Electric underfloor heating: advantages and disadvantages

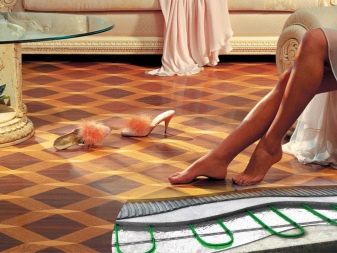

Electric underfloor heating has long been a fairly common household item in many apartments. Comfort, warmth, comfort and affordability are exactly the necessary qualities that make this practical device popular, and often simply indispensable in the house.

The correct choice of the product, verified installation greatly contribute to reliability, convenient and long-term operation.

Special features

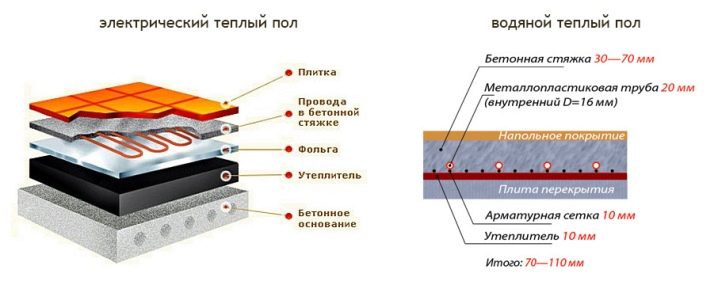

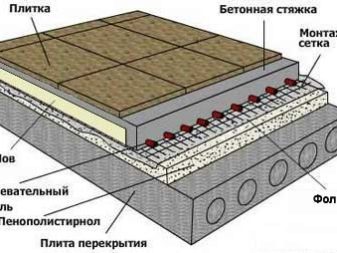

Electric underfloor heating (ETP) is a device with the simplest principle of operation: electric heating of the conductor leads to heating of the screed, which gives off heat to the final coating and then heat enters the space of the room.When using infrared film heating occurs by thermal radiation of the carbon layer that occurs under the action of electric current. Radiation heats the finish coating, as well as objects that are close to the floor.

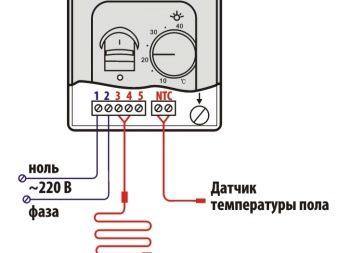

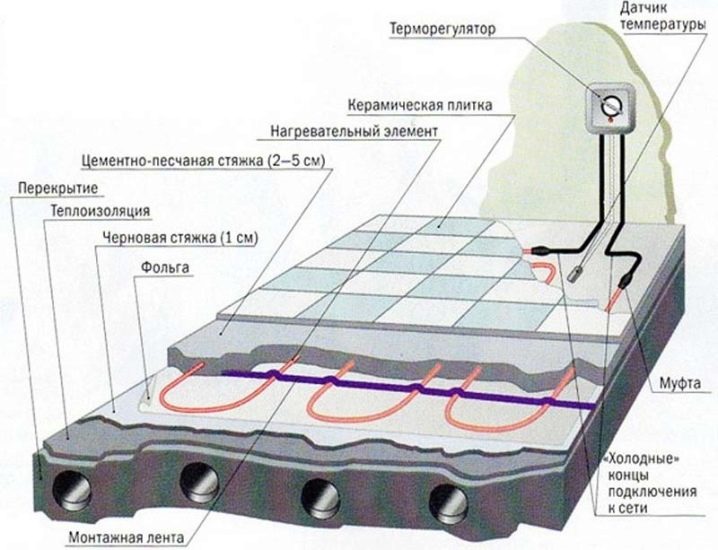

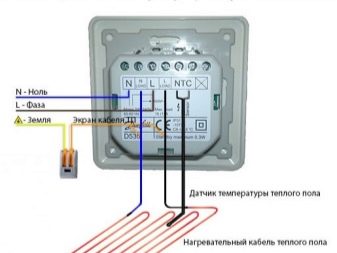

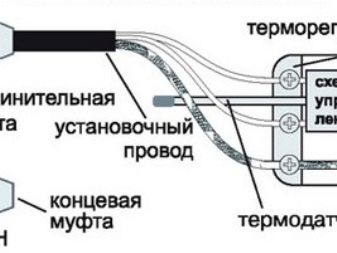

Further, as in the first case, the air is heated by convection in the room. Temperature control is implemented using a thermal sensor and a thermostat (thermostat) through which the device is connected.

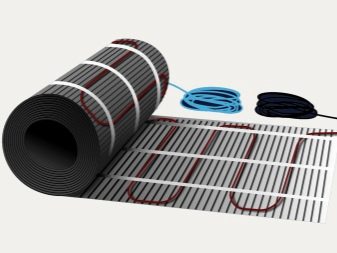

Structurally, ETP, corresponding to the principle of operation of the device in its typical version, is a heating cable embedded in a concrete screed or in a reinforced plastic mesh, sold in the form of ready-made mats. Usually this scheme in order to save electricity and to control the heating is supplied with simple devices.

Such a kit usually contains the following elements:

- Sections for heating, which, in essence, are parts of a cable of a certain length, having equipped mounting ends for power supply in the network;

- Installation tape that facilitates installation of the system;

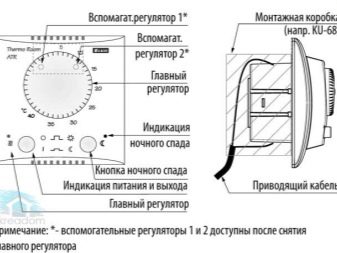

- Temperature controller (thermostat) with a control panel,determines the level of power supply to the elements depending on the level of their heating. The control panel may have several executive modules that are connected to the cable. In the program version it allows even the month of the year to be taken into account in the flexible regulations according to the specific climatic conditions

- Insulating material, which, performing the safety function, also reduces energy consumption, reducing the rate of cooling of the floor. Effective thermal insulation can save up to 30% of energy;

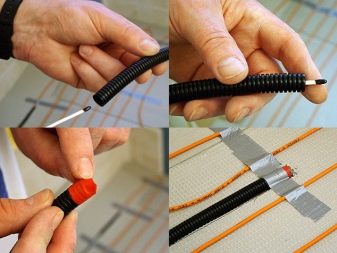

- The kit can be supplemented with a special protective corrugated tube for installing a temperature sensor.

Thus, the simplicity of the design and unpretentiousness in the care and operation - these are the main features that determine the high rating of the ETP among other methods of heating premises.

The features and partial advantages of these devices can also include the following inherent properties and qualities:

- Eliminate the possibility of water leakage;

- Relative simplicity during installation (depends on the model);

- The possibility of significant energy savings by adjusting the heating temperature using a thermostat;

- Autonomy of functioning and arbitrariness of switching on and off;

- ETP should be placed in open areas, because massive furniture helps to reduce free heat exchange, which can cause overheating and, as a result, equipment breakdowns;

- Among the disadvantages is the high cost of the device;

- Ease of use.

If we talk about the phenomenon of electromagnetic radiation, it is much less here than with other household appliances. Its level is almost 500 times less than the permissible WHO standard and is only 0.2 μT, that is, extremely small.

Advantages and disadvantages

Compared, for example, with water, an ETP by its characteristics is more practical and has marked advantages:

- Eliminates the possibility of flooding the neighbors;

- No need to coordinate the installation of the product with the appropriate authorities;

- Water heating involves laying a solid layer of screed, which is much thinner in the case of electric heating;

- It makes it easier and more accurate to set the desired temperature preferences, while adjusting the power consumption. The moderate temperature of the heating conductors is an advantagesince the electronic thermostat makes it possible to accurately, to a degree, set the required floor temperature, manually set the device on-off time;

- It is not required to install bulky stationary, mounted or built-in equipment (electric boiler or gas boiler), as in the case of water heating;

- The product is universally and effectively used in residential and office space;

- A properly installed device is more profitable, more durable and does not need annual maintenance;

- Laying such a floor does not require special tools and special skills, especially when used in mats;

- It can be freely installed in multi-storey buildings;

- The ETP is hidden, and therefore safe and saves space in rooms;

- It has a higher efficiency (due to the properties of electrical and thermal conductivity of the conductors used);

- In the presence of a tile coating that accumulates heat well, it provides significant energy savings;

- The variety of varieties produced by the production of ETP allows the buyer to make the most economical and suitable selection of a particular product, taking into account the peculiarities of the area configuration and apartment planning;

- In the sale often comes bundled (complete set or abbreviated), which may even include the necessary tools for installation.

In addition, it is important to bear in mind that this type of heating can be used as a baseline and as additional options that equally provide uniform heating of the floors and the choice of the optimal level of heating of the rooms.

At the same time, convectors (including their built-in versions or suspended on a wall), as a rule, are used as an additional heating option, without providing uniform heating and at the same time occupying part of the space.

Disadvantages:

- High energy costs for heating large areas (for example, in private homes). In these cases, you will need wiring, which will not overheat with a long supply of significant power values. In addition, proper grounding will be necessary, as well as the installation of a protective shutdown device (RCD) to increase the level of safety, especially in wet rooms, the risk of electric shock should be completely excluded;

- With significant power, the intensity of the radiation of the electromagnetic field is increased, which in fact can become far from harmless;

- Depending on the type of device and the method of its installation, for example, in a tie, when a cable is used, the height of the ceiling in a room can significantly, by 9-10 cm, decrease.

Regardless of certain shortcomings, the ETP is a very popular product, since its advantages, along with rather long service lives, make it practical and very convenient.

Cable

This method of heating has its long history and has been used in Europe for about 50 years. Many manufacturers offer a warranty of 7 to 15 years for these devices, and some claim a lifetime of up to 50 years.

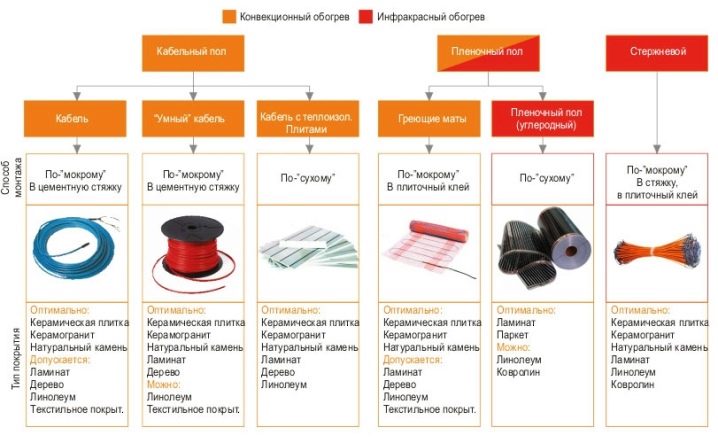

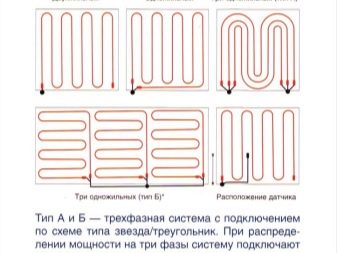

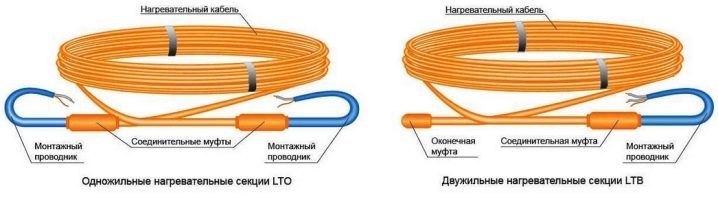

Cable heat-insulated floors are issued in two types:

- In cable bays of various lengths;

- In the form of mats.

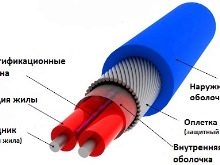

The following types of cable used in ETP systems are available:

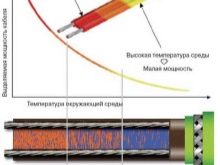

- resistive two-core or single-core;

- self-regulating (with variable resistance), in which the temperature adjustment occurs in certain places as it warms up, for example, in the case of massive furniture, heating will be less intense than at the window.

Thus, the main difference of this type of ETP is the use of resistive or self-regulating conductors.

Cable device:

- Usually equipped with a thermostat;

- Maintains temperature up to seventy degrees;

- It is laid in a cement screed with a thickness of about 40 mm. Therefore, the floors become 5–6 cm higher, which exerts excessive pressure on the floors. This must be borne in mind, especially if the apartment is located in a high-rise building.

Cable ETP provides known benefits:

- Uniform warming over the entire area;

- Fast warming immediately after switching on;

- The use of conventional thermostats, and even more so devices with programmable software, allows for significant energy savings;

- The possibility of regulating the laying period while maintaining the optimal level of heat transfer (in colder places (near the window), the conductor fits more closely than that of furniture).

Disadvantages:

- Certain energy consumption method;

- The complexity and complexity of self-installation in the screed;

- It is not safe to install in high-rise buildings.

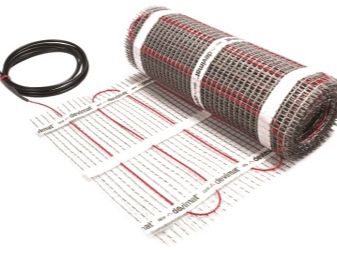

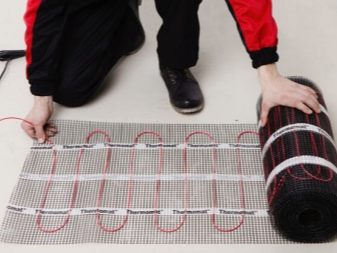

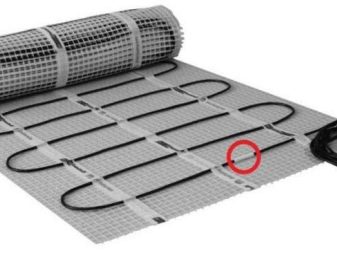

Heating mats

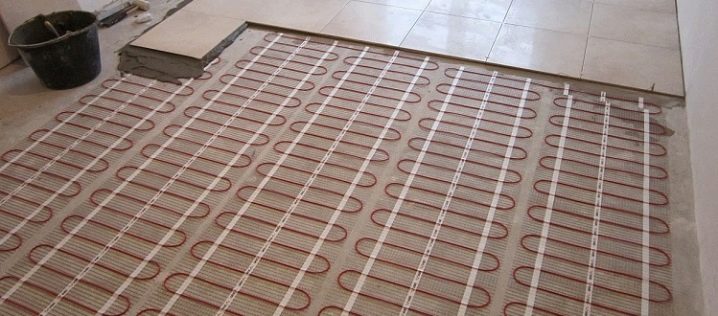

Mats are easy to use and their installation does not require additional calculations. They easily unfold, are located on the surface of the floor and are fixed with the help of special adhesive or screed.Structurally, such ETP consist of a special reinforced mesh, equipped with a thin conductor.

Features:

- The thickness of the conductor is not more than 3 mm;

- Have a strong shell that can withstand quite high temperatures;

- During installation, pre-laying of thermal insulation materials is required;

- Constructive variety of mats involves simple and cheap versions (for example, using fiberglass);

Benefits:

- Easy and simple installation;

- Fast heating area;

- Possibility of installation in high-rise buildings;

- The ability to conveniently change the thermal mode of the device.

Disadvantages:

- The cost is slightly higher than that of cable schemes;

- Not suitable for basic heating systems.

Film

Of all the electric underfloor heating, the infrared version is the only one that is “dry”, and therefore it is quite affordable for installation with your own hands. If the quality of the subfloor satisfies all the necessary conditions (the floor is even and clean), then it is quite possible to equip a room with average dimensions for a couple of days (depending on the type of flooring).Other types of ETP involve the installation of a screed or tile laid on special adhesive.

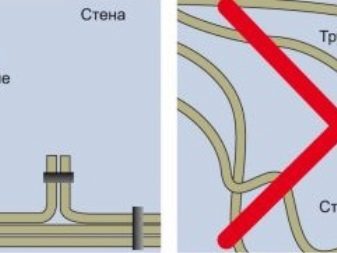

Infrared films enter the distribution network in widths of 50, 80 and 100 cm. The length varies from 0.70 m to 15 m in a roll. Rod mats - 0.82-0.83 m wide, and long rolls - from 1 m to 12 m. It is necessary to install film strips end-to-end or at intervals of 10-15 cm, overlapping the pieces is unacceptable.

The basis of this type of floor is an infrared film with embedded carbon fiber plates. This device implements one of the most productive heating schemes.

Features:

- Small thickness;

- When installing, a special fiberglass mesh with a mesh of up to 3 cm is additionally used;

- Heating is realized by heating the surface of the objects located close to them, which then give the resulting heat to the whole apartment, creating a pleasant microclimate in it without dry air;

- The device is able to withstand significant loads of both temperature and physical effects;

- If a separate heating line fails, the entire device does not lose its functionality, since the circuit elements are connected in parallel.

Benefits:

- Simplified installation algorithm;

- Fast heating area;

- Reliable performance;

- Universality;

- The lowest possible degree of electromagnetic interference.

Disadvantages:

- Increased cost;

- The need for a smooth and dense base when laying (plywood or drywall), which reduces the degree of heat transfer system.

Installation

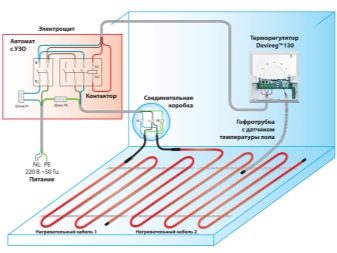

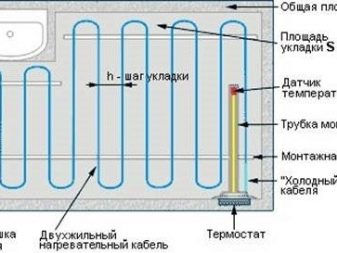

In general, the order of installation works includes the following main operations:

- Preparation (removal of cracks and irregularities) and cleaning the floor;

- Laying thermal insulation;

- The location of the mats on a pre-marked area;

- Thermal sensor connection;

- Installation of a temperature controller;

- Powering the product through an automatic circuit breaker (RCD);

- Connection of ETP parts in a single whole and control of reliability of contacts;

- Equipment screed.

At the end of the work, before turning on the device, it is necessary to sustain a time interval of at least thirty days until the screed is finally ready.

The outlined installation sequence is universal and can be guided with minor amendments in working with any type of ETP.

Preparatory measures should include mandatory verification of all parameters of the scheme, as well as control over compliance with the following rules:

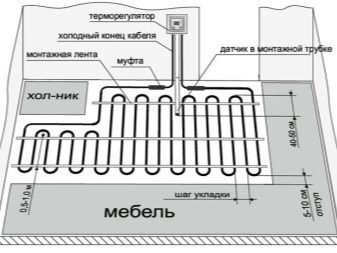

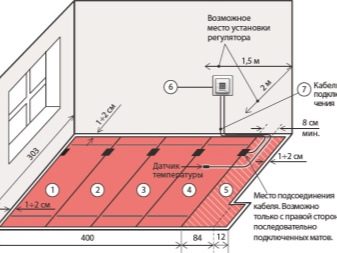

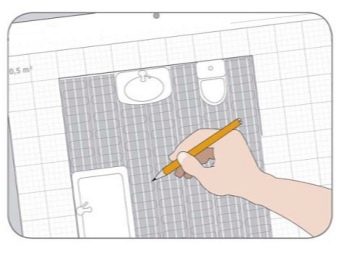

- Installation of the device is carried out on open areas where massive pieces of furniture are not located. The area of its installation should be about 70% of the total area of the room;

- With the basic version of the installation, the specific power of heating should be in the range of 130-150 W per m2 (for an additional option, the power is somewhat less);

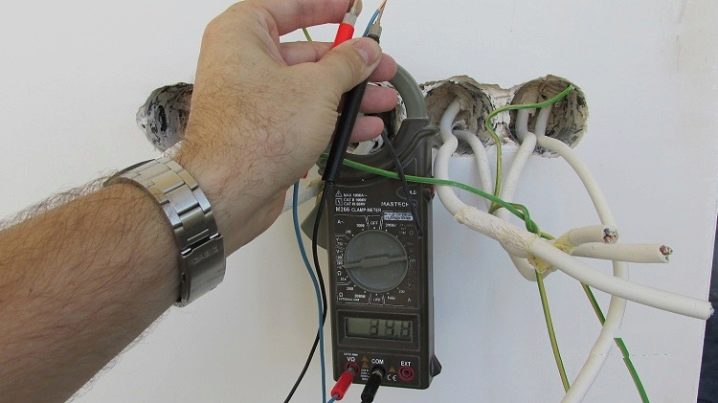

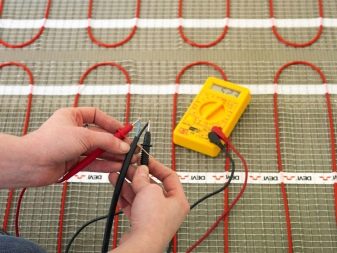

- Special devices are prepared for the devices. The complete completion of the work must be preceded by a control check of the circuit by the tester and its adjustment carried out in accordance with the instruction manual for the ETP.

Depending on the type of device, the content of the installation is different only in details, but the stages of its implementation are basically the same.

Design stage

The instruction manual establishes a number of rules relating to the design and installation stages of an ETP:

- The installation of the heating conductor under massive pieces of furniture is not carried out because of the appearance of excessive pressure on the device, which interferes with the proper air circulation at the installation site and can lead to overloads and the occurrence of failures;

- Proper installation of the conductor is carried out at a distance of about 150-200 mm from the walls.In this case, the inter-turn space should be at least 100 mm;

- The thermostat is installed at a height of 1 meter from the floor.

Thermal insulation selection stage

The type of insulation, and its dimensions are selected based on the current state of the floors and places of the intended installation:

- A thick layer of thermal insulation (20-100 mm) is usually used over rooms without heating, cold basements, on loggias and balcony structures. Apply canvas foam or polystyrene;

- A thinner layer is placed on the previously prepared surface. For this purpose, foil-coated penofol is used, which lies on the reflecting surface upwards so that it directs the heat flux into the room;

- The thicker the layer of insulation, the greater the distance of its placement from the wall. Styrofoam is placed at a distance of about 100 mm, for penofol this distance is about 50 mm. At the points where the insulation is adjacent to the walls, a special damping tape is installed to compensate for temperature changes in the dimensions of the material under the influence of heating or cooling.

Foundation preparation phase

Includes leveling irregularities and cracks in the floor and general cleaning.With a clearly uneven surface, a cement screed is made or other technologies are applied. It is important to remember that laying the cable on wooden floors increases the level of heat loss. Also, the wall is broken down for wiring.

Installation stage

For accurate operation of the sensor it is placed at a distance of 300-400 mm from the lower edge of the wall, between the turns of the conductor. Devices (sensor, thermostat) are located in the corrugation, which should not be bent.

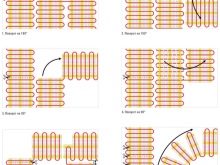

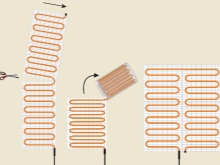

The content and sequence of laying the conductor and the mats are different:

- First of all, measure the resistance of the cable. Then the special tape is fastened on the floor with ready-made fasteners that simplify the procedure, or a plastic clamp and a metal mesh pre-placed on the floor are used, to which the fastener is made. The second method is more common because it adds extra rigidity to the structure. The conductor is placed 150-200 mm from the wall;

- Easier to fit the heating mats. Placing them on the floor, measure their resistance. Then, in the process of laying the dimensions of the mats are precisely trimmed. The distance between sections is left at the rate of 50-100 mm.

- The tester measures the resistance of the product.Discrepancies with the data on the passport should not exceed 10%.

Screed performance

Its thickness includes the diameter of the conductor and is:

- for cable products - 30-50 mm;

- for heating mats - about 30 mm.

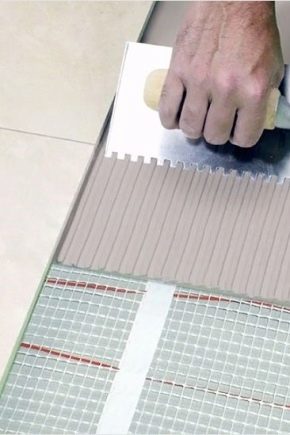

A faster and more practical way to screed is the use of tile adhesives.

Stage laying flooring

If the coating is a tile, then the feature of its installation is the use of a special adhesive mixture, designed to work with a warm base (it has the accepted marking). Apply glue gently with a spatula. After about 20-26 hours, you can begin to grout the joints. To start operation only after complete drying of the adhesive. Laying the solution on the mat, you should avoid the formation of "airbags" that contribute to overheating of the conductor.

For safety reasons, select heating parts in a reliable protective sheath and connect the ground. Modern ETP necessarily equipped with a protective sheath, which is then connected to the appropriate ground terminal on the shield. If there is none, then a metal mesh is placed on top of the conductor,which, after connection, is connected to the corresponding protective bus.

This design will also add extra rigidity to the entire device. If the ETP is placed in a private house, then a separate circuit must be equipped for it.

How much electricity is consumed?

In apartments of multi-storey buildings ETP floor is preferable to use. The choice of heater design depends on the type of coating, as well as the parameters and conditions of the dwelling. At the same time one of the main selection criteria is the power of the device. The correct calculation, reliable, leak-free heat insulation of the house and the floor, as well as proper use of the thermoregulation capabilities provided for by the specific design of the ETP, contribute to the reduction of energy costs.

The main factors that affect the level of electricity consumption ETP are:

- Features of the climatic conditions of the place of residence;

- The materials of which the house is made (the coefficients of their thermal conductivity are different: wood - 0.1-0.2, brick - 0.35-0.7, foam concrete - 0.1-0.3). The level of thermal conductivity of the main building material with the laying of insulation (mineral wool, PPP) varies.Calculation of the dimensions of the insulating layer is made taking into account the peculiarities of regional climatic conditions. Warming is one of the significant factors in the productive work of an ETP;

- The quality of insulation of window and door frames;

- Reliability of ventilation channels;

- The quality of floor insulation. Under the conductor or the mat must be insulation and reflective material (foil);

- Flooring properties;

- The volume of energy used by the ETP also depends on the person: the mode of tenants' stay in the room, their temperature preferences;

- Characteristics of the thermostat.

The calculation of the total power is based on the actually heated area, which is only a fraction of the total area of the room, since it does not include the size of the furniture located in the apartment, large-sized equipment and sanitary equipment. The remaining area and will be actually heated.

Before carrying out calculations of power, it is important to determine the option of heating - basic or additional. ETP manufacturer usually marks the power in the product data sheet. Typically, the value of the comfort level of power ETP (cable or mat) is 120-140 W / m2.For infrared film ETP - about 150 W / m2.

If the heating of ETP is assumed in the basic version, then for the heating conductor or the mat the maximum value will be 160-180 W / m2, and for the infrared version - 220 W / m2.

The calculation procedure is simple: the recommended power rating is multiplied by the actually heated footage (excluding the space under the furniture). 30-70% is subtracted from the obtained value (depending on the thermostat supplied). The power of each individual heating circuit is calculated separately.

For cable ETP indicates the total capacity and power per linear meter. The power density of cable mats is usually from 100 to 160 watts / m2 (less often up to 200). At the infrared ETP - from 130 to 230 watts / m2. Rod mats typically have a power factor of 130 to 160 watts / m2.

It is important to consider that the specific power is different for different rooms:

- for the bedroom - from 110 to 150 watts / m2;

- for the bathroom - from 140 to 150 watts / m2;

- for loggias (glazed) - from 140 to 180 watts / m2.

Calculation for example. In a room of 14 m2, the actual heated area will be about 9.8 m2 (70% of the total area). With an ETP power of 150 W / m2, the flow rate will be 150 • 9.8 = 1470 W. For a typical daily consumption of 6 hours, the consumption of electricity per month will be 6 • 1.47 • 30 = 264.6 kW • h.At a price of a kilowatt / hour of 3 rubles (depending on the region), the cost of an ETP will amount to 264.6 rubles • 3 = 793.8 rubles. By setting the program thermostat to the economical mode, the level of energy consumption, you can reduce this figure by 30-40%.

The calculation of ETP power is made with a margin. The actual average annual calculation result, taking into account the warm season, will show a smaller value.

It is easy to check the power consumption in real time, using the meter readings when other electrical appliances are disconnected.

Temperature control

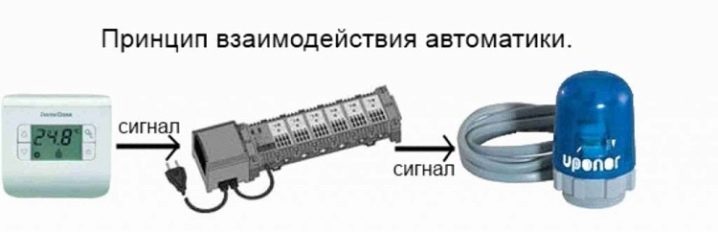

A simple thermostat has the function of maintaining the desired temperature in the room. If the set values are exceeded, the regulator turns off the power supply, and the heating function resumes when it cools. More complex are programmable thermostats, allowing you to set the desired heating algorithm. Some models have several standard programs, taking into account the time of day, as well as weekends or working days. This device fixes signals from a temperature sensor and regulates the flow of electricity to a cable or film.

Thermostats (thermostats) are available in two types: mortise and overhead.The first are easily installed in the wiring box. Invoices are usually installed in premises for heating equipment or, together with the RCD, are packed in a special cabinet.

Type of thermostat - the current moment in energy savings. Professionals believe that even the most expensive thermostat, controlled through a computer, can pay off in one heating season.

On average, this device operates at its highest capacity for about 15 minutes per hour and then operates in the maintenance mode. Automatic models work according to the settings. The more functional the thermostat is, the more accurate and economical is the operation of the system as a whole. The operation of the temperature controller in the manual control mode allows you to save up to 30% of energy; in automatic - up to 70%.

Thermostat models are extremely convenient and useful; they automatically turn the heating process on and off according to the time of day and according to the situation (they turn off at night, while the tenants leave, by heating to a specific temperature).

Common mistakes

The overwhelming number of faults in the ETP have their reasons for errors during installation or damage to the conductor during its installation or after it.

ETP is successfully used in different types of premises - in a high-rise or private house, bathhouses or loggias, and so on. It is used as a basic method of heating, and as a minor.

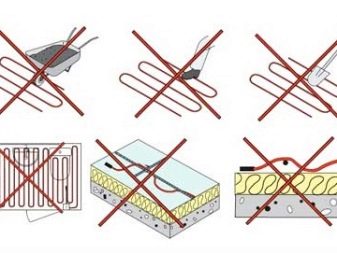

It is important to correctly select the power of the system, to ensure proper thermal insulation, and during installation do not make the following fairly common mistakes:

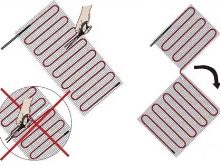

- Laying ETP under heavy furniture and appliances. The lack of cooling of the floors causes the conductor to burn out;

- The bends or overlaps of the wires also lead to faults in the conductor or insulation, and therefore to a breakdown of the device. When using the infrared type ETP, damage to the heating film should be avoided;

- Lack of control over insulation resistance at various stages of installation work, and especially before laying cement or other screed. Possible deviations of the indicator should be within 10% of the nominal. If significant discrepancies are found, the work must be stopped and thereafter, after determining the insulation damage, rectify the fault and resume work;

- Mounting infrared ETP, often do not make the insulation of current-carrying fragments in the sections of the film cut, which entails fixing leakage current by the devices and turning off the power;

- Installation of the device under weighty furniture or permanently located household items of considerable dimensions. Installing an ETP in these places is both meaningless and fraught with product breakdowns;

- It is necessary to buy a cable that is optimal for its installation length, since two-conductor shielded conductors,

- Used in most ETP, can not be cut, it can lead to damage to the conductor. In other words, cutting the conductor at the place of its use is not recommended;

- Turning on the conductor to check its serviceability until laying and drying of the screed. Even short-term inclusion can cause breakage. Much more convenient conductor is checked by measuring its resistance;

- Laying conductor (mat) on unprepared (contaminated and dusty) basis. To clean it is convenient to use a powerful vacuum cleaner and primer;

- It is strictly unacceptable to put the sensor in the solution. It is more correct to place it in a solid corrugation without holes, where the solution cannot enter. Its excessive kink is also unacceptable. Failures of temperature devices occur, and for their repair they should be easily removed from the installation sites;

- It is advisable to sketch the layout of the ETP with the markings and landmarks. You can just take a picture of the conductor. This will help to avoid damage to the device when carrying out possible repairs in the area of the floor in the future;

- It is important to avoid the appearance of air bubbles in the “hot” part of the conductor, which is especially dangerous when laying a “thin” ETP in an adhesive composition. By negligence, such an error leads to the imminent failure of the conductor;

- Turning on the device immediately after installation for “quick” drying of the screed causes damage to the conductor. It is necessary to withstand a considerable time interval.

Which to choose?

Some additional general and private information about electrical heating devices will be useful and will certainly help to make the right choice.

Often ETPs are sold in sets containing a sufficient set of components required for installation, and sometimes even tools. In order to save money when installing their own hands, the components are selected at the discretion of the buyer.

Conductors are produced in two versions - single-core and two-core.The first one is not quite convenient to install due to the fact that the necessity of its application is the need to loop the heating circuit (the ends are output to the junction box).

Functioning in a resistive scheme, like a regular spiral, they heat throughout their length, and this greatly reduces the efficiency of the system, extending the heating time and complicating the adjustment process.

The stranded conductor of one core works in a resistive circuit, while the other closes the circuit with a special end coupling. Experts believe that for bedrooms and children it is more expedient to choose the use of a mat with two-core conductor. For the bathroom is quite suitable mat with a single cable.

In self-regulating conductors, heating occurs during the passage of electricity through a semiconductor matrix, the conductivity of which decreases during heating, which leads to a drop in energy consumption. In this case, self-regulation occurs on all sections of the cable; for this reason, cold places get warmer. Such a conductor can be cut, carrying out the necessary adjustment in length (there is a cutting step of 25 and 50 cm).

The main drawback of the cable version is the thickness (up to 8 mm), so they require complicated mounting of the fill, at which the height of the room decreases.

For this reason, in the case of self-assembly, experts recommend heating mats. At the same time, the cost of the device is reduced by about 30%. The version with mats is simpler both in calculations and in installation.

For comfortable operation of the ETP, a programmer is included in its scheme, which ensures the uniform heating of open spaces, as well as the necessary reduction of temperature in closed areas. The programmer will protect the circuit from overheating, reduce energy consumption and significantly extend the life of the device.

Far from the last important criterion of choice is a manufacturer with a good rating, reviews and recommendations of experts. It is possible that in such cases the cost of an ETP will be higher, but the quality and service life will be much longer.

Today, the top six foreign manufacturers of ETP include:

- Firm Devi from Denmark. Its devices today are the benchmark of quality, which is valid for 20 years.Control multitasting of the final product (three stages). Products of this company are reliable and at prices lower than those of other foreign firms;

- The largest Finnish corporation Ensto. Thin conductors and mats of this brand (FinnMat), manufactured for our market, are manufactured taking into account all the features of climatic conditions and operating traditions;

- British company Energy. Including has in its assortment a two-wire photopolymer conductor that can be used in conditions of high humidity;

- Norwegian firm Nexans, which produces the widest range of products, is known for its innovations. The ETP of this company is popular in our market, especially the jointless coupling is highly valued, which allows using the program thermostat to control the temperature in the apartment;

- Spanish firm Ceil Hit. In the list of its products - heating conductors, mats, sets of equipment and equipment for ETP. Products developed by the company are versatile and reliable;

- German company Eltherm. Products of this company have many positive reviews around the world. The company's products are reliable, durable and functional, and the cost of its products is low, which ensured the popularity of its products on the Russian market.In the list of products of the company there are not only ETP of the most varied target purposes, but also anti-freezing protective systems and devices for maintaining the optimum temperature of pipelines.

From Russian firms producing ETP, have a high rating:

- "Heatlux" - GC "Special Systems and Technologies" - the leader of the domestic production of ETP. Produces ultrathin heating systems. Infrared film floors from this company are available in 0.34 mm thick, 2 types - with a capacity of 150 and 220 W / m², intended for heating from 1 to 10 m². The peculiarity of the company is the widest list of models and their modifications, which allows you to choose a variety of ETP options for any coverage and premises of non-standard configurations.

A variety of constructive ideas, high technologies in production allow the company to export products to more than 40 countries of the world and successfully introduce such innovations as ultrathin ETP.

- Firm "National Comfort" (sister company "Teplolux"). Her products are reliable and of high quality. Prices are reasonable. Exports products to more than 40 countries of the world;

- LLC Chuvashteplokabel. Applies advanced developments of leading European companies. Using high-quality local raw materials, produces devices at low prices. By the criterion of correlation in the quality-cost dyad in our market is in the lead;

- The company "Spayhit" - one of the most successful Russian manufacturers of ETP. Produces cable products, mats and types of instrumentation. Supporter of integrated housing solutions. In the sold kits includes everything you need for installation.

Ultra-thin ETP is one of the practical and successful modern developments and innovations that are widely used today both abroad and in Russia.

Such ultra-thin floors are superior to traditional schemes in several ways:

- They are made in the form of mats and installed without “wet” procedures that require considerable time;

- Keep the same floor level;

- Their installation does not require possession of professional skills. Reliable in operation, and when a fragment of a device fails, it simply changes;

- At its total cost, an ultrathin floor costs the cost of an ordinary ETP.(if the cost of installation, including the cost of a coupler, is added to the cost of conventional equipment, the total cost is approximately equal to the cost of a super-thin system). At the same time we get a clear gain in quality and reliability;

- The ultrathin device is not afraid of overheating, because it uses fluoroplastic, which creates an adequate margin of safety in these cases;

- The use of ultra-thin ETP possible up to the immediate and final laying of the floor covering.

- Ultra-thin ETP are universal, comfortable and safe both during installation and during their operation.

Laying ETP under carpet or carpet, and these are materials with high thermal insulation parameters, has its own characteristics:

- Under the heating conductor, on the “rough” floor, it is advisable to spread a sheet of foiled film;

- The preferred temperature set on the thermostat should not exceed 30 degrees. In this case, the floors will warm up gradually;

- Since carpet products quickly overheat and become unusable, especially in areas where furniture legs are located, ordinary conductors are installed in a screed or in a solid layer of self-leveling mastic.For “dry” installation, when using infrared ETP or a conductor on a mounting plate, the heating conductor is placed only where there is no furniture.

In a wooden house, as an option for laying ETP under the carpet, the heating conductor "Alumia" of the company "Teplolux", which is designed for "dry" installation, is perfect. The Alumia system is mobile. Also, Devidry 100 mats are convenient for such a house (it has remarkable sound-proof qualities), which are installed without filling in lags.

On the balcony (loggia) it is more profitable to use heating conductors. The thickness of the screed will be approximately 45 mm. Inside this structure does not accumulate air, but because it serves for a long time and does not overheat.

In this video you will find a video tutorial on the process of laying ETP.