Pros and cons of electric floor heating under the tile

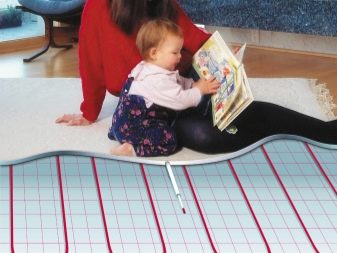

Ceramic tiles - one of the most popular types of flooring today. Its wide prevalence is due to the high level of strength, wear resistance, moisture resistance, heat resistance, ease of maintenance, in addition, the tile is hygienic and very diverse in colors and shades. Technology and installation features allow you to successfully use it in bathrooms. However, the tile surface is cold and requires special heating. That is why under the ceramic coating is very convenient to apply electric heating.

Special features

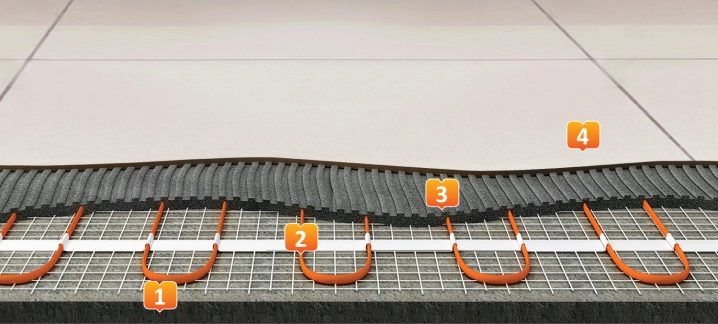

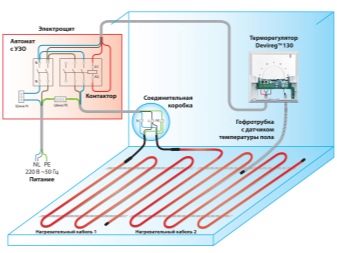

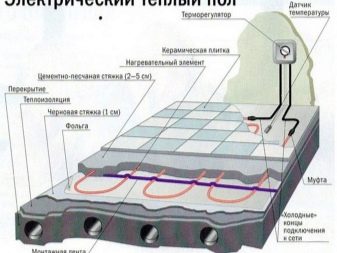

The main element of an electrically heated floor is a heating cable, mounted in a screed of concrete or sold in the form of ready-made mats.It is possible to control the operating modes of such a floor using thermostats that set the required temperature. Such is the basic functional diagram of the operation of this device.

Electric floor heating:

- eliminates leakage and does not require pipe cleaning;

- relatively simple to install;

- energy costs can be quite reduced by adjusting the temperature with thermostats;

- the operation of such a heater is autonomous and does not depend on the central heating system, it can be turned on and off at any time;

- Underfloor heating should be placed in open areas, furniture can reduce free heat transfer and cause overheating, which will lead to system failure.

- relatively high cost;

- safety and ease of use;

- creates a particularly comfortable environment in the bathroom.

In addition, the tile coating itself is able to accumulate heat, which saves utility bills.

It is important to note that in the technical and medical literature, the topic of the influence of electromagnetic radiation on human health has been discussed for a long time. Such radiation from warm floors is minimal compared to radiation from other household devices,since it is about 500 times lower than the permissible standard of the World Health Organization - 0.2 μT. In other words, in this case, this effect is almost nil.

These features mainly explain the high rating of electrical heating circuits.

Advantages and disadvantages

Any heating system has its pros and cons. If we compare the electric variant of floor heating with water, then the first one has clear advantages:

- electric heating is safer in the sense of a possible bay of neighbors;

- there is no need to coordinate its installation with the supplier of heat energy;

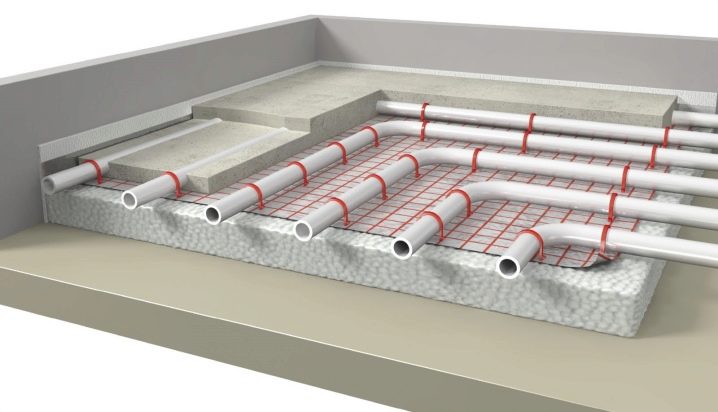

- Installation of water devices requires an impressive layer of screed, which, being an additional load on the floor, also reduces the height of the ceiling. With electric heating, the required fill layer is substantially less;

- In this variant, it is easier and more accurate to establish optimal temperature conditions of operation (practically up to one degree). In this case, the product consumes less electricity;

- a properly designed and installed system can last for decades without repair and does not require annual maintenance;

- possibility of installation in high-rise buildings;

- the electrical system is completely hidden from the eyes, and therefore there is no possibility of getting burns or injuries. In addition, it is more aesthetic and saves more space in the room;

- heating with a heated floor does not dry out the air;

- there are no heat leaks, which means higher efficiency;

- tile floor itself accumulates heat, which gives a good effect in terms of financial payments;

- The variety of existing types of underfloor heating ensures the optimal choice of system for a particular type of room

Electric floors are used as a basic heating system, and as an additional.

In any form they provide: uniform heating of the floors, the optimum temperature throughout the space of the room, and the emerging ascending convection currents preclude the formation of drafts.

Disadvantages:

- High installation cost.

Types of heating systems

Depending on the configuration, methods of installation and design features, heating systems are divided into cable, infrared, which, in turn, include types - film, rod, as well as special mats.Each type of warm floor has both its advantages and disadvantages.

The defining characteristic of a cable is the use of a resistive or self-regulating conductor. Resistive conductor is performed in two versions - single-core and two-core.

Its features are:

- It can be equipped with a thermostat. The self-regulating cable provides for the temperature adjustment of the place in the room, for example, in the area where the furniture is located, heating will be less than in the area of windows or doors;

- Able to heat up to 70 degrees;

- It is laid in a concrete screed with a thickness of about 4 cm. Therefore, for example, the floors in the bathroom are raised by 5–6 cm, which additionally loads floors. This is important to consider when it comes to multi-storey building.

In this case, the cable version has the following advantages:

- uniform distribution of heating throughout the area;

- high heating rate after switching on the system;

- the use of software or conventional thermostats;

- the ability to adjust the laying step, while maintaining the optimal level of heat transfer. So, in cooler places (near the window) the cable is laid more tightly than near the furniture.

Disadvantages:

- significant energy costs;

- the complexity of self-assembly;

- Installation of this system in multi-storey buildings is not recommended.

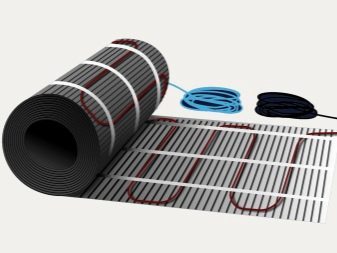

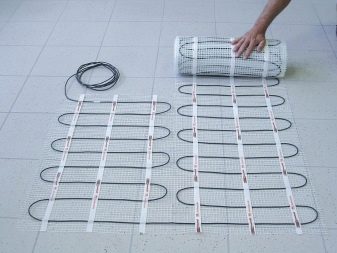

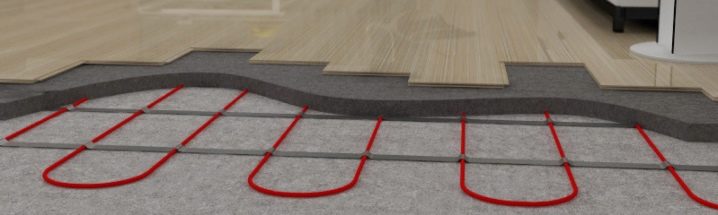

Heating mats are a special reinforced mesh, equipped with a thin thermal cable.

Features:

- As a rule, mats are made with a thickness of no more than 3 mm and a small weight;

- durable shell able to withstand significant temperatures;

- the need for installation in the pre-laying the insulating layer;

- a variety of heating mats provides simple and cheap options (for example, fiberglass);

- availability of thermostat.

Benefits:

- the simplicity of the installation allows stacking independently;

- fast warming up of the room;

- possibility of use in multi-storey buildings;

- possibility of adjustment of the thermal mode.

Disadvantages:

- higher cost than classic cable systems;

- It is not recommended to use as a main heating system.

The main element of the film floor is an infrared film with carbon fiber plates embedded in it. This is perhaps one of the most heat-saving and efficient domestic heating systems.

Features:

- small material thickness;

- during installation, additional fiberglass mesh with a mesh of up to 3 cm is required;

- the heating process takes place due to the heating of the person and objects around him, which then give heat to the space. Thus, a comfortable microclimate is created in the apartment, without air drying;

- infrared fabric has great strength and is able to withstand significant temperature and mechanical overload;

- when a separate heating thread is damaged, the product does not lose its working qualities due to the parallel connection of elements.

Benefits:

- simple installation process;

- fast warming of the room;

- reliability;

- universality of use;

- low level of electromagnetic radiation.

Disadvantages:

- high price tag;

- incompatibility of the material of the film with glue for ceramic tiles. That is why fiberglass is additionally used;

- when laying, a solid base of plywood or drywall is required, which reduces the heat transfer rate of the system.

Rod warm floor as one of the types of infrared systems includes carbon rods embedded in the polymer film. The operation scheme is identical.

Features:

- higher parameters of the mechanical strength of the material;

- suitable for all types of flooring. Additional substrate is not required.

Benefits:

- high strength - the product is able to withstand the most massive furniture, without fear of overheating or deformation of the base;

- compatibility with various materials and compositions for gluing;

- continuous and independent cycle of operation of each section due to their parallel connection.

Disadvantages:

- high cost.

Calculation and installation

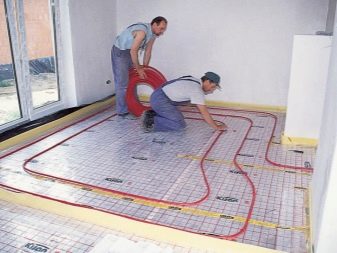

Work on installing a heated floor with your own hands should begin with a detailed calculation of the power of the device and drawing up a phased plan for laying its elements.

It is important to keep in mind the following aspects:

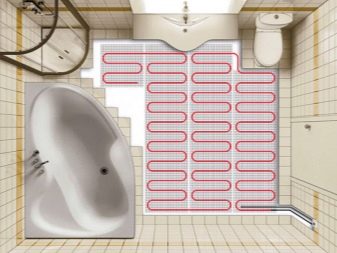

- If the system is functionally the basic option of heating, then its power should be 150 W / sq. m. For lower floors, it can be a little more - 180 W / kV. m. The area of its installation should take at least 70% of the area of the entire premises. If it is planned to use the system as an additional one, then its sufficient power will be 110-130 W / sq. m. In places of permanent furniture placement, heating elements are not installed due to possible overheating of the cable;

- The gaps between the walls and the nearest cable turns should be at least 50 mm, and the gap between the central heating pipes and the cable should be at least 100 mm. The inter-turn cable pitch depends on the power of the device, the length of the conductor and the heated area.

H = S × 100 / L, where

- H - inter-turn distance (cm);

- S– heating area;

- L is the conductor length.

The length of the conductor is calculated by the formula:

- L = S × Ps / Pk, where

- S– heating area;

- RS is the required power density per 1 sq. M. square meter;

- Pk– specific power of the conductor according to the passport for 1 linear meter.

During the installation of the conductor immediately takes into account the place where it connects to the junction box and thermostatic device. Cable crossing is not allowed.

It is very important to foresee in the arrangement the location of the thermal sensor, which should be laid exactly in the center of the loop at a distance of about 40-50 cm from its edge.

The order and features of laying a warm floor may have differences depending on the type of device, but the sequence of its implementation is almost the same:

Project part

To make a high-quality and thoroughly thought-out project is to avoid unnecessary expenses for the purchase of materials and to lay the high quality of the installation of the whole system.

There are a number of rules that should guide the design of heating systems:

- Do not install the conductor under massive household items, because due to the added pressure, the heated air does not rise to the top, but follows the heat source, which leads to overloads in the operation of the device;

- The cable should be placed approximately 150-200 mm from the walls, and the inter-turn distance should be not less than 100 mm;

- heat regulator for convenience and reduce labor costs set at about a height of 1 meter from the floor.

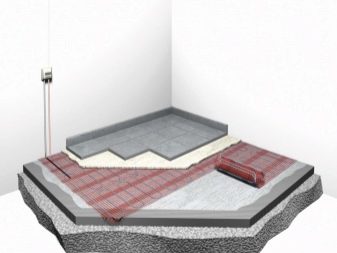

Selection of insulation

The selection of insulation parameters depends on the current quality of the ceiling, as well as the installation site of the system:

- It is more expedient to lay a thick layer of thermal insulation over the basement or unheated premises, as well as on the balconies. Usually used from foam or polystyrene foam. In this case, it is more expedient to put a thick material to the top of the floor leveling. The recommended thickness is 20-100 mm;

- A thin layer of thermal insulation should be installed on a prepared surface. For this purpose, foil-coated penofol is used, laid down with a reflective area upwards, which will direct the heat flux into the space of the room;

- The thicker the insulation, the greater its distance from the wall. For expanded polystyrene this distance is 100 mm, and for penofol it is 50 mm. Places in which thermal insulation will abut the walls are glued with a special damping tape, which is designed to compensate for the temperature change in the dimensions of the material.

Foundation preparation

Then go to the next step:

- Surface preparation necessarily includes the removal and leveling of the floor areas that protrude, as well as the removal of cracks and dust removal. If the floor surface is not level, then it is necessary to make concrete screeds or apply self-leveling floors (with a lack of time). Laying the conductor on wooden or plywood floors leads to heat loss;

- Shtabenie walls.

Thus, the choice of electric floor heating under the tile should be carried out on the basis of the specifics of the premises, financial resources, as well as personal preferences.

Installation

To correctly measure the temperature of the system, the temperature sensor is placed with a gap of 300-400 mm from the edge of the wall, between the cable turns. Both the thermal sensor and the temperature controller are placed in the corrugation, which should fit without kinking.

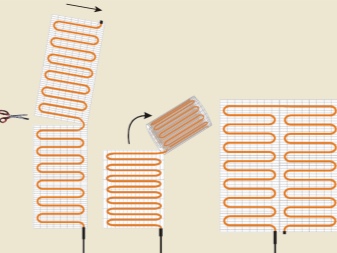

Technologies for laying cable and mats are different:

- The cable resistance is initially measured. After that, a special tape is fastened to the floor with fasteners, which is located on the tape quite often, simplifying the fastening procedure. There is another option - fastening with the use of a plastic clip to a metal mesh previously located on the floor. This method is preferable because it gives the surface additional rigidity. The cable itself is placed at a distance of about 150-200 mm from the wall. Laying is carried out in the form of a snake;

- Heating mats are much easier to install. To prepare the system for start-up, you just need to lay them on the floor and measure their resistance indicators. At the same time in the course of laying their shape should be customized by cutting the grid. The intersectional distance is taken at the rate of 50-100 mm.

Testing phase

The resistance of the heating element is measured by a tester. Discrepancies in indicators with the parameters of the product passport should not be more than 10%.

Screed device

The height of the screed depends on the diameter of the cable:

- for cable devices, it is in the range of 30-50 mm;

- for mats - no more than 30 mm.

Since the concrete screed dries out for a long time and affects the height of the room, the use of tile adhesive is a more convenient option.

Laying tiles

A special feature of laying tiles here is the use of a special adhesive mixture used specifically for working with a warm base. Such mixes are issued with marking "heat-insulated floor" or with indication of the recommended temperature range at operation.

Putting the solution on the mat, it is important to prevent the formation of "air bubbles", leading to overheating of the cable. Glue is applied with a special spatula, carefully to avoid damage. After 20-25 hours you can walk on the floor and rub the seams.

The operation can be started after the glue has dried completely.

Tips

In order to choose the right heating system, it is important to know that the products can be sold in sets containing either the minimum or the complete set of elements required for installation, which may even include the necessary tools. The cost of such kits depends on the length of the cable, the amount of electricity consumption (power) and their composition. To save, if the installation process will be done by hand,You can choose the components of your choice.

Cables are available in two versions - single-core and two-core. The first one is not quite convenient in installation, since its prerequisite is the need to loop the contour (the cable ends are output to the electrical distribution box). In addition, single-core cables function in accordance with a resistive circuit like a regular spiral, they heat up along the entire length, which significantly reduces the level of efficiency of the system as a whole, complicates the adjustment process and lengthens the heating time.

A two-core cable assumes that one core can work according to a resistive circuit, while the other core ensures that the circuit is closed through a special end coupling.

Self-regulating cables are very practical, in which heating is performed during the passage of electricity through a special semiconductor matrix. The peculiarity of this scheme is that in the process of heating the matrix, its conductivity decreases, and therefore the energy consumption decreases. Such self-regulation exists on all sections of the cable, therefore cooler places get warmer more intensively.

In addition, this cable is much more convenient to cut, choosing the required length, because there is a cutting step of 25 and 50 cm. The main disadvantage of the cables is their thickness (diameter is about 8 mm) and they require pouring, which greatly complicates installation and decreases and the height of the room.

For the most part, when it comes to self-installation, professionals advise choosing heating mats. In this case, the cost of the system is about 30% lower. In addition, this option is much simpler in the calculations, and during installation.

Expensive, but also the most reliable option in terms of safety (there is no influence of electromagnetic radiation) is a film (infrared) floor.

Experts believe that for bedrooms and children it is more expedient to choose the use of a mat with two-core conductor. For the bathroom is fully suited mat with a single cable.

For ease of use, a programmer can be included in the circuit. This device ensures uniform heating of open spaces, as well as a decrease in temperature in closed areas. This protects the system from overheating,reduces electricity consumption and significantly extends the life.

A significant selection criterion is the manufacturer of the equipment. It should be with a good rating and reliable. It is likely that the cost of equipment will be higher, but the timing of high-quality operation is much longer.

Reviews

Analysis of user reviews indicates a greater popularity of mats compared to just the cable option. This is primarily due to the pouring of the screed, which increases the load on the floor, which dries long, reduces the ceiling height and requires relatively complex additional calculations.

In Russia, imported products are sold by firms De-Vi, Electrolux, Ceilhit, Alcatel, Kima, Siemens, Thermo, Ensto, as well as domestic products, for example, from the company “Thermolux” and others.

One of the most popular and best heating systems today is the production of the Swedish company Electrolux, it is distinguished by:

- the widest range of system components;

- stylish design and thoughtful design solutions;

- the presence of automated control circuits, in which the built-in thermostats control the operation of the entire system;

- low energy consumption;

- a variety of mats in size - from 0.5 to 12 square meters.m, which makes it possible to make their laying in different rooms, regardless of their shape and size, even on the balcony;

- optimal prices;

- high level of quality. In the heating systems of this company are used exclusively reliable elements, characterized by long service life.

One of the advantages of products from Electrolux of various series is also the fact that to install them is quite simple laying on the base. There is no need to calculate inter-turn conductor pitch. The coils are firmly fixed on a special substrate, which virtually eliminates the possibility of their shift both during and after pouring the solution. Elements of the system can be cut to obtain coverage of the desired size. It is important to monitor the integrity of the conductor.

Successful examples and options

The main task is to choose the appropriate version of the system according to the energy consumption, the method of installation and the available means.

One of the most successful variants of a warm floor is an ultrathin floor, which is extremely common today abroad and has become popular with us for some time. Today it is one of the best developments of all currently available types of electrical heating.

So, the heat-insulated floors of the “Thermolux” series MiNi include a thin (3 mm diameter) heating conductor, mounted on a 50 cm wide glass mesh, in 5 cm increments. to thermostat. A standard kit includes a thermostat with the ability to set the desired heating modes. On request, the product is also equipped with a “Thermolux PRO” thermostat with software for setting the daily or weekly temperature program to the system.

This development is much better in performance than conventional systems in several aspects:

- Such structures are installed exclusively without “wet” procedures and are made in the form of mats that do not require assembly. They are simply placed on the surface without pouring concrete, and immediately laid on top of the floor canvas coating. Thereby, the installation time is significantly reduced (with conventional concrete casting, the procedure is delayed for weeks);

- The decision to install such floors can be made at almost any stage of repair, which is impossible with the usual warm floor,which should be mounted already at the finishing stage in the rough. Ultra-thin patterns are used to maintain the same level of sex;

- You can acquire such mats yourself, without fear of making a mistake in the parameters, since their power is calculated with a certain margin. The course of installation does not require high professional skills. In operation, they are very reliable and if a fragment is damaged, it is simply to be replaced;

- In terms of cost, such a floor is comparable to a regular one, since if the cost of a quality installation is added to the cost of conventional equipment, including the cost of a screed, the resulting price will be approximately equal to the price of the entire ultrathin system. The gain in quality and durability is obvious;

- This product is not afraid of overload, because it uses the latest material - Teflon, which creates a sufficient margin of safety when the system is overheated;

- The use of the ultra-thin version of the product is possible almost up to the immediate and final laying of the coating on the floor.

The ultra-thin underfloor heating option is inherently versatile, as comfortable and safe as possible both during installation and during its use in practice.

On the pros and cons of an electric floor heating under the tile, see the following video.