Advantages and disadvantages of beech stairs

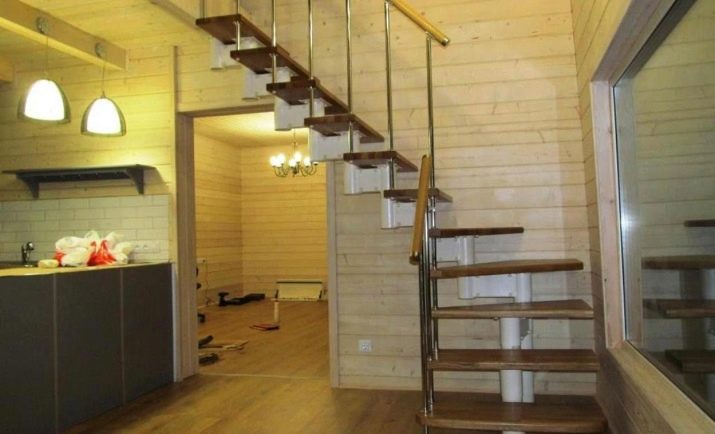

When building a house in which more than one floor, much attention is paid to the stairs. They can be very different in form and in size and materials of which they are made. At all times, people have sought to maintain harmony with nature and maintain the health of their families. Therefore, the use of natural materials is so common. Beech wood is one of the best options for making stairs due to its qualities. Before the final choice, you need to know all the pros and cons of this material.

Properties of beech wood

In nature, beech grows in Europe. It can grow up to 40-50 meters. From it get one of the most valuable wood species.

Drawing on the wood of this tree is special - it has narrow heart-shaped shiny lines, so that after polishing a beautiful pattern is obtained.

In dry conditions, beech is incredibly durable and strong. But with prolonged exposure to moisture begins to rot.

Besides the fact that products made of beech can withstand high mechanical loads, it is possible to steamed. In this case, get a beautiful and interesting work. Wood processing is low-cost and usually does not cause any difficulties.

Note the main features of beech wood.

- The density of beech wood is approximately 670 kg / m3.

- In a dry room, the compressive strength of the fibers along - 46 MPa, bending - 94 MPa, and when stretched - 129 MPa.

- The specific gravity also depends on the level of humidity. On average, it is 630-650 kg / m3.

- The composition of wood consists of natural substances: approximately half is cellulose, one fourth part is lignin, and the rest is pentosans and hexosans.

- Color is different. Due to the absence of a visible core, the fibers have an almost uniform color over the entire surface. Distinctly visible, as if lightened rays, which diverge from the middle to the outside. The wood of old trees has a pronounced red-brown color.

- The combustion temperature is 19.7 MJ / kg.

- Thermal conductivity is about 0.16 W / (m * K).

- High hygroscopicity. However, due to varnish coating, the degree of absorption of water vapor from air is reduced.

Benefits

Besides the fact that beech is an environmentally friendly material, it also has a large number of various advantages. And in terms of price, quality and hardness, this is the most attractive option. That is why beech wood stairs are widely popular and in great demand.

Stairs made of solid beech wood at a cost price are 20-30% cheaper than stairs made of solid oak or ash, and they are not inferior to them in aesthetics and functionality. And their lifespan can count more than a dozen years. If the installation is carried out correctly, and the operation does not violate the normal conditions of use, the wooden staircase made of beech wood can withstand very significant and long loads, which is important.

One of the excellent properties of beech wood is good ductility and flexibility. Because of this advantage, it is perfectly suited for the production of complex handrails, unusual shaped risers, curtain rods, curved bowstrings.Decorate the staircase can be a variety of decorative elements made of beech.

Beech wood looks very attractive and is not inferior in its beauty to the mahogany. This can be easily seen from the photos. A graceful pattern on such boards always looks beautiful both in its natural color, and after coating procedures with paints and tints.

Steps and parts of beech stairs are recommended to be coated with wax, because it perfectly protects the tree from mechanical damage and from other negative effects.

The comfort of such a ladder will always be at a high level, since the beech has the ability to conduct well and keep warm - thus, to the touch, the beech rail will always be warm.

If you pick up high-quality components and lining will be carried out correctly, the steps will serve you more than one year, and your feedback about them will be only positive.

disadvantages

Cons quite insignificant. Beech has a high capacity for excessive absorption of liquid and water vapor from the air, and this is probably one of the main drawbacks.For this reason, products made of such wood are not used outside the premises.

Due to the increased hygroscopicity, beech can easily undergo processes of decay, the spread of various types of fungi and mold. To avoid such consequences of improper use, the ladder is specially treated with antiseptic solutions and a specialized coating that protects the surface of the tree.

Despite this, it is still very important in the house to maintain constant values of humidity and temperature, for example, with the help of automatic air humidifiers. During sudden drops in the listed parameters, the tree can lose its shape: crack or warp.

In the case when the decoration for concrete marches was chosen, beech wood was used, it is very important to follow the thoroughness of the insulation from the moisture of the concrete base.

Beech woodworking includes rather delicate technologies for drying and warehousing, constant quality control of products. Even dry wood can change its shape somewhat due to the desire to achieve a balance between the moisture in the material, because it does not evaporate anywhere and is not used.This balance is dependent on the ambient temperature and ambient humidity.

There are no deep pores in the pores of the tree. Because of this, applying patina or similar compositions presents certain difficulties.

Features of material processing

During milling, due to the mono-structural beech wood, there is a possibility of blunting the cutting tool. The width of the lamella should be no more than 70 mm, since the wide details lead to the curvature of the products. Carbide knives are used for planing.

Very balusters look and turned poles of beech. When the pattern is finished, the part is ground and polished to a perfectly smooth surface. And after coating with varnish, turned products “will start to play” with special beauty.

Another reason why beech is widely used in the production of stairs - wood can be bent after steaming according to a previously set pattern. That is why for the manufacture of staircases with smooth turns of handrails and bowstrings, beech is recommended. In the construction of spiral staircases there is a spiral string, a step is attached to it.Such a bowstring is made of bent and glued beech slats.

When working with beech, it is necessary to carefully select the lamella by color. Tinted products carried out with a spray. The color and structure of the workpiece before you glue it, you need to properly select. Due to this, tinting on large planes will be uniform.

To cover beech stairs it is recommended to use two-component and urethane-alkyd varnishes.

Making beech stairs

Processing beech wood can be called a time-consuming exercise. For this reason, some parts are recommended to be made from previously purchased blanks that are sold in hardware stores and specialized firms.

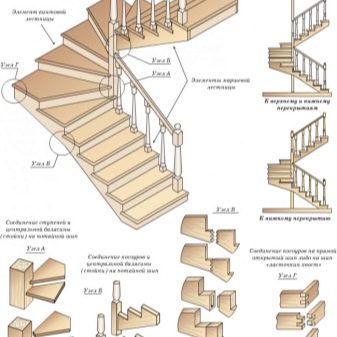

The initial stage of the manufacture of the staircase from beech - design kosour, steps and handrails.

It is important to closely monitor the process and avoid mistakes, because in the future, assembly and operation can turn into unpleasant problems. All calculations need to be rechecked.

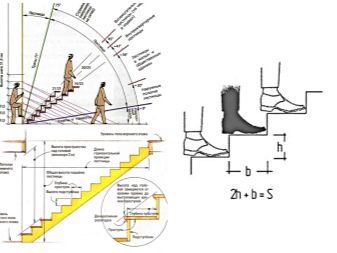

The design takes into account several important details.

- First, if the steps are high - their width should be reduced. In another case, the rise will be heavy.

- Secondly, so that tall people do not experience discomfort when using a beech staircase, the distance between the steps and the ceiling should be at least 190 cm.

After designing, you can start creating kosour. It is not necessary to make them yourself - you can use ready-made elements of stairs made of beech. Next, prepare the required number of risers and treads.

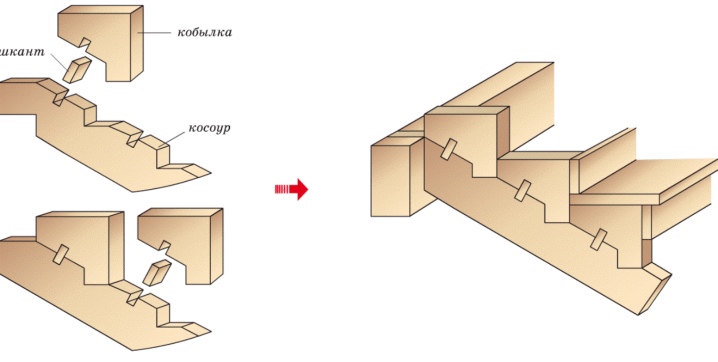

The next stage is the installation of steps and rails. Steps are fastened with the help of fillies - special blanks. In the process of assembling elements used screws or nails.

After completion of the work with the steps go to the creation of a railing. Installation of railings begins installing balusters. Following the balusters installed handrail.

The final step in the manufacture of beech stairs is the finishing of the assembled product. Be sure to apply a paint overlay.

You will learn more about making beech ladders by watching the following video.