Infrared warm floor: the pros and cons

Heated floor - a pleasant and useful device in the house. It is comfortable to walk barefoot in the cold season, it provides comfort in all rooms, including a children's room, where most games take place on the floor, and has a number of other advantages.

As practice shows, the infrared warm floor is optimal in many respects. However, it also has its pluses and minuses, which should be considered in detail.

What it is?

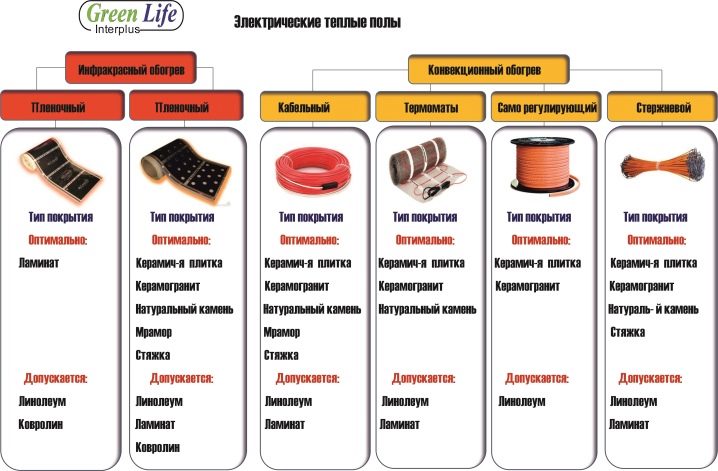

There are not so many types of heating systems for floor heating: water and electric floors. Electric, in turn, is divided into several more varieties (cable, on heating mats, infrared or infrared), of which the most modern and progressive is the infrared floor.

For the domestic market, infrared floor heating is a relative novelty. Not everyone appreciated it at its true worth, so there are many discrepancies in the information about the advantages, disadvantages and design of the system itself.

Foil floor is a system of heating elements of organic carbon origin and energy conductors, “packed” in a high-strength polymer film.

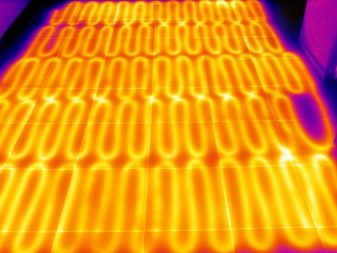

An important role here is played by the method of heating the floor surface. This is due to infrared radiation, in which carbon or graphite plates convert electrical energy.

Infrared radiation seems to many to be hazardous to health, because in nature its source is the sun, and in large doses it causes nausea, dizziness and rapid heartbeat. However, it is important to understand that the body is affected by short-wave high-power rays, which increase the temperature of the internal organs. Especially with the variability of the wavelength.

In a heating system based on infrared radiation, this problem is solved by the fact that the wavelength remains uniform and constant, it is identical to the long-wave infrared rays of the sun.They affect the body in a completely different way: they increase immunity, trigger the work of the renewal and regeneration mechanisms, and have a positive effect on the emotional state.

Heated floor is just a warm floor, one of the many advantages of living in an age of innovative technologies and amenities, and there is no good reason to neglect it, because with it you can make your home more comfortable.

Do not take this as a panacea and a powerful source of health and beauty.

Kinds

Infrared floor heating is of several varieties.

Rod

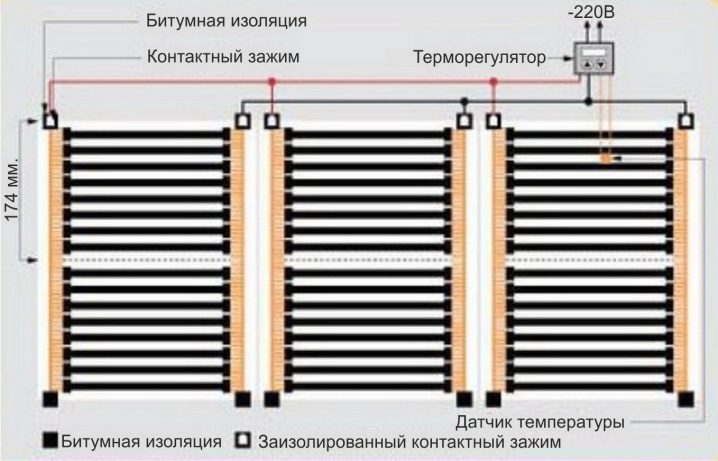

Such a system consists of narrow and long mats consisting of graphite-silver or carbon-silver heating rods in a copper sheath. The rods are arranged in a row at a short distance and are interconnected by stranded wires.

The modern market offers core IR systems in two variations: individual cables and rods that need to be properly assembled and soldered (cheaper than ready ones), and finished bays or coils.

Of the two existing types, this type of infrared floor is less perfect. \

When installing it is important to observe a number of nuances:

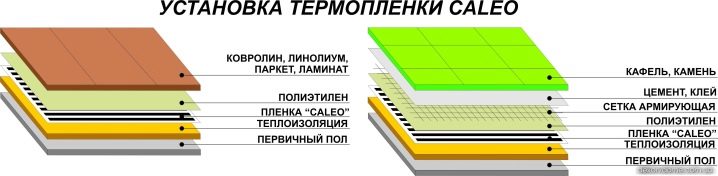

- In order for the system to work properly - for heating the floor, and not the ceiling of the neighbors below, - it is necessary to lay a substrate of heat-reflecting materials under it. Purchased separately from the floor.

- The mats are interconnected by hand using masking tape (test fastening).

- Mats can be located either close to each other, or at a short distance, but layering them is strictly prohibited.

- The presence of a thermostat is a must.

- When the system is mounted, it is connected to the mains and checked for operability. If everything is assembled correctly, elements of the thermal system are connected with a coupler.

- A protective thermal film is laid over the mats.

Film infrared floor

Unlike the rod type, this type of warm floor is represented by a continuous roll film, inside of which heating and silver panels are placed. The foil floor is quite large in size, but it comes with a marking with a small step, along which you can cut the film into fragments of any size.

The film floor in many ways surpasses the core one: it is mobile (it can be dismantled and moved to another room), it is easier to install, it has a self-regulating temperature setting mechanism.

Advantages and disadvantages

In favor of the infrared floor speak his dignity.

The comfortable temperature of the floor surface makes it possible to walk on it barefoot, without wearing warm socks and slippers. This is not only a pleasant sensation, but also a benefit: the shape of the foot is correctly formed from walking barefoot in etei, the general tone of the body rises, the skin of the foot remains healthy, without peeling.

Infrared floor is in many ways better than cable and water:

- It can be installed both in an apartment and in a private house, while it is forbidden to install water in an apartment building.

- The installation of the infrared floor is much simpler and faster, since the heating system is already mounted inside the film, and it remains only to lay under the flooring.

- The infrared floor does not take away a single extra centimeter from the height of the room, unlike the cable one, which “raises” the floor by 4-6 cm, and the water floor - by 10-20 cm.

- Even flexible cable is difficult to roll with very small pitch, and the modern IR floor is designed so that the heating elements are located close to each other or inside is a solid carbon plate, which contributes to the most uniform heat release.

- Such a system is more economical to maintain than a cable electric floor, as it does not require energy to heat metal screeds.

- The cost of the system, the necessary tools and installation is much lower than for cable and water systems.

- Unlike the water floor system, where the water heats up and cools slowly, the temperature of the infrared film system can be adjusted in a few seconds. This property is particularly beneficial floor for rooms that in the cold season for a long time left without owners, for example, for a country house or cottage.

- IR floor is easy to dismantle entirely and reinstall elsewhere.

- Infrared radiation ionizes the air and destroys harmful bacteria along with unpleasant odors.

- No risk of condensation.

- During operation of the system, only the heating of the floor surface occurs, and not the air in the room. As a result, the air does not dry out and it is easy to breathe in the room.

- There is no static electricity.

- Infrared film does not have to be used on the floor. She can warm the cold room from all sides, even on the ceiling.

- The heating and wiring systems inside are protected by a dense polymer film on top. If a large amount of water is accidentally spilled on the floor, it will not burn out.

- Heating elements function as separate sections of small dimensions. If one fails, the rest will continue to work. In this case, the floor will continue to heat up evenly.

- Infrared floor is able to replace the heater. At the same time heating of the room turns out as uniform as possible. Heat does not go up, does not form stuffiness in the room.

- In warm regions, an infrared floor with a heating temperature of up to 33 degrees can replace a centralized heating system. The maximum temperature of heating of many floor coverings is 30 degrees, while for comfort in the house is enough 25.

- Neutralizes the harm to health caused by cold surfaces in the bathroom or nursery. Manufacturers even claim that the infrared floor works the same way as the sun's rays work - by heating not the air, but objects, so it is not only not harmful, but also good for the tone and health of the body.

- The infrared floor is absolutely suitable for any type of flooring, whether it is tile, laminate or parquet.

It has infrared floor and some drawbacks:

- The system requires laying on the most even surface of the “rough” floor.

- There are several contacts in the infrared floor device, through which electric energy will flow, but not all of them work equally well, and the first time you can not get to the desired point. In this case, you will have to reconnect to another contact.

- The system of carbon heaters operates at 220 volts, which is potentially unsafe for health. The presence of grounding and an automatic system for shutting down electricity in the event of a malfunction exists, but nobody gives a 100% guarantee that they will work at the right moment.

- The service life of the system itself is quite long, but the sensors and temperature controllers do not differ in wear resistance. Their age limit is 7-10 years.

- The infrared floor is more economical than cable, but, nevertheless, it works on electricity and increases the cost of electricity. The more the tariff grows, the more expensive it will be to operate.

- Such a heating system is completely dependent on electricity. If it is disabled or interrupted, it will not work.

- The segmented structure of the heating system is a convenient and useful thing. Due to this design feature, the film can be cut, and the floor will continue to work if some fragments fail, however, these fragments can no longer be restored.If several sections in a row are damaged, they cannot be replaced, and the floor surface in this place will no longer heat up.

- On the floor with infrared heating system can not put furniture. There is a risk of overheating of the system in closed areas. The way out is to put furniture that relies on several points, but does not touch the floor with the entire lower surface, which does not always look harmonious in the interior.

- It is possible to lay such a system under a coating of any type, however, soft floor coverings (linoleum, carpet) must be protected from overheating using a sheet of hardboard or chipboard. The additional distance between the heating system and the flooring will degrade the thermal conductivity and reduce the value of the maximum floor heating temperature to 21-25 degrees.

Specifications

If the flooring is primarily chosen in appearance, the heating system is always hidden from view, and the most important selection criterion is technical specifications.

These include:

- The necessary power from the mains - from 220 to 230 volts, at an alternating current frequency of 50 Hz. This parameter characterizes the amount of electricity needed to operate the system.Measured in Volts, Watts and kilowatts per square meter per unit of time (1 hour). The minimum threshold is within 150 W / sq. m. For different film models, this figure can vary by 5-15%. The maximum threshold is 220 W / sq. m. Also, plus or minus up to 10%.

- Power consumption (power consumption). These are real indicators of daily energy consumption, which are ultimately reflected in the receipt for payment for electricity. Here the numbers are not so frightening - power ranges from 12 to 60 watts per hour per square meter.

- Speed of operation (heating). The film floor is fully heated to a temperature that is not set to the controller in 15-20 minutes.

- Maximum floor heating temperature or heating efficiency. This figure depends on the manufacturer. In some cases, the limit is 33, and in some - 60 degrees. The second option is not only doubtful, but not rational. Most floor coverings, even under a warm floor, are not designed for heating above 30-35 degrees. In addition, the higher the efficiency of heating, the greater the consumption of kilowatts and power consumption.

- The wavelength of infrared radiation is from 5 to 20 μm. This is an important indicator, because short waves adversely affect health.

- The melting point of the polymer film. Also depends on the manufacturer. The indicator varies in the range of 160-263 degrees.

- The basis of the heating system - carbon or graphite.

- The length and width of the film. The minimum width - 50-55cm, maximum - 1 meter with a thickness of less than 1 millimeter. The length of the sheet in a roll - up to 10 meters. It is important to remember that you do not need to cover the entire surface of the subfloor with film: the film will quickly fail in the places where the furniture is installed and near heating appliances. At 36 square meters. m is enough 26 square meters. m of film.

- Surface temperature of the floor above the film - up to 35 degrees.

- Producing country. Much depends on the features of production technologies, starting with how much electrical energy the system consumes, ending with the melting point.

- Life time with constant seasonal exploitation is not limited, but the possibility of breakage always exists.

Design

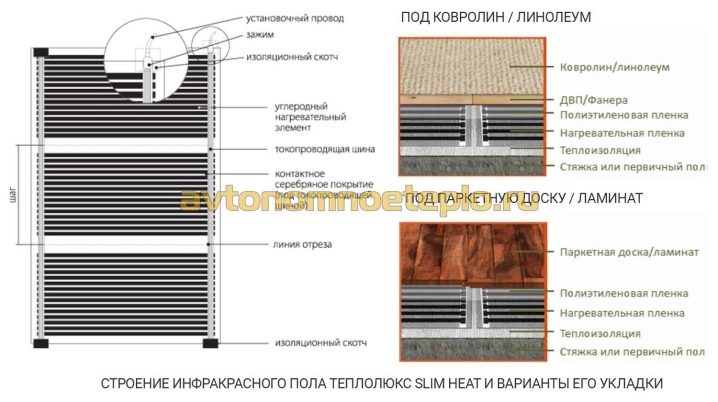

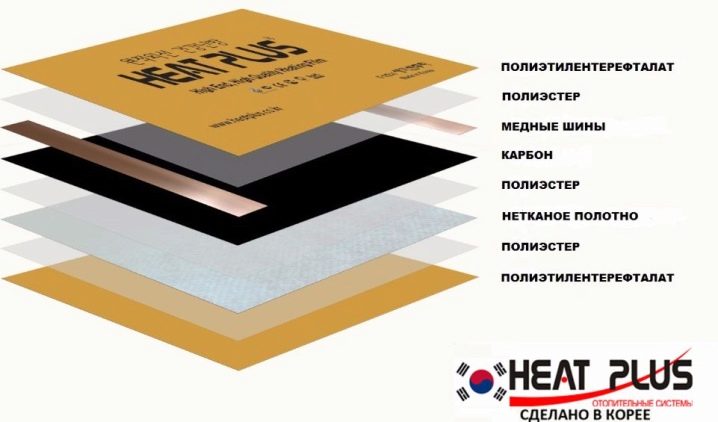

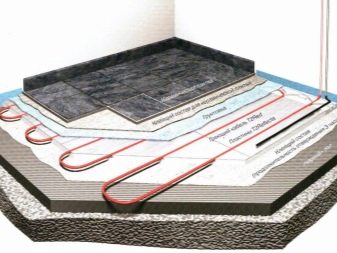

The unique properties of the infrared floor are provided by a competent combination of structural elements and the materials used. The film heat-insulated floor of the following elements consists.

Film base

It is at the same time a stabilizing and protective element of the structure, and, despite its minimal thickness, does an excellent job with its tasks.The base itself consists not only of polyethylene or polypropylene.

On top of it is a lavsan substrate (shielding film), widely used in technical and medical production.

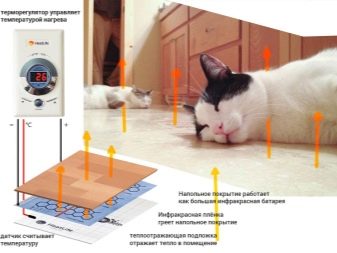

The reflective surface is necessary so that the heat does not go to the subfloor, but is transferred to the top. In places where the infrared film is not laid, a reflective film is needed to level the temperature difference.

This synthetic material has strength, elasticity, wear resistance, does not accumulate moisture and melts only at 260 degrees Celsius. A metallized coating or heat-reflecting layer is applied on a PET substrate with a thin layer.

Carbon bands or fibers

These are elements that heat up and generate heat with an efficiency of up to 98%. In the more modern models of infrared floor, the fragmented heating system is replaced by a continuous heat distribution plate.

Silver, copper or copper-silver tires

Thin metal strips in the design, according to which the electrical energy converted to heat is suitable for the heating elements.

These thin plates successfully replace the cable, and the entire thickness of the film floor becomes smaller,than one layer in the device cable electric floor heating.

Coating or laminating film

It is necessary to protect the entire structure from external influences. For example, from the ingress of water into the cracks between the fragments of the floor covering.

Such a film can be resistive. It is distinguished by better heating abilities, but the resistive film does not fit all floor coverings. For example, it is not combined with tile and porcelain, requires careful handling.

High temperature adhesive

It holds all the elements. The glue does not melt, does not flow when the carbon or graphite strips are heated, does not emit odor and toxic substances.

The entire infrared system consists of small area elements that function independently of each other. At damage of one site the system continues to work properly.

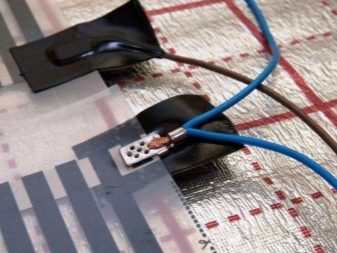

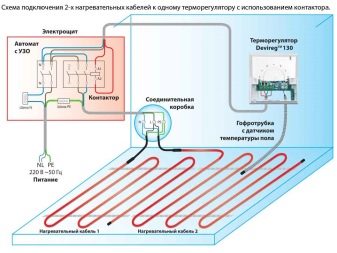

In addition to the film itself, a temperature sensor (a device that measures the temperature level) and a thermostat (a device that regulates and maintains the temperature at the right level) are included in the installation kit with a temperature controller. It may also include wires for supplying electrical energy, clips and clips for fastening wires and connecting several film fragments to each other.

Not all components are present in the kit, some must be purchased separately. So, the system can be with the sensor and without it, but the sensor is necessary to control the work, so it will have to be purchased separately.

In the absence of clips, bitumen insulation will be needed (this is adhesive roll material that is glued at the junction of the contacts and the insulation of the connection points).

Components of the kit vary depending on the condition of the subfloor and the finish. In some cases, additional light-reflecting and heat-reflecting film in the roll is needed to level the surface and ensure uniform heating of the floor. It is laid on the draft floor before laying the infrared film.

The topcoat determines whether thermal insulation is needed on top of the film that will protect the flooring and the infrared system itself from overheating. As a rule, insulation is required in cases where a non-rigid coating such as laminate and floorboard is used, but soft materials - linoleum, carpet.

The layer of insulation may be wooden. It simultaneously levels the surface for laying the finishing material and extends the life of the system and the floor.

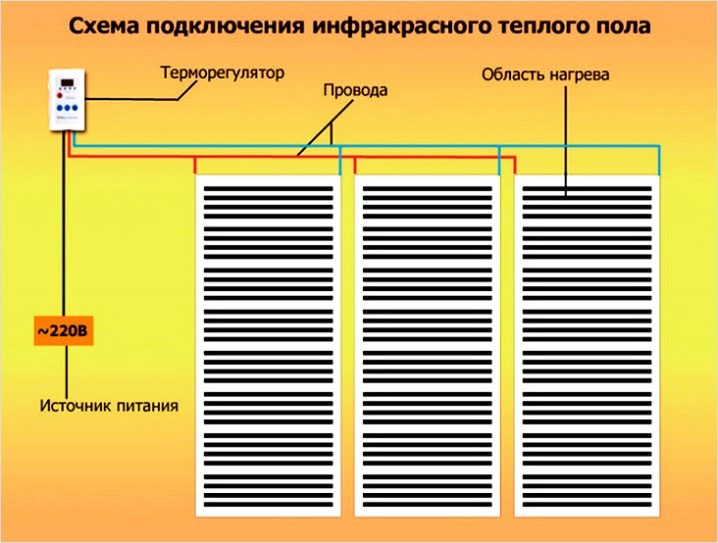

Principle of operation

The device works due to the fact that its design converts electrical energy into heat, uniformly heating the floor covering.

The heating process proceeds as follows: inside a sealed “package” of laminated fire-resistant and moisture-resistant polymers, using copper-silver or aluminum tires (strips), electrical energy is transferred to the heating elements, converted into heat, and infrared rays are heated by the principle of sun rays. not the air, but the object itself - the surface of the floor.

This principle of action leads to the fact that the floor quickly warms up to a comfortable temperature and does not overdry air.

This is not always beneficial in terms of the fact that centralized heating can be cheaper, but it is possible to adjust the level of heat in the house as needed and use the system at any time of the year.

Taking into account the fact that the maximum heating temperature is rather high, in those regions of the country where severe frosts do not rage, the warm film floor can work as the main heating.

Rating of manufacturers

The integrity and reliability of the manufacturer - a pledge of high quality goods.There are no unambiguous leaders in the production of infrared heat flooring on the market, but according to user feedback, conclusions can be drawn about firms that have proven themselves in practice over the last ten years:

Caleo

The South Korean manufacturer knows a lot about high-quality floor heating systems, because this country is the birthplace of the origin of the infrared floor and a guideline for other countries in terms of product quality.

Their advantage is the patented production technology, ease of installation of the finished product and satisfactory prices. The thickness of the film Caleo is less than 0.5 meters, and it can be laid even under linoleum without insulation.

Rehau

This company is a typical representative of a good and reliable product of German quality. Rehau infrared floor evenly distributes heat over the floor surface, has safety and durability guarantees, and is distinguished by a clear and simple product assembly system.

Ensto

The Finnish concern produces high-quality products that are suitable for use in a cold climate country. A separate line of FinMat is produced altogether, taking into account the climatic features of the regions of Russia, so they can be used in the most problematic areas.

Devi

Danish manufacturer - the standard of quality among imported products. Their products are characterized by high heat resistance; factories are regularly tested and updated in the technical process, many of which are aimed at reducing the level of energy consumed.

On the "smart" timer, which does not allow wasting electricity in vain, the company has a separate patent. Products suitable for almost all types of finishing floor.

Energy

Supplier of English products to the domestic market. Their products have gained popularity due to reliable components, the use of advanced technologies and environmentally friendly materials.

More than 20 years, the company maintains its policy - good quality at an affordable price.

Unimat

A serious South Korean competitor to many companies. Unimat specializes in the production of core infrared floor.

Its unique characteristics allow the system to be used for heating the surface in any operating conditions - in the bathroom, in the kitchen, on the street (verandas, attic), in the bath and sauna, and even in the pool. Warranty on products - 20 years.

Ceil hit

The only Spanish manufacturer in the top ten among the suppliers of warm floor to the domestic market.

The company has a rich, almost half a century history, during which it reached significant heights in the use of infrared heating systems.

It is popular in many countries, including South Korea, where the main forces for the production of infrared floor are concentrated.

Calorique

Not without American products. This company is focused on the production of film floor. With a thickness of just 0.3 millimeters, their infrared floor does its job by 5 points, while ensuring safety and long service life.

"Heatlux"

The leader among domestic producers of an electric heat-insulated floor. With a 25-year warranty on products, it differs with the relevant standard requirements and the most affordable price.

Spyhit

A Russian company that manufactures electric floor heating systems, and puts them on the market in a completely ready-made configuration for assembly. This greatly simplifies and speeds up the installation process, and saves finances.

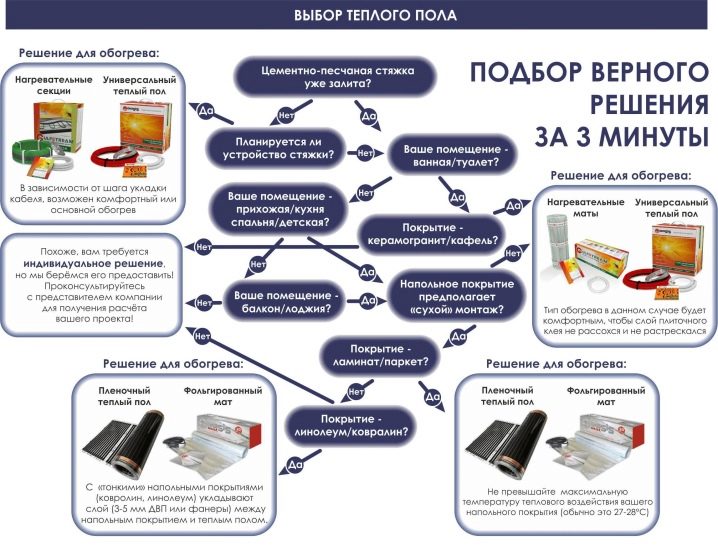

How to choose?

When choosing an infrared floor heating, it is important to consider three factors:

- type of room (in the bathroom, in the kitchen, in the living room or bedroom, in the children's room, on the balcony, in the loggia; in a private house, in the country or apartment);

- on which plane it will be located (on the floor, on the wall or on the ceiling);

- under what kind of finishing coating it is supposed to lay (under parquet, laminate, tile or porcelain, under wooden floor, under PVC tile, carpet or carpet, under quartzinil or PVC tile, under brick or wallpaper).

Depending on these conditions, experts recommend making a choice in favor of a self-regulating film or core floor. In different rooms in the house you can install different types of infrared floor heating.

By type of room

The type of room is important for choosing an infrared floor.

- Bathroom or bathroom. These rooms more than others need a warm floor, since for long-term use of finishing materials they use different types of tiles. Since under the tile more suitable rod infrared floor, it is worth stopping the choice on it, but at the same time carefully protect the system with a waterproof film with a high melting point.If water gets on the system, it will burn.

It is possible and necessary to install an infrared floor in them, it will fight against cold, damp, unpleasant smells and bacteria that actively reproduce in a humid environment.

- Kitchen. Here, too, the surfaces are easily washable and have little susceptibility to mechanical damage. In the case of a ceramic finishing coating, it is reasonable to choose a core floor, and film is more suitable for laminate or parquet.

- Living spaces. In children's rooms, living rooms, bedrooms, offices, the floor should be not only warm, but also as safe as possible. The most modern smart thermostats are equipped with film systems. In addition, they are easier to install and harder to damage.

- Cold rooms. When choosing the floor to balconies, loggias, verandas, it is worth making a start not from the type of floor, but from the characteristics given by the manufacturer. Since such rooms are located close to the street, heating systems must be distinguished by a high degree of heating.

The indicator for the balcony should be above 33 degrees, since there will be large heat losses in this room.

- Apartment. Here the decisive factor is the power of the system. For an apartment with centralized heating is enough 150-180 W / sq. m

- Private house, cottage, country cottage. Such rooms are usually larger and colder. Any type of floor, whose power is in the range of 200-230 W / sq. m

By type of surface

Consider how to choose the IR floor for different for different types of surfaces:

- Rough floor. Both options will be equally good. It is important to bear in mind that the surface should be as flat as possible, and the installation of a film floor is easier than a rod one. In addition, under the core type, an additional reflective surface will be required, and in the film type it is provided for in the design. In other words, here it is worth making a start only from its financial capabilities and technical characteristics of the product.

- Walls and ceiling. Clearly, a film floor is more suitable for them, since the core floor will take a little more space from the room volume, and it will be much more difficult to mount it on inclined and sheer surfaces. It is important to bear in mind that the finishing should not give weight to the IR film.

By type of finishing material

Consider how to choose the floor according to the type of final coverage.

Different types of tiles and porcelain tiles

Foil floor badly coexists with materials that are held on the adhesive compositions with alkali content. With regular temperature exposure, they can corrode the surface of the film and damage it.

Therefore, under the quartz vinyl tile and tiles, ceramics more suitable rod floor with good power. It is suitable for clean styling and for use as an adhesive tie.

For reliability, there should be a leveling and protective layer of small thickness between them, for example, MDF sheet;

Wood based coating

Features of the combination of infrared floor with wood floors, ranging from the floorboard and ending with different classes of laminate, are more related not to the device of the electric floor, but to the floor covering itself.

For easier installation, it is recommended to choose a film IR floor with a maximum heating temperature of up to 30 degrees.

But on the product for decoration there must be the following items:

- marking that allows laying the product on a warm electric floor;

- E1 emission class (minimum formaldehyde content per 100g of product weight);

- type of locking connection “click” or “lock” (the adhesive method is not suitable, since the glue will melt and the coating will “skew”).

Soft coatings

If the floor in the room is planned to be covered with carpet, covered with carpet or linoleum, in order to save installation time, you can choose a film floor. There is no big difference in this case, since the presence of a layer of fiberboard, chipboard or MDF between the heating system and soft coating is mandatory.

Firstly, it is necessary to ensure that the coating lies evenly, secondly, it protects the infrared floor from overheating under thick synthetic or natural fiber.

Efficiency

The advantage of a heat-insulated floor is checked for a long time in thousands of houses and apartments. Numerous reviews confirm that the infrared warm floor evenly heats the surface of the flooring and works without interruption.

It is also noted that dampness appears less frequently in the house, and unpleasant odors disappear in the kitchen and bathroom. However, the effectiveness of a heated floor as the sole source of heating is still a controversial issue.Today, even the infrared floor cannot cope with this task 100%.

The following video will show how to do the installation, installation and connection of the film floor.