How to build a staircase in the cellar?

Ladder is a necessary element of any cellar. It is used for the descent or ascent. In this case, the design should be reliable. It is worth considering the different types of stairs that you can make yourself.

Material

For the construction of stairs, you can use different materials. The most common options are several.

Tree

Wood is one of the most popular types of raw materials. This material needs high-quality processing to be able to withstand high loads. Special treatment is able to protect the wood from rotting, dampness, the formation of mold fungi. The greatest attention should be paid to the end of the wood and mowing. This will increase the period of operation of such a ladder.

Metal

Ladders from this material should be treated with a special tool that will protect them from corrosion. This design with proper care will be reliable and durable. It is necessary to paint steps in 3-5 layers. To do this, you can use enamel or oil paint. Apply each subsequent layer is possible only with the full drying of the previous one.

Concrete

Despite the fact that the presented material is characterized by its durability, it needs special protection. To protect the surface of concrete, you can use tile trim or paint in several layers. However, these methods require large expenditures. You can install linoleum or adhesive mats that are cheaper.

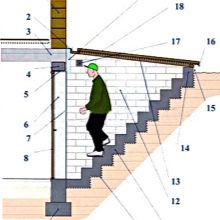

Requirements

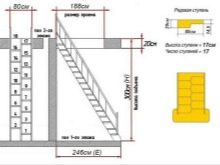

Whatever ladder with steps for giving you chose, before installation it is necessary to look through all the projects. It is necessary to make the drawings correctly and find out which fittings are needed. The staircase, which is set to descend into the basement or cellar, must meet certain requirements:

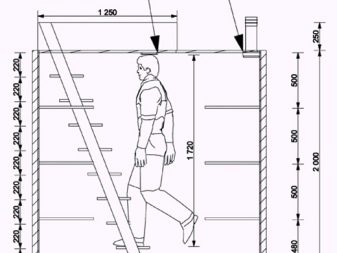

- The optimal width of the steps is 60 cm, the minimum option is 35 cm.If you plan to drag a bulky cargo to the basement, an excellent option would be 80-90 cm wide.

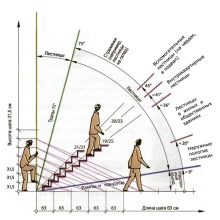

- The optimal slope is 75 degrees, however, it will not allow carrying the load together. In this situation, even the most difficult to rise, if you hold something in your hands. The best option would be the parameter 45 degrees.

- The vertical height of the step should be from 15 to 20 cm, horizontally it can vary in the range from 25 to 35 cm.

The ladder should be solid. The design should be resistant to moisture, which is present in the basement.

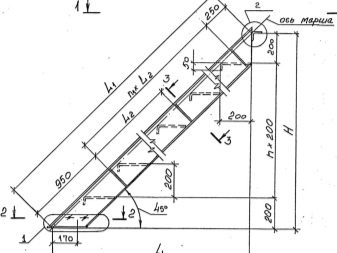

Calculations

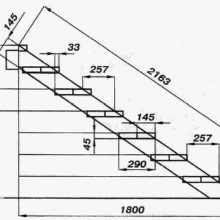

In addition to the need to choose the material for the stairs, it is important to develop a design of optimal size, which will be convenient to use. When designing, some parameters should be taken into account. For example, the width of the staircase is based on the size of the room. The optimal width is considered to be 70-90 cm. It can be increased or decreased depending on the characteristics of the cellar.

The greater the slope radius, the more comfortable the staircase will turn out. However, in this case, it will take up more space.

Clearance is an indicator that reflects the distance between the steps and the ceiling. If you do not take into account this parameter, being in the basement, you can hit the overlap. The distance from the upper foot should be more than 20 cm.

Particular attention should be paid to the size of the steps. From this parameter will depend on the ease of operation of the stairs. An important role is played by the height of the steps. The best option is 15-20 cm. The upper and lower stages provide for deviations from this indicator. We should not forget about the handrails, which also need to calculate the size.

They are rarely envisaged in the cellar, as it requires additional costs. These stairs take up extra space. To avoid this, it is recommended to install handrails only at the top and in the middle of the stairs, the lower part can be left open. The fence should be low, but sufficient so that if necessary you can lean on it.

Organization methods

The choice of one or another way of organizing the stairs is based on the features of the room.

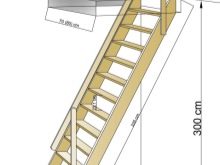

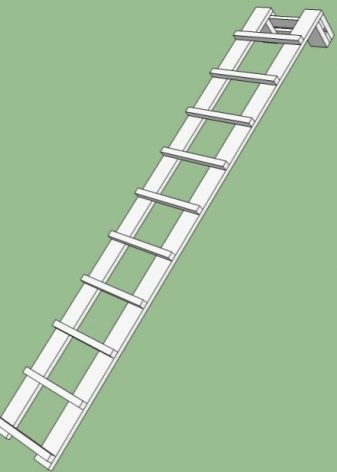

Added type

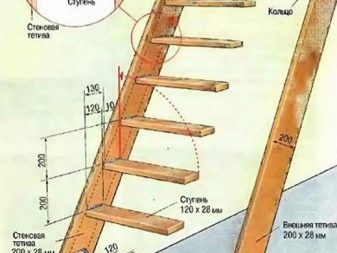

This option is widely used for arranging the descent into the cellar. Many people mistakenly believe that under the ladder they understand two vertical racks, which are connected to each other by means of horizontal bars. In fact, it is a reliable, practical and durable construction, which is made of metal or wood. This option is relevant for small basements.

To use the stairs as convenient as possible, it is necessary to fix it at a certain angle at a distance from the wall. You can install the stairs in the center of the room, and place shelves along the perimeter, filling them with products. Another option for the manufacture of a ladder is a design with two bowstrings as a stand. It is of the additional type because there are no other supports besides the floor and the ceiling.

The presented option is optimal for a small room. However, it has a flaw. To get something from the lower shelves, you will need to go down to the floor. Install a similar ladder at a certain angle, so the design involves the installation of a handrail.The ladder of this type can be made of metal or rods, which should be slightly rough in order to avoid falling. To create a wooden staircase you will need standard tools that are present in almost every man. In the case of a metal structure there is a need for a welding machine.

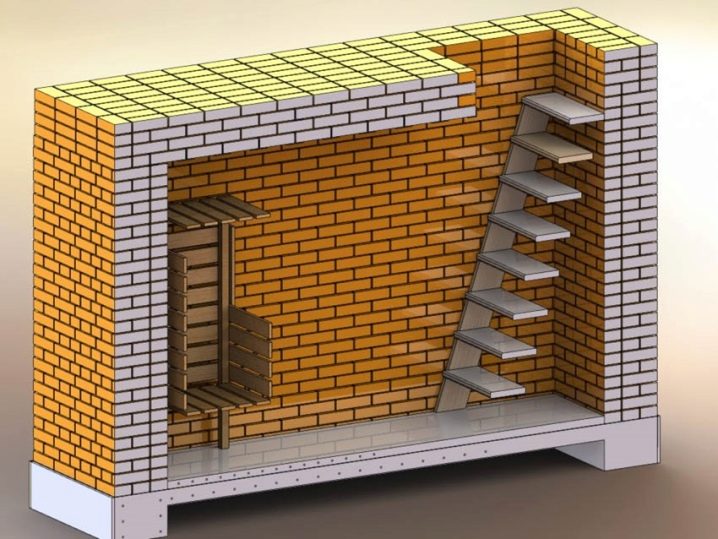

Marching

This is the most convenient option, however, it is suitable for buildings for spacious rooms. When it comes to large areas, usually 1 staircase is installed. If the footage of a particular room is limited, it is necessary to perform a staircase construction in 2 march. Usually they are placed at a right angle, they are connected by zabezhny steps.

It is possible to make a similar construction from wood, concrete, a brick or the combined materials. If we are talking about the concrete staircase, it needs reinforcement and complex formwork. The structure can be reinforced with a metal frame. Often similar to the frame and create a staircase with wooden steps. This design will provide her with good airing. In addition, the combination will increase the service life of the stairs.

As a distinctive feature of such structures it is worth highlighting the fact that you can organize a gentle slope, a comfortable width of the steps and their optimum location.

If the ladder does not lean against the wall, on both sides it is worthwhile to protect it with a railing. This will increase user security. The number of marches usually does not exceed two.

Screw

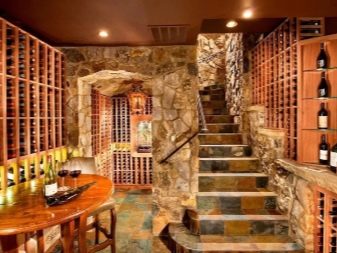

Screw designs for arranging the entrance to the cellar are rarely used. Usually, people stop their choice on this option only due to the fact that there is no possibility of installing the descent by other means. Outwardly, this is a twisted version of the ladder that does not have linear marches. More often such a structure is installed in the central part of the cellar. Shelves and racks are placed around it.

This layout It is very convenient because you can get everything you need without leaving the stairs. Screw-type staircase provides for a central rack serving as a support. Stairs are fastened around it. Fix them in different ways depending on the choice of source material. In the case of metal construction, the steps are welded to the stand.

The wooden staircase provides for the presence of a stand and steps made of wood, which are connected with special screws.

Among the advantages of the screw descent is to highlight the optimal use of space. The disadvantage is the fact that it is inconvenient to go down this ladder or climb with a load in your hands. When choosing a material should take into account this nuance.

Manufacturing

The construction of the stairs in the cellar depends on the type of construction, its size, reserved for not square. Consider different options.

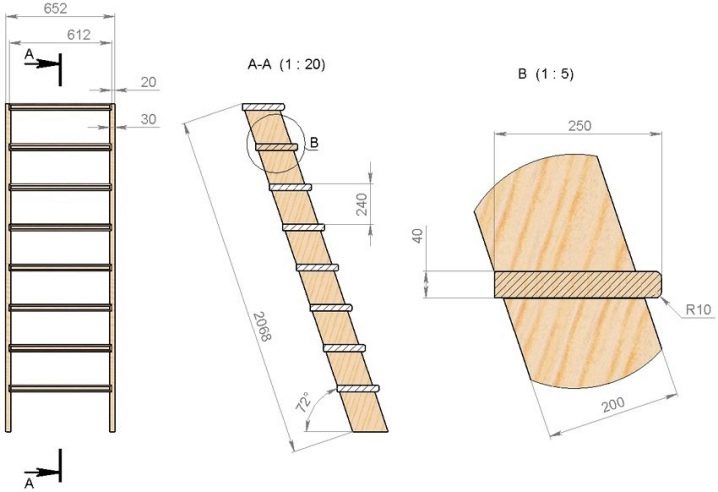

240x60x30

To make a structure 2.4 meters long, 0.6 meters wide and in 30 cm increments, you will need:

- 2 boards of treated wood measuring 10x15x240 cm for supports;

- 7 transverse bars 5x10x80 cm;

- 28 screws.

The construction technology consists of successive stages:

- It is necessary to lay the boards for support on a horizontal surface. From the edge measure out 30 cm, set the crossbar.

- Fastening is carried out with the help of two screws to one kosour. On one crossbar you will need 4 screws.

- Carry out the fastening of the remaining crossbars, the distance between them should be the same.

200x80x22

In this case, the number of required materials is designed for the manufacture of a 2-meter ladder, whose width is 80 cm, and the height of the steps is 22 cm.

- two boards of 10x15x200 cm;

- 6 boards 6x20x80 cm;

- bars 5x5x15 cm (12 pcs.);

- nails or screws (60 pieces + stock).

Provides a slope of 30 degrees, which is the most convenient to use. It is required to attach bars to the available support. Mount them at a distance of 26 cm from each other. The slope should be 60 degrees (the ladder will be at an angle of 30 degrees).

The fixing of the bars is carried out by means of two nails. With a single hardware, you can increase reliability. In this way it is necessary to fix all the supporting bars. Next, perform the installation steps, which are fastened by nails or screws in three places.

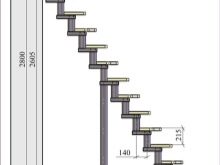

Metallic

It will not take much effort to make a ladder out of metal pipes, and it will take little time to complete the building. Fastening is carried out by means of the welding machine or use the inventory equipment.

First way

If the length of the ladder is 220 cm, while the width is 0.7 m, and the pitch is 25 cm, pipes with a diameter of 50 mm will be required.To create cross-pieces, use 7 rolled products of 70 cm each with a round section of 30 mm. From the top of the pipe it is necessary to measure 25 cm and attach the first degree with a butt joint. In the same way is the installation of the following cross.

Second method

In this case, under the metal ladder imply a frame. Steps can be metal or wood. You will need a channel measuring 50 x 100 mm and a corner of 0.5 x 0.5 m. Initially, you need to prepare a support for the steps. In this case, one side is the width of the tread, and the other is the height of the riser.

The angle between these supports should be the same as the slope of the stairs relative to the cellar floor. To create one stage will require 2 blanks. The channel must be installed with the side part upwards and marked on it the points where the steps will be mounted. It is to this place that the workpiece is welded. The angle of inclination should be 90 degrees.

After installation of the supporting pillars, they need to be strengthened. To do this, it is required to weld a steel corner with protruding supporting fragments in the places of their joint. At this stage, the frame of the ladder is considered ready.You must begin to finish the march. To make the overlay, you can use a corrugated sheet or lumber. With the help of similar structures you can close the risers.

Concrete

When it comes to building stairs to a room that is characterized by dampness, a concrete option is considered the best choice. Concrete differs in anticorrosive property, such ladder will not bend when using, it will not creak. It is worth making such installation exclusively at the stage of construction. If you want to make your own hands, you need to know: this process is time consuming. Such a construction will be expensive.

It is extremely important in this case to accurately calculate the amount of cement, sand and lumber you need. This concerns the height of the stairs, its slope, the size of the steps. Since this is a monolithic structure, then it will not be possible to make any adjustments.

It is important to consider the strength of the foundation. A concrete staircase will be massive, which will have a greater weight load.

First make the lower part. Then you need to install the flanging.This will prevent the casting mixture from escaping and make a place for fixing the supports of our steps. With the help of these crossbars you create a view of a ladder. Next, you need to mount lumber to kosouram. You can use reinforced corners of metal. Particular attention should be paid to the stage located at the very bottom, as it requires increased reliability. Make reinforcement.

With the help of metal rods, you can add strength to a concrete structure.

Before the concreting process, it is necessary to cover all the joints of the structure with cement mortar. So you can avoid drops, making further finishing work more simple. First you need to pour and form the first two steps.

Be sure to avoid the presence of hollow sections. Concrete mix is required when pouring pierce any object. This will eliminate the formation of air cavities that reduce strength. Next steps should be subjected to vibration, after which they should be given a final appearance with a wide trowel.In the same way they fill and stack all the other steps.

Reviews

The users of the cellar stairs have their own opinion about the convenience of the structures. According to their opinion, the best choice is the version of the marching type with one march and railing. Such a staircase is convenient and safe, - noted in the comments left in the vast world wide web. Analogs of screw type cannot be called convenient, users consider. Twisted system limits movement, complicates the descent and ascent with a load in his hands. Of the materials, the best, according to the owners of private buildings, is concrete.

How to make a metal staircase in the cellar, see the video below.