Laying floorboard

Parquet is the choice of those who want to show their good taste, status and wealth. It has a large number of advantages: environmental friendliness, quality, durability and decent appearance. Also, the process of laying floorboard will not be difficult if you follow all the recommendations and rules.

Types of material

Before you purchase a floor covering, you need to know which types of flooring exist today.

- Plank board made of solid array and does not have big differences with a solid board.Its cost is much higher than other types of coatings. Use single plank board, mainly for rooms with a large area.

- Also suitable for such premises two-lane boardas it is wider. It consists of two strips. They can be integral or consist of separate parts - modules.

- For spacious rooms has great relevance three-lane board. It consists of several narrow slats, which are made of various wood species.

- Four-strip boards are also made from different breeds. They are the narrowest. Their cost is very low. Such coverage has many disadvantages. This coating is poorly restored and polished, as it has a thin layer of wood, is highly susceptible to moisture and contains harmful substances.

- Massive parquet board Larch is one of the most resistant materials. Differs in durability, beauty and resistance to water. Coniferous breed is very popular.

Technology features

In order to lay the floorboard yourself, it will be enough to follow the correct installation technology to avoid mistakes.

Before carefully prepare and adhere to a certain technology. First, pay attention to the surface of the floor. It should be smooth, strong, without damage and cracks. With their presence it is necessary to eliminate these disadvantages.

Since the floorboard is not suitable for rooms with high humidity, it is not recommended to lay it in the toilet or bathroom. Also, the temperature in the room should not be below 19 degrees.

You must first decide on the flooring. It can be a variety of substrates, insulation. Another feature in the installation of this coating is that it must be laid away from the wall so that the shadow does not fall on the joints.

Mounting methods

There are many methods of installing floorboard do it yourself.

The floorboard can be put in the "floating floor" method. With this technology, dies are fastened to each other in a locking manner by connections, and not attached to the base. This technology is suitable for laying laminated flooring. The glue-free connection method is performed by cutting out specially designed fasteners - grooves and locks,which easily and quickly connect with each other.

The main advantage of this method is that over time, the strength is not broken. Mounts are resistant to any changes in temperature and humidity in the house and large loads such as heavy furniture. When using the glueless method of connecting boards it is hard to make a mistake, so if you are laying the floorboard for the first time, you can not worry too much about this.

After you varnish the coating, the joints will not stand out much, the boards will lie in a single canvas, even if you put it in front of a light source.

This type of connection allows the dismantling of parquet boards without taking into account the direction in which they were laid, if they were damaged or deteriorated.

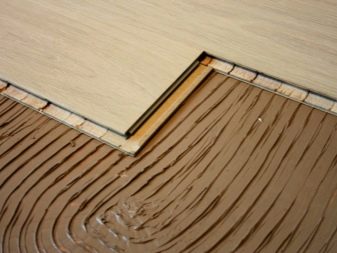

Glue-free method, of course, is the most technologically advanced. But laying with an adhesive method is important when the rigidity of the base is necessary, as well as when the room is large, as the parquet boards are completely glued to the surface of the base.

Glue is used special, intended for gluing parquet boards.

It is not recommended to use glue on a water basis as such covering is capable to be deformed. Glued lower grooves of the floorboard and are connected to each other. For more reliable sizing glue can be applied in two layers.

There are also longitudinal and diagonal method of laying. These types of installation differ in that they begin to be laid in the longitudinal way from the wall opposite to the entrance, and in a diagonal way they are laid from one corner. The diagonal way looks decent, but you will have a lot of extra trim, work will be more difficult and not economical.

Another way of laying floorboard - deck. This technology is relatively simple: one board stays next to another.

Laying along the direction of light is the most comfortable method of all, since the long seams do not cast shadows and the surface looks completely flat and solid. But it is in demand only for those premises where the windows face one side. If the light penetrates from all sides, then this effect of integrity will not work.

Mounting across the direction of light is good,when you need to make the room visually roomier. This method is suitable for a corridor or a narrow hallway.

When direct laying boards are placed parallel to the wall. This method is the most economical, since with it there are very few extra trimmed boards.

When diagonal laying boards lie on a diagonal. On trimming leaves a small number of boards. The method is perfect for wide rooms where special coverage will attract attention. But do not cost to lay the floorboard diagonally, if you plan to force the room furniture.

It is very easy and convenient to prick the floor on one board, as it takes less time to work. The boards are first fastened along short seams, and then the whole strip is laid on the base. It is worth noting that there should be a gap between the floorboard and the wall, since the tree tends to expand and contract depending on the temperature in the room.

If the coating is designed for a long period of use, it is better to cover it with a second layer of varnish. The joint of boards at the same time is protected from the ingress of water during wet cleaning. In this way, you can extend the service life of the coating.

Oddly enough, but the floorboard can also be mounted on the ceiling. You must start from the corner, which is located opposite the door near the windows. Laying floorboard on the ceiling can be parallel to the light that falls from the windows. An important condition for laying the floor remains a small gap of a few millimeters between the wall and the floorboard.

Foundation preparation

Before laying the floorboard, you must make sure that the base is firm, even and dry. These qualities will be inherent in the concrete screed and adjustable wood floors. For rooms that do not have high ceilings screed suitable. And under the floors of wood, you can lay the necessary communications.

The uneven surface of the floor with large differences will creak strongly and will be able to deform the parquet covering. Therefore, the alignment of the surface is so important. You can use a hydraulic level to keep track of irregularities and height transitions. The screed can also be produced using special self-leveling compounds. But in order for such a base to completely dry, it will take two or three weeks.The floor of moisture-resistant plywood also has its advantages. Aligning such a foundation is much easier.

If irregularities are pronounced on the concrete floor, it will be reasonable to level it with the help of a self-leveling floor and self-leveling mixtures.

First, the surface is primed and poured, and then special tools are used to roll this mixture. This floor is not afraid of moisture and it will never leak, you can also achieve a perfectly flat surface.

Concrete

If you decide to lay the flooring on a concrete base, you should check it for the presence of cracks, large drops, dimples and recesses. This surface can be poured with a special mixture and allowed to harden, leaving it for several days. But if the concrete is in very poor condition, then you should completely get rid of the old concrete screed and pour a new surface. And only when it is completely dry, it will be possible to lay the floorboard.

Wooden

In order to prepare a wooden floor for laying floorboard, you must carefully check it. After all, it may be failures, cracks, large differences between the floorboards.This floor should be well leveled. First you need to putty all the cracks and then sand the wooden base. If the floorboards are creaking and staggering strongly, then they can be attached to the logs with self-tapping screws. But if they have completely failed, then it is better to disassemble the floor and replace the unfit boards with new ones.

Which substrate is better?

Options for substrates for flooring there are a great many. Before you make a choice, you need to know why it is needed and which is better, as well as what is its compatibility with different types of parquet.

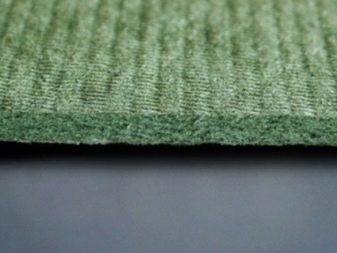

It should be noted that for the floorboard or for wood, installed on the floor logs fit soft backing. For example, cork or made of polyethylene foam. Such substrates are very relevant, because they are easy to fit and have a low price. In addition, they have good thermal insulation, especially in combination with aluminum foil, and great moisture resistance. But they can quickly subside and succumb to the influence of sunlight.

It is recommended to lay a substrate with a minimum thickness of 3 mm under the floorboard.

Polystyrene backing will be suitable also for any floor, both for wooden, and for linoleum and a parquet. It is distinguished by its thermal insulation properties, environmental friendliness, does not deteriorate from water and time, keeps its shape and is not influenced by insects and other pests.

It is convenient to lay a polystyrene foam substrate and it has a reasonable price.

Another variety is coniferous substrate, which appeared on the construction market not so long ago. Its main advantage is environmental friendliness. Although it is made from natural ingredients, it is water resistant. Its structure allows to increase sound insulation, at the same time it smoothes the imperfections of the surface on which the flooring will be laid. Also allows you to create a suitable microclimate under the floor. Its thickness varies from 2 to 5 mm, which is perfect for apartments and houses. The disadvantage of such substrates is the emergence under them of various fungi and mold, as well as the high cost.

Cork backing well suited for the floorboard. It masks well the irregularities and cracks, has a high sound insulation.The floorboard will not creak and deform when walking.

Such a substrate is divided into several varieties:

- The technical substrate is not amenable to moisture.

- Bitumen-cork most durable, as it contains a mixture of different breeds.

- The rubber-cork substrate is able to retain heat and moisture.

But the cork substrate has its drawbacks. Under heavy furniture or where there is a large cross, the substrate may become flat. It is undesirable to use it in a room with a warm electric floor, since the thermal conductivity of the cork substrate is very low.

In rooms with high humidity fit the substrate, which is composed of rubber. Its cost is rather high compared to non-ecological substrates.

Piling plywood under the floorboard is very relevant for those surfaces where there are many irregularities. Plywood has good thermal insulation and keeps the floor temperature at the same level, it also has high sound insulation properties. But it does not have good moisture resistance, so the room should be dry.

Also suitable for this type of coating substrate of MDR. It is made only from natural materials, so it is eco-friendly, keeps heat well and does not let in sound, is resistant to water and chemical solvents and has a long service life. Unlike cork substrate, it can be used with a warm floor.

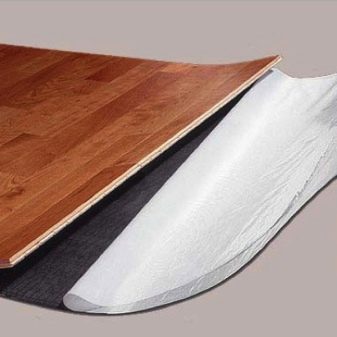

Another type of substrate is substrate tuplex from a polyethylene film and a layer of foam polystyrene granules between them. Perfectly fits the floorboard. With its structure, tuplex removes condensate that can accumulate under the floor covering, which contributes to its longer service life. It can be used together with a warm floor.

The lack of negative qualities makes it most in demand in the construction market. At the same time it has a lower price than the substrates made from natural materials.

Adhesive backing also often used when laying parquet boards. It is also called elastilon. This material has a porous structure and an adhesive layer with a protective film on one side. This allows you to firmly fix parquet boards. It has good thermal insulation and sound insulation, durability,may correct bumps on the floor surface.

Step-by-step instruction

To get started, start preparing the base and remove the old flooring. To level the surface, use special mixtures, if necessary. Concrete screed must be primed. Irregularities on the draft wooden floor should be well sanded.

The base can be considered suitable if the difference in irregularities does not exceed 4 mm. But if the parameters do not fit the established parameters, then the surface is recommended to be leveled more carefully.

After completion of the preparatory work it is necessary to put a substrate that will protect the coating from scratches, moisture and deformation.

Since the floorboard must undergo acclimatization, the coating in sealed form must be kept indoors for a couple of days. It is recommended to turn on the floor heating system for 14 days before starting repair work, then turn it off a few hours before laying. This is the procedure to help create a favorable climate in the room and avoid thermal damage to the finish.

Since wood is a natural material, deviations in its color and texture are likely. You can make a creative drawing of the boards by opening several packages in advance and “trying on” the boards. The length of the boards can also be short and start from 40 cm. Lamels from 1 m long and more are suitable for the middle of the room.

You can put them in different ways, but the most popular is the layout of the herringbone, which creates the effect of a different texture.

The next step will be measuring the width and length of the room, as well as planning the installation work. In order to lay the parquet flooring extremely evenly, create a pattern for future installation on the layout. The dimensions of the final row should not exceed more than 6 cm. In this case, a proportional displacement of the first is necessary.

Laying on the "floating" technology must be carried out according to certain rules. It is produced from the longest wall in the room. Expansion wedges are placed diagonally. It is recommended to do this after the assembly of several rows is completed: the finished flooring is shifted with a bracket, and struts are installed in the formed joints.

It is necessary to start the assembly by cutting with cutters at the first row of strips of the protruding part of the lock, then install the boards and begin assembly along the end edge. Extreme tile can also be trimmed if necessary. Subsequent rows are made up of the remnants of the previous ones. For parquet boards with a classic locking joint, the end fasteners are initially combined, then the junction of the tile along the length is made with the indispensable tamping with a percussion block.

It should be said that it is much easier to work with lock connections. Their docking should occur as needed across or longitudinally. For certain types of surround lock additional adjustment of the plastic insert is not needed. It is enough to precisely fasten the plates between them. The last row of boards should be carefully adjusted to size with scraps, then assembled using locks and inserted into the gap between the wall and the extreme row. The floorboard should be fixed with a special metal bracket.

If the edge of the bar rests against a pipe or another similar obstacle, then draw a line on it where you need to cut off a part and drill a hole with a certain margin of about 15 mm.The board is set in place and the cut is processed with a special solution, then the cut piece is attached with glue. Then it is necessary to remove the wedges after the assembly, connect the “warm floor” system and gradually increase the temperature, install decorative skirting and door sills. Another important point is that the formation of gaps in the openings between rooms is a mandatory requirement of manufacturers.

When installing the floorboard by the adhesive method, the scheme of work does not coincide with other methods. Apply glue mortar to a previously prepared base and spread evenly with a special tool or spatula. The boards in the first row will need to remove the edge. To make the flooring using the right technology, you need to tamp it with an assembly bar and load something heavy on it for better fixation of the boards. In the same way, installation or replacement of parquet boards to the base with carnations is carried out. The tile or laminate joint must be treated with a special sealant.

Tools and materials

In order to lay the floorboard on the screed will require special tools.Usually when you buy this cover in the kit comes with a set of tools. It is also necessary to have polyurethane adhesive or sealant, backing, assembly wedges, hacksaw, electric jigsaw, metal staples, pencil, tape measure and primer. If the question arises as to what to saw, then a jigsaw or a circular circular saw is suitable for this.

From professional construction tools you may need a hammer drill. In order to do the job qualitatively, you need tools designed for long life and heavy loads. Otherwise, a cheap device will quickly fail. For an electric jigsaw, get extra saws. And for the hammer drill, you will have to buy additional drills so that nothing distracts you from your work.

These tools are suitable for laying floorboard with plinth. But if difficulties arise in the installation, for example, when bypassing pipes, you will need additional tools, such as a drill, a mounting foot.

It is believed that the main advantage of the floorboard is that it is quite easy to install. The main thing is to study all the details of the technology and acquire the necessary tools.

Warm floor

It is believed that the floorboard has good thermal conductivity. But as an additional warming, you can use a special film substrate or "warm floor". For such a coating will suit a special type of water heating, which is compatible with the floorboard.

Water heating does not heat up as fast as electric, and high temperatures have a negative effect on such a coating.

When laying, make sure that the floor is at room temperature. It is necessary to raise the temperature gradually, by 3 degrees a day and make sure that there are no sudden changes, otherwise the floorboard will deform and deteriorate. If such a system is present in each room, it is necessary that both the floor and the heating end in the door openings.

Proper care

The parquet board does not tolerate moisture and scratches, therefore it is recommended to follow certain recommendations to save it. Sand on the shoe can easily leave small scratches on the floorboard. Therefore, you should ensure that your shoes are always clean and dry. Before entering the house should put a mat that will hold on to all the dirt and moisture from the shoes.

If the parquet is laid on the balcony, it should be glazed so that the sand does not fall from the street. And no matter how high it is, as a strong wind can understand the grains of sand to the level of the 4-5 floor.

Also, the floorboard does not tolerate constant exposure to sunlight. Faded traces and stains may remain on it, therefore it is necessary to have curtains on the windows.

Not only abundance, but also the complete absence of moisture can cause a change in the shape of the boards. Humidity should not exceed 50%, and the optimum temperature in the room should be 19-25 degrees.

In winter, use air humidifiers, and in summer, avoid a large temperature difference when you turn on the air conditioner. It is also important to air the room several times a week.

In order to avoid damage to the floorboard from furniture, use different nozzles made of rubber, place special pads under the legs of heavy furniture, and carpets under the tables and chairs. Just try not to walk on such a surface in shoes with heels.

It is strictly forbidden to do wet cleaning too often, use caustic cleaners, use a washing vacuum cleaner.Before you stop cleaning, you need to choose special care products for the floorboard. These can be special brushes, nozzles for vacuum cleaners, microfiber mops or natural fabrics.

Cleaning should be dry and wet. Wipe this floor only with a damp cloth. Care products must be selected depending on the type of floorboard. Their advantage is not only to clean the surface of the floor from pollution, but also to protect it from dust, water and scratches.

The floor should dry completely after such a cleaning, but if any stains remain on the surface, wipe it with a dry cloth.

Regardless of which room the floorboard is in, be it a kitchen or a bedroom, various stains may remain on it. They are not always easy to remove, so use mineral water, white spirit or a solution of alcohol and water. So you can easily get rid of any pollution.

To care for the parquet board with oil coating should also follow certain rules. Such a board can dry quickly and lose its original appearance. To do this, apply on the floor regularly a special protective agent, but at least once a month.Special oil intended for the floorboard will not allow losing the brightness and saturation of the coating. Deeper work on the restoration of the floorboard should be carried out every year. Such care will extend the service life for many years and will not allow you to lose a decent look to your floor.

In this video you will find a master class on laying floorboard.