Choosing enamel for concrete floors

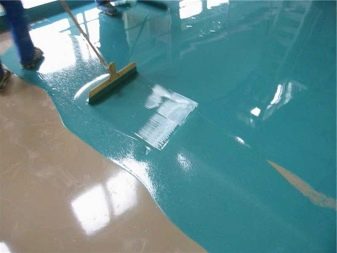

During repair, everyone is looking for an effective, practical, durable and cost-effective means for processing coatings of various types. If the room is decorated with concrete floors, it is recommended to pay attention to the special enamel. This tool is perfect as a final finish of the draft coating.

Due to the liquid structure, the composition easily penetrates the pores of the concrete. The result is a durable film that not only saves the floor during use, but also gives it a stylish appearance.

general characteristics

Enamel is a special glassy compound.After it is applied to the concrete, a wear-resistant layer is formed. Dense structure that protects the floor from daily loads, is obtained due to the concentration of special binding components that make up the enamels. Due to this treatment, the lifetime of concrete coatings is increased several times.

Each enamel product has certain characteristics that must be considered during operation.

Kinds

The modern market offers a huge variety of different paints. Types of enamel:

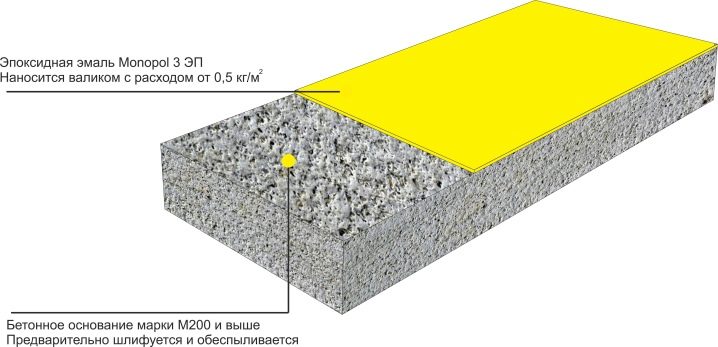

Epoxy

The tool of this type is a two-component. Advantages - durability and durability compared with polymer products. Disadvantages - limited choice of colors. This type shows a high resistance to constant loads, due to which it can be used on the basis of residential premises or objects with high traffic.

Also available in water epoxy enamel. It uses resin, mineral fillers and additional substances for rich color and reliable protection. The basis is a suspension of pigments.

Acrylic

This type of water-based enamel.Manufacturers also add resins and polymers. The tool may have a different texture: both matte and glossy. Also stands out a separate species - semi-matte. Due to this characteristic, enamel has excellent decorative properties.

Experts note that acrylic enamel without problems tolerates increased moisture and sudden temperature changes. She is not afraid of aggressive components and mechanical damage. After processing the floor composition of the service life of the coating will increase significantly.

Polyurethane

The main advantage of the compositions of this type - high resistance to fading. They also dry quickly, reducing the time for repairs. Enamel is used both inside and outside buildings. The process of complete curing of the material takes 2 weeks.

Urethane alkyd

After processing the concrete floors with this composition, they will become resistant to abrasion. After drying, a smooth glossy film is formed on the surface. Urethane-alkyd enamel can have a varied color. Experts strongly do not recommend applying this composition in several layers with a break less than one week.

Popular brands

Paint and varnish products are produced by many enterprises. The main brands are located on the territory of the Russian Federation. Examples of main products:

"Profi"

Paintwork products "Profi" - this is a cost-effective and reliable method of treatment of concrete floors. Also, the tool is used to update the coverage. The material can be safely used in houses and apartments where small children and animals live. This is possible thanks to the safe substances that make up the enamel. "Profi" is recommended for use in schools, kindergartens, sports and medical facilities.

It should be noted that this enamel can be used not only for concrete floors. With the help of its treated metal, concrete and wooden surfaces.

Paint specifications:

- profitable consumption - about 250 g per m2;

- the period of service (with significant loads) - about 3 years;

- drying time - 8 hours;

- attractive appearance.

Tex Profi

High-grade alkyd-urethane enamel, designed for use in buildings with increased operational loads. It is also suitable for processing open locations: terraces, verandas and more.

Customers can choose from 5 different colors. The composition boasts durability, reliability and high covering properties.

Olimp brand products

This tool is perfect for final processing of concrete floors. Alkyd enamel has proven itself as a wear-resistant coating. Finishing will help prevent dust formation on the surface. Also, a protective film for a long time will protect the concrete from damage caused by mechanical loads. It should be noted that the tool can be applied to the canvas in several layers due to the high hiding power.

Characteristics of soil-enamel:

- minimum service life - 3 years, subject to constant and intensive use;

- resistance to the formation of mold and fungus;

- resistance to various reagents: household chemicals, gasoline, oil, etc.;

- material consumption: liter per 10 "squares".

Enamel "Novbythim" (NBH)

A polymer-type product that contains natural resins, acrylic pigments, bright dyes and special components that accelerate the drying process. Due to the increased performance for everyday loads, the paint is used at the basepublic premises: gas stations, shopping centers, warehouses, car workshops and other institutions.

The special structure of the film has a water-repellent characteristic and is not afraid of chemical elements. The strength of the composition is capable of carrying the movement of bulky transport and constant exposure to sunlight.

General characteristics:

- drying time - 5 hours;

- the possibility of applying in several layers;

- consumption of 300 g per square meter;

- working temperature range - 5-30 degrees Celsius above zero;

- a special function is self-leveling (texture is restored from brush marks and other defects).

Tips for using Novbythim enamel:

- Experts recommend applying the material on a wet concrete floor.

- During operation, monitor the temperature in the room. Create an optimal microclimate, without strong temperature changes.

- Make sure that the surface treated with paint, do not fall aggressive acid solutions.

Acrylic enamel on concrete "Prestige"

This tool is designed specifically for the design of concrete surfaces.The production process uses natural solvents, coloring pigments, acrylic resin and other necessary components. Enamel is ideal for the color of floors in production workshops, industrial laboratories and workshops for the repair of transport. Also, it can be safely used on the basis of open parking.

A special property of enamel is that it hardens even at low temperatures. The maximum value is 10 degrees Celsius below zero.

Using:

- The product is sold ready to use (in certain cases, xylene is added to the enamel - a special solvent). Before applying the material on the floor, it must be thoroughly mixed.

- It is possible to apply a product only on a dry and pure surface, without pollution and dust. In the process of repair it is recommended to use a roller or brush.

Enamel "Epostoun"

This type of coating is a two-component materials. Water-epoxy agent perfectly copes with the task of protecting the concrete floor from external factors. The material contains: various resins (epoxy and amine-containing), mineral components, suspensions and other substances.Experts strongly recommend applying the product on a wet floor.

Properties:

- water-epoxy-based enamel is odorless and after drying creates a semi-matt coating;

- the material is not at all afraid of increased moisture, steam and various mechanical damage;

- regardless of the indoor climate, enamel will retain reliability and durability due to weather resistance.

Characteristic:

- full drying time - 24 hours;

- texture - homogeneous;

- consumption - about 180 grams per square meter;

- environmentally friendly and safe material.

Professionals assure that "Epostoun" can be used on the basis of both industrial and civilian premises:

- shopping centers;

- warehouses;

- vehicle repair workshops and garages;

- cellars;

- medical facilities (health facilities);

- kindergartens;

- pharmaceutical institutions;

- food enterprises.

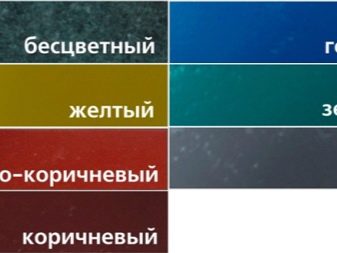

Color spectrum

Widely used enamel colors:

- Gray. The most versatile and widely used color. It is a neutral tone that harmonizes easily with the rest of the trim. It can often be found on the basis of car parks and warehouses.

- White. Classic color, popular in both residential and public spaces. Such enamel is recommended to be used on objects with a lack of lighting.

- Red brown (brown). Dark and rich color. It is often chosen for floor treatment in a car repair shop or garage. On a dark color, dirt and dust are less noticeable.

- Green. Green color is often used in the design of sports halls, kindergartens and educational institutions.

- Blue. Enamel in blue color is widely used in various medical institutions: hospitals, hospitals, clinics.

Different manufacturers of product color may vary in saturation. Also it is necessary to take into account that the appearance of the material directly depends on its texture: glossy, matte, semi-matte.

Expert advice

When selecting products, pay attention to whether the product meets the standards of GOST. No matter what you decide, paint with ordinary enamel or make a choice in favor of premium products, it must be of high quality.

Before use, be sure to read the instructions for use. Each product must be used differently.Some types of enamels must be applied on a wet surface, other types are used only on a dry floor.

Keep enamel out of the reach of animals and children. If the substance has already been used, be sure to close the container with the paint lid tightly before storage. Ensure that direct sunlight does not fall on the container. Increased moisture also adversely affects the product.

Protect hands with rubber gloves. In the process of covering the floor with a protective agent and then ventilate the room.

Enamel for concrete floors is a practical, reliable and cost effective way to protect and decorate the surface. The modern market offers a huge variety of products for any wallet. Products differ in performance, cost, color, method of application and scope.

The choice of paint and techniques for pouring concrete floors, see below.