Rules and recommendations for grinding the concrete floor

Concrete is a unique building material that can withstand considerable loads, so this substance is used in various industries, among which are the arrangement of concrete floors.

To make the surface unique, it is desirable to polish it. It is important to follow the rules and recommendations for grinding concrete floor. This will provide a solid and durable products, which is perfectly resists external factors.

Special features

Grinding a concrete floor is its processing with special abrasive materials in order to level and strengthen the structure. After these procedures, a smooth surface is created, which is perfect for further processing.

A type of grinding concrete is polishing it. This process involves the removal of a very small layer of material with its successive compaction. This allows you to give a semi glossy structure. Grinding is used for the formation of flooring in institutions such as hospitals, shopping centers, water parks and suburban areas.

Ground concrete floors have several significant advantages over other floor coverings:

- Durability. The material can serve for several decades without loss of basic technical parameters. If desired, you can perform periodic polishing, restoring the decorative features of the floor.

- Glossy concrete floor looks very similar to materials such as natural stone or self-leveling bases. With the help of various components, you can change the design of the surface (eg quartz).

- Relatively low cost. To equip such a floor is quite simple, since all materials are available on the market, and working with them does not require special skills.

- Polished concrete can be used as a base for decorative finishes using laminate or parquet.This base is perfectly flat and does not contain significant differences, which eliminates the rapid wear of boards.

Concrete processing today is carried out in 2 main ways.

Dry

In this case, working tools remove the concrete without additional solutions. This results in a lot of dust. These substances in contact with the lungs are deposited and are practically not derived from them. Therefore, applying this approach, you should use high-quality personal protective equipment. With this technology, you can remove the concrete with a thickness of no more than 2 mm.

Wet

Use it when the floor is supplemented with mineral chips or mosaic. During the treatment of concrete, water is supplied to the surface, which prevents the formation of large amounts of dust. But this already leads to the formation of liquid dirt, which is also not very pleasant.

With the help of wet technology, you can already shoot up to 5 mm of concrete, but such work requires special skills.

What to grind?

Concrete is a durable material that is quite difficult to destroy mechanically, so grinding is done only with a special tool, which is complemented by various working tools. These designs can be divided into 2 large groups.

Professional equipment

This includes special grinding machines that allow you to handle large volumes of surfaces. Driven by both electric and gasoline engines. There are many types of such equipment, different power and performance. Among them should be allocated helicopter cars. They are equipped with 4 blades, which are already in contact with the floor.

Additional mechanisms allow you to change the speed of rotation of work items. Thus, you can get a different level of grinding, depending on the purpose of the floor.

Professional equipment is used to work with classic concrete surfaces and bases with topping. The latter type of foundation involves the introduction of dry cement and other components into the top layer of the screed. This allows, after grinding, to get not only strong, but also beautiful grounds. Such additives can increase the service life of the concrete floor up to 15 years.

Household Sander

Devices of this type are small and compact. In some cases, they can be replaced by an ordinary grinder, which is complemented with diamond circles.

This type of equipment is characterized by low power and small dimensions. This allows you to perfectly handle the concrete, even in the corners of the room, which is not always the case with an industrial machine.

But the quality of processing of a concrete surface depends not only on the power of the device, but also on abrasive nozzles. It is they who destroy the upper layer of material, removing unnecessary elements. The working tool can be divided into several basic types.

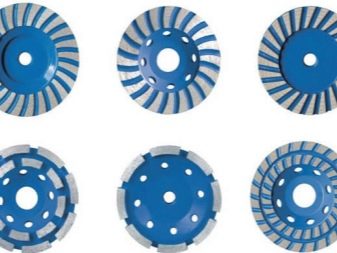

One of the most common are disc nozzles. Outwardly, they resemble grinding wheels that equip grinders. But the abrasive part can have a different structure, which allows you to grind the base with different strengths.

Depending on this, there are such subtypes of disk tools:

- Turtles. The main purpose of these structures is the finishing of the bases. Products are distinguished by a flexible base, which is covered with diamond chips. The circle is fixed to the working body with the help of a classic velcro. This allows you to quickly perform a tool change after abrasion.

- Washers. The surface of such a disk is covered with diamond chips of various sizes, so the tool is used for roughing the floor, as they remove large crumbs well.Manufacturers represent several combinations of the working surface, which is intended for grinding surfaces of different hardness.

- Cups. Outwardly, these products resemble a circle, but their design is more similar to a plate. Along the perimeter of the circle there are special grooves with diamond components. It is they who remove the concrete when exposed to its structure.

Depending on the level of grinding floors cups are divided into the following types:

- Double segment - the main purpose is to remove the upper thick layers.

- Square. The circle works well when the surface is covered with large individual pieces of frozen mixture. At the same time, the tool resists loads well and does not lose its technical characteristics.

- Boomerang. The working surface is distinguished by a small grain that allows you to process only finishing floors, where you need to get high quality sanding.

- Frankfurt. This tool is used for fine grinding. With it, you can get a glossy surface that is different gloss. Depending on the grain of the work item, the final design may vary.

How to do it yourself?

Grinding a concrete floor is a time-consuming task that can be done at home. To get a beautiful surface, it is important to properly prepare it for processing.

This process involves the following steps:

- It is necessary to begin preparation with survey of an old floor. If reinforcement or other metal inserts are present on its surface, then it is advisable to remove them. To do this, use the grinder, with which the metal is cut from the base structure. When the amount of metal is significant, then it is better to arrange a reinforcing screed with a thickness of 2-5 cm over the base, depending on the base drop.

- If there are cracks or chips on the surface, they must be removed with cement mortar. Polishing is not started until the substance dries at least half the strength.

- It will be correct to check the level of the base before starting. The technology allows you to polish the surface with a slight slope, but after processing it will look different. The procedure is simplified using laser levels that allow measurements in several directions at once.

- Processing begins only after the concrete has completely hardened and gains all the strength. This applies to new surfaces that are formed in new buildings or during major repairs. You can find out the rigidity of the floor with the help of a grinder and one of the attachments.

- If the number of mounds or pits is quite large, then roughing is necessarily used. This will level the base and make it smooth. Please note that if the depth of the pits is quite large, then this procedure is not always cost-effective. It is better in this case to level the floor with a concrete screed, and only then proceed to the treatment.

Grinding technology does not involve complex operations.

It is important to observe several recommendations:

- Before treatment, the floor should be covered with special primer mixtures, which increase the adhesion of concrete.

- The next step is to choose a grinder and attachments to it. If the room is small, then you can use an ordinary grinder. The larger the circle to it, the sooner you will process the base.

Particular attention should be paid to the disks.For grinding you should buy a few circles, which are distinguished by grain. The best option would be the size of the nozzle 25-40 mm. If you want to get a glossy surface, then you will additionally need to purchase a disk with a size of 1500-3000 mm.

Grinding is performed only in protective clothing, respirator and goggles. It is important to comply with the basic safety techniques of working with grinders or other grinders. Please note that with the dry method a lot of dust is generated, which does not allow long processing time. The procedure is performed sequentially, after the dirt settles.

Grinding is carried out until the floor surface acquires the desired structure and smoothness.

Initially, the base is processed in circles with large spraying, and then with smaller grains.

When the floor is completely sanded, you can begin to wash it and further processing. After drying, the base can be varnished or special polyurethane compounds. This will give it a unique design, as well as extend the service life.

Successful examples and options

In any home (apartment or house), thanks to a polished or sanded floor, successful design ideas can be realized.

Such a high-quality polished concrete surface looks simply because of the gray color, but because of the well-chosen white walls and furniture with black upholstery, the interior turned out to be very interesting.

Another example of a magnificent interior is a strict living room with a wall-imitation of masonry, to which a concrete sanded floor is ideal. This combination looks piquant and unusual.

Polished concrete floor will look great in the kitchen-dining room of the appropriate style. This may be the interior in the style of loft, industrial and even modern. Such rooms look aesthetically pleasing in the sense of design and sanitation, and also very original.

The process of grinding a concrete floor can be seen in this video.