For which premises is suitable cement-based self-leveling floor

One of the problems of indoor flooring is the uneven structure of its surface. It does not allow to process the base qualitatively with the help of decorative finishing materials. One solution to this problem is a self-leveling floor. Such materials are distinguished by self-leveling abilities, which minimizes human participation in the distribution of the surface structure.

Distinctive features

Cement self-leveling floors are modern materials that form a flat surface during installation. The thickness of one layer can vary over a wide range.

Cement based floors have several unique characteristics:

- The frozen surface has high compressive strength. This allows not only to level the floor, but also to further strengthen it;

- Cement perfectly tolerates moisture without losing its original characteristics;

- The products are compatible with various finishing materials, including methyl methacrylate mixtures;

- Relatively low cost. This concept is relative, since if the mixtures are used as classic screeds, the volume and, accordingly, the financial costs increase;

- Cement mixture well passes moisture, which allows the surface to breathe, minimizing the impact of liquid on the structure of the material;

- The grounds of this type are perfect for arranging "warm" floors;

- Easy installation. Practically everyone can equip a self-leveling floor even without experience in construction;

- Almost perfect base alignment. This material is much better than the classic sand screed, which does not allow for precise leveling of the surface.

Application environment

Cement self-leveling floors are universal leveling compounds that are not used as a decorative coating.

Their main purpose is to create a flat surface for finishing materials:

- laminate;

- parquet;

- linoleum and others.

Screeds of this kind are used in various types of premises. You can put them both in the toilet and in the living room.

Theoretically, they are universal and suitable for both exterior and interior work.

In living rooms are used self-leveling floors, which include the minimum number of polymers. This eliminates the release of harmful substances into the air.

But many experts recommend classic cement-based blends to be used in rooms with high humidity.

Therefore, this option is optimal for a bathroom or kitchen, where moisture is constantly released.

For residential premises that are distinguished by minimal humidity, a gypsum-based screed will be the best option. It dries much faster, but it does not apply on the street. Today, special polymer-cement screeds have been developed, which allow to obtain a rather thin leveling layer.Its thickness can reach 3-10 mm depending on the manufacturer. But while the technical characteristics of this product is much better. Therefore, the floor based on polymer components with a thickness of 1 cm competes with the classic cement coating with a thickness of 3 cm.

Polymer-cement mixtures are used only inside industrial premises. Often they can be found in warehouses or other similar objects. A feature of this product is that after pouring it, you can simply paint it and start using it as a finishing coating.

Types of cement floors

Self-leveling floors are made of various substances that ensure the strength and durability of products. Today, the highest quality mixtures are made on the basis of cement.

Depending on the composition of these materials can be divided into several subspecies:

- Sand cement floors. Sandy substances are classic and the most common. According to the characteristics of these solutions are very similar to conventional cement screeds, which are used to further level the surface.

- Cement-gypsum compositions. The combination of these substances allows you to get a solution that resists loads well and dries quickly.

- Polyurethane-cement and epoxy-cement floors. The products are highly durable and durable. Their peculiarity is that they perfectly tolerate not only physical but also chemical loads. Therefore, they are used in enterprises with certain working conditions. The floor of such materials forms a seamless structure that does not collapse even with constant differences in high temperature temperatures.

It should be noted that the composition of almost all types of self-leveling floors based on cement include polymer components. It can be either epoxy or ordinary acrylic. Depending on the percentage of these substances, the coupler gets different properties. Today, there are special polymer compositions, the bay of which, you can get the so-called "liquid glass".

Classic self-leveling cement floors consist of several main components:

- Cement. Its quantity is determined by the purpose of the material and the environment of its use. Depending on the brand of cement, the substance may receive different strengths.

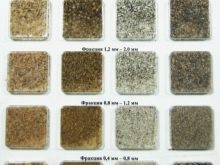

- Fractional sand. In the manufacture of products using only quality components of the same size.

- Mineral and polymeric additives. Their number is also regulated by production technology.

Surface structure

Cement-based self-leveling floors can technically be considered as classic screeds. They differ only in consistency and composition. But at the same time, no one bothers to use them instead of the standard solution of cement and sand.

Depending on the purpose and structure of the material, self-leveling floors of this type are divided into the following subspecies:

- Basic. Substance is used to level significant differences. They allow forming a screed with a thickness of up to 8 cm. They are not used as the main surface, since they do not differ in the required technical parameters.

- Mixes for middle layers. The main purpose is to align small defects with height differences up to 3 cm. Often, this mixture covers the base layer, which allows you to get a strong and durable structure.

- Finishing. Compounds of this type quite accurately level the surface. On such bases already and put laminate and other decorative materials.A cement floor of this type can be applied with a thickness of no more than 1 cm.

Foundation preparation

The quality of the self-leveling floor depends largely on the structure of the surface on which it is applied. Therefore, before laying the cement-based mixture, the bases should be properly prepared.

This process consists of several procedures:

- The basis for self-leveling compounds is concrete. Therefore, before installing floors, remove all old flooring from the surface. If the old structure does not imply a concrete screed, then it is desirable to equip it. This is especially true of country houses, where the floors are made of wood.

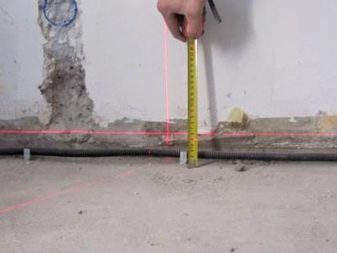

- When the old coating is dismantled, check the ground drops. It is important that this value does not exceed 20 mm. If protruding bumps are encountered, then it is desirable to eliminate them mechanically. The best option would be the usual knockdown irregularities. An alternative may be the use of Bulgarians and special electric tools.

- In order to obtain a strong adhesion of the filling mixture with the base, it is important to seal all cracks and remove dust. Immediately before the application of liquid floors, the surface is primed with special solutions.

Apply the mixture

The technology for producing cement-based self-leveling floors is quite simple and involves the following sequential steps:

- Initially, around the perimeter of the room, special damper tapes are attached. They are used to cushion a solidifying tie during material expansion during freezing and operation.

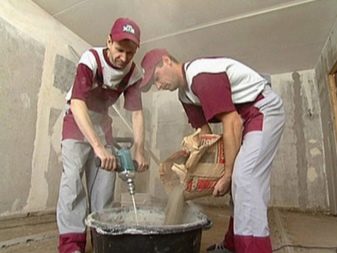

- The next step is to prepare the mixture. To do this, use a construction mixer, which allows to obtain a uniform consistency of the product. It is important to adhere to all the proportions that are indicated on the packaging of a particular mixture. If this is not observed, then the solution may simply not be distributed evenly over the surface.

- When the mixture is ready, it is consistently covered in the room, starting at the far corner. Operations are best performed with the help of several assistants. You can level the surface with a notched trowel and roller. It also removes excess air from the structure of the cement screed. Special needles are used as shoes that do not harm the material.

You can walk on this floor in a day. Although the time of solidification depends on the thickness of the layer and the composition of the product. Specific characteristics can be found on the solution packaging.

Cement self-leveling self-leveling floor - a great alternative to the classic screed. It allows you to get not only flat but also durable surface. It is important to use only the compositions of well-known manufacturers, which ensures that the physical characteristics of the final base.

How to fill a bulk floor, see the following video.