Heating boiler binding: types of structures and subtleties of the process

Heating boilers can be of great benefit. But only if they are installed correctly and included in the heating system, taking into account all the nuances.

Special features

If the heating apparatus can be likened to the heart of the heating system, then the boiler strapping is the vessels and peripheral organs.

When using such a system, the following actions are carried out:

- ensured normal temperature in the heating circuits;

- the air contained in the line is discharged;

- maintains a normal supply of coolant;

- uniform heating is monitored;

- the connection of various heating circuits and their adjustment to one or another temperature is supported;

- increasing the efficiency of the distribution of the resulting heat.

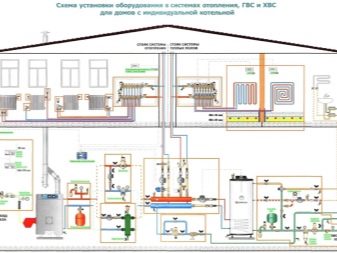

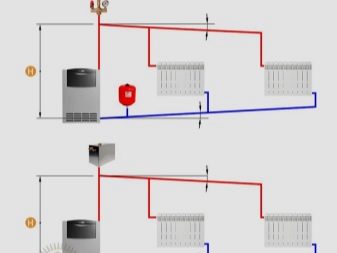

Types of heating systems

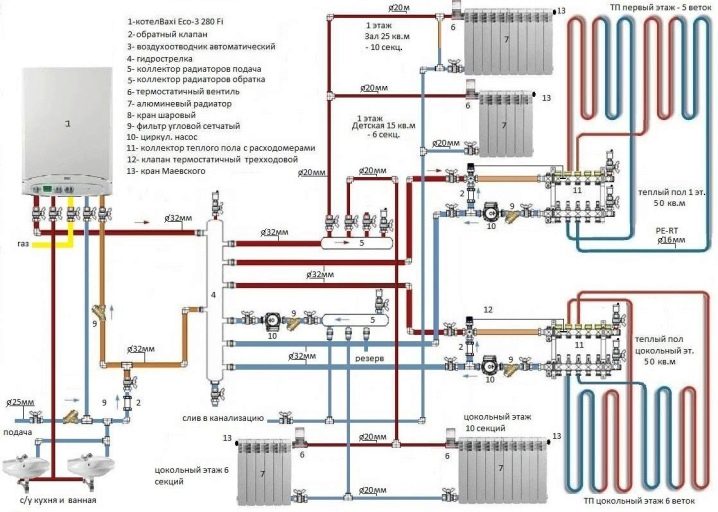

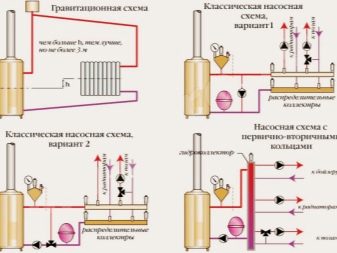

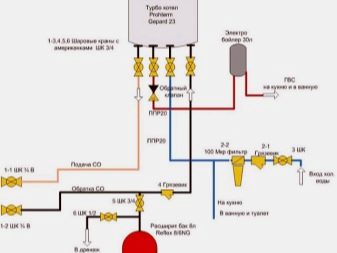

Such diverse moments cannot be equally fulfilled in all existing heating systems. Connecting a double-circuit gas boiler provides, in particular, that both circuits should not work in parallel. Therefore, in the wall-mounted version, the boilers are always tied around the same. The use of natural water circulation is unacceptable. A number of models are even equipped with a special built-in pump; if not, you will have to use an external system.

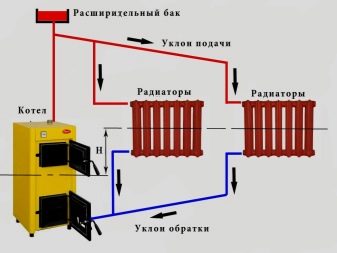

The classical approach involves the movement of the coolant on the initial pipeline up. Then water or antifreeze disperses on the risers, equipped with devices that do not allow to break the circuit into separate parts. The heating of the room is monitored by radiators, which are equipped with a choke and several jumpers. The second sector of the supply line is equipped with a water stop valve, the top of the expansion tank is supplemented with an air outlet. To return the coolant to the boiler, the lower stroke of the liner is used.

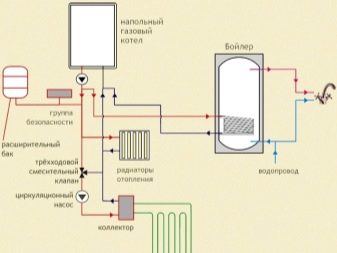

The inclusion of a floor boiler in the system is somewhat different, but the installation of a circulating pump remains a mandatory requirement. The advantage of automated systems is greater ease of operation and increased comfort. It is possible to provide a clearly defined temperature for specific rooms.

When choosing a wall plan, there are such weak points as:

- increased technical complexity of execution;

- significant cost of component parts;

- the need to constantly balance the details;

- high service charges.

A few to facilitate the work can be due to the primary secondary rings. This reduces the number of technical systems that monitor the effect of heating. But on each ring will have to install a separate pump. Only such a condition and allows you to make the flow of the coolant is really uniform for all consumers. Competently perform the work will only appeal to specialized organizations.

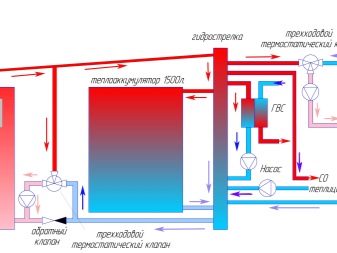

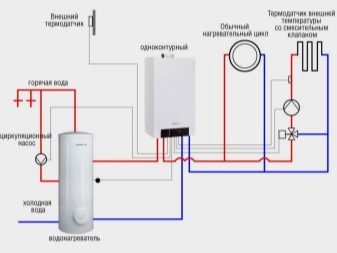

In some cases, boilers supplement the heat accumulator. The storage tank must be connected in parallel with respect to the circuit.The optimal place for a tank is the gap from the boiler to heat-consuming devices, that is, radiators or underfloor heating. In the presence of a drive, it is not necessary to connect the system with forced water circulation. However, this means that it will be necessary to install pipes of a larger diameter, because only they provide reliable liquid flow along the entire pipeline.

It is recommended when installing the pumping scheme to install several pumps at once. One is located from the boiler to the battery, and the other on the distribution line after the TA or on the line where the coolant flows out. This technique allows to reduce the accumulation of condensate in the boiler. In addition, heat exchange between hot water in the heating device and home batteries is improved.

Theoretically, the natural circulation can provide the same efficiency, but in practice it will require precise calculations and rigorous execution.

Moreover, the addition of a heat accumulator only aggravates the matter, since the energy stored in it, if it is not directed where it is needed, can even lower the heating effect.And this is not only discomfort, but also additional expenses for fuel or electricity. Therefore, no matter how much you want to get rid of the choice of a circulating pump, it is not recommended to do so. Not even all professionals are able to prepare a heating system with the necessary characteristics.

Must be mounted in any type of strapping security group, which includes the following elements:

- a valve that promptly discharges excessive pressure;

- pressure gauge that allows you to control pressure;

- an air outlet relieving contours from accumulating traffic jams.

Important: safety devices must be mounted very first, and no exceptions to this rule are allowed.

Even just one tap or valve will cause a lot of problems.

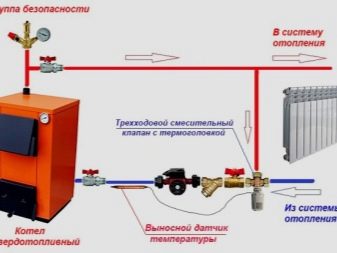

Further, in the circuit with a heat accumulator, a tee is usually mounted, which creates a small boiler circle. It is designed to solve the most important task - raising the temperature of the water coming into the boiler from the return pipes. The valve is directly connected to the heat sensor supplied prior to entering the return circuit into the boiler.If the returning coolant is cold, the valve opens at 100%, water flows only along the shortest path. It does not enter the storage tank at all. But it costs the heat sensor to send a signal about the heating of the return circuit to +60 degrees, as the valve automatically closes. This does not happen too quickly to eliminate jerks in the functioning of the system.

As the water warms up, its passage into the battery increases, and more goes to the batteries. Therefore, the passage of fluid along the shortened route is reduced. The thermostat located inside the valve finally closes the short circuit as soon as the chilled water flow becomes acceptable in temperature. If there was no such protection, a large amount of return water was cold, because the boiler physically does not have time to warm everything up. Prolonged contact of the input of the heat generator with a cold stream provokes the formation of condensate, which adversely affects the state of the metal case. It gradually erodes, weakens and is able to fail only by the end of the first heating period.

From the mixing valve with three strokes to the point of reverse injection is a few more devices. The circulation pump on the shortened heating circle must be autonomous from the main pump unit. Even closer to the boiler itself have the so-called expanzomat. In literal translation, this "mysterious" word means only an expanding tank. For your information: the start of the expansion chamber is carried out strictly by means of taps or valves, this is the only way to ensure a painless replacement, maintenance or repair if necessary.

Further, when the branching unit of the short segment is passed, the supply pipe sticks to the top of the battery. A pipe is led out of the tank leading to the return circle, which is connected to the valve with three strokes. This allows you to close the contour line from the boiler to the drive. Following the tank at the inlet to the radiator flow, another valve with three strokes is mounted.

To connect the pipe connecting other parts with the return channel, a sanitary tee is used.

But these solutions are acceptable in unchanged form only for feeding with heat from the radiator system. The situation is different when working with warm floors.When installing non-condensing-type boilers, it will be necessary to mount the assembly from pumps and mixers. There is no other way to balance the temperature conditions of the boiler and the heated floor. But the special heating arrow will not be needed, you can mount pipes with a cross section of 25 mm.

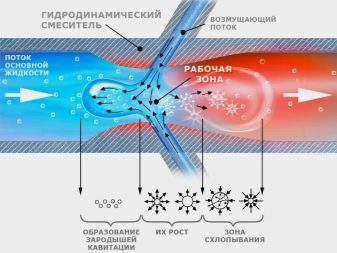

In some cases, it is necessary to use the hydraulic hands. The similar device is by default put in the majority of modern heating systems. But even if an old boiler is installed, which is tied without using a hydraulic needle, the situation is fixable. For self-manufacturing arrows you can use just a normal piece of heating pipe. And if it is not, then the accompanying documents reflect how it should be and how the installation is made.

For your information: the most powerful pumps installed for pushing water through pipes are almost always equipped with a hydraulic separator.

Quite popular boilers of long burning on solid fuel again differ from all options already described. It is crucial to choose the right place where the heater will be placed.

When designing its location and contour of the strapping should be guided by such fundamental considerations as:

- comfort of use;

- Free access;

- security;

- compliance with basic technological standards.

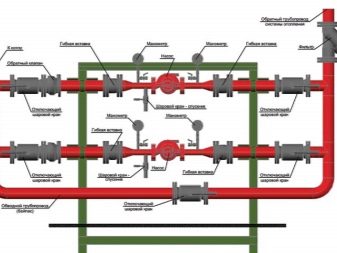

Usually long-burning boilers are connected on both sides. To connect a return loop to them, often use tees of the required binding diameter. It is useful to use the same nut, which is usually used for sgonov. Such fasteners minimize the risk of leakage at the junction of the tee and heater. To tees screw transitions with an outer diameter of 2 inches and with an inner thread of 1 inch (this is called futorka).

To be able to cut off the wings separately, use ball valves. Thanks to them, the heating system becomes flexibly adjustable. You can even repair or change parts in turn, without stopping the heating as a whole. Moreover, it becomes possible to use only one pump for circulation if the second one suddenly breaks. Additional expansion tank must be closed execution, connect it to the reverse course.

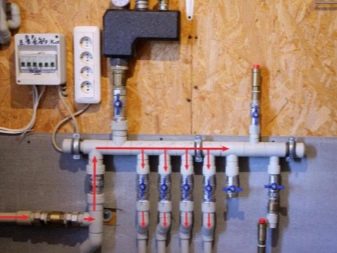

To connect the flow from the boiler to the pumping complex, they often use handicraft manifolds. But this does not mean that you can make them thoughtlessly. The most convenient collectors - with disassembled contacts "American" sample. It is very easy to repair, change or customize them.

It is very useful to supplement any trim for any boiler with mud filters, which will positively affect the equipment's service life.

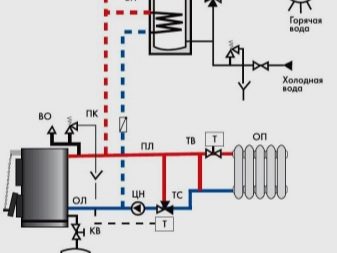

Often boilers are put in order to feed the DHW circuit. If a two-circuit apparatus for natural gas is chosen for this purpose, 5 fittings cut outside are removed from it.

They are designed to provide the following actions:

- the passage of hot water in the heating line;

- direction of the heated coolant towards consumers;

- a bunch of boiler with a gas line;

- cold flow entry;

- water return (this is the procedure recognized by engineers as the optimal solution).

But it also happens that you need to tie the automatic single-circuit boiler. Its peculiarity is that it is necessary to adjust the control of heating through the adjustment of the burner flame.But the system will be simpler, it is almost always possible to dispense with wiring in accordance with the instructions of the passport to the boiler. Usually, only two nozzles are used: water is poured one at a time, and leaves the heater through the other. Only in some versions there is still a connection to the boilers of indirect heating.

A three-way valve helps to link these mechanisms. It is necessarily installed and configured in such a way that the heating of the fluid in the drive has the highest priority for the system. As soon as the meter detects that the water has cooled there, it gives a command to redirect the heated stream. During the summer months, the boiler stops completely, thus avoiding a quick break from contact with high-rigidity tap water. Installation with two pumps is allowed when the heating and plumbing lines are connected in parallel (the latter is via a boiler).

Items

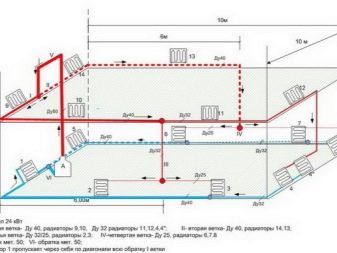

The specific filling to a great extent depends not only on the type of the boiler and additional equipment, not only on the output of the fluid in one or in two circuits. For example, the strapping scheme for a two-story house has its own nuances.

The key element - the boiler itself - is calculated primarily taking into account such parameters as:

- total area and volume of heated rooms;

- weather stereotype and wind conditions;

- the presence of windows, their size and tightness, the quality of thermal protection;

- type of roof, the degree of its warming, the presence or absence of an attic;

- thermal insulation of walls, floors and ceilings;

- main construction material.

If an antifreeze fluid is chosen as the coolant, you will have to install the most powerful pumps and increase the cross-section of pipelines. Otherwise, the flow of heat into the house and the rate of warming will not satisfy the residents. Since there is ethylene glycol in antifreeze, you have to be more careful when using parts made of polypropylene and rubber. Moreover, this reagent is also harmful to cast iron and non-ferrous metals. Therefore, in most cases it is necessary to install stainless steel pipes and radiators.

The batteries themselves can have a varied level of heat release. It depends on their size and the material used. To increase the length or shorten it, respectively, add or remove sections.Mayevsky's faucet and a thermostatic expansion valve help to achieve a uniform heat supply to the entire surface of the radiator. Since maintenance may be required during use, it is useful to install a shut-off valve.

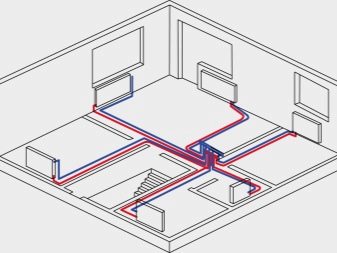

Heating batteries are installed strictly around the perimeter of the heated room - below the windowsills and near the entrance door. Optimum results are achieved when using steel pipes without seams or pipes made of polypropylene. The lower the internal hydraulic resistance, the more efficient the system will be. Any two-story houses must be heated with the use of expansion tanks. Since the long intricate contours inevitably have a lot of pressure inside, therefore, only the periodic discharge of the expanding liquid into the tank keeps the system stable. The situation is excluded when, due to a pressure jerk, water rapidly boils and damages the pipes themselves and their connections.

Closed heating systems involve the installation of a tank at the nozzle of the return circuit to the suction nozzle of the pump. The tank itself is raised to a minimum height of 1 m.The diameters of the components are always selected individually.

In addition to the products listed, the following can be mounted:

- filters for water and gas;

- collectors;

- check valves;

- safety valves;

- air valves and a number of other components.

Installation

Even the simplest strapping, which is done by hand, implies a competent choice of pipes. So simple and loved by many people products, like pipes made of polypropylene also need to use properly. The ease of operation should not be misleading, although you only need to use a soldering iron. PN25 pipes, which are reinforced from the inside with aluminum foil, are allowed.

Such designs perfectly manifest themselves in heating systems operating under pressure up to 2.5 MPa with extreme heating of +95 degrees.

To connect to the warm floor, you can tie the boiler pipes category PN10. Their walls are very thin and designed for pumping water heated to +45 degrees under a pressure of 1000 kPa. Polymer pipelines can be used in both open and hidden gasket layouts, but thermal expansion must be taken into account. A bunch of fittings with pipes is made either by threading,either using cold (hot) welding. Threading simplifies things, but the cost of such a decision immediately grows.

Before welding, the foil must be cleaned, otherwise the strength of the connection can be forgotten. Glass fiber, when used for reinforcement, does not require such treatment. Cold welding with the use of specialized glue is almost out of circulation now, because it does not guarantee a reliable joint. If the system has two small heating boilers or a greater number of them, piping is possible in parallel oriented passages. As practice shows, it can be more economical than using a single boiler of the same amount of power.

In order for the water not to move through the temporarily disconnected circuits, it is very important to take care of blocking them with separating valves and other shut-off valves. In some cases, the equipment is mounted on a base pillow (clay, 0.1 m high), on top of which sheet metal or asbestos is placed. The main requirement is to install the boiler at a lower level than installing batteries. Copper pipes should be resorted to only ifwhen it is planned to heat the house with very high temperatures and pressures. In all other cases, there is no point in these expensive components.

Tips

When equipping a heating system in a private house with natural circulation, pipes of at least 3.2 cm in internal diameter should be installed. It is recommended to plan the layout, including in the apartment, in such a way that there are fewer turns and other difficult areas. The straight contours of the pipes laid out horizontally should decrease by about 0.5 cm or more by 1 m of the coolant flow. When using a collector, a separate cabinet is provided for it. Usually a pipe with a section of 1.25 inches is placed between the boiler and the pipeline, and between the collector and other devices - with a section of 1 inch.

To learn how to tie the heating boiler, see the following video.