Parquet scraping: what is it and what is it for?

Parquet flooring is always beautiful, and it looks with proper care just as good as flooring made of modern, fashionable materials. Plates made of natural wood can be laid out in the form of different forms - for example, a “herringbone” or in a checkerboard pattern. And even if the flooring is very old, there is always the opportunity to update it in order for it to serve the owners as long as possible. For this, a method such as scraping is often used. From this article you will learn what it is and why it is needed.

What it is?

Scraping the old parquet is the process of updating it, which occurs according to a certain algorithm.

Each stage is accompanied by the fact that the tree layer, which is damaged, is removed using a certain technique.

The final step is the fine grinding of already prepared parquet floorboards to obtain a clean and smooth surface that can be coated with special parquet wax or varnish.

When to do?

On the restoration of the parquet should think about if:

- its service life is already very long and there are cracks, scratches and signs of floor trampling which cannot be eliminated during normal cleaning;

- with a strong fading or darkening of the lacquer coating;

- if the parquet strips start to loosen and the floor starts to creak strongly;

- when wood material has lost its normal color;

- if a new parquet floor is laid in the room - in this case, scraping is necessary to ensure that the surface is smooth, without rough edges;

- if, when walking on the parquet floor, a characteristic muffled sound is heard under it: this means that voids have formed under the floorboards, which is a sign of their imminent detachment.

Difference from grinding

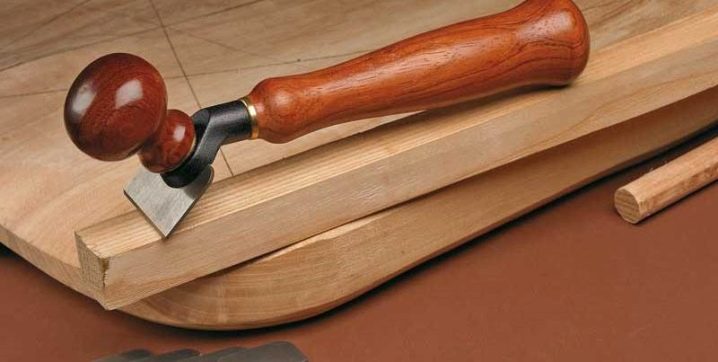

The concept of "scraping" comes from the word "cycle". This is the name for a hand tool that can be used to cut a thin layer of wood materials.Grinding is a process that resembles scraping, but the top layer of wood is not cut, but is scratched using abrasive tools.

Due to the widespread use of wood sanders, they have become more popular than manual cycles, so some people think that sanding is no different from spitting.

However, this is not entirely true, and there is a difference between chiseling and grinding. The parquet is polished during cosmetic, rather than complete repair, when the surface layers of wood are removed. With a full parquet scrubbing, wide and sharp blades are used; they process rough surfaces with mandatory final grouting in several stages.

Scraping parquet flooring is carried out in stages and helps even if the floorboards are badly damaged. As for grinding, it is performed only for cosmetic purposes with the elimination of minor damage.

What first - glue wallpaper or restore the floor?

If the work is carried out by a professional master cycler, it will be much more convenient for him to ottsiklevat floor before pasting wallpaper, because the machine for grinding will not spoil the wallpaper or freshly painted wall when passing close to the wall.It is always worth remembering that even the best scraping equipment will not be able to collect all the dust, and it will still remain in the air.

Therefore, the question of how to self-dust properly without dust at home can be answered that dust-free polishing is a myth.

A good machine for scraping, of course, will collect the bulk of the dust, but after the completion of the work general cleaning will be necessary. It is best to clean with a vacuum cleaner, because wood dust is very fine. Therefore, it is optimal to carry out all work on scraping before pasting or painting - in this case, cleaning can be carried out without fear of spoiling the newly glued coating, on which dust will settle anyway.

What ottsiklevat?

The type of working tools will depend on how you plan to restore the parquet flooring. Despite the fact that at the present stage you can find many varieties of modern equipment used for these purposes, there is still such a tool as a manual cycle. It allows you to perform the restoration in the old manner, manually, but it should be borne in mind that this process will be very long, and the expenditure of physical forces - enormous.

Hand loop is a very simple tool.Its ideal option is a width of not more than 5 cm and a short handle for maximum ease of use. It is important to pay attention to the fact that the knife of the cycle was sharpened as sharply as possible, and the angle of sharpening was 40 degrees. In addition to the main hand tool, you will also need different types of sandpaper (from P 40 to P 150), several brushes of different sizes, putty, construction varnish for subsequent coating, a roller, a spray bottle, a vacuum cleaner (either construction or household) and scissors.

You can use a special machine for cycling.

The range of special tools on the market is very wide, but the purchase of such a device often does not justify itself.

The cost of the cheapest car is from 50 000 rubles and above, and if we are talking about highly professional grinding machines that can provide a perfectly smooth surface of any floor, they can cost up to 500 000 rubles.

It is best to rent a grinder, paying a modest rental price and a security deposit for the equipment. Since the rent is charged at a daily rate, it would be better to take the car early in the morning. When using a grinder, it should be borne in mind that the master will also need a manual cycle,because it is possible to polish parquet in high quality corners or hard-to-reach places (if they are indoors) only by hand. All other working devices are the same as in manual cycling.

It is important not to forget about safety in the form of a respirator, goggles and headphones.

Putty is sold already finished, it is not necessary to knead it yourself in order to save time. Usually used putty water-based or solvent-based nitrates. It is desirable that it is combined in color with parquet dies.

Technology

Renovating self-sawn parquet is quite possible. The main thing is to follow certain steps in accordance with the recommendations of specialists.

Sometimes it is practiced to scrub or polish parquet flooring without furniture removal, but it will be best to do all the work in an empty room: first, the furniture can be touched with a scraper machine and damaged, and secondly, if in the future you suddenly need to update your furniture set, untreated surfaces, in comparison with unscoped ones, will look quite unaesthetic.

To begin with, the floor and the whole room must be prepared for the work. As already mentioned, it is best to take out the furniture completely and remove the baseboards. Often the plinths are removed by the grinder, especially if they are very old. In the case of a satisfactory condition of the floor (it does not creak, there are no loose or dropped parquet strips), the preparatory work will consist in deepening and strengthening the nails with which the dies are fixed.

If they are securely fastened, this will help prevent the sudden breakdown of the scraper tool. The floor surface is thoroughly cleaned of dirt and washed out.

When using a scraper machine, it is important to check the compatibility of the wiring for the load with the power of the apparatus, as well as its serviceability.

The usual power indicator of such power tools from 1 to 2.5 kilowatts.

If the bars in some places are not firmly, they must be completely removed, cleaned the place where they were fixed, and then replaced them with new ones. With a piece parquet, this is easy to do by nailing a new blank with a small nail with a narrow head and strengthening it with glue on the tree.

Creaking parquet before work can also be eliminated. As you know, dies creak, because the wood is gradually aging and dries. In order for the floor to cease to creak, dies are required to attach to each other thin nails, which are clogged in different corners.

You can also make and fixing with the help of special pins with the subsequent application of PVA glue or any wood glue on the wood. A pin made of wood is inserted into a hole that is drilled at an angle. When the glue is dry, the pin can be adjusted to the floor level.

If there are several minor gaps in the parquet between the planks, thin preparations should be prepared in advance, preferably from the same kind of wood. They should be treated with glue from one side and the other, and put in the slot. When the glue dries, the rest of the plank, which protrudes above the general level of the floor, is simply cut by a plane.

There is also a simpler way to eliminate the gaps in the form of filling space with putty, but it can take a lot of it, and when the material dries out, it is likely that it will crack.

In the case of a large number of gaps to carry out their one putty, of course, it makes no sense. Will need additional wood materials in the form of slats. In order to make the dies more pliable, they are recommended to be strongly heated with a hairdryer used for construction work. After the appearance of the characteristic odor of the strap should be as close to each other, and between them insert the workpiece soaked in glue.

For information on how to polish the floor, see the next video.

After the preparatory work is completed, you can start the start of cycling. If we are talking about the manual method, this is a very laborious process, therefore at the present stage it is practically not used. It is advisable to use a manual cycle for work at the walls of the room and in the corners where the chipper can not reach. In this case, the cycles work along the parquet fibers, lightly pressing while moving. For smoother sliding hand tools on the dies, they should be slightly wetted with a spray bottle.

Depending on the amount of work carried out by the cycles, its blade should be sharpened.The main sign that the cycle is blunted is a heavy wood flour, not thin wood chips. If the blade is fine, but the chips become too large, you need to make the angle of inclination straight.

Despite the fact that carrying out manual scraping in full is becoming less and less popular, there is practically no dust with this method.

In addition, the savings in money are huge, but because of the enormous complexity of the manual cycle, they are most often used only if small areas are required.

Machine tsilivaniya over the past few years have changed greatly. Now there are drum, tape instruments (with one or even three disks-nozzles), as well as “boot” machines, with which you can work in the corners. Scraping with the use of special equipment is advantageous in that the technique of using any installation is much simpler than the manual method, the whole process is much faster, and the removed surface of the parquet floor looks perfect and beautiful.

Deep cycling is done using emery paper. The 16th number is used for removing varnish, the 24th is for removing paint, and paper 40 is used to eliminate the actual wood layer.Select the sandpaper should be after assessing how worn wood flooring. The process of erasing paper should be carefully monitored and replaced with a new one in time, and the force with which the drum of the tiling machine “presses” on the parquet can always be adjusted using the lever.

Usually, when cycling is removed from one and a half to five millimeters of coatings (with the inclusion of varnish and paint).

When the tiling machine is turned on, it is imperative to lift it slightly above the floor to avoid damage. Keep the machine above the floor should be up to the moment when it will pick up a sufficient number of revolutions. If the machine is turned off, the algorithm of actions is the same: lift above the floor before disconnecting from the network. If you need to make a turn, the car should also be slightly raised.

The completion of the process of primary (rough) cycling is considered to be the result when the color of the parquet becomes “like new” - in other words, it acquires the shade that was originally.

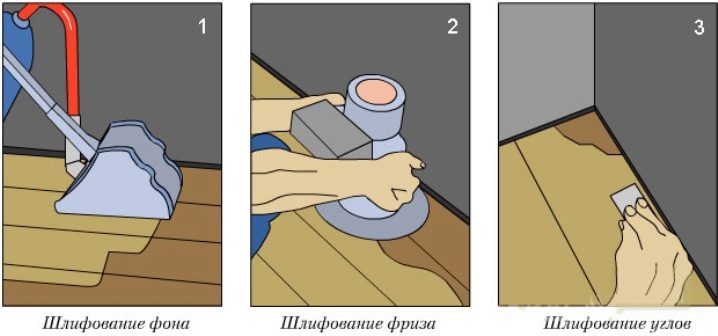

After the initial tiling, grinding begins. Its task is to achieve the maximum level of smoothness and brilliance of the parquet surface.Sandpaper at the beginning of the process is applied No. 40 and is gradually replaced by a more fine-grained: 60, 80 and more. Each grinding cycle is accompanied by the use of thinner paper: this step by step eliminates the presence of deep scratches, which inevitably appear as a result of rough cycling.

For grinding there is a tape variety of special tools with three discs - a surface grinder.

Proper and complete grinding occurs in stages. The machine must be driven in different ways: parallel to the wall and diagonally. If you have to deal with the mosaic structure of the parquet or with any artistic masonry, the movements of the instrument must be spiral-shaped, directed inward. Each pass must be accompanied by a tool offset by a distance equal to half the width of the sandpaper or the drum itself. It is best to start polishing from the farthest corner of the room, gradually moving towards its center.

Sanding parquet should always be along, but not across wood fibers. If you walk across, a pile will appear that quickly ruins the look of the parquet flooring.After the end of the process, the corners and hard-to-reach rooms with a manual cycle or a “boot” in the pendulum direction must be sanded on the main square. When the surface becomes smooth and shiny and there are no defects and lint on it, the grinding can be considered finished.

After sanding, you can proceed to coating the floor with varnish, oil or wax. To do this, remove from the floor all the dust that was formed during cycling and grinding and prime the surface well. The primer provides wood cover with the necessary protection and significantly reduces the consumption of oil or varnish.

In addition, after lacquering, an unnecessary bluish tint may appear, and the primer helps to prevent its appearance.

Toning or lacquering parquet with your own hands is a very crucial moment. It should be borne in mind that the oil mixture and wax is much easier to apply than varnish. An incorrect lacquer coating can lead to the fact that the parquet will need to be scraped again, which is very undesirable, since each time a certain layer is removed from the wood slats and they become thinner.

It is necessary to varnish the parquet in several stages:

- it is important that the parquet is well prepared and cleaned;

- the first and very thin varnish coat is applied with a roller or a wide brush;

- after applying the first layer, the varnish should dry completely, it will take at least 2-3 days to complete its drying;

- after drying, the surface should be re-sanded using fine-grained emery paper no. 80;

- after grinding to eliminate dust and dirt;

- The whole process should be repeated three to four times, each time reducing the grit of sandpaper during grinding.

How many times can you?

Many people ask how often you can update the parquet floor in this way. The possible frequency depends on the type of wood parquet. When it comes to hardwood, such parquet can be ottsiklevyvat more often than soft materials, which is quite logical.

The frequency of cycling also depends on the thickness of the parquet dies. If it is one and a half centimeters, the floor can be processed up to five times. If the thickness does not exceed a centimeter, the scraping is carried out no more than three times.

When re-cycling parquet should not forget that the minimum thickness of the board should be two millimeters.

Care rules

If you properly care for the recycled parquet flooring, it will serve for decades without the need for re-restoration. It is important that a certain level of humidity is observed in the room. To do this, you can install an automatic device for humidifying the air in the room, which will prevent premature drying of the wood and the creak of the floor.

As a humidifier, you can install an aquarium with fish: and beautiful, and aesthetically pleasing, and useful.

It is important to ensure that street sand does not fall on the floor. This can be avoided by bedding at the entrance mat. Since natural wood is particularly susceptible to ultraviolet rays, care should be taken to thicken the windows by hanging curtains or blinds on them. To prevent scratches from furniture legs on the parquet, they should be upholstered with felt. Cleaning the floor is allowed only in a wet way and always manually.

Beautiful interiors

The floor in an apartment, in a room or house made of natural parquet always looks presentable and beautiful, regardless of the tree species from which it is made. There is a cheaper option for parquet flooring,which received the name of the shield: when performing its surface layer, more expensive wood materials are used, and at the bottom there are coniferous species of wood, which should be taken into account when polishing.

Of course, the elite version with oak parquet to this day is the most reliable and time-tested. The strength and strength of the oak is always in first place compared to other trees. It is possible to scrape such a floor up to 8 times during the entire period of its “life”.

Oak parquet flooring does not require such scrupulous care and for decades can not change its original color, except that it gets dark, but it gives it an additional charm.

Work on high-quality oak parquet is always easier and much faster than with other materials, which justifies its high cost. Oak parquet will look great in a residential building or apartment, but it looks best in large rooms for various purposes: museums, concert halls, reputable banks and other public institutions.

Due to the emergence of modern parquet processing technologies, different types of wood can be whitened, lightened to the required tone without damaging the texture and the inner layers.Previously, birch or maple coatings were considered the lightest, but now even parquet from red oak can be made almost white, which causes the wood texture to be completely unaffected, but on the contrary, will be underlined properly.

If desired, oak parquet can be painted black, which will perfectly match many modern styles.

Neutral colors of natural wood will suit any interior ensemble (pine, birch, maple). There is no originality in this, but you can choose any furniture and style. Parquet of combined colors with alternating dark and light shades will perfectly fit into the modern style - hi-tech, minimalism or even a loft.

The parquet of dark color can look universal in the event that indoors there is furniture of dark brown color of any shades. It is the most preferred for the classics, but it also looks good in interiors decorated in oriental colors.

The dark tones of the parquet give the room additional comfort and intimacy, despite the fact that they contribute to the visual narrowing of the space. Although in large square-shaped rooms, this may, on the contrary, be an advantage.

Black parquet from oak, tinted in a special way, sometimes looks too heavy, but if the furniture in the room is also made of natural wood species of dark shades, the overall ensemble will look rich, stylish and presentable.

If the owner of the parquet floor is lucky, and the wood to be subjected to the scrubbing process is of good quality, after carrying out the main work, you can think about which tone to choose to cover - dark or light. Staining of the floor is also possible provided the strength of the material. If it is possible to completely change the color of the coating without affecting its structure, this is an excellent way out when it is planned to radically change the color of the wallpaper, furniture and general background in the room.

Modern machines for scrubbing and polishing allow for a gentle way and as soon as possible to restore the parquet flooring, and high-quality wood opens up the widest opportunities for the restorer to update the floor and keep it for many years.