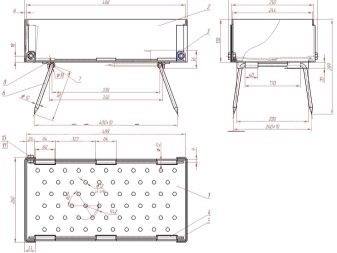

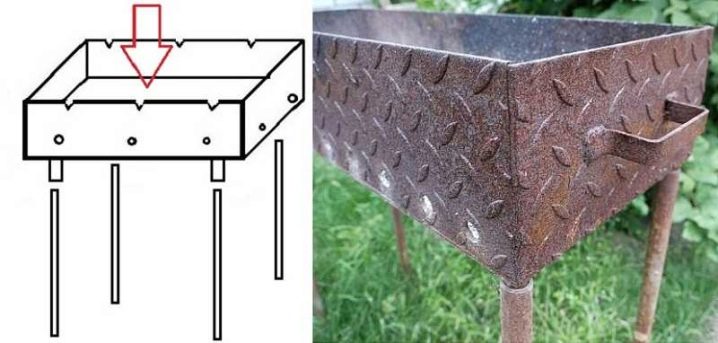

Schemes of production of supports under the brazier

In each country house must be a brazier. Most often it is used only upon arrival of guests for cooking meat, less often - for other dishes. But one thing is for sure: the brazier is a stationary construction. In the manufacture of this design can get a grand, it all depends on your decisions.

Preparation for production

Before describing the process of manufacturing barbecues, you should pay attention to the fact that the brazier itself almost never lies on the ground, as this is inconvenient. He must have a stand. The design can be quite simple and consist of four pillars, the supports can also be more functional: have shelves for utensils or skewers. Also, some products can serve as an element of decor: ornate forged patterns will decorate any area.

When working on the manufacture of the stand or the joint construction of the barbecue and stand, you must have:

- welding machine, electrodes and mask;

- electric screwdriver (better battery);

- Bulgarian and cutting wheels;

- gon;

- roulette wheel;

- sheet metal, old barrel or cylinder;

- corners of 20х20 mm;

- pens;

- hinges;

- hardware and fasteners;

- pipe.

Stands for various braziers

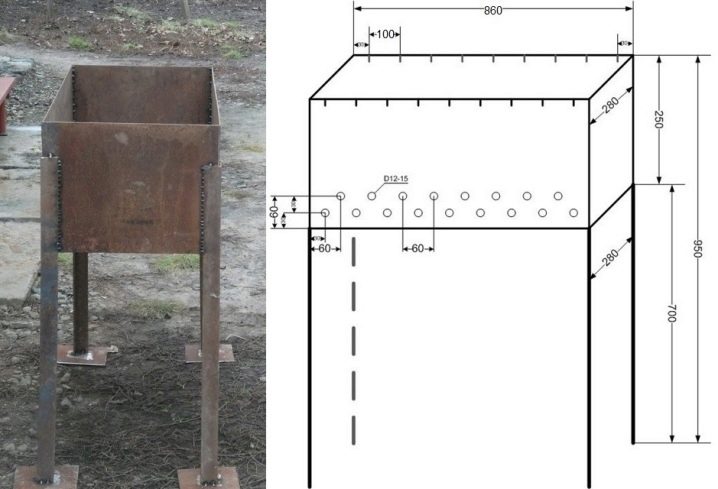

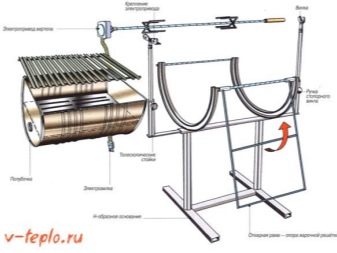

The type and shape of the supports depend on the design of the barbecue itself. In some cases, these will be strong racks, but often in stationary barbecue stands are characterized by a complicated structure and the presence of additional functionality.

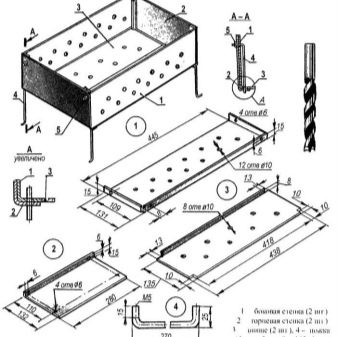

The easiest option is to use the corners of a large or medium thickness. They are simply welded to the grill itself. Often, a footboard is attached to the bottom of the corners so that the corners do not bend.

The stand for barbecue from the barrel is not too difficult to manufacture. As a brazier, they use either a whole barrel or half of it. The most difficult thing in the process of creating such a stand is to make the correct semicircles to fit the size of the barrel, and the remaining parts are easily attached to each other by welding.

Braziers are often made with minimal use of welding and with easy-to-install legs. This type of construction does not have special aesthetic properties, but it copes with its main task perfectly.

The manufacturing process has a certain degree of consistency.

- It all starts with a search for a large sheet of metal on which the entire barbecue layout will fit. After all the sizes are drawn and with the help of the grinder one whole piece is cut out, as it is long and very difficult to cut thick metal with a hacksaw.

- Next, you need to gently with the help of the grinder to make the notches in the folds (bending the sheet metal without them will be almost impossible).

- Then you need to weld the corners. After this stage a box is obtained, this is the grill itself. Small pins are welded to the bottom plane at four points. They are selected on the basis of what the legs of the structure.

- As the legs are usually used metal tubes of a round or square shape. They can easily be made to the desired length and adjusted depending on the landscape. Also these legs are removable - they can be easily replaced by others if necessary with their own hands.

Corrosion protection

For the manufacture of more complex and beautiful designs, forging skills and a high level of welding machine skills are required. And it must be remembered that the metal is subject to corrosion and rust on the surface. Otherwise all your labors will be quickly nullified. Basically, heat-resistant paints and enamels are used for such purposes, since they do not “overfly” at high temperatures. Also, these tools will save from moist air and exposure to oxygen.

Often used special primer, which can be purchased at any automotive store.

If you have free time, you can conduct a process such as bluing. After it, the metal surface is covered with a dark heat-resistant film. First you need to free the entire surface from dust and dirt, after which you should place the item in a container with a solution of caustic soda. It is necessary to keep the part in it for two hours and at a temperature of 120-140 degrees.

The choice of stands for the grill is very diverse. You can take the easiest option or approach this case with creativity. If the first time something does not work out, do not be upset: the second time you choose a stand under the grill will be muchsimpler.

How to make a grill with your own hands, see the next video.