Features of plank floorboard

Parquet board - flooring, which is chosen to give the room a noble and elegant look. It combines high quality, wear resistance, the structure of natural wood and an acceptable cost. Many well-known companies in the market of building materials are engaged in the production of parquet: Polish BarlineK, swedish TarkettFinnish Karelia, Coswick, Wood Bee other.

Varieties and many colors of the floorboard give the opportunity to choose exactly what your interior needs.

Production technology

Parquet board is made of several planks of wood, which are glued with an adhesive composition. There are three layers located perpendicular to each other:

- lower. It is made from inexpensive wood or moisture-resistant plywood.Preference is given to these materials due to the fact that they have a more solid and stable structure and geometry;

- the middle one is coniferous woods;

- front or top. This layer is made from planks of expensive types of wood, such as oak or ash.

All layers are pressed together and covered with several layers of protective compounds, for example, varnish or oil. Some manufacturers use impregnation, saving boards from excessive moisture or spilled liquids.

Species

The floorboard in the collections of manufacturers is presented in three forms: one-, two- and three-way. Their difference lies in the method of manufacturing the facial layer:

- three-strip board. This is a budget version of the parquet. The most common and traditional choice. The front side is made in the form of 3 rows of parallel planks of the tree. Have them as a continuous cloth, and with rows shifted in length. Due to this, the final appearance of the coating looks interesting and unusual. This option is used to create a classic herringbone or braided pattern on the floor;

- two-lane board. The top side is made of two tree segments,that are perfectly matched to each other. This variant imitates parquet from natural wood best of all;

- single board The most expensive version of the parquet. This is due to the fact that a monolithic lamel of wood veneer is used for the top layer. The manufacturing process here is more labor-intensive and expensive, and this is the reason for the cost of the final product. The final flooring will look like a floor made of natural solid wood. By choosing this type of parquet, it is possible to visually expand a small room and emphasize the size of a large room. It differs from others in the method of connection - here it is a thorn-groove, not a lock. The thickness of such a board is usually 14-15 mm;

- currently available from some manufacturers multiband floorboard. The front layer of such a board is made of planks of the tree, which are selected manually. Due to this, an unusual effect is achieved. The focus is on color, not tree structure. Such a parquet will look perfect in rooms with a modest and minimalist design, and will also become a bright accent that attracts the eye.

Advantages of single sideband coverage

Plank flooring has several advantages over other types of flooring. The most basic is a solid piece of wood from above. It is aesthetically more attractive and pleasing to the eye. In addition, this feature allows you to increase the wear resistance of the coating and its service life. Laying is not complicated by the selection of boards to each other, so as not to disturb the overall pattern of the canvas. It is easily combined with other floor coverings.

How to choose?

There are several factors to consider when choosing a single plank board. As a rule, parquet distinguish:

- by sight saw cut trunk. There are three types of cutting: radial, tangential and rustic. The first is the most expensive. The longitudinal fibers of the wood and the smooth pattern create the perfect flooring. The second is done tangentially with annual rings. Drawing and coloring will be unique and unique for each plate. The third type is performed at any angle, which explains the heterogeneity of the color and structure of each saw;

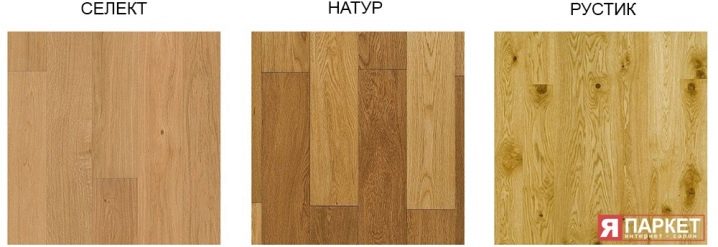

- by type of selection. Breeding is the choice of wood for cutting, drawing, color and integrity of wood. Types of selection:

- selekt - the most high-quality raw materials, radical cutting, smooth, uniform surface, clear structure and color;

- natures - cut tangential or vertical. Defects in the form of knots are acceptable, the pattern is varied with bright transitions;

- Rustic - selection only for quality and color, small defects are allowed that give the uniqueness of the board, the drawing is “alive” and unusual;

- by type of wood. The flooring market provides parquet from classical wood species - oak, ash, beech, walnut and more rare - wenge, merbau or kempas. Oak flooring - the most beautiful, versatile and durable option. American single-walled walnut is not inferior to oak in popularity, and its pleasant brown shades will give the interior a classic look. African wenge is a bright structure and color, and the Indonesian merbau will give a semi-nobility due to golden veins;

- in wood processing. The main type of treatment is heat treatment. The wood is heated to a temperature of around 200 degrees Celsius. This increases the stability of the board and protects it from unwanted changes under the influence of external factors.In addition, this tree is better painted and retains color.

It happens and brushed board. Brushing is used to give relief to the product. Special brushes treat the entire surface outside, removing the soft fibers of the tree;

- according to the method of coating. There are two options: oil or varnish. The oil consists of a mixture of resins and waxes, gives the floorboard a more natural look and emphasizes the relief and structure of the tree. Lacquer increases the durability of wood, depending on the expected load increases the number of coating layers (from 6 to 9). The first option is more difficult to care, it requires a rare use of reducing compositions. In addition, the varnish is less environmentally friendly;

- in general appearance. Pay attention to chamfer products. It can be standard or rounded. It is also worth examining the board for the presence of chips, cracks and places of bulge, check the integrity of the joint system and layers of wood.

How to choose the right floorboard, see the next video.