Flight of stairs: optimal dimensions and important installation requirements

The staircase is an indispensable attribute in any private house, even one-story, for example, to enter the attic. When designing and erecting, first of all, attention should be paid to such details as flight of stairs, taking into account their optimal dimensions and important installation requirements.

Special features

The flight of stairs is the main part of the stairs, consisting of steps that are fixed to the supporting beams or kosoura. In country houses, depending on the height of the rise and the existing free space of these elements may be one or more.The steps on them can be simple or foreign, they differ in size, height, step and quantity. The main prefabricated parts of the flight of stairs are the steps, supporting bows, bowstrings, railings.

The flight of stairs in a multi-storey building can be made of wood, metal or reinforced concrete. The first option is the most common, since the wooden elements are easiest to fasten to each other, it is possible to create any decorative forms. The flight of stairs made of metal is more durable, but their installation will require time-consuming professional work, for example, welding.

The most reliable and durable structures can be made of concrete, but this is the most difficult process that only an experienced builder can handle.

You can determine the main types of staircases for a private house:

- Direct - the easiest to install and manufacture prefabricated elements. It is a series of identical steps, can be used for a small rise. The greater the height, the steeper the straight flight of stairs will be, and, therefore, it will be more difficult to climb.

- Zabezhny rotary is such a construction solution in which several steps are turned relative to the main row. The angle of rotation can be 45, 60 and even 90 degrees.At the same time you can save space in the house, and the view of the whole staircase in the house becomes original.

- A march with a vertical platform, at which a series of steps is rotated by 90 or 180 degrees. Stairs after construction will be as convenient as possible. This is the best option to climb to the top floor. Spans can be located adjacent, parallel or perpendicular.

Different design of staircases inside the building provides for their different placement along the centerline. The most common are straight lines, when all the steps are arranged in parallel and in a row — such a method is used in typical projects and does not require special architectural and engineering solutions. Oblique flight of stairs, when the guide line is not straight, looks very original, although it is difficult to design and install.

Curvilinear, when adjacent steps are not parallel and their edges do not coincide, are used in spiral staircases. This solution, despite the complexity of construction, is not only original, but also allows you to save free space.

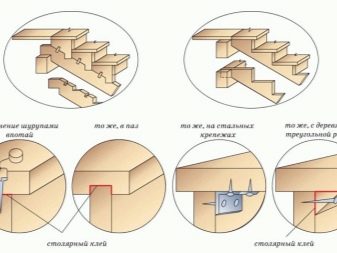

Stair flights in a private house, made of wood, have the following components:

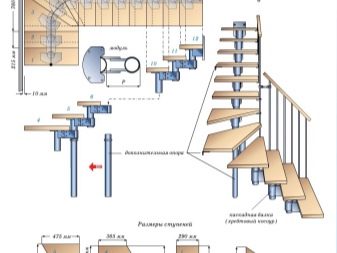

- Bearing beams are the main element of any ladder on which the main load is placed.It is their strength that determines the safety of the entire structure. Another name is kosour. Often skewers are made with teeth, on which steps are fixed directly. These elements are usually two, but the wall can perform the function of the second kosura.

- Bowstring, closing the end of the march, which performs a decorative function.

- Steps, height, width and number of which is determined according to the created drawings and projects.

- The risers, closing the bottom of the stairs. Perform a decorative function, but make the project completely complete.

- Vertical supports serving for additional reinforcement, they are also required for the construction of intermediate horizontal platforms.

- Railings or fences are used for added convenience during the descent and ascent, security. If the height of the march is more than 1 m, then you should definitely take care of their installation.

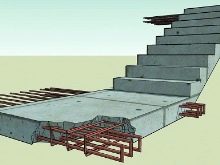

Ladder marches in the individual construction can be prefabricated and monolithic. The first type is mainly made of wood, but there may be metal versions. Such ladders from prefabricated elements are assembled and fixed directly in the provided place.Monolithic structures are erected by pouring mortar into a wooden formwork, where a metal frame should be provided. Thanks to this method, it is possible to create not only straight lines, but also various figured, curved, screw most durable and durable stairs.

The type, number and parameters of the elements of the staircase must be selected on the basis of the height of the climb, free space. Before installation, you should definitely create drawings and calculations of parts and materials. There are also certain regulatory requirements and standards for their construction.

Regulatory requirements

In order for the staircase to be comfortable and safe, it is not enough to have a competent project of its own, there are certain regulatory requirements of GOST and SNiP for their construction, and during installation it is best to follow them. Marching stairs made of various materials have different requirements for size, weight, volume, vertical load and other characteristics. They can be studied in detail according to GOST R 53254-2009, GOST 9818, SNiP II-25-80, SNiP II-23-81.

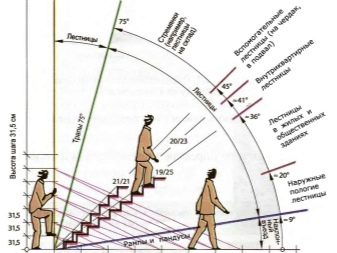

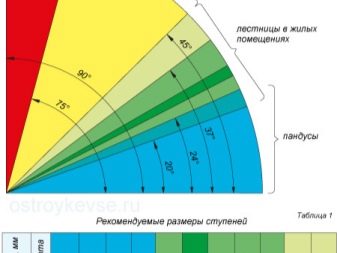

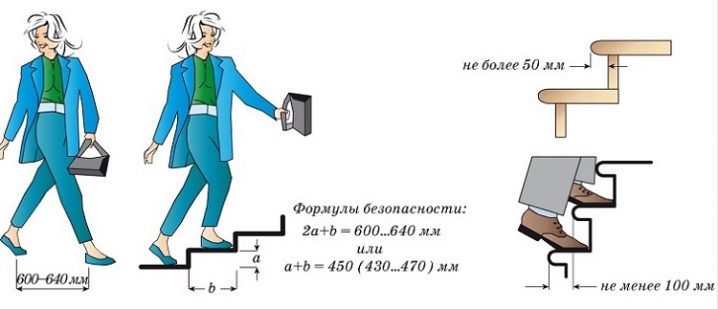

For reinforced concrete products, the weight of the flight of stairs can be from 875 to 1560 kg, the span width is not less than 0.9 m, the step width is from 20 to 25 cm, the risers are from 15 to 25 cm.The slope is usually chosen at 20-30 degrees, but should not exceed 45 degrees. The steps for one march can be at least 3 and not more than 18, depending on their number and angle of inclination, the maximum permissible length is also formed. If there are several spans, then the width of the intermediate platform must be at least 1 m.

Reinforced concrete stairs according to the norms of SNiP should not have open sections of electrical wiring, gas pipelines and pipes that operate combustible liquids. According to the standards for reinforced concrete staircases, it is forbidden to place fire cranes, cabinets and drawers that are not related to the laying of communications, and to block them with open door leaves. Heating radiators, if provided, must be placed in special niches of the walls.

Metal staircases according to the norms of SNiP are made of steel or cast iron, the surface of their elements must be galvanized or painted. The step size varies from 15 to 25 cm, the tread width varies from 13 to 22.5 cm. The joints of the parts are made using welding or bolts. The calculation of the strength of metal staircases is performed according to the norms of SNiP II-23-81.

A single-march, double-march or three-march wooden staircase is built according to the norms for the erection of wooden structures SNiP II-25-80.The flight of stairs made of wood should have from 3 to 18 steps with a width of 20-25 cm and an access road of 12-22 cm, the span width is not less than 900 mm, the slope does not exceed 40 degrees. For bearing beams of a standard flight of stairs, conifers are selected; for other elements, use of larch is allowed.

An important characteristic of any flight of stairs - wood, steel or reinforced concrete, is a retained load. For all types in a private house, it should be 360 kg per 1 square. m. Calculate this value yourself quite problematic, but an experienced master, and so can determine the approximate reliability of the erected structure. For example, wooden support beams should be taken not less than 10 cm wide and not less than 3 cm thick, use fixing bolts or screws not less than 60 mm.

Bias

The choice of the slope of the staircase in a country house is largely determined by the ease of lifting and safety of use. Of course, not always the free space in the room allows you to create the most comfortable staircase, in this case you have to make several spans, intermediate platforms or lower landing stages.The experience of numerous projects in private houses shows that the optimal slope of the flight of stairs is 27-38 degrees. Under such conditions, it is convenient and safe not only to ascend and descend, but also to bring up large-sized objects.

If the free area does not allow to make a flight of stairs with an optimal level of slope, then resort to various tricks.

You can, for example, create an additional span, perpendicular to the main one, wrap up a few run-in steps, or create a full-fledged second march with a transitional platform fixed on supports.

If it is still impossible to achieve a smooth slope and the flight of stairs has a large steepness, then for convenience and safety it is necessary to provide it with a railing. In addition, it is possible to position the steps more often and not to make too much height between them. Most often, staircases with a large steepness and a single span are made in one-story houses to enter the attic or attic. But it should be remembered that the simplicity of work and the saving of free space do not always favorably affect comfort and safety, because the ladder will have to be used for many years.

Step

The step of the flight of stairs should be chosen so that, firstly, the foot of the person is conveniently placed on the surface, and secondly, so that you can lift your legs freely, without tension. Therefore, for any, even the most economical project, it is worth choosing a depth of 23–33 cm, the vertical distance between two adjacent ones is 10–18 cm. This condition is observed for interfloor and other lifts during one or several spans. In the case of one flight of stairs with a floor height of 2.2-2.5 m and such a step, the maximum number of steps will be 15-18. It should be understood that with a height of one step more than 15 cm, the rise becomes uncomfortable, especially if there are children or elderly people in the house. Putting the weight up is also problematic. Therefore, it is better to make more steps so that you can comfortably use the flight of stairs.

A large step height (more than 18 cm) for the staircase is relevant if it is used occasionally, for example, to climb an unexploited loft.

March height

The height of the flight of stairs, based on the number of steps and the vertical distance between them, is easy to calculate. For example, with 15 steps and a height between them of 10 cm, this value will be 1.5 m.From here it can be seen that for the inter-floor ascent of one march will not be enough, the staircase needs an additional span.

You should not make the height too large, then the construction will need additional supports, the maximum taking into account interfloor overlaps is 3 m. At the same time, the minimum value for climbing to the second floor is 1.5 m, making it less simply is not advisable.

Requirements for railings and fences

When constructing a flight of stairs in a private house, according to their own design, they usually make their own railing dimensions, guided by beauty, convenience and safety. But for staircase fences, there are also requirements established by GOST 25772-83, for them in individual residential buildings the height for railings must be at least 0.9 m. It is recommended to construct barriers if the height of the flight of stairs exceeds 1.5 m.

It is not necessary to support the railing at each of the steps, as long as the distance between them does not exceed 0.5 m. Fences must be securely fastened, this primarily determines the safety of the climb. In the case of wooden staircases, they are best attached to a metal anchor or screws with corners. Metal structures optimally welded to the steps or bearing beams.

How to calculate yourself?

The length of the bowstring and support beams, the height of the flight of stairs, the number, depth and height of the steps are calculated based on the height of the living space. It is important to consider not only directly the distance from the floor to the ceiling, but also the width of the floor, the release of the stairs to the second floor. Preferred preferred slope design. If, according to these parameters, the length of the march will exceed 3 m, then it is best to do not one, but two or three flights.

In any case, it is necessary to pre-make a drawing of staircases in profile with an indication of all sizes. From it it will be clearly seen how the elements will be located and how best to fasten them together, how many fasteners need to be taken. Even from the detailed sketch, you can calculate the amount of materials required for the manufacture of the whole structure. In the case of manufacturing a monolithic reinforced concrete stairway, according to the drawings, the volume of the structure is calculated, and the quantity of concrete necessary for casting is determined on the basis of it.

Tips

Competently designed, reliable flight of stairs should have the following advantages:

- sufficient strength;

- resistance to moisture and low temperatures;

- long service life;

- possibility of use in different weather conditions, in different climatic zones;

- ease of descent and ascent;

- aesthetic appeal.

The choice of material for the flight of stairs depends not only on the financial capabilities of the owners and the complexity of manufacturing, but also on other factors. It should think well when buying a particular raw material. For example, wooden structures are lightweight, easy to handle and assemble, look impressive and allow you to create almost any shape and original design. But wood, even with good processing and reliable varnish coating, is prone to rotting, mold and mildew, relatively brittle and combustible. Therefore, wooden staircases are not recommended to be erected in rooms with high humidity, under the open sky, where natural factors will adversely affect them.

In the interior of the dry room wood for stairs can be used. The choice of a particular wood species also plays an important role.Conifer varieties are always successful, especially for the manufacture of load-bearing supports, supports and bowstrings due to its strength. For the manufacture of steps, platforms, railings, decorative parts perfectly fit larch, beech, ash, oak. All wood should be well dried, after sawing and processing varnished and antiseptic.

Metal staircases optimally choose in houses with brick or concrete walls. They must have a reliable support for fastening and gripping the supporting beams. The metal itself is not only durable and has a strict stylish look, but must be combined with the rest of the interior. Since metal stairs are most often assembled by welding, installation work must be carried out before the rest of the interior decoration.

Concrete flight of stairs should also be erected in brick and stone buildings, so that the floor and walls could withstand the heavy load of these structures. Monolithic variants must be supplied with reinforcement, so that welding work will be required here.

To fill the required forms will need a wooden formwork. Concrete itself looks very cold and inconspicuous, so for such marches always need a decorative finish, so the whole project will be expensive.

Stairs leading to the attic and consisting of one march, optimally located in the hallway, hallway or on the veranda. The most successful choice is a wooden or metal construction with one span and a slope of 30-45 degrees. The role of the second kosour can be performed by the load-bearing wall, so the project is simplified. If the structure is made of wood, there is no need to make a bowstring, railings and risers. Bearing beams should be securely fastened to the floor and the ceiling on metal anchors or screws, after their installation should be fixed steps.

In order for the staircase to be safe and comfortable, it lasts the maximum number of years, it is necessary to select high-quality materials, comply with the standards of GOST and SNiP, install in accordance with the technical requirements. If the flight of stairs is made of reinforced concrete, then during pouring in the room a certain temperature and humidity must be observed. After it, the solution must be kept for a certain time. For strength, you should use a sufficient amount of reinforcement for reinforcing mesh.

To avoid corrosion, the metal structure should be painted or the parts should be galvanized before assembly. Places of joints and welding after installation must also be treated with a special solution. Metal, like wood, is also subject to severe deformation, especially when temperature drops, which should be taken into account during installation.

Wooden staircases are most susceptible to wear, damage, moisture, and therefore need careful treatment and further regular maintenance. Even if the permissible humidity and temperature are maintained all year round, steps, kosouri and wooden railing are deformed after some time and can become covered with cracks. Therefore, they need additional protection, cleaning, varnishing.

All work on the manufacture of wooden staircases can be made at home, in the garage, workshop or in the yard. For cutting steps, bowstrings, kosur a regular handsaw, hand or electric saw is suitable. All parts are cut according to the dimensions on the pre-created drawing, then processed with fire retardant and antiseptic, covered with varnish. After drying, you can begin to assemble the stairs.

First of all, they are fastened to the wall, floor and ceiling of the string, if necessary, vertical supports and intermediate platforms.Then placed steps, risers and a string. The last step to install the railing and decorative items.

How to make a ladder, see the next video.