Choosing the thickness of the floorboard

In apartments where there is a struggle for every centimeter of the height of the room, the thickness of the floorboard, taking into account the screed and the substrate, is of no small importance. Accuracy in the selection is necessary so that there are no problems with joining door sills or calculating the load when laying on logs (fixing on a wooden crate or bars).

Volumetric characteristics affect the speed and complexity of installation, sound insulation, floor heating, the duration of operation and the possibility of restoration of the floor covering.

The thickness of the floorboard

The parquet board can be of two types: massive and sandwich. Depending on the manufacturer, its thickness usually ranges from 7 to 26 mm.The smaller the cross-section height of the plank, the cheaper the entire flooring will cost.

Massive board

In the classic version, the thickness is from 18 to 20 mm, and 15-16 mm can be found on the market. Available with or without finishing. Indispensable when laying on logs.

It is made:

- solid wood hardwood - from the usual parquet differs only in size;

- with a two-layer slat system - a combination of two layers of wood, a connection of wood with high-quality plywood.

Sandwich

It is produced from several wood layers with the arrangement of fibers perpendicular in relation to each other. Between the elements bonded with glue. Sandwich parquet boards are available with mandatory finishing.

The multi-layered structure makes it possible to reduce the possible change in linear dimensions, the deformation of the floor due to temperature changes or a sudden change in humidity. The alternation of the directions of the fibers provides a depreciation of the coating when walking, reduces the voltage on the system of fastening the slats between themselves and to the substrate. (a photo)

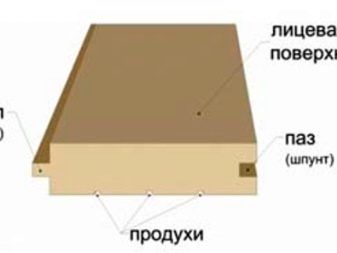

Structure

Three-layer parquet board has the following structure:

- Outer layer consists of a lacquer coating or oil impregnation. Such processing increases the protective properties and wear resistance of the working surface and does not affect the determination of the thickness of the strip.

- Upper layer - from 0.5 to 6 mm, made of valuable wood species. They must combine beauty and high strength. The most commonly used oak, beech, maple, cherry, alder, wenge and others. Pleasant appearance enhance brushing, bleaching, planing and heat treatment.

- Middle layer - 8-9 mm. It accounts for the main mechanical load, so coniferous wood with high density is used. There are two options:

- in the form of a solid slab - increases stiffness;

- glued together slats (slats) - gives the flexibility of parquet boards, which allows to level the roughness of the subfloor.

At the ends of the middle layer are fastening elements strap - grooved or locking system.

- bottom layer - 1.5 mm, produced in the form of a solid plate made of softwood or plywood waste. The base provides extra rigidity and keeps the entire strap structure on it.To protect against moisture, it is impregnated with water-repellent agents.

Price

The price of hardwood is always higher than softwood. This is due to the complexity of processing, the rarity of the plant species and the time required for it to grow to a mature state. The strength and durability of the floorboard rock does not affect.

The combination of expensive and cheaper wood species significantly reduces the price of flooring, therefore, with an equal thickness, the price of an array will always be higher than a sandwich.

Durability

Thickness directly affects the life expectancy of parquet boards

For solid solid wood boards, under all conditions of care, the service life lasts from 40 to 100 years.

Maximum allowable strap wear:

- for piece (solid) - up to half of its thickness;

- for double-layered - 5-7 mm (withstands from 4 to 6 sanding), the rest of the wood is responsible for the strength of the connection of the boards together.

For a sandwich, the average lifespan ranges from 7 to 40 years.

The maximum allowable wear directly depends on the thickness of the upper layer, which is the case for parquet boards of this type:

- With a total thickness of the strap from 0.5 to 10 mm - the face layer is only up to 2.5 mm. Polishing and restoration are not provided. Service life up to 8 years. It is recommended to use in rooms or utility rooms, in which rarely someone drops in, but the floors should correspond to the style decision of the whole house or apartment. Thin parquet boards are indispensable in situations where otherwise it is impossible to organize the threshold or with a small height of the room.

- From 13 to 16 mm - the top layer to 4 mm. This makes it possible to carry out 2-3 grinding. The covering is suitable for rooms with small passability: bedroom, office, living room.

- With 20-26 mm face layer ranges from 3.6 to 6 mm. Such boards cope with high loads even in public institutions: schools, clinics, cafes, conference rooms. In the apartments they are used for decoration of the kitchen or corridor. The largest samples, from 22 mm, are ideally suited for the restoration of old buildings, during the construction or repair of summer houses, country houses. Grinding depending on the top layer can be carried out 3-5 times. Service life from 15 to 40 years.

- At 35-40 mm - the thickness of the working layer reaches its maximum value, the duration of use from half a century. Such parquet coverings are used in concert and sports halls, hotels.The price is incomparably higher than normal.

Intermediate repair of parquet flooring begins as the varnish is worn or oiled. Under the conditions of operation and the initial quality of the outer layer, the need for cosmetic intervention will occur in the period from 2 to 7 years. It is impossible to repeat the factory quality at home, so the need for polishing the floor and treating it with varnish will occur earlier than the first time, the frequency between sanding will be significantly reduced.

In order to increase elasticity and provide floor ventilation, there are cuts or grooves in the back side of the board. The magnitude of these recesses is not taken into account when determining the thickness and have no effect on the durability of the product.

Screed thickness

The screed is the upper part of the design of the subfloor, it is necessary to level the surface. The quality of installation and the durability of the operation of the floor covering largely depends on its smoothness. Allowable height difference per square meter - 3 mm, linear - 2 mm.

Three types of screed are distinguished by thickness:

- up to 2 cm - fill using self-leveling mixtures;

- up to 7 cm - from reinforced concrete using reinforcing mesh or reinforcement;

- up to 15 cm - from a monolith with fittings inside, it is at the same time both the floor and the foundation of the house.

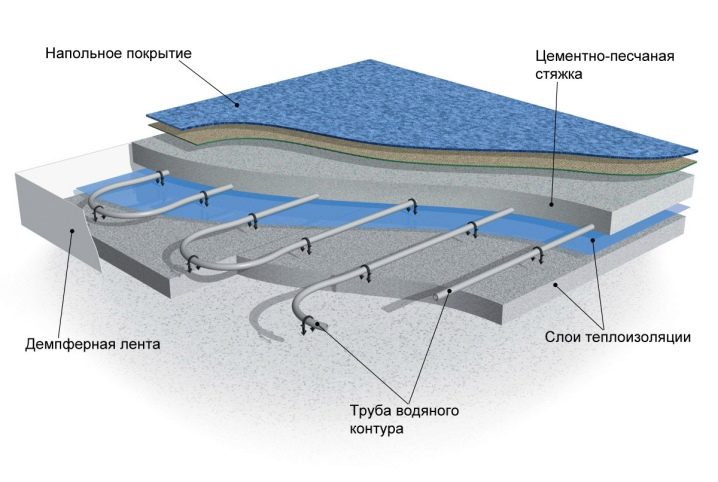

Thickness of the strip for "warm floors"

Parquet boards with a thickness of more than 10 mm can withstand an increase in temperature to the level of + 27C. The lacquer layer and the strength of the sandwich will not change. However, the heating should take place slowly to avoid the destruction of the wood. Only water system can meet such requirements. The thickness of the screed from the pipes for uniform heating - at least 5 cm. When installing, waterproofing must be laid. Laying option one - sticking to the screed.

For the "warm floors" are not used parquet boards with slat thickness:

- up to 10 mm - they do not withstand mechanical stress, cracks appear from temperature differences, the floor’s already short lifetime is reduced;

- from 20 mm - due to low heat conductivity, it is necessary to spend significantly more electricity for heating.

The recommended flooring option for heated floors are bars - 13-15 mm.

Substrate thickness

The main function of the substrates is to smooth out irregularities, increase depreciation, eliminate echoing sounds when walking, warm the floor, in some cases strengthen waterproofing.

Types of substrates:

- synthetic - polyethylene foam, foil, polypropylene;

- natural - cork, coniferous - vapor barrier is required;

- composite - Tuplex, bitumen-cork, rubber-cork, "Parkolag" (prohibited due to toxicity in some countries).

Available in thicknesses from 1 to 12 mm. Selected based on the flatness of the surface of the screed and the cross-section of the board. Violation of the allowable limit of the thickness of the substrate leads over time to the emergence of zones of bursting and seals, thereby increasing the difference in permissible heights. Loads on the locking system and the top layer of the plank become critical, cracks appear, the lacquer coating collapses, and the connecting elements break.

The option of calculating the thickness of the substrate, starting from the parameters of the floorboard:

- for slats up to 7 mm - 2 mm;

- for strips from 8 to 16 mm - from 2 to 4 mm, optimal - 3 mm;

- for strips from 10 mm - from 4 to 10 mm.

The use of substrates depending on their thickness:

- 2 mm - evens out minor irregularities, is the best choice in cases of an ideal tie under the floorboard up to 16 mm. It can be used in all rooms.

- 3 mm - suitable for leveling small differences in heights and floor insulation for floorboards up to 18 mm, the best choice for apartments in high-rise buildings.

- 4 mm - according to the characteristics it practically coincides with the previous value for foam and composite materials. It is not recommended to apply in places with a large cross: in the kitchen, in the hallway, hallway.

- From 5 mm and above - it is used in cases of use of thick slats and in little-visited places: storerooms, closets, dressing rooms, in an equipped attic of a country house.

With a qualitatively aligned screed, the optimum thickness of the substrate for the floorboard is 2-3 mm.

Calibrated plywood with a thickness of 1 to 2 cm is often used as a substrate. Experts advise that in this case the thickness of sheets be selected 5 mm thinner than the floorboard. To reduce the effects of seasonal temperature changes and moisture protection, a vapor barrier film with a thickness of 0.2 mm is laid under the plywood base. In rooms with high humidity or humid climate, instead of film, special waterproofing coatings are used.

How to choose the floorboard, see the following video.