How to build a staircase to the second floor with your own hands?

The construction of a private house often involves the presence of a second floor or insulated attic. This design allows you to expand the living area of the building and significantly save on the construction of an expensive foundation. And also in a two-story house it is much easier to organize a suitable layout. However, the presence of several floors involves the construction of stairs, which stops many novice builders. In fact, it is easy to make a quality staircase design with your own hands, knowing certain features.

Design features

Before you choose a ready-made staircase of famous manufacturers or start purchasing materials for a self-made construction, you need to figure out what exactly any staircase consists of. The fundamentals of the design are so elementary that there are practically no differences between different types of stairs.

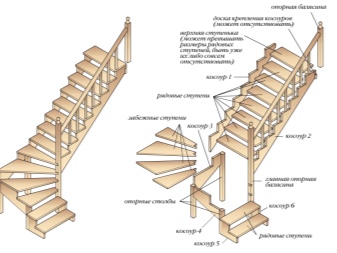

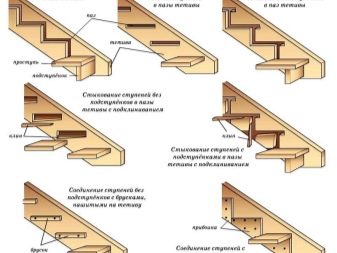

- Any staircase consists of steps, whether it is a small staircase of the porch or a spiral passage to the second floor. It steps take on the main load. In almost any design together with steps, the risers act as the main element. Their main function is to hide or decorate the attachment points and the internal structure of the whole structure. But both of these elements do not hang in space, but rely on the next one — a kosour or a bowstring.

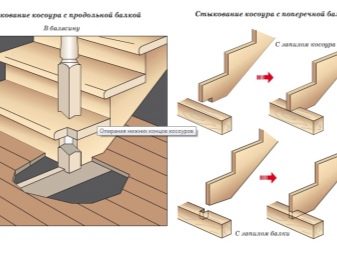

- Kosoura represent two boards sawtooth form. The step itself is laid on the horizontal part of the cut, and the riser is attached to the vertical part. In some cases, for example, when the ladder is located near the wall, you can use only one cross-hair, and attach the other side of the riser directly to the wall.

- Bowstring, in contrast to the kosour, consists of two straight thick boards in which grooves are cut. In such grooves, made on one pattern, are inserted steps with risers.For greater reliability of such a staircase, the bowstring is tied with wooden or metal bands.

- And also one of the important, though optional, elements are railingwhich reduce the risk of stumble and fall from a height. In some cases, mount the platform and the support level.

Kinds

The most used interfloor stairs in modern houses can be divided into three types: spiral, mid-flight and staircase on the bridge.

Marching

More simple and common is the device marching ladder. Depending on the height of the floor, it is single-marketed or multi-marketed. Marches are segments with different numbers of steps. Usually their number does not exceed fifteen, but the most convenient are the marches in nine steps. As well as the main staircase can be open type (without risers) and closed (with risers). The choice most often depends only on personal preferences, since there are no differences other than appearance in such types.

Open staircases are often used as a temporary solution and are later replaced with more complex structures.

Marching ladders can rely on both the kosour and the bowstring, there are no advantages of this or that support.Next to the wall it is more convenient to use a single kosour, but if you wish, you can also make a string, this will just slightly increase the material consumption. With all its advantages, marching design has one major drawback - it takes a fairly large space.

To save it, such stairs are made with corner turns, otherwise its construction in a small private house is simply unjustified. The steps of such a ladder are called in-transit and are performed in a trapezoidal shape. The most common turns of the march are 90 degrees (quarter-turn march) and 180 degrees (half-turn). If the degree of turnover is 360, then such a staircase turns into a spiral one.

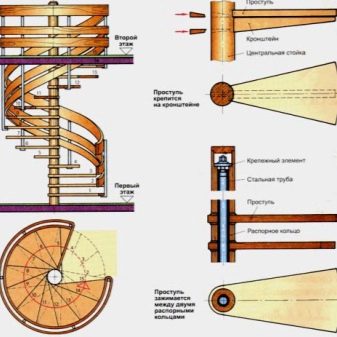

On the Bolets

With the increasing popularity of high-tech style in interior design, the popularity of such stairs has grown. Their main constructive element is a bolt fastening, due to which they received such a name (“bolt” is a “bolt” in German). Due to the absence of a frame on which the steps would rest, the ladder turns out to be “floating” in the air.

The role of the carcass is assumed by bolza, which are mounted to the rail.Although in some cases the design involves the use of one kosoura or one bowstring attached to the wall.

The main advantage of this staircase is that for the repair and dismantling of one element there is no need to dismantle or replace the entire structure.

Screw

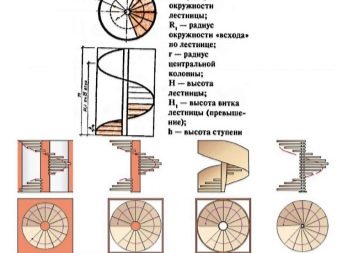

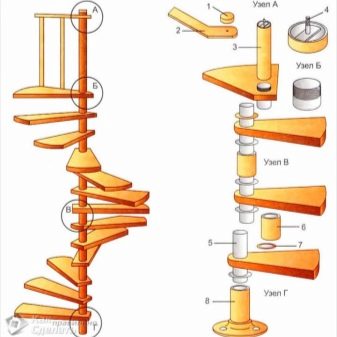

Often a spiral staircase is set to save space and beauty of design. It really is perfect for small houses with high ceilings. However, such ladders are narrow and steep, and also much more difficult to manufacture and assemble than ordinary marching structures. They cannot be used by two people at the same time, and it is practically impossible for them to lift any large-sized furniture or equipment.

Spiral staircases are divided into two subspecies. In the first case, the design is a central support to which the steps are attached, and one curved handrail. In the second case, the central support is missing, and the curved handrails are attached on both sides. Such a subspecies is more difficult to manufacture and imposes certain requirements on the quality of the materials used.

In some cases, the spiral staircase may be located near the wall and some steps can be additionally fixed in the recesses created in the wall. The classic screw design is round, but the ladder can be made polygonal or complex arbitrary shape.

Which one to choose?

The project of a ladder is created simultaneously with the design of the house itself. To select the right design, consider the following:

- where the stairs will be located: near the wall or in the center of the room;

- how many people will climb and descend the steps, how old they will be. Older people may have difficulty climbing up the high steps, and if there are small children in the house, the presence of a handrail is simply obligatory;

- Are weight lifting planned for the second floor? The minimum load on the steps is 200 kilograms per cubic meter, and the railing is 100 kilograms per cubic meter;

- the angle of inclination should be constant along the entire length of the ladder and should not exceed 40 degrees;

- the span should be at least 80 centimeters, and the height of the railing should not be less than 90 centimeters;

- the gap between the balusters should not exceed 15 cm, they should not stand too rarely.

Materials used

Most often for the manufacture of stairs used planed wood without irregularities, thorns and other defects. Before work, such material is dried and treated with stain. After that, the tree can be covered with one or two layers of special varnish. Quality wood for the construction of the stairs is wood of the first grade only with a moisture content not exceeding 10 percent.

If the moisture content of the material during assembly work is higher, there is a chance that after drying the structure deforms sufficiently. It is possible to use both low-cost types of wood and elite expensive materials.

Pine wood is light gray, high-strength, but easy to process. Low cost is one of the biggest advantages. And also birch wood has a low cost. The absence of a pronounced wood pattern allows you to realize interesting design ideas. Ash, on the contrary, has a pronounced woody pattern due to the special structure of the fibers. Despite the high compliance during processing, ash is more durable than birch or pine.

Solid oak wood has a light yellow color and high cost due to its high strength. Classic oak stairs will last a very long time and will bring a little luxury even in the simplest interior. Competition oak can make the maple, which due to the lack of pores has an even higher strength and durability. However, in addition to the high price, this material has another significant drawback: it is very difficult to handle.

In addition to wood, the stairs are made of materials such as glass, plastic, concrete and metal. Nevertheless, such ladders are rarely made by themselves, since special tools will be required for fastening their elements. For example, for a welded metal structure, besides the welding machine itself, a Bulgarian, a special vice, a metal table, metal drills and much more are needed. It is better to order such complicated ladders to be made from professionals.

How to make yourself?

Since the most simple for making with own hands is a wooden march construction with a kosour, it makes sense to dwell in more detail on it.It is also the most secure with the right height of the railing.

Calculations

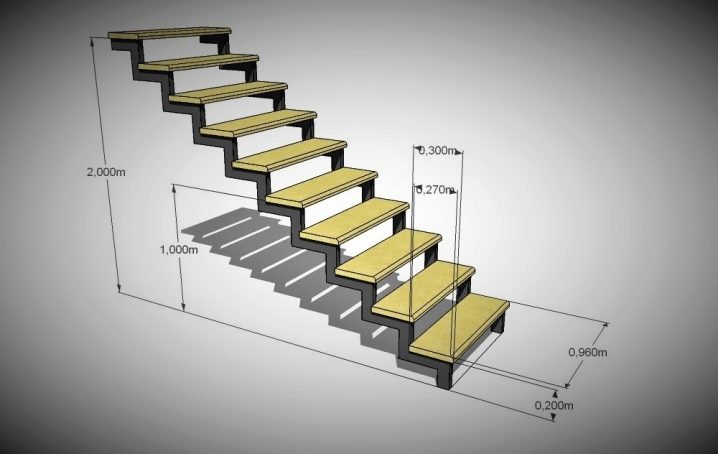

First you need to correctly calculate all the dimensions, the number of steps and the width of the span. The height of the room and the length of the wall or place reserved for the stairs, take up the foundations. Having reduced these dimensions to scale, it is necessary to construct a drawing of a right-angled triangle: the height and length will be the legs, and the hypotenuse is the staircase itself.

Ideal is such a scheme where the angle of inclination of the stairs will not exceed 40–45 degrees. The tread width should not be less than 200 mm; therefore, the natural length of the lower leg is divided by the tread size and we get the ready number of steps.

Then we divide the natural height of the second leg by the number of steps and we get the average height of the riser. Their height should not exceed 120 millimeters, and if this has happened, then they will either have to increase the length of the stairs, or choose another design, for example, a screw one. All the resulting dimensions are applied to the drawing, it turns out a finished sketch, according to which it is easy to make kosour and steps yourself.

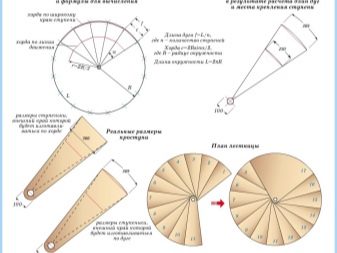

The width of the span depends on personal preferences and the free space of the room, but cannot be less than 80 cm. The calculation of the stairs in Balz is carried out in a similar way.For the screw design, more complex drawings will be needed in the form of a circle of a certain diameter, cut into sectors — steps.

Building

In order to make parts with your own hands did not bring unexpected unpleasant surprises, it is necessary to transfer all dimensions from the drawing to the material very precisely and follow the detailed instructions. The choice of quality material will greatly simplify the process of construction: good dry wood is easily sawn and fixed. It is most difficult to make an even kosour, as the strength and aesthetics of the finished structure depend on it. For him, a solid board is chosen without bitches and cracks. The thickness of this board can vary between 45–50 millimeters.

The treads themselves are made of planks with a thickness of 30–35 millimeters and should be 1.5–2 centimeters in width greater than the space made for them on the kosour. The edges of the treads should be made rounded and neatly polished in order not to accidentally get hurt on a small sliver and not put a splinter. If a staircase of a closed type was planned, then it is necessary to make, in addition to the treads, also the risers.For them, even a thin board with a thickness of 1.5–2 centimeters will be suitable, because the entire load will fall on the kosouri, and they will only slightly support the step and close the internal space.

Handrails or balusters is best to buy ready-made immediately with fasteners. Wooden elements will only be fastened with screws, and metal to be welded using a special apparatus. If there are elderly and small children in the house, then at each step it is necessary to put two balusters at once, but if not, then one is enough. For a staircase on a single-sided one, the production of parts follows a similar pattern, but without risers and with the purchase of metal ones instead of wooden railings.

Making a circular spiral staircase with your own hands is incredibly difficult. Starting from the inability without special equipment to make bent parts at home, and ending with the specifics of the design, patterns and fasteners, to which it is almost impossible to buy in an ordinary hardware store. The way out of the situation can be the installation of a usual swiveling mid-flight ladder with a 360-degree angle or the ordering of a finished product from professionals.

Installation

Installation is the most difficult and crucial stage after all the elements are manufactured or purchased. During installation, you must constantly check the details of the level or plumb, so that the entire structure is properly fixed and does not constitute a danger. First of all, you need to install kosouri on the tags that are pre-installed on the floor of the first and second floors.

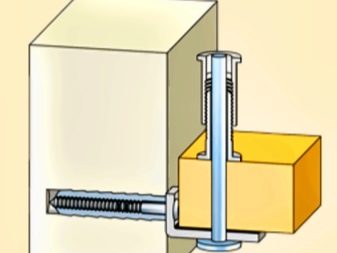

On the floor of the first floor there is a special support bar to which you need to fix the bottom of the kosour. And at the top of the stairs you can use metal supports connected to the ceiling beam with anchor bolts. The risers are screwed to the installed kosouram, on top of them are mounted treads with screws.

You can mount both of these elements at once, starting at the bottom up and connecting one step after another.

Then you can mount balusters. At the lower and upper edges of the stairs, support posts are placed that limit the design of the railing and support it. The balusters themselves can be of different types and fastenings: some are screwed with screws, others are drilled or special grooves are sawn.Installed elements cover the top with handrails, which are mounted on the support uprights at the edges of the stairs.

If the railing is quite heavy, you can put a few extra racks. In such cases, instead of balusters, you can use long wooden strips that are installed parallel to the staircase.

After assembling the entire structure, it is possible to process the surface of the resulting staircase with a grinding machine and sandpaper of various grit. After that, various antiseptic compounds that protect against insects, mold, mildew and rot are applied to the tree. After applying all the necessary solutions, let the tree dry completely and then varnish it in several layers.

If the tree needs to be darkened, then before the varnish can be applied stain and also give a completely dry. After all applied coatings have dried, the ladder is ready for operation.

Useful tips from the pros

A ladder is not only a building structure, but also a source of danger of injuries in a private house. It is necessary to make this construction the safest: low comfortable steps, reliable material and, of course, strong handrails.Do not make the stairs of slippery tiles or wood, varnished in several layers. If it is necessary to coat the wood with varnish, then at each step you need to make a few scratches with emery paper on the dried varnish - they will not catch the eye, but they can save you from falling. And also a wooden staircase can be upholstered with a heavy carpet - it will also eliminate sliding.

The main thing in such a finish is to carefully fix the carpet at each step with small screws so that it does not come off at the most inopportune moment. It is not necessary to upholster the stairs with linoleum - this will only increase the risk of falling, since linoleum is rather slippery even on a plane.

If the ladder is made of metal profiles, it is best to select those with a square cross section. Due to the presence of rigid edges, they are more stable than those with a circular cross section.

The size of the stairs most of all depends not so much on the area of the room as on the height of the ceiling. In a small country house with low ceilings, it makes no sense to make a wide spiral staircase, and in a large mansion with ceilings of more than three meters it will look strange to have a long, open flight structure.Before proceeding to the calculations and manufacturing, it is necessary to make sure that the floors of the second floor will withstand the chosen structure. Otherwise, you will have to install additional supports, and this will greatly reduce the living space of the first floor.

No need to independently build a drawing of the flight of stairs from start to finish, you can find ready-made options on the Internet and adjust them to the required dimensions. When making a decorative railing or balusters from a picture from a magazine or the Internet, one should not expect that it will turn out “not worse”. To create such complex elements as carving or forging, not only knowledge, but also many years of experience with certain materials and tools are needed.

The easiest way is to assemble a free staircase not bound to a wall. But such constructions can be used either as a temporary option or for attic spaces and garages.

Interfloor staircase made of wood in a private house must be fixed on the wall. The space under the stairs can be adapted for a small closed pantry or open bookshelves. The ladder itself can be made in the form of cubic shelves, the upper part of which is steps.Under the stairs hanging on the Balzi, you can organize a small corner of rest, putting there a rocking chair with a rug or a small soft sofa.

As practice shows, to make and install even the most elementary ladder is not so easy, especially if experience with such a design has not yet been obtained. In the construction of such a traumatic construction in your house, negligence in the installation and especially in the calculations is unacceptable. With obvious doubts about their own skills, it is best to seek the help of professionals. It is not necessary to order a turnkey finished work, it will be enough consultation and expert assistance.

How to build a staircase to the second floor, see below.