Features and advantages of polymeric floors

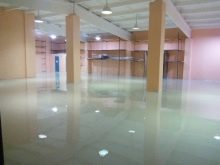

The traditional linoleum and parquet coverings were replaced by floors made according to the new polymer technology. They quickly gained popularity among users. Such floors are installed in many houses and apartments, but before buying a certain option, you should carefully consider all the nuances and features of the coating. It has a number of specific characteristics that distinguish it from other types of flooring.

What it is?

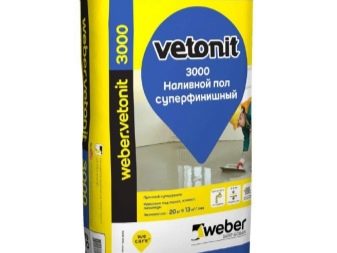

Polymer floor is a uniform floor covering, which is installed by pouring on concrete or other material. Made in the form of a mixture, it by diluting and mixing the composition acquires the desired consistency. The finished mortar is poured over the floor using a specific technique, and after a specified time it hardens, forming a smooth, even surface without joints.

These floors are designed to cover the disadvantages of the main floor. due to polymerized materials in its composition. The self-leveling floor technology was developed in the 60s of the XX century. The main innovation of this coating was its ability to self-level using polymer compounds.

It was used mainly as a finishing layer for the concrete surface, because concrete was the most popular type of framework. Another important property of liquid linoleum was the imparting color to the floors in the rooms.

Features: pros and cons

Like any floor covering, polymer solution has its advantages and disadvantages.

The advantages of this material include the following characteristics:

- The coating is very elastic, which explains its ability to resist such influences as seismic activity, seasonal deformation of the building and various other fluctuations.

- The floor is sufficiently resistant to water, it does not have an absorbent surface, which prevents the penetration of moisture into the premises that are at a lower level. The surface itself when interacting with water does not lose its qualities.

- The coating device provides fire safety. Even under the influence of very high temperatures, the floor is not deformed and does not increase the radius of ignition.

- The technology of applying the solution is very simple, so this type of coating allows you to cope with its pouring.

- In the course of operation, the self-leveling floor does not require much time and effort for maintenance. It is quite simple in this regard and does not create the need to frequently perform cleaning procedures.

- The last property is due to the fact that the surface does not accumulate dust, because of the lack of joints and irregularities, dirt does not accumulate on a similar floor as quickly as on other floor coverings.

- An important plus is the long life of the material. In the absence of serious mechanical effects, it can last up to 20 years.

- Liquid linoleum is very pleasant to the touch, because its surface is smooth. However, even with such evenness, the coating does not slip.

- Self-leveling floor will not be affected by contact with various chemicals. Even caustic compounds will not damage the surface with their effects.

- Such a floor is classified as environmentally friendly.It does not include chemical compounds harmful to health. Due to this, for all the time of operation, it does not emit any vapors and does not cause allergic reactions.

- For coverage characteristic combination of versatility. It combines with bases from virtually any material with proper pretreatment.

- Bulk linoleum can be embodied in a variety of design options. It will look great with any interior styles. With this technology, you can create not only beautiful, but also an exclusive design of the room.

Despite the large number of positive qualities, there are a number of negative nuances regarding this coverage. Compared with traditional linoleum and other overlays on the floor, polymer blends have a very high price. It is more expedient to choose expensive products, because in the price range there is a clear correlation of price and quality. Therefore, the coverage of large areas can greatly affect the condition of the wallet.

Mandatory procedure for pouring the floor is leveling the base. This requires additional time, effort and money.In the process of pouring it is necessary to strictly observe a number of conditions - to provide an absolutely dry base, because if you apply liquid linoleum on a wet base, the result may not meet the expectations.

There should not be a temperature difference of more than a couple of degrees - this can also affect the quality and durability of the coating.

This type of coating can not be dismantled. If you decide to change the floor, you will not be able to completely get rid of liquid linoleum, and the only way out will be to apply a new material over the previous one. The process from the initial stage of applying the composition to readiness for operation takes quite a long time. It sometimes takes more than a week to finish the floor in a room.

The disadvantages of this type of coating are not so critical and are easily compensated by numerous advantages. Elimination of all problems is reduced only to a competent calculation of the time of repair and financial costs.

Mixes and tools

One of the important stages of preparation for the application of a polymer coating is the provision of all the necessary tools and materials for the process.

The main raw materials include:

- A mixture for priming, which includes quartz sand. It is selected in accordance with the instructions of the manufacturers of the self-leveling floor.

- Blend selected coating;

- Putty for adjusting the surface of the base;

- Finishing varnish;

- Additional color decor (optional).

You should have the following equipment with you:

- Capacity for liquids of not less than 20 liters;

- Shallow bale roller for applying a ground coat;

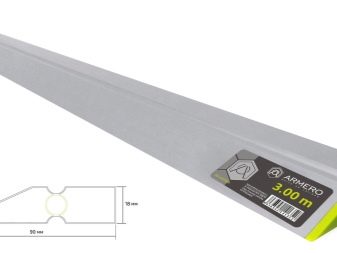

- Construction rule;

- Household gloves;

- Drill with adjustable speed. It is important to choose a nozzle of such length that can reach the entire depth of the tank with the mixture. This will make the composition perfectly homogeneous.

- Needle roller to remove excess air from the surface;

- Spatula to distribute the mixture in hard-to-reach areas;

- Special soles with spikes to move around the layer without a strong impact on it;

- Solvent to get rid of the remnants of the material on the tools.

Having at hand all the necessary components, you will greatly facilitate the process of pouring the coating.

Preparatory work

Before you begin to fill the floor, you need to carefully consider the choice of coating and prepare the floor surface, following the following algorithm:

- Be clear on the purpose of the room and its type.

- Calculate the possible value of subsequent loads on the floor during its operation.

- Think about the need to use in the design of decorative elements.

- Calculate the ratio of price and quality. The main criteria for the calculation are the surface area of the floor, which determines the amount of material, the desired design and brand of the selected product. The price range usually varies from 300 to 600 rubles per square meter.

- Calculate the required amount of materials. Remember that 1 liter of the mixture is needed to cover one square meter with a layer thickness of 0.1 cm. Based on the desired thickness of the coating, it is easy to determine the amount of material for the entire room. Some manufacturers develop products with more economical consumption, adding a special filler to the mixture, which increases its density.

- Remove the old lining.

- Clean the floor from debris, glue residue and other traces of the old coating.

- Prepare the base for pouring. Features of this stage depend on what material is the base.

For concrete pavement carry out the tie, making it as smooth as possible. After installing the screed should be completely rid of moisture on the surface. Dust is removed with a construction vacuum cleaner. It is important to rid the surface of excess fat by using solvents for this.

If the surface is old, then the relief on it can be eliminated by pouring the epoxy solution into the cracks and deepening before screed. For a porous surface, a special solution with a high degree of penetration into the structure — siling — is suitable. The wooden base is unsuitable for pouring such a floor, but with proper processing even it can serve as an excellent base for a new floor.

It is necessary to open the surface and replace the unsuitable elements of the floor. When closing, strengthen the position of the boards relative to each other. Having got rid of the old paint, it is necessary to repair cracks and notches with a special putty for wood. Having polished the leveled surface, it is necessary to install a special self-leveling coupler on it.

If ceramic tile is used as a base, it is important to check the strength of its attachment. After should be putty all irregular areas. With the help of an organic solvent, you need to rid the tile of excess fat. Having taken care of all the necessary details, you will be able to properly prepare the surface for the application of liquid wallpaper and contribute to the long service life of the coating.

How to do it yourself?

It is not necessary to invite repair specialists to fill self-leveling floors. Since the technology of coating is very simple, you can carry out the procedure yourself.

Before starting the process, note that the polymer floor is classified according to several criteria:

View

Polymeric self-leveling floor has a different composition depending on the base material. The coating for a concrete floor may differ from its counterpart for wood or ceramic, because each material is characterized by a special adhesion force.

3D shading also has special variations according to the place of use. It can be used for rooms in apartments, private houses, warehouses, refrigerators.Production facilities are also equipped with similar coatings very often.

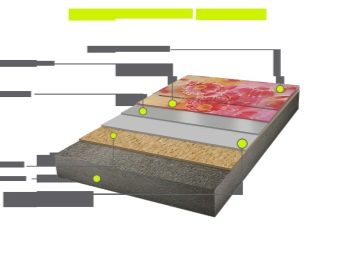

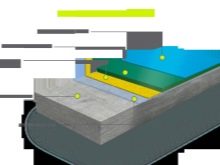

There are several types of layers - ground, bulk and finishing. The ground layer should be enriched with quartz sand, which significantly improves the adhesion of the material to the surface. Additional may be antistatic and anti-slip coatings.

Often, flood floors include other textures, such as laminate. Such solutions look especially unusual with the addition of colored pigment atypical of a hue material, such as blue or violet.

A special type of coating - self-leveling liquid floor, leveled under the influence of gravitational forces. This technology does not allow the slightest error in the level of the floor, but it greatly facilitates the process of laying.

At the first stage, sizing of the expansion seam in the lower part of the wall of the room is carried out. To do this, usually used dimpfernaya tape. After the screed has been made, it is necessary to stir the soil mixture. Then it is applied in several layers on the floor.

To waterproofing was normal, make sure that the humidity does not exceed 50%.

Mix in the tank mixture for pouring the floor according to the instructions with a drill. Try to make the consistency of the composition as homogeneous as possible. Filling with polymer is carried out by smooth distribution of solution on a surface by means of the construction rule. To get rid of excess air, the surface of the coating is treated with a needle roller.

It should be added to the surface of the decorative elements. Last you should do the coating with a finishing varnish for the final fixation of the result. It is carried out by drying the main layer. For a base of 0.1-0.2 cm drying occurs in a couple of days. Seams near walls should be treated with a special sealant. Floors are ready for operation finally after 7-8 days. In the process, be sure to use needle soles.

Material

There are several types of self-leveling floors:

- Epoxy materials are considered the most flexible.

- Methyl methacrylate in the composition of the coating allows it to dry out in a short time.

- Bulk linoleum from polyurethane has a high degree of strength.

- For industrial premises, liquid urea coatings are used.They are applied using a special coating technology that does not require stopping the production process.

- Polyester blends have the most affordable prices, but they are considered the lowest in quality.

Colors and design

An important element for liquid linoleum is its color design and texture features. You can select a transparent, glossy, grungy, decorated and mixed types of coverage.

Among the colors you can see the shades of natural wood, especially if the appearance of the coating imitates wooden masonry. These include beige, brown, red-brown and deep dark chocolate tones. Very often on a beige basis you can see patterns of a darker color.

In addition to reserved shades, rich colors and prints are often inherent in coatings. Geometric shapes, lines and zigzags are among the popular ones. No less popular are the drawings on the 3D floors. They differ depending on the choice of the concept of style and purpose of the room. Original look ashy and white shades. They make the space visually wider.

In addition to the pattern, there may be decorative elements in the composition of liquid linoleum. These include a variety of stones, sparkles, shells and other components of the chosen design concept.

Care rules

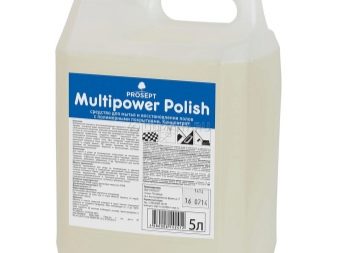

In order for the self-leveling floor to maintain its gloss as long as possible, it is necessary to take proper care of it. It is similar to the care of the parquet floor.

Dry or wet types of cleaning are a way to maintain good floor conditions. During wet cleaning, you can use special tools for the polymer floor, which is based on special acids. In case of severe contamination, the composition is left on the surface for 5 minutes. After it is necessary to thoroughly wash the tool with water.

In industrial premises for floor washing, it is preferable to use special units with powerful pressure, which remove deep contamination from the surface. Toxic substances cannot be over-exposed on the surface of floors, otherwise there is a risk of damage to the polymer structure. Periodically, you can cover the floor surface with a special varnish to update the appearance.

Manufacturers and reviews

In order not to make a mistake in choosing a mixture for flooring, you need to inquire in advance about various manufacturers. The following companies are among the most popular:

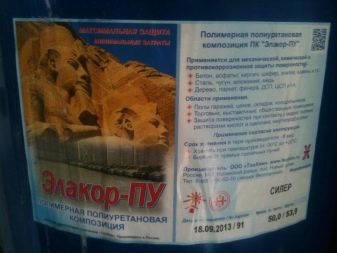

- "Elakor PU" offers products that are resistant to stress. The hardener in the mixture and a wide color palette is complemented by a high resistance to chemicals.

- Gipcreet thermafloor offers a special polymer coating that has a very light texture. A distinctive feature of the composition is an absolute guarantee of the absence of cracks.

- Company "KrasKo" produces such products, in which the ratio of quality and price is quite favorable. These materials create floors that can withstand various loads.

Successful examples and options

Polymeric floors can be very interesting embodied in an apartment or a private house. A large role is played by the functional features of the rooms where the mixture will be poured.

In the kitchen, floor design is often devoted to product or geometric themes. Mainly used color contrast or a set of juicy citrus tones.

In the hallway, the coating is a "pie", the top layer of which can be made on the basis of a marble slab and have a very elegant appearance.

If you want to feel real comfort, returning from the street, you can add a polymer coating with creative lighting.

The bathroom is characterized by a marine theme. Floors with a 3D effect will create the feeling that you are walking on the surface of the ocean. On the basis of two-component mixtures, beautiful realistic effects are created, the marine flora and fauna are embodied.

In the bedroom, self-leveling coating appears in the form of floral patterns, giving the atmosphere of tenderness and romance.

Choosing for your home or business polymer flooring, you can not go wrong. They are not only comfortable, but also incredibly beautiful. Being in a room with such a coating, you will feel the comfort and aesthetic pleasure.

How to pour the polymer floor, see the following video.