Aluminum windows: advantages and characteristics

Aluminum windows are considered as the actual decision for arrangement of the modern dwelling. These products are in demand due to their technical characteristics, variety in design and versatility. Before buying it is recommended to study the advantages and characteristics of this material.

Special features

Aluminum windows have numerous features, due to which they are significantly different from other double-glazed windows. First of all, buyers are attracted by the decorative component of the material, reliability in use and easy care. However, the positive properties of the products do not end there.

Consider the advantages of aluminum windows in more detail.

- High strength. Products have high durability, so they can withstand the windows of any type, regardless of size and weight. The claimed strength is achieved thanks to a special aluminum alloy that combines copper with magnesium.

- Environmental friendliness. Aluminum falls into the category of natural materials. It does not release harmful substances into the environment; in the production of profiles only environmentally friendly materials are used that are not capable of harming human health and the external environment.

- Long term of use. Manufacturers provide a guarantee for their products for a period of 50-80 years. This period is not final, since aluminum structures last much longer without losing an attractive appearance and functional qualities.

- Reliability and resistance to wear. Such constructions are resistant to intensive use, are not deformed from impacts, and are resistant to abrasion. Products can be constantly washed without fear of loss of functionality or aesthetic component.

- Resistance to the environment. Aluminum is characterized by high endurance, so the material is not afraid of temperature changes, high levels of humidity, contact with acids or UV rays.

- Light weight Products are lightweight, so they do not exert a strong load on the walls.

- Variety in design. Manufacturers offer their customers a different design, among which is popular quality imitation of natural textures: wood, stone. The profile can have any color range, produced in matte or glossy design.

- Plasticity and different configurations. Due to the flexibility, aluminum blanks can take any shape. Round and oval products are widespread. Due to these qualities, the designs allow to realize any design ideas.

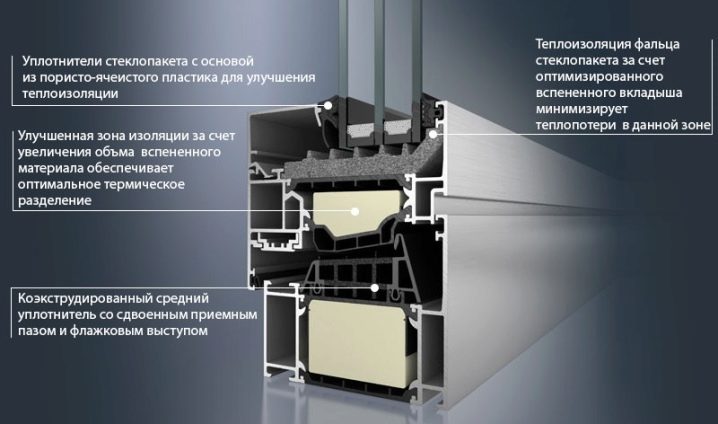

- An insulating layer has been added to the window system., which eliminates heat loss and provides high-quality sound insulation.

- Fire safety. The material does not undergo a burning process and does not contribute to the spread of the flame. Products do not emit harmful substances under the influence of high temperature, due to which aluminum fire protection structures are considered the best option for a window system.

Among the shortcomings there are several factors.

- High price. Pricing for such a product will not seem to every buyer affordable, but if you take into account the long service life, ease of maintenance and reliability, the declared price is considered to be justified.

- Aluminum is metal. This raw material is characterized by a high level of thermal conductivity, which means that the double-glazed windows quickly heat up under the influence of the sun's rays and cool down promptly in cool weather. Manufacturers are trying to fix this defect by installing a special heater.

- Aluminum profiles do not pass airtherefore, such double-glazed windows must be combined with walls made of “breathable material”.

Double-glazed windows made of aluminum material have a high level of strength, versatility, resistance to aggressive external influences. Due to the fact that not so many constructive variations of profiles are produced, it is very easy to make a choice of the necessary type of products.

Technical requirements

Technical requirements in accordance with GOST 21519-2003 and 22233-2001 impose certain requirements on the products. The window construction should consist of a frame and sash with double-glazed windows. To ensure the sealing of the joints is applied sealing rubber. The grooves themselves are sealed with special formulations. Each product has the necessary list of accessories, due to which the doors open in several ways.

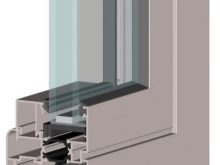

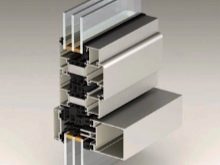

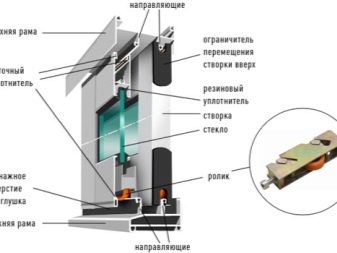

Aluminum profile does not have a pronounced drainage chamber. Therefore, the node adjoining the outer seal to the glass unit is significantly different. The glazing is fixed inside the profile with a bead. Outside the product is fixed with a thin wall of the profile of frame or folding type. The design does not have an outer air gap in the area where the glass unit is adjacent to the profile.

Installation of glass in profile is made on a rigid polymer gasket, which eliminates touching the glass with aluminum, and also does not allow the lining to be displaced during use.

Aluminum windows must ensure safe operation, withstand loads of different types withstand in accordance with building codes and requirements. Conditions of safe operation are specified in the project documents. In some cases it is allowed to use certain constructive solutions,which are confirmed by GOST 30698-2000 (use of tempered glass) and 30826-2002 (the use of laminated glass).

Kinds

Aluminum windows are available in two variations:

- cold profile;

- warm profile.

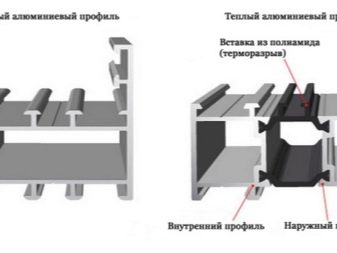

Cold profiles are systems in which there is only one chamber without auxiliary insulation. Such products can be used as dormer windows, facades, installed on the balcony, in the pantry rooms, shop windows and other non-residential rooms. The window profile has light fittings, the design itself has a minimum weight.

The windows of the warm profile have a seal, a special thermal insert, through which you can control the process of thermal efficiency. The insert is made of a special plastic - polyamide, along with fiberglass, whose thickness is 1.8-3.5 cm. The thermal conductivity of the heat-insulating insert is 150 times lower than that of aluminum. This solution allows to achieve maximum insulation in a complex with high-quality sound insulation. Such a window glass is considered the best option for a residential building.

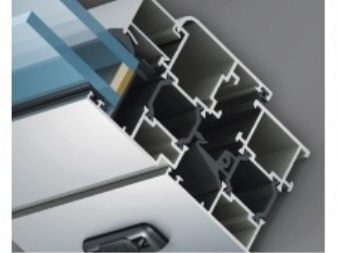

Aluminum window constructions are made from lightweight profiles. Manufacturers have developed technologies for creating structures of rather large dimensions (panoramic double-glazed windows). Inside the frame is a simple glass. But there are also warm frames that have a multi-layer structure.

Window designs may vary in their opening method. There are several options that can equip any home with high-quality functionality.

- Sliding. In such systems, the frame block has a mechanism by which the flaps move sideways and overlap each other. With this solution, you can save space on the balcony and surprise your guests with unusual interior design. The system qualitatively protects the room from precipitation. Movable structures have a significant drawback, which is the lack of security of the lower guide. Because of this, precipitations fall into it, which contribute to the freezing of windows in the winter season.

- Swivel. These are the simplest designs, the opening of the valves in which is carried out by turning. Windows are easy to maintain.On narrow balconies, such systems may not have enough space to fully open the sash. Depending on the pivot axis, the sash can rotate in a vertical or horizontal plane. Some manufacturers offer sashes that open to the outside.

- Swing-out. These are the most common systems with the help of which you can not only open, but also open up windows for ventilation.

- Folding. Folds in the design recline inside the room to provide full ventilation. Often users use similar systems instead of vents.

- Deaf This is the most simple and reliable system in which there is no opening mechanism. Such windows are often used as facade. The disadvantages include the inability to wash the product outside, if it is located on high floors. As a rule, on balconies such systems are used for side walls. If you use the construction for glazing of the loggia, you will need to remove the glass unit, clean it, and then reinstall it.

Design

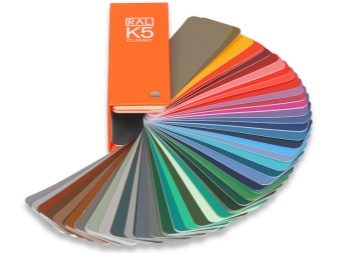

The top layer of the profile is painted directly at the factory using a powder technique.No solvents are allowed during the process, therefore the method is considered safe. The coating has a high level of durability, so it is not afraid of exposure to precipitation. The original color is preserved for many years.

Profiles can have any shades, are available in matte and glossy variations. Users are available not only color products, but also designs that mimic different natural materials. Profiles for wood, marble or granite are in demand.

And also demanded electrochemical anodizing. The technique is to create on the surface of the oxide film, which is absorbed into the product and ensures maximum durability. Before the compaction process, the film is tinted, which results in a golden, black ebb or imitation of the color of old birch.

Previously, aluminum profiles were biased because of their simple design. Now manufacturers have made a different perception of the material, offering users different design solutions.

The most popular option is the construction, trimmed with wooden plates.They look natural, so it seems from the outside that the dwelling is equipped with wooden double-glazed windows. At the same time, the products retain all the properties inherent in aluminum profiles.

Accessories and components

Window designs are equipped with fittings and components, which are an integral part of the kit. In the products there are seals that are responsible for tightness, protecting the premises from drafts and heat leakage. Demand for several types of seals.

- EPDM sealbased on natural rubber. This option is considered the most popular, and it is used by many manufacturers. It is characterized by resistance to negative environmental influences, is not afraid of temperature changes and has an affordable price.

- Rubber products. Differs at an affordable price. The material loses its elastic properties upon contact with low temperatures, therefore it is rarely used in Russia.

- Silicone seals They are considered leaders in their operational properties: they are not afraid of severe frosts, temperature changes, exposure to sunlight.However, the material has a high price tag, so it is rarely used.

- Thermoplastic elastomer rarely used, as it begins to soften when exposed to high temperatures. He is not able to boast high performance and has an overestimated cost compared to rubber analogues.

The fittings are fixed on the glass unit in europas or inside the profile itself. Aluminum double-glazed windows have an external similarity with wooden and plastic fittings, but differ in some features: because of the increased rigidity and strength of the product, less locking parts are used on it, due to which the design is simple.

Handles also belong to accessories. They can have any color solution and shapes. If we talk about functionality, there are standard parts that are responsible for opening and closing, as well as more modified versions with the option of a lock, removable handles. There are anti-burglary solutions that guarantee protection against unauthorized access.

The hinges have a traditional surface appearance, but there is an option hidden.Mosquito net - an assistant in the summer season against annoying insects.

How to install?

Installation of aluminum glass is similar to the installation of other types of windows. The only difference is in the assembly of the frame and the adjustment of the assembled product. Compliance with all stated requirements and rules ensures the reliability and uninterrupted operation of the glass unit. As an example, consider the installation of tilt-and-slide and sliding systems.

Training

Before the installation process, it will be necessary to dismantle the old structure and prepare the window opening.

To dismantle the old product will need:

- electric jigsaw;

- construction hammer;

- chisel;

- meter crowbar.

For installation you need:

- electric jigsaw or saw;

- chisel;

- crowbar;

- nails;

- foam for installation work;

- electric drill;

- perforator;

- screwdriver;

- building level;

- knife for construction;

- wooden blades;

- metal drills;

- dowel-nails.

Dismantling the old window

Dismantling the old frame is as follows:

- using a saw or jigsaw frame is sawn in several places, which will ensure easy removal of the box;

- in places the frame is cut off by a crowbar and is removed;

- then the window sill is removed, this is done with a hammer and chisel.

Preparation of a window opening consists of several stages.

- Removal of concrete fragments, old fasteners.

- If there are damages or distortions in the window opening, you need to start alignment. For this suitable cement-concrete solution. After that, it is recommended to wait a couple of days for the solution to harden.

- Before installing a new glass unit, spray the window opening with water and prime it.

To prevent damage to the window opening, all efforts should be made in the window plane, and not perpendicularly. This action allows you to easily remove fasteners.

Installation of aluminum construction

Aluminum double-glazed windows are delivered to the buyer in a disassembled form: double-glazed window and frame with the necessary fittings. Installation of the window begins with the installation of the window frame. You will need the following sequence of actions:

- it is necessary to put the frame in the window opening and align it with wedges;

- correct location is checked using the construction level;

- then you need to create mounting holes around the perimeter of the wall and frame;

- fixing of anchor plates is made with the help of dowels-nails to the wall and frame.

The formation of the mounting seam is carried out in two steps.

- It is necessary to “zapenit” the frame around the perimeter and wait a couple of hours.

- Then the wedges are removed, which were used when pulling the frame.

- The openings should be sealed with foam. When the material hardens, all the excess must be cut.

- A distance of 5 mm should be provided from the side wall to the window frame. If the distance increases, auxiliary plates will be required.

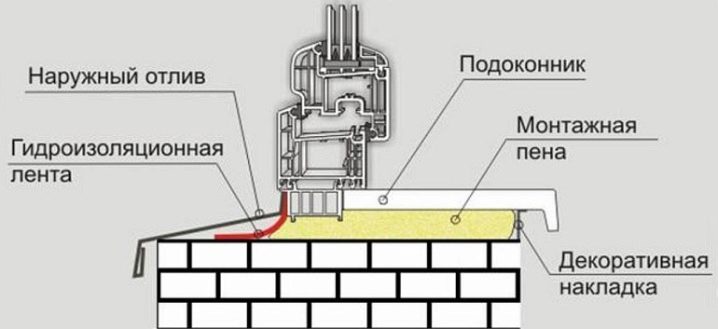

Installation of sills and window sills

This process is accompanied by the following sequence:

- a vapor-tight tape is fixed on the outer perimeter of the window frame;

- at the bottom of the frame (from the outside) you need to fix the ebb with screws;

- all gaps are filled with construction foam, the excess is cut off, the joints are covered with sealant;

- then the window sill is put under the frame and inserted into a special groove;

- with the help of the construction level should be checked the location of the window sill;

- Part must also be planted on construction foam;

- the joints between the frame and the sill are treated with sealant.

Installing the element under a slight slope will protect the structure from moisture.

Work with a double-glazed window and accessories

Installing glass and adjusting accessories is the final stage of installation of aluminum structures. During work, you need the help of another person who will support the details and help throughout the process.

Installing the glass consists of several important steps.

- It is necessary to place the liners around the perimeter of the frame. Each manufacturer encloses an instruction in which the correct order is indicated.

- The double-glazed window is mounted and fixed with the help of beadings. The hammering is carried out with a rubber hammer.

- Before you hang the sash, you need to check the accessories on the list and put the handle horizontally.

- Folds on the lower hinges.

- Then a loop-corner is inserted into the upper loops.

- The fixing is done with a pin and pushed upwards. It is necessary to act until the appearance of a characteristic click.

- The flap must be pressed against the frame so that the pin easily enters the loop and does not jam.

Manufacturers and reviews

The production of aluminum windows is a sophisticated technology that requires special equipment. In this regard, it is recommended to purchase products only from trusted manufacturers. They provide a long warranty on their goods and are ready to offer their customers innovative technologies. Consumers opt for several brands that have proven to be a reliable and trusted manufacturer.

Schuco

This is a German company, which occupies a leading position in the production of aluminum structures. It has been known since 1951, and at the moment its products are popular all over the globe. The brand produces practical designs that have an attractive design. Windows are characterized by energy efficiency at the level of a passive house. The manufacturer cooperates only with proven suppliers for the manufacture of glass and fittings.

Buyers leave positive feedback about this manufacturer. According to consumers, the designs are distinguished by high durability, long service life and attractive design.The color of the parts does not fade even after prolonged contact with the sun.

Provedal

Provedal is a Spanish concern for the production of aluminum windows. The manufacturer manufactures products with anodized coating, which is characterized by a long service life. Buyers from dozens of countries choose these products for their high quality. Consumers appreciate high-quality fittings, a variety in design and color scheme.

Reynaers

Reynaers is a Belgian trademark that attracts its customers with a wide range. The manufacturer offers its audience a variety of colors, so that the windows are able to fit into any interior.

Buyers report high quality products, reliable fittings and long service life. Separately, consumers emit wood-aluminum structures that look stylish and attract the attention of passersby. Products look like an expensive woody glass with all the qualities characteristic of aluminum.

Alutech

It is the leader of Eastern Europe in the production of aluminum structures. Production facilities are located on the territory of the Russian Federation, Ukraine and even in Belarus.The manufacturer equips its plants with modern equipment, due to which window designs are of high quality. Double-glazed windows optimally fit into the office and residential interior.

The production process uses an aluminum alloy with the addition of components that give the product sufficient strength. Users note that they choose this manufacturer due to the environmental safety of products, attractive appearance and claimed reliability, which is confirmed by years of operation.

Tips and tricks

To ensure long-term operation of the new window, you should follow the recommendations of experts. Ensuring the described rules ensures the reliability and durability of the installed products.

Professionals recommend to follow certain rules during installation.

- Before installation, you should check the new glass for flaws. Examine the product on the fact of cracks, scratches, distortions and other defects that may affect the quality of the installation and the glass itself.

- Adjustment with metal plates is not allowed.Alignment can only be done with wedges made of plastic or wood.

- The sealing process is carried out strictly in the direction from top to bottom.

- The slopes of the aluminum window is recommended to finish using drywall or plaster.

Compliance with these rules eliminates common errors and extends the service life of products. Double-glazed windows, established by the rules, are long and ensure the implementation of the tasks.

How to care?

Extend the service life of products can not only with the help of proper installation, but also due to proper care. It is very easy to care for the construction, it is enough to follow the recommendations of specialists.

- Contact of aluminum parts with other coatings must not be allowed. These include concrete, stone, wood, cement and brick surfaces. This rule prevents corrosion at high levels of humidity.

- To protect the structure you need to handle the material, which is located in the zone of contact. For processing are used insulating compositions on a bitumen basis. Wood can simply be treated with varnish.Modern manufacturers cover structures with additional processing, but as a safety net, the described method should be used.

- The key to proper care is maintaining cleanliness. To do this, systematically remove mud and dust deposits with the help of cleaning agents. You should choose products that are designed to work with this material.

- Many people use drugs as the basis for which silicone is used. The tool is applied to the surface of products using a soft cloth or sponge, and then washed with warm water. Then you need to wipe the profile with a napkin. Alternatively, you can use a cheaper method - soap solution.

- The use of abrasives and substances that contain solvents are not allowed. If on the surface of the profile there are scratches, there are compositions with aluminum resins on sale.

- In order to maintain the performance of the seals, you will need to regularly wipe them with funds with a base in the form of silicone oil. Substances qualitatively remove contamination, allow you to restore the elastic properties and protect products from moisture.

- As an alternative to the previous method, you can use a soap solution. However, after it you will need to wipe the seal dry and treat its surface with talcum powder.

- The opening mechanism needs to be given special attention. Caring for this part is simple: twice a year it is necessary to make cleaning with the help of special tools that do not contain solid particles, acids. After processing, it is recommended to lubricate the mechanism with engine lubrication with mineral components.

The described rules can significantly extend the use of aluminum windows and contribute to the preservation of an attractive appearance and functional qualities.

In the next video, you are waiting for the mounting features of aluminum windows Reynaers MasterLine 8 HI.