Engineering and flooring: what's the difference?

Arranging the floor is an important task that can be solved with the help of various materials. Particularly popular today are products made from natural products, which are distinguished by safety and durability. Increasingly, buyers prefer the floorboard, which fits perfectly into any modern style of the room.

Design features

Modern manufacturers produce many beautiful and high-quality materials for finishing the floor. One of the most popular and common are coatings in the form of parquet and engineering boards.

The use of such finishing materials is very much in demand today, since both versions are distinguished by high quality and environmental friendliness. To understand what these substances are, you should be familiar with their structural features. We begin our acquaintance with the analysis of the floorboard.

A similar name appeared in the 40s of the last century. Today, parquet products are one of the most sought after on the market. This material consists of several main layers:

- Stabilizing layer. It is located below and is the base of the board. Its main purpose is to create a linear structure of the product. Technically, these are boards of small thickness and width, which are perpendicular to all other layers.

Such a structure allows minimizing the load and reliably relieve the voltage that is present between each of the levels.

- Bearing layer. For its manufacture using technical wood, which has a different direction of the fibers. The thickness of this layer can vary in the range from 6 to 9 mm.

It should be noted that the material perfectly resists both longitudinal and bending loads.

- Decorative layer. For its production using valuable wood species.The most popular are oak, ash, maple and cherry. The thickness of this layer does not exceed 6 mm.

To give the cut a unique design, it can additionally grind, brush or smoke;

- Protective layer. It is a paint or lacquer, which does not allow decorative wood to quickly collapse under the influence of external factors.

For such purposes, various substances are used, among which polyurethane, alkyd varnish, several types of oils (linseed or saffrole) and wax can be distinguished.

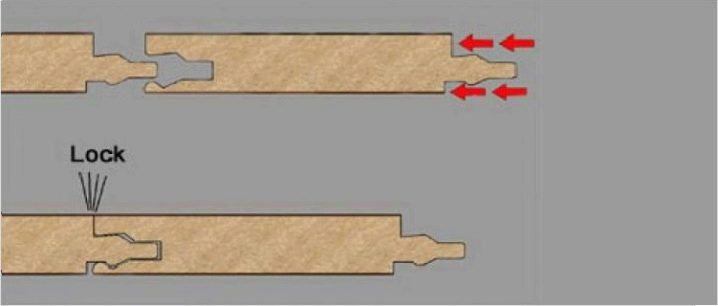

At the ends of the carrier board with a router, special locks in the form of spikes and grooves are cut out. The shape of these parts can be different, which allows them to be divided into 2 types:

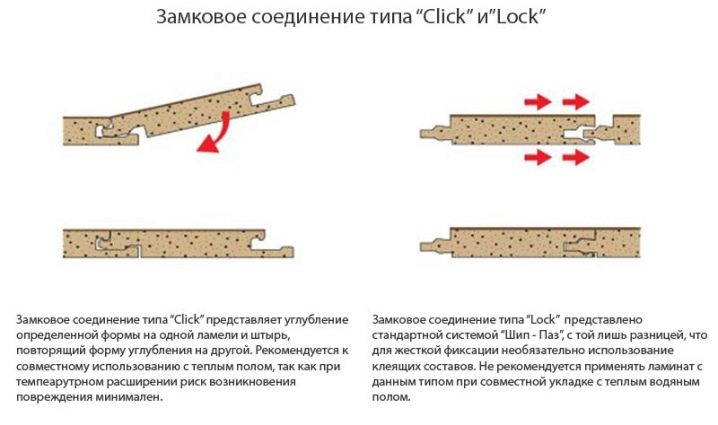

- Click. The locks of this variety are complex in form. With their help, you can get a very high quality and durable connection boards. Installation of such structures requires a kind of spike insertion into the groove at an angle of 20-40 degrees. When joining, connections with practically imperceptible gaps are obtained.

Breaking such a connection is very difficult, but it is important that the floor is completely flat.

- Lock. These locks are the simplest, although they also consist of a spike and a groove.But for fixing the boards among themselves, you just need to combine them together and drive them into each other with a light blow.

The strength of such compounds is somewhat lower than that of the previous species, so these locks lose their popularity and are used less and less.

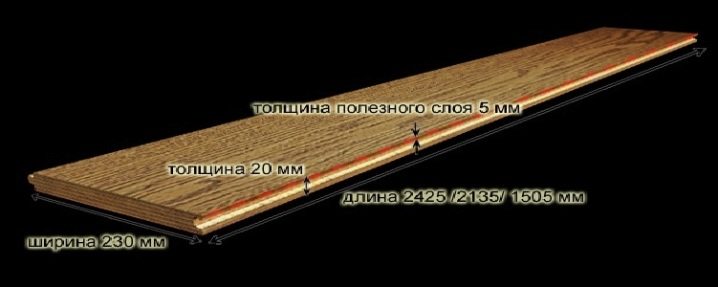

Engineering board is a floor covering, which includes plywood and veneer of valuable wood species. Sometimes these products are called double-layer parquet.

This material consists of several layers:

- Carrying board. Plywood consisting of 6-8 layers is used as this element. For the production of engineering boards use only products of higher grades, with a thickness of up to 14 mm. A thorn-groove junction is present on this layer. The main lock here is the Lock-system, which simplifies the connection of paintings.

Please note that the laying of the engineering board is performed only on special adhesives.

- Decorative layer. This element consists of decorative veneer, the thickness of which can reach 6.5 mm.

The peculiarity of this layer is that it is made only of hard wood (oak or ash).For decoration also use various techniques and approaches (for example, staining).

- Protective layer. From above the board is covered with various types of varnish, oil or wax. This allows you to limit the absorption of moisture by veneer, as well as minimize physical damage to the surface.

The main differences

Engineered flooring and parquet are very similar materials, but there is a cardinal difference between them. There are several differences between engineering and floorboard:

- Dimensions. The thickness of the engineering board is somewhat larger than parquet, which makes it possible to better perceive the load.

As for the width, the parquet production has a limited value of this parameter. Due to the technology of production of parquet.

- The possibility of restoration. Technically, both of these substances are amenable to secondary grinding. But an engineering board can be restored up to 7 times, whereas for a parquet counterpart this value is not more than 4;

- A feature of the engineering board is that it better tolerates moisturetherefore it can be laid in bathrooms. But here it is important that the top layer is made of wood that can withstand high humidity.Parquet is different in that it suffers even more from temperature drops, therefore it should be installed only in relatively warm and dry rooms;

- The floorboard does not withstand high temperaturestherefore, it is not recommended to use it together with heated floors, but its analogue made of plywood is perfect for such conditions;

- The period of operation of the floorboard is halfthan its counterpart. Engineering structures can be used for up to 40 years, while parquet will last only about 20 years;

- The design of the floorboard and engineering board is different in many styles.. Compare these features is quite difficult. Here you can find the texture of wood of valuable and rare species (American walnut or mahogany). But it should be noted that the floorboard consists of several strips of different thickness,

- Engineering elements are made single-sided (solid sheet of wood);

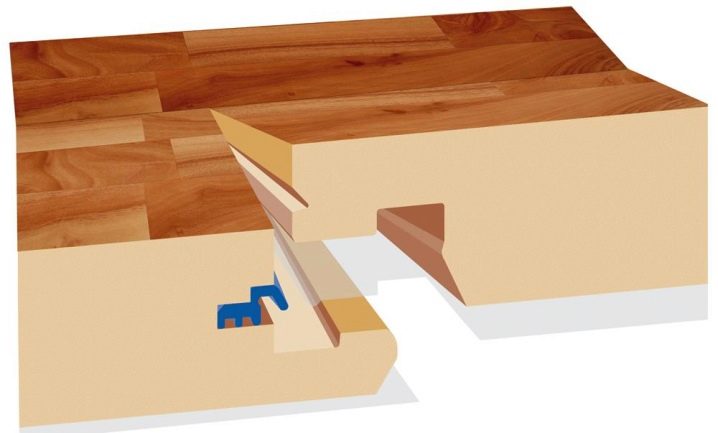

- Installation of floorboard can only run with a floating approach. If, however, different adhesive compositions are used, they can be absorbed into the wood, leading to the separation of the material structure.

- The engineering board is more universal.as its laying can be carried out either on glue or simply on a flat surface;

- Installation of engineering boards can be done without technical clearance. between the surface and the wall. For the parquet counterpart, it is mandatory, as it allows the tree to expand qualitatively with changes in temperature and humidity;

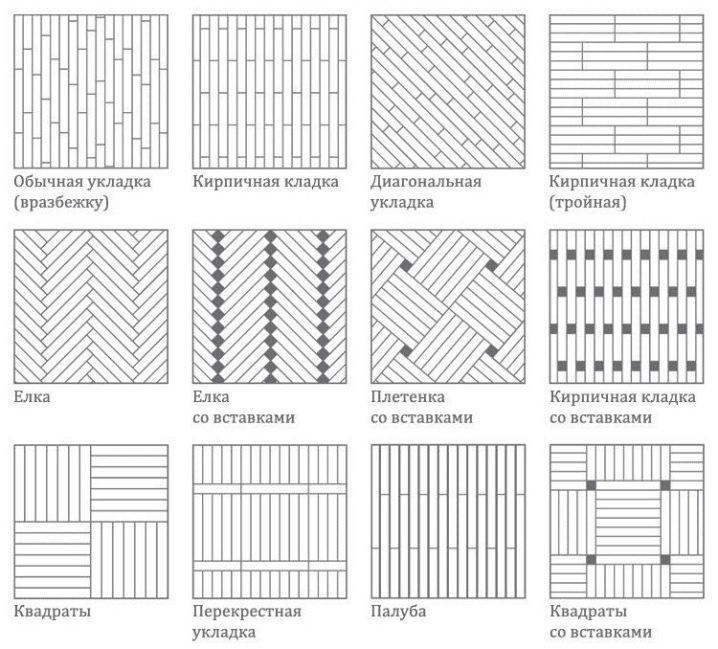

- The parquet board can be placed at installation only in a breakout. Products of engineering type creeps in almost any way. Today, herringbone and deck are particularly popular;

- Engineering board retains heat much betterthan its counterpart, so this material does not need additional insulation layer, like parquet varieties.

What is similar?

Flooring of this type have unique characteristics that allow to solve various problems very high quality.

Although the structure of the boards is different, they still have several similarities:

- Engineering and floorboard consist of several layers. This gives them the properties of this product.

If used improperly, both substances can stratify, losing their structure.

- Single type lock connection.The type of connecting groove depends only on the specific board manufacturer. This allows you to select the material according to your preferences and requirements. Previously, engineering boards did not have locks, so their installation was carried out only with glue;

- Versatile styling. Both boards can be mounted in both floating and adhesive ways;

- Materials do not emit any harmful substances into the environment. This is due to the fact that they are bound with the help of only environmentally friendly compounds. Therefore, such products can be laid even in children's rooms, without fear for the health of the child;

- The top layer does not fade without losing its decorative properties, but the wood can heat up, keeping the heat in itself for a certain time.

Therefore, boards of this type can not be covered with carpets to prevent walking on the cold floor.

- The possibility of restoration. Engineering and floorboard can be polished with special mechanisms.

This allows you to restore the decorative properties of the upper layer, making the product almost new.

What is better to choose?

The floor coverings are very similar, as they consist of natural wood,which gives them a unique design.

When buying this product, several recommendations should be considered:

- If you want to get a strong and durable coating, give preference to an engineering board. It perfectly perceives the load and is not so demanding on the external conditions of operation;

- when installation is carried out independently, then only the floorboard will be the optimal solution. It can be laid relatively quickly even without some experience. To form a high-quality floor from an engineering board, it is necessary to hire experts that will lead to additional financial expenses;

- floor design also depends on the material. The engineering board has more unique patterns. But, to get them, you should properly lay the material on the floor.

Parquet materials are classics that imitate wood and give the room warmth and comfort. It is increasingly used in modern designs, where you need to create practicality;

- Purchase materials made only by popular manufacturers with a good reputation. This will save you from buying low-quality goods.

As for the cost, this value is almost the same.First of all, it all depends on the manufacturer, the number of layers on the board and the quality of the material. When buying, pay attention to these characteristics, preferring products of famous brands and manufacturers. It is also important to take into account user feedback, which will allow you to select products that will last a long time without losing their properties.

Parquet and engineering boards are similar materials that have many differences. But this difference can be leveled, if the right approach to the installation and operation of surfaces, so the choice of products depends only on the buyer, as well as his taste preferences and financial capabilities.

In the next video you can see the main characteristics of the floorboard.