Features of laying parquet

The decoration of the walls and the ceiling does not exhaust the whole range of work on decorating the home space. Of great importance is the type of material laid on the floor. Even such a high-quality and convenient solution as a floorboard requires careful attention.

Special features

A parquet board not only looks beautiful, if it is chosen correctly and properly laid down, the maintenance meets the standards, its service life reaches 25 years at least. Depending on the material capabilities and personal taste, you can choose the breed from mixed forests or from the tropical zone.

However, homeowners and builders are forced to solve many questions: what should be the basis, the type of front cover, how to make a “pie” and so on. Any wooden floor should be treated with protective mixtures and decorative compositions, their choice is also not easy. Finally, there are a number of nuances in the selection of care products.

Kinds

It is quite reasonable to begin the search for the optimal solution by finding out the appropriate type of parquet material. The artistic type of parquet is in demand very widely and harmoniously in any design approaches. It differs in pretentiousness and a non-standard type of drawing, a combination original fragments. Usually, not just a set of dissimilar rocks is used, but rather expensive types of materials. Technological complexity further increases the price of this product.

There are a number of types of finishes, such as:

- inlay is the introduction of materials;

- market;

- intarsia is the installation of a picture in depth.

The subspecies of the artistic version is modular, which involves gluing dies along the perimeter. They form a perfectly smooth pattern, for the most part they are simply geometric patterns.Putting modules is much easier than piece products, and the speed of installation is much higher.

In addition, reduced demands on the mode of operation and reduces the required frequency of repair. Most often, for artistic coating take strong breeds, such as walnut or oak.

The shield type of parquet also has its own characteristics. It is built on the same concept as a simple piece, but the modules are still in production combined into large conglomerates. The ease of installation is somewhat overshadowed by the fact that the pattern is set immediately and cannot be arbitrarily adjusted. The base is made of various materials, including chipboard. The variety of shields is relatively small.

As for wood species, both bamboo and oak parquet have their advantages. It cannot be said that some of them are definitely worse. You just need to evaluate which characteristics are more important in a particular situation. Bamboo is notable for its excellent hardness and good resistance to negative environmental factors. Wash it easy.

Oak boards are distinguished by their maximum strength and long life; they may have a less original, but more varied appearance. Selecting them for a particular design is pretty easy.Among the trees traditional for Russia, larch is also worth mentioning, which is excellent in moisture transfer and eliminates the occurrence of fungal colonies. The fee for such parquet is moderate, and it also keeps warmth well.

All these properties allow larch to be a formidable competitor for raw materials from southern countries.

Laminated parquet does not incorporate a single gram of wood in its usual form. But he perfectly resists fire and cleans well. Even paint stains are easily removed from the surface. But not all variants of such material, unlike parquet made from the same larch, can tolerate the action of water.

Put laminated strips mainly try parallel to the light flux. The massive parquet can be made with one or several layers, and the most durable material is put on top. The core is usually occupied by a relatively soft layer, and plywood is located under it.

It is of great importance for the quality of the coating that the storage and layout conditions are observed, therefore it is unacceptable to deviate from these requirements! The damage to the board is irreversible.it has to be completely changed; the strongest mahogany is sensitive to moisture and easily fade in the sun.

Not necessarily limited to natural solutions. Vinyl parquet manifests itself no worse. The simplest type of it is formed by tiles mounted on glue. In a more sophisticated version, a lock connection is also practiced. The most popular subtype now turned out to be vinyl with an adhesive layer applied to the production. All work with such blocks is easily performed independently.

Styling Types

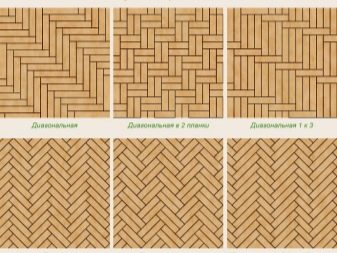

It is not enough to choose the type of parquet, you still need to decide on its optimal design. After all, such material is acquired for the sake of an attractive appearance in the first place. When the goal is set to save money, it is recommended to use deck installation, for example, diagonally. If you choose a more beautiful French Christmas tree, you can not do without trimming the ends at an angle of 45 degrees. The decision is made by choosing the appropriate geometry and size of the slats.

To make the floor more elegant and original, many designers recommend inserting decorative blocks in separate places.The look pattern of the wicker looks like a modified square. By reducing the number of pieces of parquet in one piece, you can make the ornament more delicate for perception.

Diagonal layout can also look attractive. Another thing to think about filling the floor with rhombuses, triangles and other geometric shapes.

Instruments

Regardless of the method chosen, parquet cannot be put without tools. First of all, an air pistol is needed for this purpose; it allows you to drive nails and staples into the material. Each type of nails and staples has its own specialized equipment. There are options for pistols with a shortened handle. The most popular option is a model for attaching the parquet to the bracket 90.

Conditions

The choice of the type of parquet and its installation is determined by the size of the room and its proportions, lighting and the chosen style of decoration of the room. The room temperature must be maintained not lower than +18 and not higher than +25 degrees. The maximum permissible humidity is 60%. For inexperienced installers, it is better to purchase large lamellae that fit easier and look more elegant.

It is necessary to remove not only dirt, but also all ground drops more than 2 per 1000 mm, the subfloor is dried thoroughly.

Mounting methods

Modern laying of an array of parquet can be stacked on such grounds as:

- on warm floors (extremely rare);

- over plywood sheets with lags;

- on concrete;

- on special substrates;

- over wood

On the warm floor

It should immediately be warned that this solution has many more negative sides than positive ones. So, any step by step instructions for installing a heated floor indicates that it is a single heating system. The coating is also involved in it, but the low thermal conductivity of the parquet destroys the whole idea. It is possible to avoid heat loss by laying solid layers of insulation - only this is expensive, long and absorbs a lot of space. And the thermal inertia during heating of the room will still be great, even if it is not a self-installation on a water floor, but a professional one.

Under heating, the tree cracks completely inevitable. Moreover, the gap will cover the entire surface. By intensifying the heating, involuntarily, they activate and intensify the process of deformation of the parquet.Multi-layered parquet board feels a little better in such conditions, but it contains toxic formaldehyde. At temperatures of +26 degrees and higher, it is released into the atmosphere at home, and the result of such a "chemical treatment" will not please anyone.

On plywood and logs

Where promising and more convenient is a dry prefabricated type screed made of plywood sheets. For your information: even if a decision is made to put another coating or change the old parquet, such a substrate will be quite suitable (in good condition, of course). The excellent durability and the natural humidity acceptable for unheated and wet rooms favor this choice.

But it is important to remember that plywood gives off a number of toxic components. Sanding plywood at least on one side is obligatory; it is this material that should be laid correctly by yourself, creating a smooth base for a facial finish.

To minimize the resulting stresses, it is recommended to cut the plywood into squares with a side of 0.5 or 0.75 m. Adjacent rows should not be joined in the corners, it is necessary to maintain a distance. Self-tapping screws are not simply screwed in, they are embedded in a 3 mm sheet.The material of the FK category is suitable as a parquet lining only in rooms with low humidity. Birch leaves tolerate scraping better and are well ground.

On the concrete screed

The process can be performed with or without glue. In the second case, a lock connection is used. Concrete is pre-dried, cleaned and leveled. For leveling, either a reinforced layer of mortar is put in, or a mixture of cement and plaster is used. Alternatively, the substrate can also be sandblasted and ground.

The first method allows to achieve almost perfect smoothness, but the minimum drying time of the solution, which is 28 days, stretches the construction or repair.

On the substrate

The cork substrate is more natural than polyethylene, and in case of ignition it does not poison the air. Putting the material will have to screed. Cracks in the base to 0.2 cm inclusive do not pose any particular hazard and can be ignored.

It is recommended to tie sheets with scotch to avoid disintegration of the composition. The flooring is carried out under every several consecutive rows, the sheet of cork lasts for 5–6 rows of boards.

The plastic substrate for garden parquet is better suited to natural, since it is more reliable, and outdoor location eliminates the harmful effects of individual components. A soft variety of parquet blocks is attached directly to the substrate of plastic, after which the parts are joined together and laid out without lags directly on the ground.

In home construction another type of substrate can be used - it is soundproof, which is only 3 mm thick. The cork layer in it can also be used, but it has a serious rival - this is coniferous wood.

It is the latter option, known as izoshum, considered the best solution to the problem of extraneous sounds.

On wooden floor

There is also a scheme for laying parquet on a draft floor of wood. It is only important to make sure that this base is really dry and of high quality. It is very difficult to fix the flaws during installation, but they will always be felt. Errors in the design and construction will quickly provoke the following problems:

- squeak when walking;

- local irregularities;

- failures and so on.

The strictest execution of methodical standards will be absolutely necessary. Initially, the floor is polished and spattered, after which the surface grinder is used. Compensating gaps should not be made less than 0.5 cm. Prepared bases are vacuumed and treated with primers with the inclusion of fungicides.

Old wooden floors are recommended to be completely embroidered, that is, to remove the slightest deformation and weak points.

Can I put on laminate, linoleum or old flooring?

Laying parquet on laminate or linoleum is not very practical. Even if these materials are in good condition, we must not forget about raising the level of the floor. This can create many problems when installing and opening doors. Similar difficulties may arise when finishing over the old parquet.

The slightest deformation of its surface or instability of the structure means that it is better to dismantle the previous layer and prepare the substrate from scratch.

What to stick?

Choosing glue to attach the parquet to the base is not too easy. First of all, you should understand: you need a two-component or one-component composition. A good composition should have the following features:

- firmly attach the strips to the base;

- Stable elastic at any humidity and temperature;

- be safe for water and do not provoke the swelling of the wood.

- Rubber glue is well attached to the bases used in the construction of floors, including concrete, seamless and slab floors. The life of the substance is quite decent, the recommended working air temperature is +15 degrees, and for the glue itself + 18 degrees. The setting time does not exceed ¼ hours.

- Dispersive Eco-friendly water-based glue does not give strong odors. It is used mainly for piece parquet products and for plywood sheets. Given the chemical composition, you can glue only the least susceptible to water coating.

- Polyurethane The glue is distinguished by its increased strength of the coupling, it adheres well to cement and concrete, and is excellent in rooms with a high level of stress. It is acceptable for floor heating equipment. Hardens after 24 hours at 100%.

- Silane the preparation does not contain a single gram of water, is elastic, does not deform the wood, is well cleaned from various surfaces.When using two-component compositions, it is important to remember that they are highly harmful to people, up to complete solidification. Formally, silane mixtures are considered a kind of polyurethane ligaments. They are not only water, but also solvents. If it is necessary to remove such glue from the factory flooring, it will be possible to make it without stains and damage even after complete hardening. There is no need to mix the reagent with anything, to precisely withstand proportions, and so on. Curing due to the presence of water vapor in the atmosphere makes this material a weak desiccant.

- Adhesive mixtures alcohol based, which are often called solvent based adhesives, are widely demanded. Every self-respecting chemical concern supplies such products to the market. With the help of such reagents, you can glue the plywood to the concrete, but it is desirable to further strengthen the bundle with dowels.

- To fill the voids is a special glue - repair. It will help reinforce loose rails caused by poor paver operation or due to wear. It is required to drill a hole in a problem area and add some water through it.When several minutes have passed, they take a syringe with glue and inject it inside, after 40 minutes on average the process of closing the cavity will stop, and the hole will be covered with putty and varnished.

Heads of many manufacturers rankings Swedish product Bona R777. For its unsurpassed quality, it is very popular. Naturally, this increases the cost of the product, but the cost is worth it. The German Kiesel Bakit PU-P cannot boast the same strength, but it is consumed very sparingly. Under 1 m² of parquet will need to spend from 1.3 to 1.5 kg of a two-component mixture.

Primer water-based glue can be from a variety of brands. So, ProBond Primer D Plus belongs to the category of dispersion compositions. The one-component reagent is made up of carefully selected dispersions of synthetic resins, designed for cement screeds. Dusting and crumbling materials are recommended to be trimmed with a water dispersion product Vermeister Primacril.

Despite the differences in chemical composition and application, one goal is to improve adhesion, leveling and preventing tree blotting.

Floating floor technology

Laying can be carried out by alternative technology - floating.Panels are cut as needed and hammered with a working part of approximately 1 kg. The last panels in rows are fixed with metal clips.

The advantages of this approach are the following:

- low labor intensity in comparison with gluing;

- the ability to work not only with a solid board as when using nails;

- cost reduction when compared with laying lags.

How to lay piece parquet?

You can lay the parquet materials with your own hands only after the final finishing of the room and laying all communications. The surface is leveled, leaving a drop of just 1 mm per 1 m². Fill the screed 40-50 mm or lay logs. When the parquet floor is completed, it is primed and covered with 3–9 strips of lacquer.

Each of these manipulations is extremely important; ignoring it leads to creaking or destruction of the laid material.

In order to put parquet with a herringbone, you need to place it at a right angle to the light source dominating in the room and leave a gap of 1-1.5 cm on the outer perimeter. On a concrete screed in front of parquet flooring, you must place a self-leveling screed or put plywood sheets attached to the base of the dowel with nails.Next, put a primer, combined by chemical composition with glue. For its application need a spatula or roller.

It is recommended that when selecting complex layout layouts to make outlines and plans in order to avoid unnecessary difficulties and mistakes.

Features of mounting on the wall

The use of parquet on the walls looks much more original than the surface of a bar or board. But it is important to do everything as clearly and correctly as possible. It is recommended to demonstrate the color and texture unity between the floor and the walls, rather than creating a contrast.

Whichever layout is proposed, a reserve of 5% is left, because very often a trimming of parts is required. If you choose large format boards, you can decorate the surface without creating joints on the ends.

Variants of joints

On the floor, on the contrary, it is very difficult to get along without connecting the elements. Often it is required to combine dissimilar in origin coatings. The docking of tiles and parquet without a nut is often performed with sealant. It is a cheap and easily used material that combines well with other coatings. Cork lasts longer sealant, but forms a bulge.

Profiles cover up flaws, but the length of such products is limited.A flexible profile for connecting the Caesar brand can have a wide variety of colors (up to 24 shades). This bundle is perfect for the podium floor or radius transition between adjacent floors. Location at different levels is quite effectively compensated. To fix the threshold can be a hidden way, and it is not difficult. It harmoniously connects even floors with unequal thickness.

Installation rules

When laying parquet on a wooden backing, only nails without caps should be used. Adhesive mixtures are applied to the grooves. Shrinkage of the floor covering next to pipes and door openings requires some space, with more than 10 mm. The classic click lock closes initially on the ends, only then connect the parts along the length, slightly tamping them up.

Mastic coating

Covering parquet with mastic is necessary for its most effective protection from external influences. Separate mastic varieties help fight harmful insects and microorganisms.

Modern mastics are perfectly natural and do not pose a danger to people. The outer film is very durable. It is necessary to select the material according to the type of the tree, which the parquet consists of.

Hot processing with pure rubber or in combination with bitumen allows you to finish the job quickly and immediately start using the coating. But the technology is complex and requires heating the mastic to high temperatures. Cold exposure is a combination of the active substance with gasoline, white spirit and other solvents. 48 hours after processing, the parquet will be ready for the subsequent finishing or beginning of use.

Consumers can choose both colorless and colored mastic. Pine, maple boards are mainly covered with a water-based composition, and the oak massif is trimmed with water-soluble mastic.

The technology of laying floorboard, see the following video.