have turned 80 cm. In order to perform the railing, you will need boards, the width of which should be 10–15 cm, and the thickness about 30–35 mm.

To create an attractive railing, the boards can be given the desired and interesting shape. To do this, you can use a lathe. If you do not have such equipment, it can be replaced by a regular jigsaw.

- Draw on paper a pattern that has the actual size of the baluster.

- Using the usual pencil, circle the template on all the boards.

- After that, cut the shape along the contour.

- After completion of this procedure, all the boards need to be cleaned with fine sandpaper and polished.

How to install?

Sculpture balusters, like metal, should be mounted to the steps, which should not be done with flat balusters.If the flat balusters attached to the steps, then the whole structure will be unreliable and shaky. Balusters need to be inserted into the frame, which is obtained from the handrail, the upper and lower pedestals, and the lower beam.

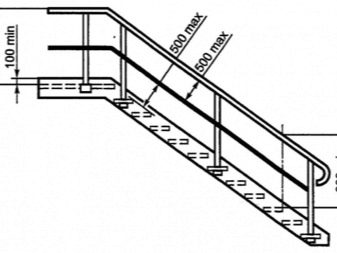

Mount balusters should be at a distance of 15-20 cm from each other. During operation, you can use two types of fasteners - for metal studs and grooves. If you do decide to install in the grooves, then you need to grind the grooves on the details of the structure, about two centimeters in size.

Remember that the staircase has a slope. The lower ends of balusters must necessarily be flat, but the upper ones are cut to the angle of the structure. The handrails are subsequently attached to them.

If you do not have such a possibility, how to install a cross-bar, then in this case the balusters are mounted on metal studs. But then the distance between the steps and the fence will disappear. And in this case, you need to take into account the fact that the balusters are needed 10 cm above. Baluster is attached with a single stud, performing such a robot, be very careful in order to prevent distortions. To prevent this, use the area.

When you finish the job with a fence, you can proceed to the railing. To do this, use a rounded and well-polished timber.

Tips

- When choosing materials for railings, consider the style of the interior, the design of the staircase itself and the complexity of installation.

- Most often for the manufacture of stair railings are best suited as wood, metal (aluminum, steel), wrought iron, plastic.

- Finished railings can be varnished, stain or painted with acrylic paints. So they will get a more aesthetic look. And in this way you can periodically update the interior, repainting fences in new colors.

- Self-made railing on the veranda in a private house can be made of shaped pipes. They must be properly welded using a milling cutter.

- Having decided to make a handrail with your own hands, remember that this will require not only high-quality materials, but also tools and equipment. Do not do without sketches, calculations and drawings, compiled correctly and according to all the rules. All this is a guarantee that everything will turn out without marriage.

How to install the railing on the ladder, see the video below.