Concrete floor on the ground in a private house: device and pouring rules

Flooring is one of the most important components of any room. Today, concrete bases are particularly popular. They are durable and practical, which allows them to be used in various types of houses. Concrete floor on the ground in a private house is perfect for many tasks. The design perfectly perceives the load, and also serves for a long time without losing its original qualities.

Special features

Concrete floors in a private house began to apply relatively recently. Previously it was thought that they were rather cold and could not provide the optimal level of insulation inside the room. But today they began to supplement the warm batteries for heating.

Technically, a concrete base can be poured on the ground even without some experience. Floors of this type are a conventional screed, which is located directly on the soil or a small cushion. And so that it can withstand high loads, its thickness exceeds 10 cm. This parameter can vary over a very wide range, since it depends on several factors.

Concrete perfectly passes moisture and temperature. Therefore, such surfaces should be used only in private houses that are heated in winter. If this structure is left in the cold, then sooner or later the water will simply break the material and cracks will appear. This will lead to the failure of the top decorative coating, which is also about to collapse after a certain time.

To exclude these phenomena, it is necessary to additionally form several layers of thermal insulation on all sides of the screed.

Advantages and disadvantages

The soil itself is a moving structure, which affects almost everything that is located on it. But concrete floors on the ground have Many advantages over other types of bases:

- Relatively low cost.You can form a tie at any time by simply preparing a mixture of materials available at any store.

- The surface after solidification does not require additional leveling or strengthening. It can easily be applied to the installation of decorative floor products.

- The material fits tightly to the soil, which eliminates the formation of fungus due to the absence of large amounts of air.

- Durability. Concrete surfaces last much longer than wood or the same reinforced concrete slabs.

But the floor on the ground does not have unique technical characteristics, as it has several disadvantages:

- After laying the layer of solution lost a significant amount of useful space. Sometimes this figure can reach 60 cm in height.

- The need to arrange high-quality waterproofing. This, in turn, affects not only financial costs, but also laboriousness of operations.

- Floors are not compatible with pillar and pile foundations. This approach does not allow to achieve high strength and protect the material from damage.

- If communication channels are located inside the screed, then repairing them will be expensive and labor-intensive.

Flooring requirements

Constructions of this type are an important building element. Therefore, several standards and rules have been developed for it. All these norms can be found in the SNiP 2.03.13-88 document. Concrete floors on the ground must meet the following regulatory requirements:

- Installation of the screed is possible only on soils that are stable and high density. It is not recommended to fill, when the soil can subside under the influence of groundwater or heavy precipitation. Soil before installation should be properly compacted.

- Application of bedding is possible only on rammed bases. Properly apply for such purposes sand or gravel. Their thickness is calculated based on the loads on the floor.

- If there are many capillary channels in the soil, it is advisable to lay waterproofing on top of the bedding. If this is not done, the moisture will rise up and destroy the lower layer of concrete in the living room. Such operations should be undertaken when the groundwater level is no deeper than 2–3 m.

- For non-heated non-residential premises is not applied insulation.If the house is planned to be heated, it is necessary to supplement the floor with a thick layer of insulating materials.

Device

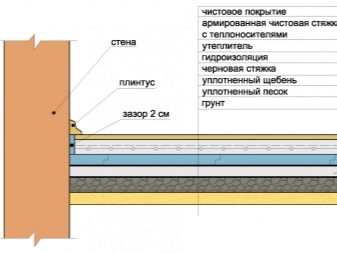

Concrete floor is a multi-layer construction. This structure allows you to provide the optimum ratio of strength and durability. This "pie" consists of such layers:

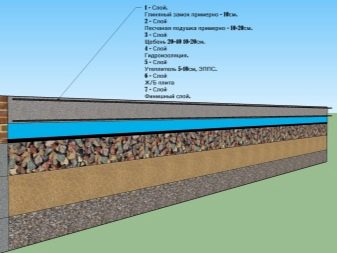

- backfilling. The bottom layer, which is the ground itself. Please note that the construction of the floor removes the sod, and in its place fill up the dense soil without admixtures of plants. It compresses with special vibrating machines.

- Litter. The main components of this layer is sand or crushed stone (complemented by a geotextile layer). The optimum material thickness after pressing is about 40 cm.

- Footing. This layer is a concrete screed, about 10 cm thick. It is protective and supporting, as well as additionally levels the base.

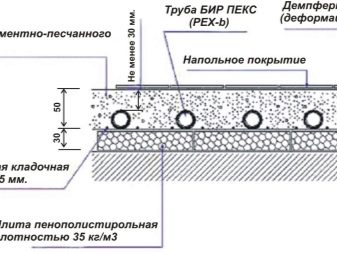

- Waterproofing layer and insulation. As a waterproofing, special polyethylene-based films are used, as well as liquid bitumen and others. The best insulation is polystyrene foam up to 10 cm.It is important to use only high density materials (EPPS and so on).

- Damper tape. It is placed around the perimeter of the foundation. It compensates for the expansion of the upper concrete layer.

- Upper screed. This layer is made of durable concrete, which is additionally reinforced with metal mesh. To prevent rapid cracking, so-called expansion joints are formed on the entire surface of the floor.

Please note that this structure of the concrete floor is not always used.

Some layers can be thrown out, and rubble, for example, can be replaced with expanded clay or another product.

Making a solution

The main component of the floor is concrete, which should be prepared. You can do it yourself at home. The manual mixture preparation algorithm consists of the following operations:

- Capacity preparation. Initially, you should find a metal bowl where the components will be mixed. Its volume is selected depending on your needs and speed of work.

- Mixing components To do this, determine the brand of concrete that you want to use.On the basis of these data, the ratio of all products in the future mixture is obtained. After that, they fall asleep in the bowl. To simplify mixing, you can lay out the components in layers. When everything is cooked, you need to thoroughly mix the sand and gravel mixture until a homogeneous mass.

- Receiving solution. This process involves adding water to the mixture. Pour the liquid gradually and in small portions. During this, the components are periodically mixed to a uniform liquid mass. Thickness is determined by eye. It is important that the solution is not too liquid, as it will diffuse.

Fill technology

The formation of a concrete floor on the ground is a rather complicated procedure, requiring compliance with the following sequence of actions:

- Firstly a rough base is being prepared. To do this, remove the top layer of soil, and in its place put a dense soil, which was obtained after digging the pit under the foundation. Try to completely remove the soil containing organic matter, as it eventually decays and proses. After leveling, this layer is necessarily compacted with a vibrating plate.

- At this stage, perform laying communications. These include pipes for water supply, which should be located directly on the ground. Distribution is carried out according to the layout, which takes into account the location of all household appliances connected to the centralized water supply. Many experts recommend hiding pipes down to no more than 1 m. During installation, it is important to constantly monitor the quality of the joining of the elements, since repairing them after pouring will be difficult to do yourself. Electrical cables can be laid in the same way if they are to be hidden inside the floor.

- When all communications are laid, perform laying litter. It will serve as a foundation for concrete. Its thickness is about 50 cm. Lay the gravel-sand mixture in layers (crushed stone, sand). It is important to compact the material with a vibrating plate after each layer placement. On top of the sand be sure to fill the screed with a thickness of 5 cm. It will act as a basis for waterproofing.

- Over the concrete floor special bitumen sheets are attached. In the joints, they must form an overlap of up to 15 cm. The material necessarily covers the foundation itself so that when concreting it is not necessary to correct the sheets. Over waterproofing stack layer of insulation.For this dense polystyrene foam is cut into sheets and evenly distributed on the surface. Try to minimize the size of the cracks in the joints of the polymer substance.

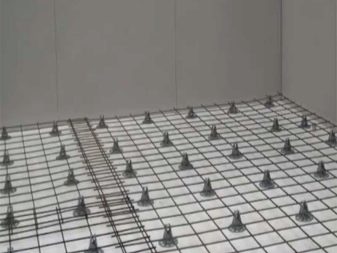

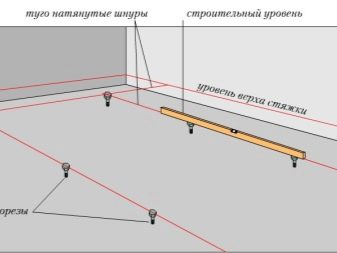

- At this stage, perform floor reinforcement using metal mesh. It is formed of reinforcement bars, which are interconnected with plastic clamps or metal wire. The cell size should be approximately 10x10 cm. The best option would be a reinforcement with a diameter of 4 mm, which perfectly perceives compression loads. If you do not use reinforcement, the floor will quickly crack and become unusable.

Please note that the lower part of the wire should not come into contact with the insulation. Therefore, the entire grid is raised above the surface using special plastic bosses. If inside the room it is planned to form a warm floor, then all the elements should be located directly on the fixture.

It is important that the cable does not overlap with itself, as this can lead to overheating and rapid failure.

- Concreting. This procedure begins with the installation of formwork. For this, all vertical supports are located only in the middle of the room.breaking it into zones. Do not attach them along the walls. Please note that it is not recommended to trim the grid. The wire should enter the formwork, in which it is necessary to make cuts under it along the entire length of the structure.

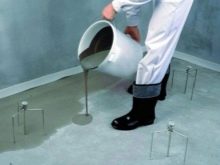

When everything is ready, fill the floor from scratch. Here it is important to carry out all at once to form a monolithic structure. The alignment of the screed takes place according to the previously installed beacons or relative to the marks on the walls. Before pouring it is necessary to fasten a damper tape along all the walls. It can be purchased at any hardware store or made from small pieces of polystyrene foam.

Finishing the floor only occurs after the concrete has completely dried. This period can last from 1 to 2 months depending on the thickness of the screed.

If desired, the surface can be sanded and get a quality base under the laminate or parquet.

Recommendations

The quality and durability of the concrete floor on the ground depends not only on the materials and production technology, but also on following a few simple rules:

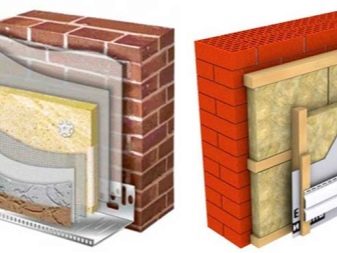

- Foundations from the outside must be warmed with ventilated or wet facades.This is necessary to minimize heat loss between the floor and the external environment.

- Do not install supporting walls on such bases. Under such structures, a separate foundation should be formed that will meet all regulatory requirements.

- If you plan to install on a concrete floor stairs or a fireplace, then its thickness should increase. An alternative option is the formation of separate bases for these structures.

- Do not use expanded clay on soils with high humidity, as the material absorbs water very well. In winter, this can lead to the destruction of its structure and subsidence of the substrate. In order to obtain an optimal layer of insulation with this substance, it must be laid with a thickness of at least 80 cm, which is not always possible in a private house.

- Fill should be a small parallel stripes. This will allow to better level the surface using manual rules. To achieve high strength, it is desirable to tamp the concrete with a vibrating rail.

- After laying the floor should be covered with plastic wrap. Thus, too fast evaporation of moisture is excluded,which may contribute to cracking of the material. If it is not possible to apply the film, then you can just pour the concrete with water periodically.

Arrangement of the concrete floor on the ground requires compliance with many rules and technologies. Thus, it is possible to achieve a high quality surface that can easily withstand heavy loads for a long time.

How to install a concrete floor in a private house with your own hands, see the following video.