Varieties and possibilities of collapsible braziers

In recent years, lovers of outdoor activities are becoming more and more, because such a pastime is not only pleasant, but also very useful for health. When planning a warm vacation company, be sure to purchase a folding grill, where you can cook fish, poultry, meat or even vegetables.

Such barbecues are also called portable, touring, prefabricated, camping, folding or mobile.

Design features

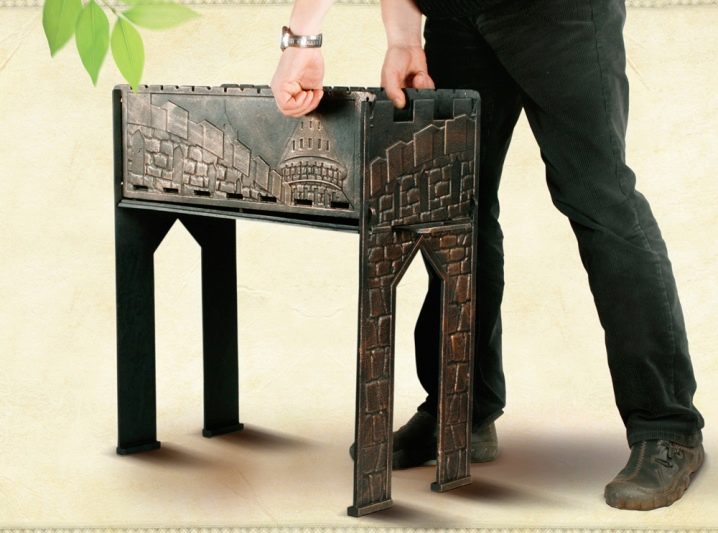

Collapsible brazier in assembled form has small dimensions, legs are removed from it, and the capacity for coal is easily disassembled into separate elements.Brazier fits perfectly in a small case or bag that is easy to carry in the trunk of a car or even carry in your hands. A distinctive feature of such models is their low weight; however, when acquiring a folding grill, it should be borne in mind that the lighter the design, the thinner the material from which it is made.

Therefore, you should be aware that the products will not serve for a long time - thin steel quickly burns through, deforms and collapses.

The following advantages of prefabricated models can be highlighted:

- compactness;

- ease of assembly and disassembly;

- low weight;

- low cost;

- mobility.

Among the shortcomings, it is worth noting the short life. However, users note another disadvantage inherent in most hiking models: after being used under the influence of high temperatures, its walls often get stuck on the legs, the folding mechanism jams and the assembly becomes almost impossible. Attempts to eliminate such a problem with the help of strong pressure often lead to a violation of the integrity of the sheet.

Some users confuse folding and modular barbecues. Despite the similarity of functions, they have a fundamental difference: folding models do not disassemble into separate parts, unlike prefabricated kits.They consist of several separate plates of sheet metal, which are inserted into special grooves of legs from bent corners.

Skilled craftsmen prefer collapsible designs, made by hand. In this case, they are stronger and more wear resistant.

A quality brazier made by yourself must comply with the following parameters.

- easy to manufacture, without the use of special sheet bending equipment and guillotine;

- wearproof, steady against adverse effects of high temperatures and the atmospheric phenomena;

- easy to assemble and disassemble;

- fireproof;

- made of environmentally friendly materials that do not emit harmful and toxic substances under the action of heat.

Types: advantages and disadvantages

For cooking delicious and fragrant kebabs in the forest instead of 4 stones that are not so easy to find, it is easier and more convenient to use a folding grill. Such designs are widely represented in stores, as well as made by own hands at home.

All of them are divided into 2 categories.

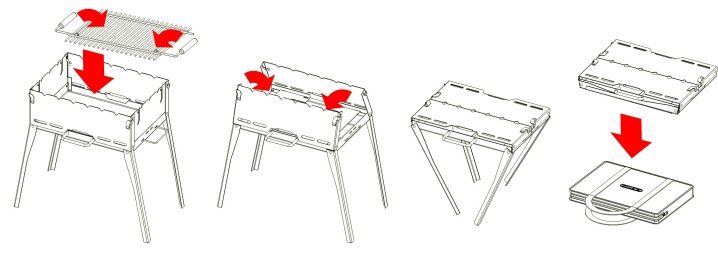

- Transforming braziers - fold and unfold, but the individual elements of the roaster are fastened together with one-piece hinges.

- Braziers-kits - fully folding models, consisting of several separate parts.

Transformers are much more difficult to manufacture, since here it is necessary to pivotally fix the individual elements, as well as think over the dimensions of the bottom and sidewalls so that they do not interfere with each other during transportation.

From the point of view of external design and functional features, there are several models.

- With folding legs. This is a traditional standard type of installation, which is a tank for coals and feet that can be removed. Such a model is a simple mechanism that is optimal for dacha use. However, you should not use it in hikes - with such a “trough”, even if without legs, to go long distances is quite problematic.

Such barbecues are often performed in mini-versions, they are also called pocket. But in any case for their transportation need transport.

- Brazier-notebook - an interesting design, in appearance and features of a collapsible device resembling the well-known computer equipment. It unfolds with the help of special hinge mechanisms, all works take no more than half a minute.

The main difference of this barbecue from the usual design is that its furnace is made in the shape of a truncated triangle (if you look at the mechanism in section).

- Brazier-book - Another popular modification, similar to the "laptop", but has a different location in length and width. Such an installation holds heat well, saves fuel and provides the necessary traction.

For lovers of outdoor recreation, both such models can be an ideal option.

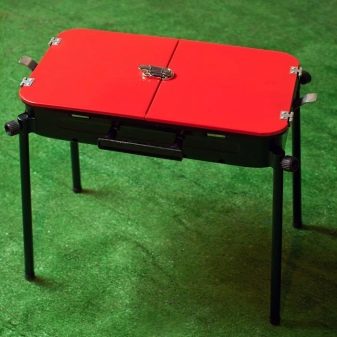

- Brazier Suitcase - represents the bottom and the cover, in each element there are holes: in the bottom - for air flow, in the cover - for protection against wind, and on the sides there are slots for skewers. Products are also made of galvanized steel. At the lower edge of the mounted additional elements that bend and serve as a support for the roaster.

- Portable grill without basket. In fact, the product is not a brazier, but simply two guides, on which skewers are laid. Instead of a tank, for coal, they put a hearth of stones or make a hole in the ground.

From the point of view of mobility and ease of transportation, this is the most convenient device, but its use requires time and effort to find materials suitable for the source and its equipment.In addition, in wet weather, for example, after rain, it is impossible to achieve the required dryness of the broiler, and it is often impossible to make a fire.

The variety of models presented in the shops for tourists and summer residents amazes with its diversity. Here, every buyer can choose a model for every taste and wallet and purchase the best option for themselves.

Materials

Folding barbecues are made from metal. Most often for portable braziers use stainless steel. This material is distinguished by corrosion resistance, so stainless steel has become the main and most popular material for the production of transitional structures.

Depending on the thickness of the sheet metal braziers divided into thin-walled and thick-walled options.

- Thin-walled models are made of metal with a wall thickness of less than 3 mm. As a rule, they are made of aluminum or stainless steel. Such models differ in low weight and low price. These installations are not intended to kindle fuel, as under the influence of open fire, they quickly deform and burn through. Therefore, wood is kindled in another place, and already hot cinders are poured into the brazier, which prolongs the life of the product.

However, despite such features, their lifespan rarely exceeds 1-2 seasons, so this option is used, as a rule, only for hikes.

- Thick-walled products are made from sheets of metal with a thickness of 4 to 6 mm. These models are heavier, so they are widely used in the country. For the winter period they develop and clean up in the room for long storage. These products are often performed in advanced versions: they have a grill and barbecue grill, adjustable blowing and a lid that allows you to cook meat and fish even in bad rainy and windy weather.

Less commonly, portable grills are made of cast iron. The advantages of this material are obvious.

- Strength. The design is not deformed and does not crack under the influence of high temperatures.

- Long term use. Cast iron is one of the most durable alloys. Such a construction can last for at least 100 years and be passed on from generation to generation.

- Rust resistance. Unlike steel, cast iron is less susceptible to corrosion, which is why it retains its appearance and physical-technical state longer.

- Efficiency.The material retains heat excellently and warms up pretty quickly, thereby significantly reducing fuel consumption (coal or logs).

- The speed of cooking. Barbeque in a cast-iron brazier is cooked faster than in steel products.

- Aesthetic appearance. The design of this brazier may include cast elements that allow you to implement any ideas. The roaster can be made in the national, modern or classic style and become a real decoration of the local area.

The disadvantages of the brazier of cast iron.

- Heavy weight. This parameter is of fundamental importance when it comes to portable channels. Transportation of this design of cast iron can be carried out only by car.

- Cast iron products are quite expensive - the price for them is several times higher than the cost of similar models of steel.

If preference is given to this material, then you should know that it can crack due to sudden changes in temperature. Therefore, if you plan a picnic with shashlik in the winter season, then such a product should not be taken with you, as in the process of cooking, there is a deterioration of the barbecue material.It is better to use this design exclusively in the warm season. But if it did happen, then you need to warm up the brazier gradually.

In contrast to stationary models, collapsible structures are not made of concrete and bricks.

Drawings and sizes

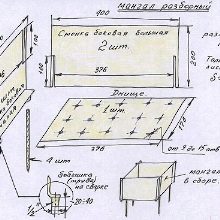

There are no universal parameters and schemes for making collapsible brazier with your own hands - each creates a model individually.

The basis of calculations should be taken:

- the number of skewers and servings of meat that must be prepared at the same time;

- the size of the trunk of the car in which the brazier will be transported in a disassembled state;

- the growth of the “main cook” - the person who is most often involved in cooking kebabs.

If the experience with metal is small, experts do not recommend experimenting with the dimensions of the installation. It is worthwhile to dwell on the standard parameters adopted on the basis of the traditional length of the skewer and the size of the bead, suitable for the production of a sufficient number of kebabs.

It is recommended to take the following indicators as a guideline:

- Width - 30 cm (based on the length of the skewers, which is usually 40 cm).

- Length - 60 cm (assumes 6 skewers located with a step of 8-10 cm).

- The depth of the rim is 15 cm, and taking into account the grate bars it is 20 cm (bred experimentally - with such dimensions, the meat is uniformly roasted, and the cooking process is not delayed in time). If you focus on a smaller height, then the meat can be burned, and with a larger size - remain raw inside.

- The height of the legs is 60 cm. It is sufficient so that the preparation of the kebab is comfortable and does not cause discomfort to those who are responsible for it. However, this parameter can be adjusted according to the size of the trunk of the car.

Below are several different drawings of prefabricated barbecues - of them, every lover of tasty food can choose the model that will meet the abilities and capabilities.

Manufacturing

To create a collapsible model of barbecue requires some skills.

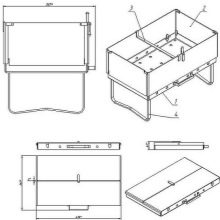

Traditionally, any camping grill contains several basic details:

- frame - 1 pc .;

- legs - 4 pcs .;

- bottom - 1 pc .;

- beads - 4 pcs .;

- grate - 1 pc .;

- hardware.

Depending on the wishes of the master brazier may have a different number of parts removed.

By the method of manufacturing brazier can be divided into two groups.

- With removable legs.This is the simplest model to perform. It has a welded body and supporting elements that are inserted into specially equipped grooves.

- Fully collapsible version. Such a model is the most difficult to manufacture, since for the connection of elements it is necessary to mount special mounting holes and fasteners.

The most common are several types of mounts.

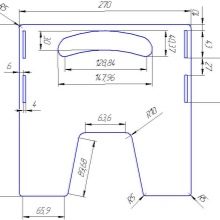

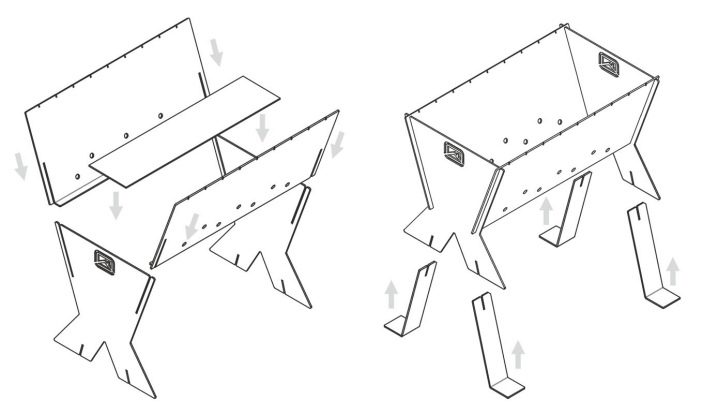

- Walls are fixed using a bent corner. At the same time, the racks are sawed out with holes of a flat oval shape, and in the walls, tick-shaped eyes that are pinched from above are punched and bent. The bottom of this design is placed on the frame formed by the drawn shelves in the lower fragments of the walls without any additional fixation.

- The second method involves the entry of the sidewalls into individual grooves of all end walls. This method is more labor intensive and requires the use of special tools.

Technology

On the Internet you can find a lot of diagrams and drawings of collapsible braziers. Below is the simplest example: a transformer.

First you need to make a drawing or download it from the Internet.It is worth remembering that all the details should be cut out of steel in strict accordance with the schemes, because, otherwise, the transformation of the brazier will be significantly difficult.

Manufacturing technology includes several steps, which are described below.

First of all, the lower part is cut out of the metal sheet by the grinder, on all four sides of which the “shelves” of 2 cm are bent. Thus, two sidewalls are made, only the shelves in them are bent on three sides: the end is not bend from above, on one of the walls vertical slots are made from above, and round - on the second.

The walls are fixed with a hinged bottom with screws. Wall-end walls are similarly made: in them the shelves are folded only on the sides.

At the finish stage, you should do three things.

- Attach the nuts to the bottom on the bottom. Directly racks are made from a bar, at one of its ends a thread of the required size is cut.

- The entire installation is drilled through in the central part, and a bolt is screwed into the hole, which is fastened with a wing nut. This is necessary so that the sidewalls are not detached when moving.

- A handle is fixed on the side bottom shelf, which will facilitate the transportation of the brazier.

- The legs are the easiest to perform collapsible. For this purpose, pieces of pipes are welded to the bottom, through which a metal bar, bent U-shaped, is passed. During transportation, these improvised legs are pressed against the frame, and during installation - stuck into the ground.

If desired, the model can be equipped with a roof.

Rust protection

It is important to ensure the safety and protection of the product under storage conditions: it is necessary to perform anti-corrosion treatment on the product.

There are two main ways to protect the metal from rust - it is painting and burnishing.

Experts recommend using powder baked dyes as a heat-resistant coating. To do this, the brazier is disassembled into individual elements and each piece is carefully treated with powder, and then sent to the oven for further roasting. Such processing significantly improves the strength characteristics of the metal - the products become strong, resistant to the constant effects of heat and adverse weather conditions.

However, this method is very expensive, and the necessary equipment can not be found in every home.

That is why most often in the home use automotive silicone enamels, which are sold in stores for car owners. Such substances are used to paint auto-silencers. They can withstand temperatures up to 600 degrees, so they are perfect for the roaster. The paint is available in cans. It is easy to use and does not require skills to work with coloring compositions.

Brazier can be painted in other colors, but they must meet a number of conditions:

- be heat resistant;

- incorporate anti-corrosion components;

- do not emit harmful substances during combustion.

All listed parameters are indicated on the package. If the required information is not found, then this means that before you is a fake.

Do not confuse fire retardant and heat-resistant enamel. The first is applied on wooden surfaces to prevent fire. It does not stand the heat and under the regular influence of high temperatures can be deformed and covered with cracks. Accordingly, the substance can not be used to create a mangal.

As an alternative to paint, you can use heat-resistant varnish,the active component of which are alkyd resins. The substance perfectly protects the surface from the adverse effects of moisture and temperature changes.

The second way to protect the metal - is bluing. To make the procedure yourself, you need to disassemble the structure, degrease every detail of it, and then boil it in caustic soda solution (for the solution, water and caustic soda are mixed in a ratio of 20: 1) for an hour.

This is a long process. It requires compliance with safety regulations, while the room must be well ventilated, but the result is worth it. In the process of bluing, the upper metal layer changes its structure, so that it does not crack and does not lose its appearance over the years.

In the next video you will see the process of making collapsible V-shaped barbecue with your own hands.

Ready models

Making barbecue, especially collapsible, requires special experience with metal and technical skills. That is why most consumers prefer ready-made models.

The advantages of finished products are obvious:

- they do not require the expenditure of effort and time to design and manufacture;

- their price is comparable to the final cost of an improvised design;

- factory made products meet all the requirements of fire, environmental and technical safety.

Among the most popular models are products of companies from the Russian Federation and other countries:

- Grillver;

- Doorz;

- Megagrill;

- Alder Smoke;

- Onix;

- Forester.

Use: Tips

The folding brazier serves as the real assistant during campaigns, travel to the nature and on trips. It is quite simple to make such a construction, but this requires at least minimal experience and a set of necessary tools (drills, welding apparatus and grinders). Otherwise, it is necessary to give preference to ready-made models.

Proper operation, compliance with the rules of storage and use of barbecue significantly prolong its service life and will bring a lot of joy to all those who use such an attribute.