Stages and leveling technology of the concrete floor

The leveling of the concrete floor is necessary for laying the subsequent decorative coating. Therefore, this is an important part of room enrichment, which includes classical and modern methods of leveling, such as wet and dry screed, filling the composition and falling asleep multicomponent mixtures.

Special features

In apartments where people live for a long time, the upper part of the concrete pavement is gradually broken, sometimes coming into disrepair. In this case, it is mandatory to carry out a major overhaul of either the entire floor, or a separately leaking part.

In new homes, concrete floor screeds are usually better prepared and look smoother. But here, too, it is necessary to take into account the individual shortcomings that arise in the joints between the individual plates. And when buying such an apartment, tenants are often more likely to make minor repairs. Before the start of repair work, careful measurements, cleaning and other types of floor preparation for leveling are carried out.

The preparatory stage includes the removal of the outer coating and inspection of all uneven places and holes found. Some of the defects exist in homes since construction and are further aggravated during operation.

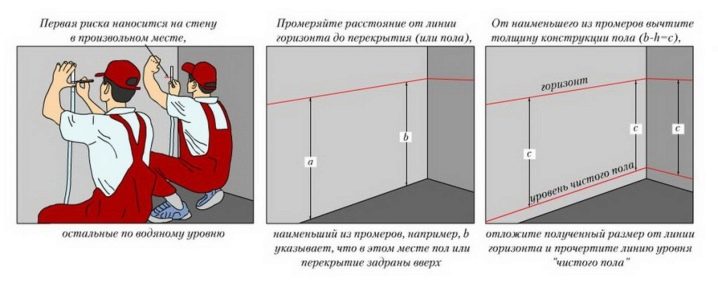

The height of the concrete cover should ideally be the same over the entire floor area. To determine this indicator, use a long tool called level. Often connected to the process and modern devices - osepastoiteli laser or water levels.

Preliminary measurements reveal, first of all, two main parameters - the highest point on the surface and the most extensive and deepest dent. The gap between them will have to be filled with concrete or other material.

Raise sagging places to the maximum level, counting from zero - between the horizon and the plane of the floor. Only after this is linoleum or tile, parquet or laminate applied to the subfloor. At the same time, we must not forget that all parts of the interior are interconnected: with an excessively elevated coverage, difficulties may arise with the opening of doors and the operation of heating batteries. In order not to redo the work twice, these factors need to be considered in advance.

What is the best level?

Ideal material for alignment, as many experts believe, has not yet been invented. Putty can eliminate minor roughness, putty and close chipped conveniently and with the help of tile glue.

The liquid mix consisting of concrete and water in combination with other fibers - the excellent equalizer in case of filling of small dents. For preparation as a filler sand composition using cement brand M-400, sand and thinner. The construction mixer mixes all the components, since it is rather difficult to obtain a high-quality equalizer manually.

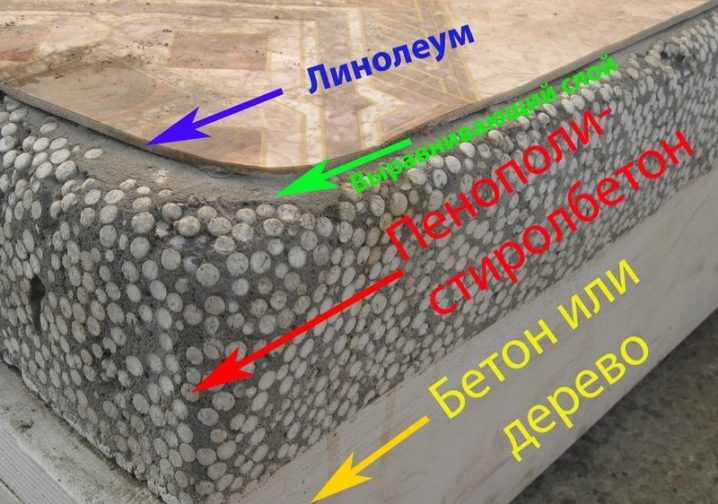

Cement mortar level significant defects, achieving a result even in case of serious damage to the concrete base during construction.Gypsum composition is used to fasten the metal guides in the process of screed, the so-called beacons. At home, when doing repair work with their own hands, ready-made dry mixes and polystyrene concrete, combining synthetic plasticity and fast, firm hardening after application, are preferable. In the case of the use of a universal ready-mix or mixed concrete and sand mixture obtained in a mixer, the floor is filled with additional grinding with a special machine.

Technology work

A completely smooth and even floor looks beautiful and elegant, while a curved covering worsens the aesthetic perception of the whole room or kitchen. In the process of overhaul, the floors in the house are the last to be dismantled, and they are first of all put in order. If the surfaces are completely flattened during the preparatory work, the floor is first leveled and then transferred to the walls and ceiling.

Among the common defects in the floor screed in both private and high-rise buildings of standard planning, experts call:

- Local small errors that look like level “nodules” that create unevenness in the floor.

- Changes and differences in the form of periodic, especially noticeable on the surface of the found waves of concrete or other material. In private buildings, such waves on the floor can be quite significant, up to several centimeters.

- Small wave drops or "chill". These defects usually remain after the application of the construction tool - the rules.

- Small cracks, lenses and cavities protruding pieces of rubble, as evidence of the destruction of the floor. In this case, it becomes unsafe to move around the house, it is impossible to securely fix furniture and household appliances. In addition, the ability of the coating to provide insulation from noise, odors and excess moisture is lost.

The floor must be cleaned, putty irregularities and chipped parts. In order to reduce the consumption of a concrete-based leveling compound or not to break a sheet of plywood, large knobs are knocked down with a chisel.

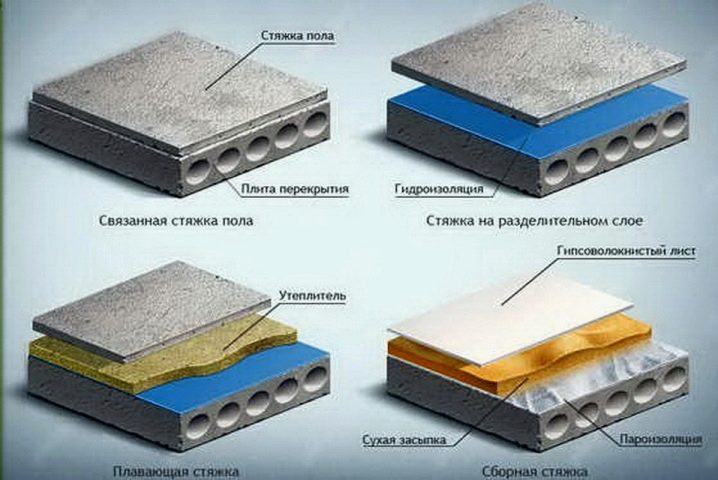

The leveling methods used by builders: the use of concrete or dry screed on beacons set in advance or without them, as well as the method of self-leveling floor covering.The correct choice of method depends on the size of the difference between the maximum and minimum levels.

If the irregularities are insignificant, up to two or three centimeters, such a technology as the arrangement of a self-leveling floor will suit. This is an expensive method, since a significant amount of leveling mixture is used per square meter. Therefore, dry screed or alignment with beacons is most often used.

In order to make a screed on the basis of a sand-concrete mixture qualitatively, metal slats are laid on the base, which will indicate guidelines for movement during the screed. The process refers to labor-intensive, but it allows leveling potholes and drops of several centimeters, making the floor ideal in any room.

Phased work is performed as follows. It is necessary:

- Prepare the floor by removing oil stains and dirt.

- Put the waterproofing material, sizing joints. Leave allowances along the walls of the room.

- Using a level, mount metal guides - beacons. The distance between them is allowed no more than one meter, otherwise leveling the surface will be more difficult.

- Prepare a concrete-sand mixture, preferably immediately to the entire flooded area. Stirring time - from an hour to one and a half, so that the composition does not harden. The most commonly used construction automatic mixer, bringing the composition to a semi-liquid state. The finished mixture should only spread slightly to the sides without spreading.

- Alignment is done from a remote corner, in small parts, using a rule. Imposing a mixture, it is immediately leveled. To securely close all dents, the mixture is scattered around, not just along the guides. In order not to form air gaps, each layer of the screed must be pierced with a metal needle.

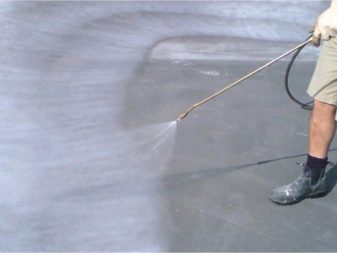

- Thick screed reinforced with other material, as well as cut for shrinkage special seams. The distance between them is selected up to three meters. After that, the filled surface is left for about a day. After this time, the coupler should be moistened with water from the sprayer and left for another two days. Then you can check whether the mixture of sand concrete has frozen well.

- At the next stage, the surface is moistened again, a film of polyethylene is placed on top to protect it from cracks.

- During the following week, the screed must be moistened daily, then the film is removed, leaving the floor to dry naturally. The process of complete drying takes at least a week or even two.

- Dry finished surface has a uniform gray color. Tapping on it with a block of wood causes the same sound of the layer anywhere in the area.

- If the alignment is done qualitatively, you can begin to mount the coating of laminate, linoleum, as well as parquet. The tile can be laid simultaneously with the last layer of the screed.

Performing alignment, it is impossible to rush too much, but it is undesirable to delay the procedure. “Cold seams” may appear. Therefore, it is recommended, especially in the case of a large room, to invite an assistant and work together.

Material

Whatever basic covering is laid - tiles, parquet boards or linoleum, auxiliary materials are used to level the floor. Most often under the flooring put plywood, layers of concrete and GVL. Only in this case, the required quality of an immaculate surface, ready to serve for many years.

Screed on the basis of sand and cement belongs to the classic version, because it provides a smooth surface even in those rooms where the drops reach four or more centimeters. Dry screed is provided with self-leveling mixtures based on quartz sand, granulated particles and expanded clay, polystyrene foam. Plywood, chipboard, fiberboard or gypsum fiber sheets that are resistant to moisture give a smooth surface.

The room

To level a floor, achieving an ideal covering, it is accepted polystyrene concrete, wet or dry mix. This method, along with the cement-sand screed, prepares the floor for laminate and parquet in the living room and bedroom, nursery or dining room. If the apartment is small-sized with a low ceiling, and the differences in the floor are not more than three millimeters, it is better to resort to the floor of the floor, which will dry in 12-14 hours. The whole process of laying the floor, as a rule, does not take more than two weeks.

Flooded polyurethane-based floor is not designed for rooms with temperature changes, it is better to use this method, starting from the second floor. But it is an excellent option for a rough base under the laminate.Before applying the self-leveling mixture, the floor is carefully primed. Then the finished liquid composition is poured onto the floor, leveling with a spatula.

To eliminate air bubbles that cause defects in the coating, a needle roller is used, piercing the filled layer. Flooded floor dries in just 15 minutes, so you should do all the operations together with the assistant. Cold water, which wets the coating, slows down the freezing.

If you have to lay linoleum, the surface is needed absolutely flat. To ensure these goals, a method such as a dry screed is suitable for differences of no more than a centimeter-one and a half. If repairs need to be done quickly, having strengthened the floor with almost no defects, the alignment is made with sheets of plywood or chipboard. Strengthen them with screws and dowels after gluing to the floor surface.

For the kitchen and the balcony is often used as the main cover beautiful ceramic tiles. There is an easy way to evenly put it at the same time as removing small defects on a concrete base. The method does not give a full leveling of the floor, however, it allows laying the tile evenly.First you need to put over the floor surface on the walls horizontal lines along the entire perimeter of the room. This will be the level at which the tile is laid.

In order for the entire tile to lie flat, the required height is achieved by increasing the adhesive layer - more in those places where the floor is uneven. Such styling is available to everyone, does not require special training and skills in the work.

Successful examples and options

The hands can be used to refine the curved old floor. In some private homes, the drops are up to ten centimeters. But for such cases there are good options recommended by experts. To get started, you need to purchase bulk dry screed. It is expanded polystyrene, sand from quartz, expanded clay shavings.

The advantages of this method:

- The operation can be performed slowly, not in one day.

- Drying is not required. After applying the last of them the work on alignment is considered complete.

- Bulk mixture has noticeable insulating qualities.

- To strengthen the top put glued PVA sheets of plywood or chipboard.

Now you can put any of your chosen flooring.Significant disadvantages of this method of alignment does not exist.

If the mixtures and solutions do not suit you, you can create a rough surface with a wooden lag in a natural way. This is a time-consuming way in which the floor level rises significantly, so it is used in rooms with high ceilings. The essence comes down to stacking cuts of wooden bars prepared for quick installation. Lags evenly fall on the pre-primed floor. On top of them fit plywood or sheets of particle material.

How to level a concrete floor, look in the following video.