Parquet boards Barlinek

Parquet board is one of the types of natural flooring, which is a structure made of glued wooden planks, topped with varnish or impregnated with oil. The floorboard has a beautiful appearance and repeats the structure of the wood from which it is made, it has a long service life and a wide variety of models. That is why the demand for such flooring is constantly growing.

One of the well-known manufacturers of similar products is the company Barlinek. Products of this brand have recently received wide distribution in European countries and in Russia

About company

Barlinek is located in Poland. It began its activities in the 40s. XX century as a supplier of lumber. Gradually developing, the company began to expand its activities, including in it the production of floor coverings from wood.The company mastered the production of parquet boards in the 1990s, and thanks to the rapidly growing popularity of this natural and not very expensive material, the concern managed to increase production capacity.

Currently, Barlinek supplies its products to 50 countries of the world and is one of the leading companies in the production of finishing materials for the floor.

In the 2000s, the technical re-equipment of Barlinek plants took place, during which all technological equipment was replaced with more modern and high-tech ones. Today the floorboard under the brand Barlinek is made on the German equipment Burkle. Currently, due to high quality, attractive design and reasonable prices, the popularity of this brand continues to grow, attracting an increasing number of customers.

Advantages and disadvantages

Barlinek floorboard has a number of undoubted advantages:

- Durability and durability of flooring. This indicator is achieved by using a three-layer symmetrical arrangement of wooden slats in a crosswise manner. In this case, the two lower layers are made of coniferous wood, and the top one is made of more valuable wood.The thickness of each layer is 4 mm. Reliability and wear resistance of the coating is also provided by the use of the technology of fixing the paintwork by ultraviolet rays in the production;

- Attractive design and a wide range of products with a variety of textures and shades. These characteristics of the flooring are provided by using as the top layer of various types of valuable tree species, including both European and exotic (only about twenty species). The aesthetic appeal of the flooring is also enhanced by the use of special processing methods: lacquer finish, brushing, lamination;

- High resistance to moisture. In the production of flooring, the company applies its own technology of fastening lamellas, the details of construction that are in contact with each other give the slats increased stability;

- Easy installation. Concern Barlinek has patented own lock joints, thanks to which the installation process of the board is accelerated several times. To cover the floor area of about 20 square meters.m floorboard of the manufacturer to a person not experienced in the repair business, it will take no more than an hour. At the same time immediately after installation the floor is ready for operation. If you need to move to another place, the floor from Bartinek can be quickly disassembled and taken with you to mount it in a new place;

For patented locking connections, see the following video.

- The use of a special type of oil-based topcoat allows you to emphasize the structure of the natural wood pattern and protect the floor from dust, dirt and moisture, while giving it a luxurious look;

- The possibility of laying parquet on "warm" floors, both electric and water;

- The possibility of the restoration of the board with the use of special tools for its processing;

- The warranty on Barlinek coverage is 30 years.

One of the drawbacks of the floorboard is that periodically you need to take care of the flooring, sand it and cover it with oil or varnish, which may require the help of a specialist. In addition, the current care of the floorboard is not possible without special detergents.

Range

Barlinek floorboard is presented in several series: “Senses”, “Tastes of Life”, “Pure Vintage”, “Pure Line”, “Décor Line”, “Life Line”.

The “Senses” series features models of oak with large elements.This board is more suitable for creating interiors in a classic style. The “Tastes of life” series is more modern. This flooring is ideal for avant-garde interiors. Designers of the Vintage line series tried to represent the aesthetics of wood as accurately as possible. Such models are suitable for any style.

Each series includes models with different finishes.

Those that are treated with oil have increased strength and antistatic properties. A parquet board, lacquered, more resistant to abrasion. Lacquer coating at the same time can be glossy, semi-gloss and matte.

You can also choose a floorboard with a different texture: someone likes the kind of wood without knots, and someone likes the knotty surface.

Barlinek floorboard is single-sided or three-lane. Single-sided models have a finishing layer consisting of a single piece of wood. Three-lane - with the top layer of three dies glued together.

As a result, the overall pattern of the floor when laying a single plank board looks larger, three-strip - respectively, smaller. Which option to choose - each consumer will decide independently depending on the particularitiesinterior space.

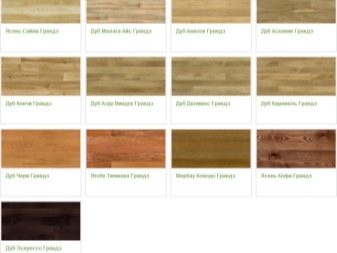

Among the company's products currently entering the Russian market are floor coverings with a top layer of the following types of wood: oak, ash, hoist, and sapella.

Barlinek floorboards can be artificially aged using brushed technology. In such models, the tree structure is seen especially clearly. A floor with such a board is ideal for rooms in ethno-historical and vintage style

Dimensions

Barlinek flooring has its own dimensions, different from the dimensions of similar flooring from other manufacturers. It has a length of 2.2 m and a width of 0, 207 m, thickness is 0, 014 m. Such parameters are most convenient for transporting a floor covering packed in boxes.

Materials

The flooring consists of three layers of high quality wood and 7 layers of varnish. The bottom layer of the floorboard is made of inexpensive and loose wood (usually softwood). It has a thickness of 3.5 mm. The next layer, laid perpendicular to the first one, is 7 mm thick and is also made of softwood.

For the finishing layer of the board, the more valuable wood of deciduous trees growing in Europe, Africa and South America is used with a high density, and therefore durability. This is precisely one of the main secrets of such a great popularity of Barlinek floorboard. Most often for the floorboard used oak, ash, maple, walnut, alder, birch, acacia, hornbeam, sapella.

Recently, models with a waist finish have become especially popular, the peculiarity of which is an interesting expressive texture, giving the floor surface a light matte shine. The type of wood used for the upper surface determines the density of the floorboard. For oak and ash flooring, the density is 700 kg / cu. m. On the front layer of the board is applied a special primer, which is compacted under ultraviolet rays.

The next stage in the manufacture of wood flooring - applying acrylic putty, which is also dried under ultraviolet rays. Next, apply three layers of primer varnish and also dried. The last stage of processing is applying two layers of acrylic impregnation.

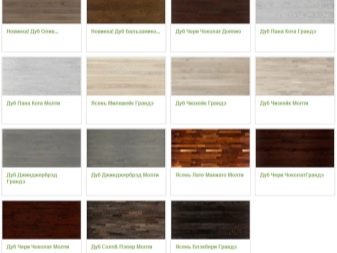

Colors

The color palette of floor coverings is conditionally divided according to tones into light coatings, dark and medium. In the light color palette you can find semi-white, grayish-white, cream, beige, gray-beige, beige-greenish, beige-brownish (coffee with milk), light brown (like sepia) shades. Medium lightness colors are represented by shades of untreated wood. In the dark palette are whitish-brown, dark gray, chocolate, natural brown, yellow-brown, red-brown, gray-brown shades.

Care rules

Barlinek offers a range of products to care for the floorboard.

For natural oil coatings

Especially for an oil-covered parquet board, a “Wash Care” cleaner has been developed, which should be used to treat floors one to seven times a week, depending on the degree of load on the parquet flooring, that is, in living rooms it is used once a week, in office premises - every 3-5 days, and, for example, in schools, shops, cafes - every 1-3 days.

Immediately after laying the floorboard, it is recommended to apply Wax Care Plus.The application should be repeated every 3-12 months (cafes, schools, shops - after 3 months, office premises - after 3-6, residential premises - after 12).

For deep cleaning of oil-coated floors, the manufacturer recommends the “Magic Cleaner” product, which copes with greasy and dirty stains, removes the previously applied caring agent.

For information on how to care for an oiled parquet board, see the next video.

For varnished coatings

Daily care for such a board should be carried out using the “Protector Concentrate”. After laying the board with a lacquered brushed coating, a special compound “Protector Gloss” should be applied to it, which forms a kind of water-repellent film on the floor surface. The floor treated in this way is easier to clean and less prone to contamination. “Gloss Tread” is spread on the floor with a mop.

For cleaning the lacquered floor, the “Protector Gloss” and “Protector Kit” tools are used. The “Protector Kit” means must be diluted with water and applied with a spray gun on the floorboard, wait 5 minutes and clean the floor with a soft brush.Then it is necessary to remove dirt and detergent residues with a damp cloth. Next mop put on the floor "Protector Gloss". The same actions are easily carried out by the polishing machine.

How to care for varnished coatings, see the next video.

For oil UV coatings

Daily cleaning of such a floor is carried out with the help of a special soap. Cleaning is carried out every 1-7 days (in living rooms - after 5-7 days, in offices - after 3-5 days, in places with high traffic - every 1-3 days).

For more thorough cleaning is an intensive wash. It is used every two years in residential premises, every one and a half years - in offices, once a year - in places with high traffic. Immediately after installing the board with UV varnish, it is coated with oil for floor maintenance. Coverage is updated every year and a half - in residential premises, every year - in office and every six months in places with high traffic of people.

How to care for a board with UV varnish, see the next video.

Reviews

Barlinec floorboard buyers mark a decent quality level for this product. In addition, according to the manufacturer's description, for each series of coverage, you can determine in advance for yourself the options for the board models, which saves time.Many also note the resistance of this coating when laying it on the “warm” floor system, as well as the ease of installation of this floor covering.

The shortcomings in the floorboard itself (chips, unevenness) do not say anything in the reviews, consumers only note the difficulty of further maintenance of the coating, expressed in additional costs for the purchase of detergents and the need for regular updates of the lacquer and oil coating.