Installation of stairs: instructions for making and assembly

In order to acquire a high-quality and comfortable staircase system, you have three ways: to purchase the structure already in finished form, to place an order of the required model for a joinery specialist, to make a staircase with your own hands.

Where to begin?

Before you build a staircase made of wood, you need to think about the individual parts. First of all, you need to determine the type of design. In private homes, two types of stairs are most often used. Each of them has its advantages and disadvantages.

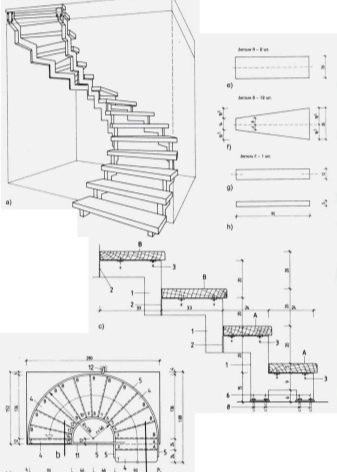

- The device of a wooden staircase of screw type will take much less free space. But at the same time, such systems are difficult to implement. Moreover, the stairs themselves come out relatively narrow,It will be difficult for a “large” person to walk on them (not to mention transporting various items or furniture of large dimensions).

- The most popular version for a private house is a wood staircase. Such systems can be easily built by hand. They are comfortable to use and quite spacious. Flight Stairs may have one or two spans. But there is no significant difference in the construction of each type.

Next, you need to decide on important parameters, in particular:

- what area you can isolate for the installation of stairs;

- what height between floors;

- what limit load the ladder design will have to withstand;

- what is the structure of the structure (type of steps, their height and width, type of fencing, etc.);

- what is planned appearance.

Calculations

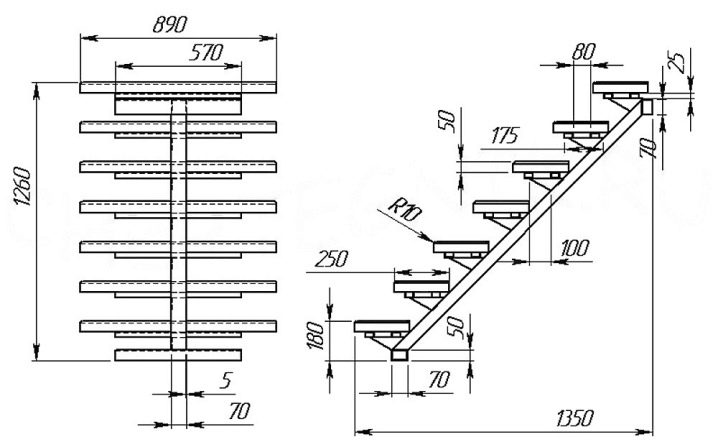

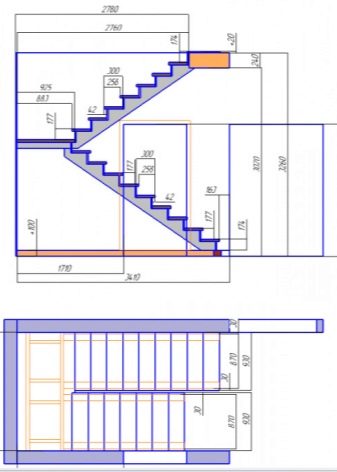

Once you have decided on the above tasks, you can proceed to the calculations of the future ladder and the creation of its drawing. Initially, we calculate all the parameters.

- The height of the whole wooden structure. This parameter is defined as the distance between the level of the final floor of the first floor and the level of the final floor of the 2nd floor.

- Width march. The limits for the greatest width of the march are absent.This parameter is set according to the availability of free space and demand. But on the other hand, the smallest size should be not less than 600 mm - otherwise you can not disagree with the person coming forward, moving along a narrow staircase will be extremely uncomfortable.

- Height and number of steps. In accordance with some regulations in construction, the height of the steps is taken from 15 to 20 cm. Usually, an average figure of 17 cm is used. The number of steps is set as a quotient from dividing the height of the whole structure by the height of each of the steps. If the result is an uneven amount, then you can lower the height of the lower stage.

- The width of the top steps (tread). There are also some regulations. This value should be between 22 and 40 cm.

- The size of the stair steps. The length of these steps is not so important, it does not matter and the angle of rotation of each step. It is important that the narrowest width of the place made it possible to go down on it, holding the railing. The size of the tread in this place should be greater than 220–250 mm, and the line of movement along the middle part corresponded to the conditions provided above — otherwise, it will be unsafe to move along the stairs.

- Distance between balusters. The distance between adjacent vertical pillars should be no more than 300 mm (so that a person cannot slip between them when falling).

- The length of the stairs. It is calculated by multiplying the width of the top of the step and the number of steps. Sometimes the resulting value may be excessively large and not fit in the allotted area. In this case, you can reduce the width of the top of the steps or make a dvuhmarchevuyu ladder.

- Fence Height. The railing should be located at such a height that it was comfortable to hold behind them. So, on a level plot, this value should be 1050–1100 mm, and on a plot with a slope of 900–950 mm.

- Among other things, it is necessary to calculate the clearance above the stairs. When climbing the stairs overhead, there should be free space in order not to bump your head. But also calculated the length of the supporting structure of the flight of stairs (kosour or string).

Selection of materials

Knowing all the characteristics of the design, you can proceed to the choice of materials. Ladders can be made of various wood species. Most experts recommend eating beech, oak or larch.But such wood is very expensive. As a rule, conifers are used. They are very strong, easily processed and have low cost.

When purchasing wood it is necessary to pay attention to its quality level. Boards should not be deformed, have rotting and knocked out knots. The wood must be thoroughly dried.

Accessories

To install a wooden staircase in the house you need quality materials.

- Bars for the supporting structure of the flight of stairs - they must be at least 50 mm thick, and their width is commensurate with the dimensions of the steps. The bar area should be enough for the entire length of the flight of stairs, it is impossible to connect two bars.

- Boards with a thickness of 40 mm for the manufacture of treads.

- Boards with a thickness of 30 mm for the manufacture of the risers.

- Balusters, handrails and other additions are better to buy ready-made, they will look more aesthetically pleasing.

- Galvanized fasteners - screws, screws, dowels and anchor bolts.

Along with this, you need to prepare the following tools for the job:

- devices for measuring and marking (building corner, tape measure, ruler);

- for the formation of holes will require a drill (electric drill);

- hacksaws for iron and wood;

- screwdriver or screwdriver with a set of nozzles;

- a set of chisels and a hammer for making grooves;

- electric plane (you can simple);

- grinding pelt.

Well and, of course, a carefully thought out drawing should be at hand.

Production technology

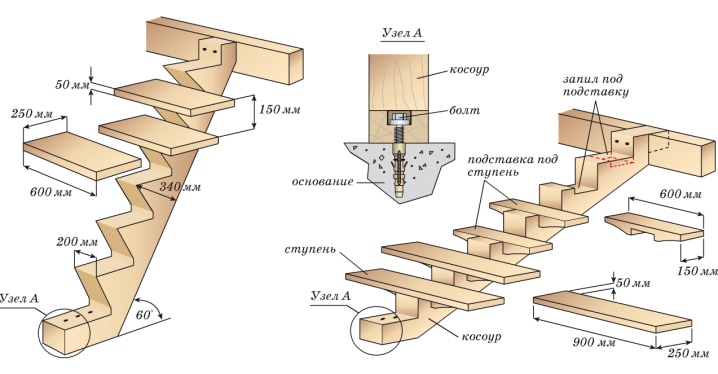

The process of making a wooden staircase in a private house with our own hands will be analyzed using the example of the most common type - the staircase on kosoura.

How to do the work in order not to violate the rules and regulations established for the selected design of the ladder, what order and methods of manufacturing - learn from step by step instructions.

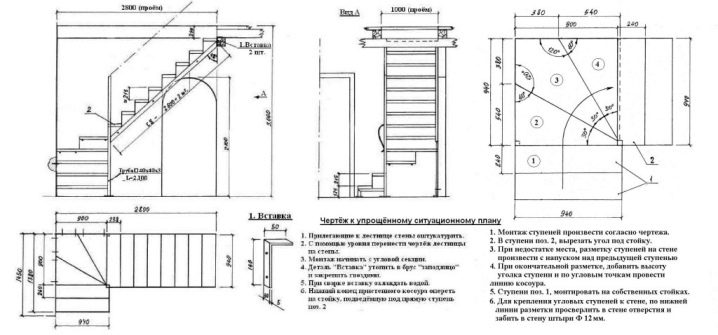

Making kosour

To create a kosour, a well-dried, knot-free, flat board 40 mm thick and 300 mm wide is taken. Now it is necessary to carry out markings on the kosour cuts under the steps (steps).

In order for the markup to be correct, you need to make a special template. It can be made from a sheet of plywood in the form of a square with angles equal to 90 ° and two slats.

We measure from the corner of the sheet of plywood the distance corresponding to the width of the step and the height of the riser.We connect the obtained labels with each other by a straight line. After that, right along the applied line on each side of the sheet of plywood we nail the slats.

By means of the made template we make a marking of cuts on a kosour under steps and risers. After the marking is completed, let's cut down the nests (cut-outs) for the installation of steps.

All cut-out areas should be strictly parallel to each other, and between the riser and the step there should be an angle of 90 °. To do this, the cuts and corners are carefully and carefully treated with a grinder or rasp.

If a staircase is planned, based on two kosoura, then we prepare the prepared kosour on the board, and duplicate the notches.

For a staircase with steps that are narrowed at one end and widened at the other (zabezhnye steps), kosouri will have a different configuration: from the outside are mounted steps with a wide edge, and from the inside - with a narrow. Zapily in such kosoura need to carry out the size of each step. So, kosour ready, set it in place. It is fixed to the floor and to the beam of the stairs (upper floor).

Manufacturing steps

The manufacture of steps for stairs on kosoura is cutting (blank) of rectangular steps from a board not less than 300 mm wide. Thickness is determined empirically - at least 40 mm.

In order to obtain a staircase from separate smooth steps, upon completion of work, a protective coating for wood should be applied to the surface of the elements made in at least 3 layers. It is advisable to use wear-resistant parquet lacquer.

Balusters

Depending on the design balusters may have a different geometric configuration.

Balusters of wood can be made in three ways:

- turned balusters - the most popular method, which is carried out on a lathe by means of specialized cutters;

- milled - on the racks of such parts there are cuts in the form of a scythe, screw or other decorative elements;

- carved balustersin other words, columns, on which there are elements of the thread, for their creation apply multi-axis CNC machines.

Making balusters of wood is a complex process that requires certain skills and equipment. Therefore (above it is said) balusters, handrails and other additions should be bought ready-made.

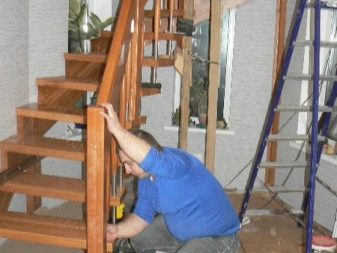

How to install?

After completion of the preparatory work, you can begin assembling the structure. Installation of the stairs is carried out in a specific order.

We mount the support bar at the place where the beginning of the stairs will be, and to the upper floor. To connect the carrier kosoura with a bar, you can go two ways:

- make cuts in the beam;

- make small grooves in the support bar into which skewers will be inserted.

We start the installation of kosourov:

- in the place where the stairs end, we install the bar and fix it with steel anchors;

- we connect the bearing elements with a bar on the top floor;

- tightly press the kosoura to the support bar on the floor;

- fix the timber with anchors.

Steps

After the carrier beams have been firmly fixed, proceed to the mounting steps. In the manufacture of stairs on kosourah, the length of the steps must match the width of the span.

First of all, you need to install the vertical part of the steps - risers. Separately, it must be said about the methods of fastening. Elements - risers and treads are connected with each other and with kosouri by means of screws and special glue.

The risers and steps can be fixed in various ways:

- by means of glue and screws flush with the surface;

- connection into the groove using glue;

- metal corners;

- by means of triangular rails.

It is necessary to say that for greater comfort when lifting, treads should be 2-3 cm to come forward over the risers.

Railing

When climbing or descending stairs, people often lean on handrails. As a result, the fence must be firmly fixed and withstand a large load.

Installation of railing starts with the preparatory work.

- In the points of junction of the steps with the supporting beam we mark the places for the installation of balusters. In this case, the side face of the baluster must coincide with the outer end of the step.

- In the planned place we drill a hole of the required diameter.

- We make a small wooden stud of round section (shkant). Its diameter should coincide with the width of the hole, and along its length it should look out over the surface of the step by 1-1.5 cm.

- In the upper part at the base of each of the balusters we drill holes in accordance with the diameter of the dowel.

- Mounting balusters made of solid wood is done by using studs,made of metal, having a cross section of 6-10 mm and a length of 60-100 mm or dowels made of wood 50-80 mm long and with a diameter of 8 to 14 mm.

Consider the installation of fencing.

- At the beginning and at the end of the structure, we install support balusters.

- We mount 1-2 intermediate posts.

- We control the compliance of the lifting angle (inclination) by applying a railing to the initial posts (if necessary, adjust the height of the posts).

- Insert shkant into the holes at the top to fix the railing.

- Apply glue to the base and recess pillars.

- Balusters are mounted on shkanta.

- Apply glue to the top pillar.

- Upon completion of the installation of all vertical elements: balusters, decorative elements, proceed to the installation of the handrail of the stairs. To do this, we cut the upper segment of the two outermost pillars at the required angle, attach a rail to them and designate a place for cutting the rest. Saw off all the tops of the planned level. Railing tightly pressed and fastened on balusters.

- The final stage will be cleaning the finished structure. It is necessary to process the protruding parts with a sandpaper, putty the gaps, clean from dust and saw blades.Wipe the entire surface of the structure with a damp cloth.

After that, the fence must be allowed to dry well, and then you can proceed to varnishing or painting.

Useful tips from the pros

To avoid mistakes when creating a structure, as well as when installing it in a private wooden, frame house, you must comply with the recommendations of professionals.

- In the manufacture of stairs, it is desirable to use a separate room (if there is such an opportunity). In order to assemble the structure as accurately as possible, and also not to harm furniture, household items, it is necessary to define a separate place where it will be convenient to assemble the future product, control dimensions, eliminate errors.

- Do not perform finishing work in the house before mounting embedded components, basic structural elements. In order not to dismantle the already installed drywall, all sorts of elements, it is necessary to install the mortgage components in advance in places that are subsequently planned to be revetted.

- Take into account the dimensions of the assembly components. If the ladder is not made in the place of its installation, it is necessary to provide for its movement, delivery to the room. It is better to divide the construction (to make it a national team) into such fragments that can fit in the elevator (if the staircase is in a high-rise building), pass through the doorways.

- Mount the ladder securely. The most important factor in installation is rigidity. It is required to carry out well not only the installation of mortgages, but also to connect all the elements of the stairs with each other, if necessary, to carry out structural reinforcement.

- Calculate the fastening elements made of glass. In order for the glass to lie securely against wood, metal, it is necessary to put gaskets made of silicone, rubber, or fluoroplastic bushes — only with the use of seals can glass be tied with other materials.

- Correctly set the stairs in the house of wood. The wooden house has a tendency to shrink, as a result, the ladder should be fixed to the concrete floor in the main part, and be tied to the logs in such a way as not to affect the appearance of the products (grooves, specialized holes should be provided).In this case, the design of the staircase must be adjusted in height - in order to compensate for the change in the difference in height between floors.

- When choosing a method of painting railings, consider the special properties of wood.because each breed reacts in its own way to the influence of paints and varnishes. In particular, it is desirable to cover the pine with an extremely transparent varnish. If you try to treat it, for example, with a stain, the railing will be covered with stains, because the pine in different areas differently absorbs the composition due to the fact that the resin inside the wood is unevenly distributed.

As a result, before proceeding with the full-scale processing of the railing, test the selected tool on a small area of wood, let it dry and look at the result.

Learn more about how to install the stairs with your own hands, you will learn from the following video.

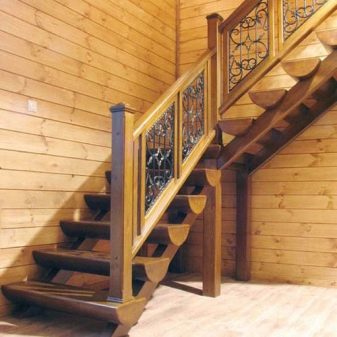

Beautiful examples in the interior

Let's look at the beautiful and interesting designs of stairs made of wood.

- Elite stairs. For a long time, such structures made of ash wood, noble oak and beech were some kind of indicator of luxury and well-being, indicating the well-being and aristocratic nature of their owners.The stairs, stunning by their own architecture, were an adornment of palaces, estates, or just rich merchant houses.

- Traditional. Indivisible ladder of wood attracts its ingenuousness. The solution in which the beam of the supporting structure is cut out in the form of steps, and the horizontal surface of the steps of the stairs is superimposed on it - the sidewall of the straight and long march looks reliable and beautiful.

- Ribbon. The tree is able to easily take the form of a spiral. Bentwood handrails, descending from ribbons, reproduce the staircase flight pattern and give the design the characteristic features of modern style.

- Economical. Identical material and railing, inscribed in a spectacular design, give this ladder a kind of transportable element, prepared for installation in a place predetermined for it.

- In this case, the architectural studio from the city of Mumbai used a curious design of the stairs in the living room of a multi-level apartment. The originality of her design is that her steps turn into a railing, moving from one position to another.

- Wooden stairs in Russian style - it is reliability, durability, various finishing of railings.