Semi-spiral stairs in the interior of a private house

There are many options for the execution of stairs between floors in a private house. Choose here is something that fits perfectly into the interior of the home and it does not take up much space. The article will discuss the semi-screw stairs and which one would be best to choose for a private house.

What it is?

A semi-spiral staircase, in contrast to a full-fledged spiral staircase, is a construction of steps on support posts that make a total turn less than 360 degrees around the axis. In addition, according to GOST, spiral constructions with turning and marches, the axis of which is a section of a circle, can be attributed to the semi-screw stairs. This design of stairs has a number of undeniable advantages, including:

- practicality of installation and installation;

- the use of such a ladder allows you to place the entrance to the building anywhere;

- adjustable height of rise and spread between steps;

- rigidity and durability of the structure;

- affordable prices (in most specialty stores).

The specificity of the design of such a ladder leads to the fact that the treads in shape most resemble a trapezoid or a triangle, as they are attached to each other overlap. The peculiarity of the arrangement of the steps leads to the fact that during the movement a large part of the total length is used.

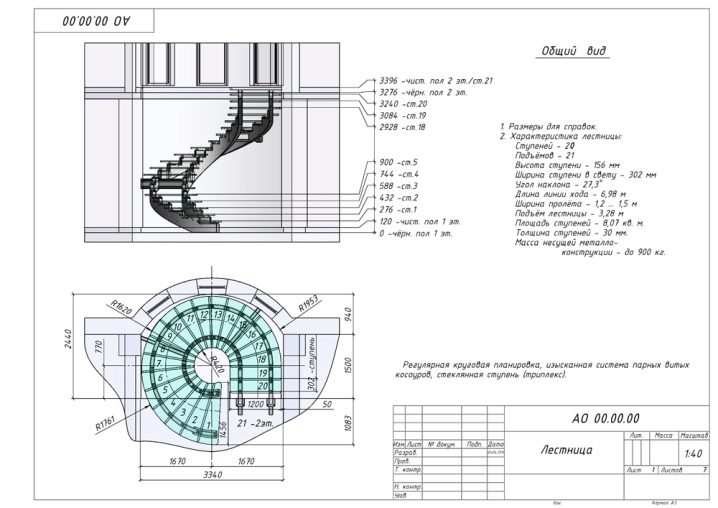

Semi-reverse spiral staircases to the second floor do it yourself is easy. Production will be much easier if you follow the recommendations of experts. First you need to prepare all the diagrams and drawings, as well as to calculate the required materials.

Measurements

You can calculate the number and configuration of steps yourself. The height of the ladder will be calculated at the corners of the niche in which it is located. If the levels do not coincide with each other, you need to choose the greatest height, after which you can already be engaged in adjusting the steps according to the set level.

Pay special attention to the fact that if the supporting structure is made of wood, installation is carried out only on the finishing surface.

Below is a list of facts and rules that will allow you to design and assemble the staircase correctly:

- in the dwelling you need to build the correct heat transfer on both floors - only under this condition it makes sense to install a semi-screw staircase;

- climbing the stairs, we spend a lot of energy, unlike normal walking, and therefore the stairs can be considered safe and practical if the height of the riser multiplied by 2 in total with the tread will be equal to the average length of a person’s step (600-650 mm);

- the stairway should be made wisely, that is, the optimal length from the first step to the ceiling is 1.5-2 meters on average, failure to follow this rule will lead to the fact that a tall person will experience discomfort;

- the steeper the staircase, the less space it will take, but the more difficult it will be to properly assemble it.

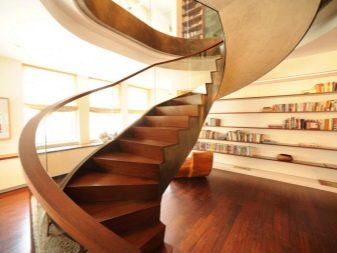

The design of the semi-spiral staircase and the interior

The semi-screw staircase, besides its original task (connecting 2 or more floors), also performs an aesthetic function - it is an important element that complements the decoration of the premises and the general interior of the building. Therefore, it is impossible to make a mistake with the selection of materials and design, otherwise the picture will turn out to be at least unsightly.

Try to use all the variety of forms and materials in order to successfully fit the future staircase into the general background of the room.

For example, the performance in the high-tech style requires brevity and simplicity of details and forms. In addition, for a room in a similar style at the time of designing a staircase and selecting materials it is necessary to avoid bright colors: it is better to prefer more moderate shades of the general background of the corridor or room in which the staircase will be located. One of the universal options in this case can be considered a ladder made of metal.

In a room with a classic design, the best fit is a staircase made either entirely of wood or having wood inserts. In this case, you need to carefully monitor the texture and shade of the material from which the railing, support legs and steps are made. Wood - a material, though practical, but capricious, and an incorrectly chosen color of steps or transitions may end up spoiling the overall interior a bit due to the sharp contrast that has arisen.

If the furniture in the room where the stairs will be located, does not fit well with the general finish, then properly selected material of the steps can save the situation. For example, to make the transition of shades from light to dark - from the first step to the last.

Features of semi-screw design

Consider the main types of semi-screw stairs. They are few, and basically stairs of this type are most conveniently classified into the following categories:

- forged - all-metal, cast and prefabricated;

- wooden solid wood, timber or wood in another form;

- combined - glass with metal or wood with metal;

- options with marble, granite or stone, as well as made of these materials;

- low-cost - made of polymeric materials, with wood decoration, mounted on a light-alloy metal frame (low cost and flexibility makes it possible to imitate even forged bindings).

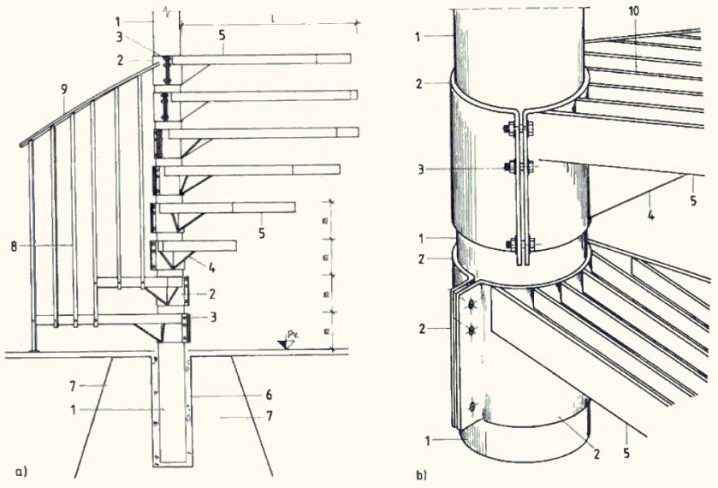

In general, the ladder is half-helix or twists around one central support, on which everything is attached, or attached in 2 or more modules to a rotating wall. In the latter case, the steps are interspersed with platforms, which are located in the corners, if the building is more than 2 floors.

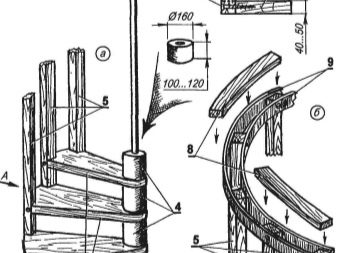

Self-assembly of wooden stairs

One of the basic conditions that will have to perform - the choice of the most dry and high-quality wood. The thing is that the material bought in a hurry, can begin to shrink, and then the ready-made construction will start to “drive” from side to side. This will at least distort the stands and steps, and the passage will have to be redone, having spent a lot of time and effort on this. This error is very common among beginners: an attempt to save on wood leads to the fact that the staircase collapses, cracks, and sometimes is affected by a fungus or something else that is not good. That is why, in practice, steps that do not rest on a metal frame cannot be made from a solid array - only from glued material.

Glued material is a bar, planed on four sides, which is thoroughly impregnated with glue mortar according to the technology, after which it is compressed into one package until it is completely dry.

The material should be laid out in such a way that the wood fibers go in both directions alternately - from layer to layer. The contour of the future steps must be drawn independently using a template from a dense material.

Do not forget to take into account the place of cutting and grinding blanks at the time of marking. From the outside, the holes for the supports and fastenings should coincide as precisely as possible: any mistake will lead to the fact that you will have to redo several steps.

Please note that in the final result, the thickness of one step can not be less than 50 millimeters in case there is a ladder with a diameter of up to 2 meters and not less than 60 millimeters (if the diameter is up to 3 meters). After the steps are laid out and ready, you can begin to cut places for landing racks on which the railing will be mounted.

One of the important moments here can be considered the work with the support sleeves. Without having before this practice, it is obviously not worthwhile to engage in the connection of the sleeves with the support yourself - any miscalculation can greatly affect the alignment of the structure and overall stability. At this stage it is best to take the help of an experienced person, for example, a qualified carpenter.

At the junction of the sleeves and steps on both sides there are metal washers with which the adjustment is made. Flanges used in plumbing can be used as washers.Since metal does not fit well with wood, washers are often glued over with a film imitating wood.

As a baluster, located on top of the railing, it makes sense to use a crimp threaded pipe. It is easiest to do this in two ways:

- a tube similar to a support is used (the threads are cut on the outside and joined to the posts using a coupling);

- the crimping tube is taken the same as for the sleeves (the thread is cut from the inside).

As a result, a rough assembly is carried out, allowing to identify defects and shortcomings of the structure. If you are engaged in assembling the stairs yourself, skipping this stage is strictly prohibited. Otherwise: if you skip the assembly of the draft, you will surely face the fact that several steps do not want to stand on the fixings, or the support is not fixed between floors due to a few extra centimeters.

This is all done in the following sequence:

- thread the support on the lower sleeve (it may differ in size with the others);

- position the steps through the washers on both sides and place the liner on top (do not forget to turn the steps to the correct position);

- continue all the way to the top of the crimp tube;

- you can try on the handrails, but with their installation it is worth while to wait.

After the defects and problems have been identified, finalize the supports, sleeves and all parts of the structure. Done!

Now you can safely assemble the ladder finally and strengthen it into place. Handrails are installed at the very end, already on the fixed structure and in no way before. If everything worked out for you from the first time, with minor problems, we can only congratulate you, since it is actually not a simple task even to configure a specialist to properly configure and build a semi-screw staircase made of wood.

You can see the installation process of the semi-spiral staircase in the video below.