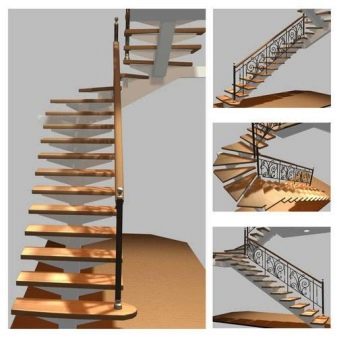

Metal swivel staircases with zabezhnymi steps: features and benefits

When building houses with the number of floors more than one common problem is the limited space for installing the stairs. The most suitable option in such cases would be a metal swinging staircase with windward steps. Such stairs, due to the variety of forms, will fit well into the modern interior and save usable space.

Types of construction

Usually a staircase with one march is mounted to go to the second floor. This lift can be divided into two marches, then between them there should be a transitional platform. To save space and a more aesthetic look, this platform is replaced with a transit stage. Zabezhny stairs are called stairs with a shape that resembles triangles or trapeziums that are attached radially to one common support.

These stairs are of several types.

- Screw. Looks like a spiral. Fully made up of the upper steps.

- Marching Instead of transitional platforms, there are trough-shaped steps with a bend of 90 degrees.

- P - shaped. Parallel marches are interconnected by a bend of 180 degrees.

- Mixed. The lower main and upper spiral stairs are interconnected by zabezhnymi steps.

Requirements for turning stairs with treads are quite strict.

At installation of such ladder comfortable smooth and safe movement has to be provided. To do this, the design should take into account the following conditions:

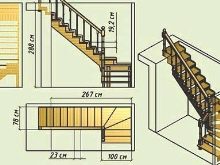

- step width along the line of motion (where the foot directly steps) is not less than 200 mm, in its narrow part - 100 mm, and wide - 400 mm;

- The height of the tread should be equal on all marching spans and comfortable for descent and ascent, the optimum is from 120 to 220 mm;

- for comfortable movement, the distance between the ceiling and the steps should be equal to the height of a tall person plus 10 cm, but not less than two meters;

- recommended tilt angle of the ladder is 30-45 degrees;

- the angle of rotation must be equal to or slightly greater than the angle of inclination of the stairs;

- railings are installed parallel to the angle of the staircase at a height of 0.8-1.0 m;

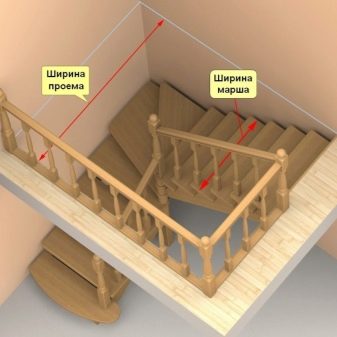

- optimal staircase width not less than 0.9 m;

- the staircase should be freely available;

- the design is located in the less visited part of the room, for example, in the corner;

- The installation of a metal ladder in a wooden building must be carried out after the house shrinks, otherwise a structural failure may occur.

Advantages and disadvantages

Like all ladders, zabezhnye also have their pros and cons.

The advantages of these structures include:

- possibility of installation on the street and in the room;

- space saving not only on the ground, but also on the next floors;

- due to the variety of forms and designs, you can create a unique work of art, originally fitting into any interior;

- long service life;

- structural reliability.

The disadvantages include:

- for safety and ease of use, accurate calculations are required when designing;

- high risk of injury and inconvenience when moving due to the width of the steps: wider on the outside and narrower on the inside (absent when properly designed);

- noise emitted when walking (it is eliminated by trimming the steps with a coating of wood, rubber, tile, etc.);

- painting or enameling is required, except if the structure is made of stainless steel;

- high price as with the purchase of the finished product, as well as in independent production;

- self-installation requires knowledge of welding production and the appropriate equipment.

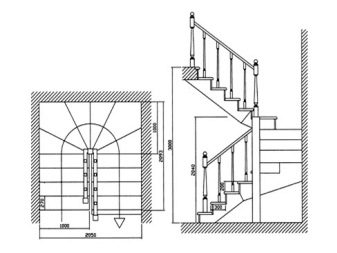

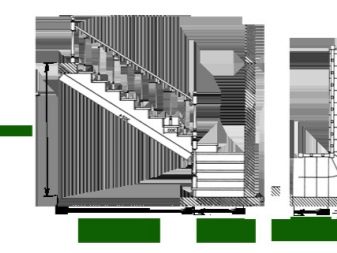

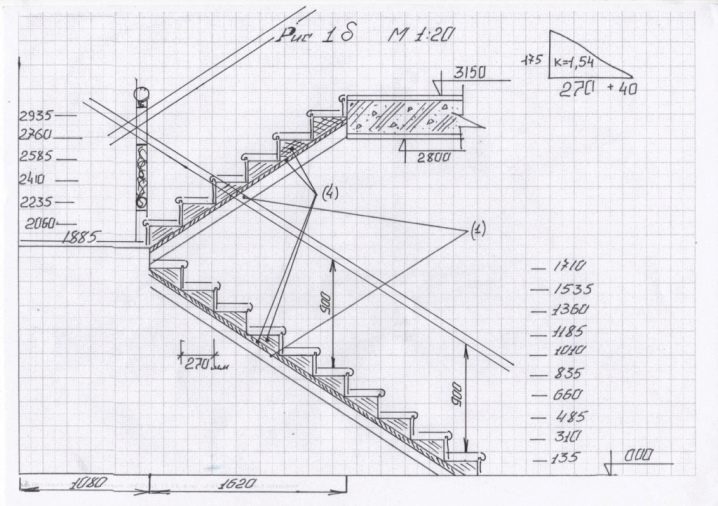

Design of a rotary ladder with zabezhny steps

One of the main stages in the construction of the staircase is design. It depends on it what size and appearance the future interfloor transition will have.

Design includes the following stages:

- the implementation of measurements;

- carrying out calculations;

- drawing up the scheme - the drawing on which the rotary ladder will be mounted.

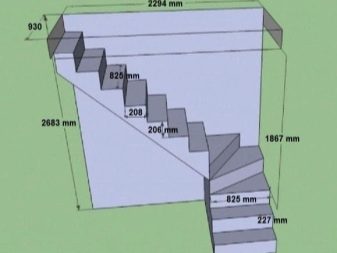

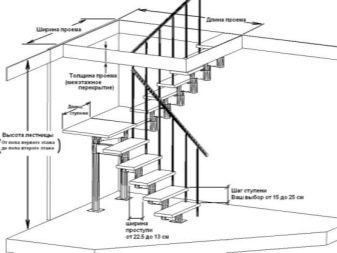

Initially, they determine the location of the staircase and measure the length, height, and width of the space under the flight of stairs.The type and size of the future inter-level transition depends on the amount of free space.

For each turntable, an appropriate calculation is made.

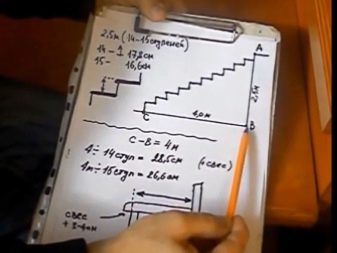

Calculation of the number of steps

The number of steps in one march is recommended from 15 to 20. If the ladder consists of several marching spans, from 9 to 11 for one span.

For a more accurate calculation, you can use the formula N = H1 / H2, where:

- N is the number of steps;

- H1 is the height of the span;

- H2 is the height of the step.

If the whole number did not work out, then it is necessary to change the height of all the steps or only the first. You can substitute under the staircase platform with the missing height.

Zabezhnyh steps are not advised to install more than 3-5 pieces, otherwise the steps will be narrow and inconvenient for lifting.

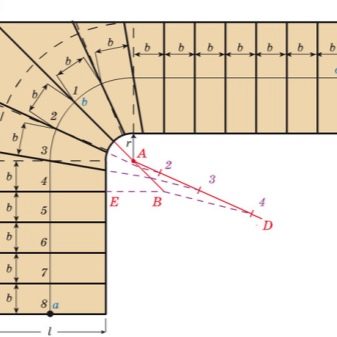

For products with a sharp turn

At the initial design stage, the master determines the axis from which the bend radius of the ladder is located. For bending at an angle of 90 degrees, the axis is at the junction of the lines of the extreme straight steps in the marches. If the angle is 180 - then right between the two spans. To ensure that the steps are not too narrow, the axis can be moved out of the span by 1/8 of the width of the march.

The outer edge of the inlet section is equal to the gap from the axis to the outer edge of the straight marching steps. And also from the axis it is possible to draw arcs passing along the inner edge and middle line.

Along the line of motion, it is necessary to postpone segments equal to the width of the foot, approximately 200 mm long. Through these segments to hold the rays from the central axis. This will be the silhouette of future steps.

For model with a smooth transition

Stairs with a steep transition are inconvenient for movement, therefore, a softer transition is often used.

In such a transition, the change of steps into a triangular shape begins with a march span.

This calculation is more complex, and it is recommended to perform it in a computer version or on paper with respect to the exact scale. And then lead to the natural size, tracing each step separately.

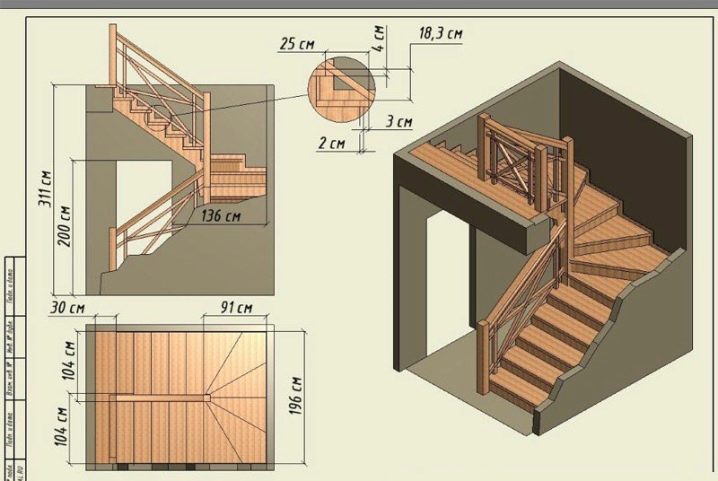

For U-shaped stairs

- Initially, the outlines of marching spans are indicated in the drawing. Between them should be ¼ of their width. The radius of curvature of the inset section is equal to half the width between marches plus the width of the march. Then, this radius is deposited from the upper edge of the endurance steps and the axis of the staircase curvature is located.

- After they have found the radius of curvature, the upper, lower arcs of the main turn and the middle of the stairs are drawn from the axis.

- The next stage is the distribution of steps. It is recommended to start from the center. Along the midline, segments are laid with a length equal to the width of the step. This line must be exactly in the middle of the step, and from this line the following steps are consecutively marked.

In contrast to the soft transition, it is necessary to decide where the intake area will begin. The fewer steps there will be in this area, the safer and more convenient this area will be.

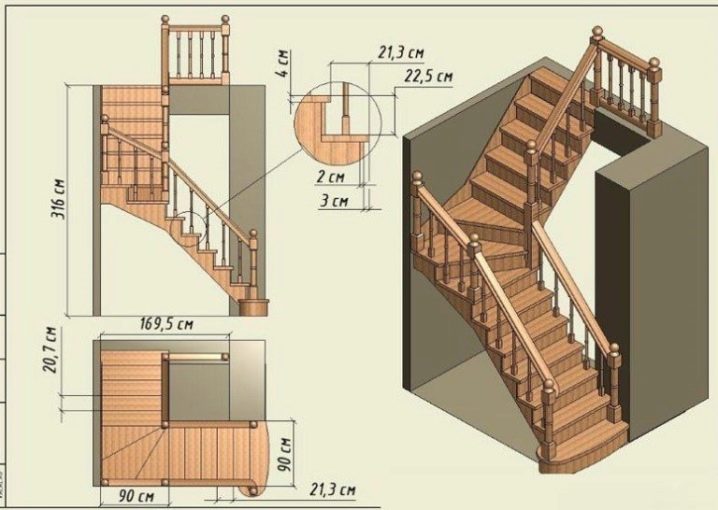

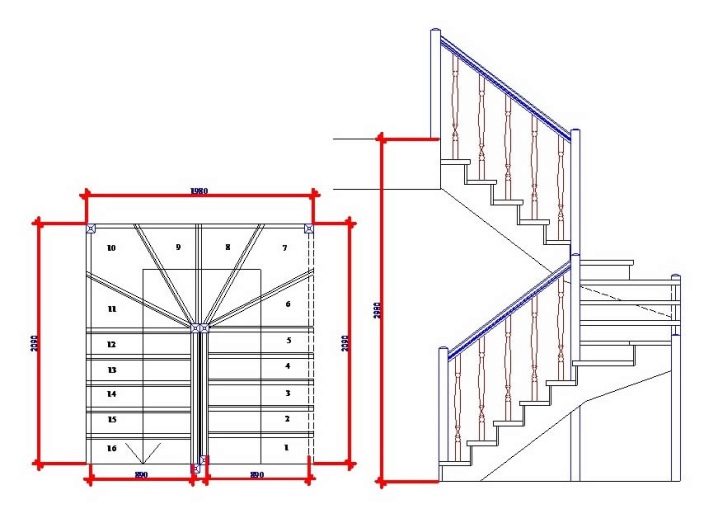

For a staircase with a turn of 90 degrees

To save space and secure fixation, it is more convenient to install the structure in a corner of the room.

The calculation must begin with a drawing of a circle with a radius equal to 1/2 of the span width. In the future, this will be the median line on the roadside.

In relation to the vertical of this circle, we draw a line (axis of rotation) at an angle of 45 degrees. The tangent line to the axes of the circle indicates the line of movement along the stairs. Then this line is divided into segments equal to the average width of the steps.

There may be two options for the distribution of steps:

- the axis of rotation divides the middle level in half;

- steps are proportionally deposited in both directions from the axis of rotation.

Next to the steps located perpendicular to each other, join the steps of the marching flight.

Then we find the intersection point of the last stage of the lower march and the first stage of the upper march. This will be the center from which the radial lines are drawn through the segments on the line of motion. This center can be adjusted so that the size of the outer width of the step is 400 mm and the inside one is 100 mm. These lines are the contours of the steps.

The resulting drawing is a scale scale scheme.

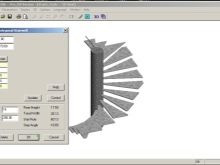

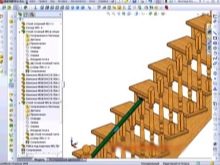

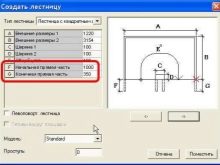

For more accurate dimensions, it is better to make calculations in a graphic editor or a special computer program. Programs will allow you to create a three-dimensional model with an indication of all the parameters.

The following programs are best known:

- "Compass" - to work in it do not need to have special skills;

- Solidworks - a program for the creation of engineering buildings;

- Consultec Staircon - allows you to create a 3D project and calculate the necessary costs.

But the data obtained in drawing up a drawing on paper is enough to build a reliable and durable ladder.For ease of construction and to obtain the most approximate dimensions, such drawings are best drawn up on graph paper. This will facilitate the conversion of sizes to full size. And minor inconsistencies can be eliminated during installation.

Installation of a metal rotary ladder

After carrying out the appropriate calculations and having the exact dimensions of the parts, you can determine the amount of material: metal sheets, pipes, profiles. Channel bars with a cross section of 100 x 200 mm or 150 x 200 mm, pipes with a rectangular cross section or angles of steel are usually used for the manufacture of supporting beams. The recommended metal thickness is not less than 8 mm, for steps of 3 mm. If the steps are wooden, then 40-50 mm.

For reliability, it is advisable to attach the turntable to the wall with anchor bolts pre-installed in the wall.

For the ladders on the bowstrings, on each side there are special corners that serve as a support. And on the kosoura welded ridges corresponding to the size of the steps. Next, the frames are attached under the steps or directly steps.

When assembling a ladder, it is better to carry out welding work outdoors, or the room should be well ventilated.Be sure to comply with safety regulations.

Ready designs

If you are unsure of your abilities, pay attention to the finished structures on the metal frame. Most likely, the cost of such a design will be slightly more expensive than its independent production. However, it will be performed by an experienced technician who guarantees safe use. To make a frame riser is quite difficult.

At this time, metal stairs on the frame with zabezhny steps are used not only in private homes, but also in manufacturing, and in public buildings. Due to its compact size, this design, without taking up much space, will provide a safe and comfortable transition between floors.

To learn how to make a staircase with hands with steps, see the following video.