Epoxy floors: advantages and disadvantages

Of great importance in creating any interior has a floor. Among the masses of types of flooring, epoxy self-leveling floors are a popular finishing option today. They stand out noticeably against other analogues, have advantages, although they are not without drawbacks.

Features: pros and cons

Epoxy base floors are a special technology used in any type of room. If earlier this time mainly industrial objects were equipped, today the range of application of this facing has been significantly expanded. Thanks to the advanced equipment and the latest production methods, it was possible to significantly reduce the costs of companies for the production of materials with high quality and performance characteristics.

Benefits

At epoxy bulk floors the mass of advantages, they:

- more often they are distinguished by a perfect smoothness of the surface, allowing to place any pieces of furniture on the floor without bias;

- decorate the floors of any type of premises (appropriate for floor finishing of living rooms, laboratories, enterprises, garages, production halls, shopping centers, hospitals, shops, cafes, educational institutions, printing houses, food industry facilities);

- performed according to the developed State Standards, recognized as an ecological type of finish that is safe for human health, is a refractory method of facing the floor;

- have great strength and wear resistance, due to which they are a durable type of floor covering designed for several decades (up to 40 years);

- able to withstand various fluctuations in temperature, withstanding stress in places with high humidity, can be used in completely unheated houses in the cold season;

- they are easy to clean, due to the seamless application technology they allow any surface cleaning, do not accumulate dirt, wash well and wipe, do not create an environment for the appearance of microorganisms;

- not limited in design solutions,due to which they can be an independent accent of a particular room, able to indicate the idea of a design, or visually increase the space due to the color and texture used;

- depending on the design decision of the floor covering, they can be part of the floor composition, being a waterproof material that can zone the space of any room;

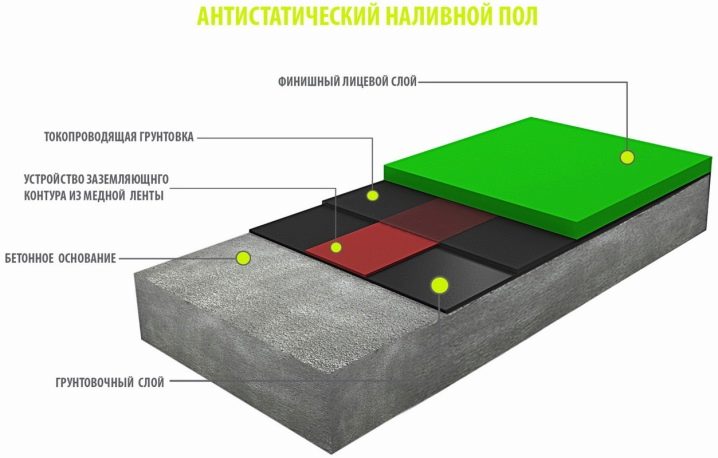

- due to the convenience of the technology, it is possible to perform seamless floor casting of large rooms, being a chemically inert type of floor covering and an excellent dielectric;

- used in the decoration of the apartment, can be used in any room, decorating the floor of the living room, nursery, bedroom, kitchen, loggia, balcony, study, home library, corridor or hallway;

- due to the variety of materials presented by trademarks for sale, allow each buyer to choose the most appropriate option, taking into account taste preferences and the available budget.

The material is convenient because any scratches or chips that were formed during the process of substantial mechanical damage can be easily removed with an epoxy paint and a small brush.Such a floor has an odor that is weathered when the composition dries on the floor. For its installation does not require waterproofing work.

disadvantages

With a lot of advantages, the epoxy self-leveling floor has several drawbacks:

- regardless of the components of the mixture, it requires careful time-consuming preparation of the working surface, otherwise the quality, visual and practical characteristics deteriorate;

- in premium varieties, there is a high price for cladding and related tools for mounting, which in some cases does not coincide with the planned budget;

- It can be difficult to dismantle large problem areas, because finding the material to match the existing finish is quite problematic;

- demonstrates all the imperfections of the floor covering, small scratches and chips should be repaired immediately after the appearance: they are evident;

- extremely difficult to completely remove from the surface at the end of its service life, does not provide for repeated application.

The choice of decorative coating is not always successful. Often drawing on the surface is motley, which requires to limit the amount of furniture in the room.In other cases (variant 3D), the pattern creates the effect of misinformation of space, especially if a picture with a precipice or a precipice is chosen as the basis. The print should be chosen extremely thoroughly, without disturbing the harmony of stylistics.

Characteristic

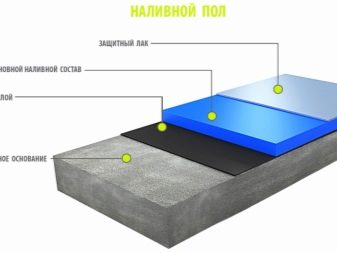

The epoxy self-leveling floor has a slightly spreading structure capable of filling non-critical surface irregularities.

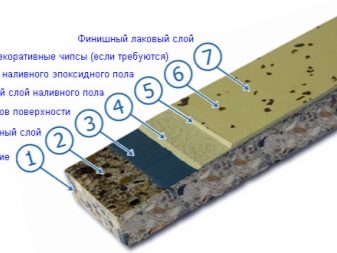

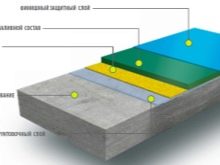

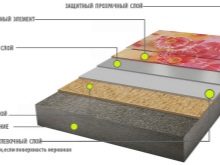

Depending on the specific operating conditions, Epoxy floors can be classified according to the thickness of the cladding, they are:

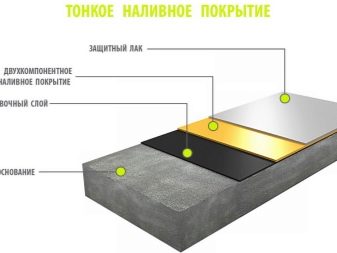

- Thin layerstacked in 1 filler layer, the thickness of which is minimal and does not exceed 1 mm (usually from 0.5 mm), while the practical properties and attractiveness of the appearance of the material leave much to be desired (intended for pouring in rooms of the apartment with a small cross);

- Classic, made of several layers of casting, each of which is 1 mm, which significantly increases the resistance of the floor covering to mechanical damage, abrasion, resistance to abrasive mortars (an excellent floor covering for an apartment and a country house).

In addition, epoxy self-leveling floors are divided into:

- Industrial varieties intended for industrial premises with high traffic and a maximum level of permissible load of mechanical or chemical type, characterized by a variety of colors and textures;

- Quartz-filled fillings reaching up to 6 mm in thickness, characterized by the presence of quartz sand in the lower layer, which increases the adhesion of the material to the base, improves the resistance of the pouring to accidental mechanical damage, exposure to abrasive and chemical agents, and temperature changes;

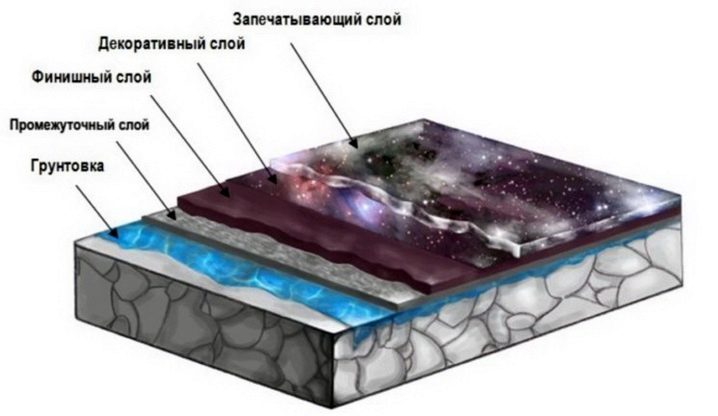

- Transparent epoxy self-leveling floor, differing in layer thickness of 2-5 mm, depending on the type of the planned surface, the distinctive features of which is the minimum thickness of the optically transparent hardening film, light resistance, anti-static (excellent material for decorating the floor with photo printing and 3D-drawings).

Tools and materials

To do it yourself, you need to take care of some tools:

- grinding machine;

- ordinary vacuum cleaner;

- epoxy packaging;

- drills with a nozzle for stirring;

- long pile roller;

- squeegee;

- needle roller;

- gloves;

- paint shoes;

- respirator;

- spatula.

The minimum set of materials is an arsenal in which there are:

- deep penetration primer;

- epoxy floor;

- polyurethane varnish;

- sealant for seams (at walls and doorways).

Device and technology

Filling a self-leveling epoxy floor is not as difficult as it may seem at first glance. You can make a high-quality installation yourself, using the necessary raw materials and tools, which, if necessary, can be replaced with what is at hand.

The process itself, which consists of several stages, is much easier to tile:

- Before installation, you need to prepare the base: It is important that its humidity does not exceed 4%, and the temperature in the room ranged from +5 to +25 degrees. The temperature of the mixture can vary from +15 to +25 degrees. If the floor is wet (you can attach a piece of plastic film for a day to detect condensate), installation of the epoxy floor is excluded.

- Initially prepare the floor: it is cleaned from debris, dust, oil stains and paint residues. The better to prepare it, the less you need to fill material. All irregularities, chips, cracks are masked with a putty or filled with a rough filler floor, which will make the base perfectly smooth.

- After that, the ground primer on 1-2 layers.If the base is smooth, you can once again roll the floor with a roller with a primer, or using a spray gun, which reduces the consumption of the solution and makes the application layer uniform. Each new layer of primer is applied only after the previous one dries.

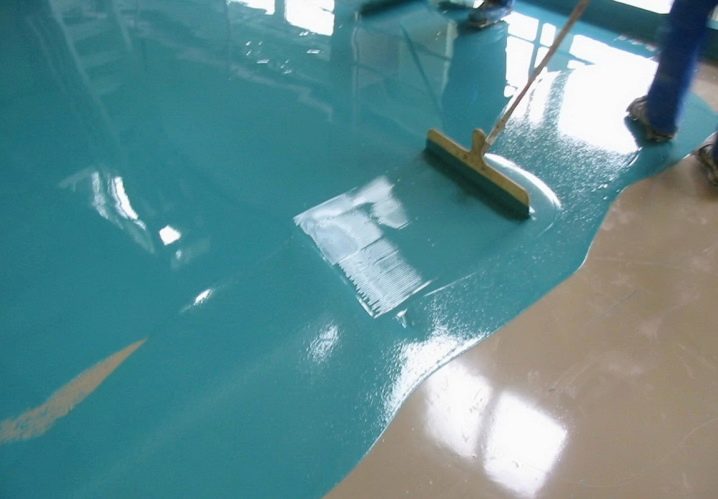

- Epoxy mass is prepared in parts strictly according to the instructions indicated on the package. After that, it is applied to the surface of the floor, focusing on the highest point. The maximum allowable slope of the horizontal plane is 2 mm per 2 sq. M. m working surface. Observing the technology, it is important to apply the material in wide strips, while evenly distributing it over the surface of the prepared floor using squeegees. To do the job in the corners perfectly, you need to use a spatula.

- Since traces may remain on the surface of the dry floor, it is necessary to use paint-patches. When the material is completely filled, it is rolled over the entire area with a needle roller, which will eliminate air bubbles. It is important to prevent drafts and sudden changes in temperature while the lining is drying out.

In addition, it should be borne in mind: the solution begins to harden after 30 minutes, so the work should not be delayed.You need to constantly add portions of the material to the surface, leveling the finish to one level.

- Usually, self-leveling epoxy floors dry within 7 hours. However, in reality it will take about two days. When the polymerization (drying) is over, you can pour the finishing layer of the material. If the design is designed floor decoration, it is performed at this stage before the finish layer. This may be a small blotch of spangles, art painting of the floor with special acrylic paints according to a pre-designed sketch, a usual banner print with a digital image or a 3D picture.

- After the drawing is applied and dried, it is poured with a layer of topcoat and allowed to dry. Then it is necessary to treat the flooring with polyurethane varnish, after which it is necessary to allow it to dry for two days. As soon as the last layer finally hardens, furniture can be brought into the room. The installation technology of epoxy resin-based flooring is good for a concrete floor and allows for the filling of natural stone.

Colors

The color solutions of the self-leveling epoxy floor are varied and follow the conceived idea of the designand the purpose of a particular room. In offices, production shops they are monochromatic, sometimes transparent. In areas with low traffic, white, beige, olive, gray, blue, sand and terracotta colors are used. In apartments, the situation is more resilient: the surface is covered with multi-colored paints based on liquid acrylic for a self-leveling floor.

More often this combination of shades:

- chocolate and milk;

- black and white;

- gray with cream or white;

- purple, golden yellow and blue;

- turquoise and sandy.

Decor

One of the original design techniques is the use of stencils for decorating, by means of which various monochromatic and colored patterns are applied to a colored monochrome lining, imitating carpets, special compositions, zoning the space. In addition, the subject of the pattern used for decorating self-leveling epoxy floors depends on the type of room in which the floor is finished.

The most interesting pictures of decorating the space are:

- paints of the deep sea with their inhabitants;

- floral stylized ornaments;

- African and other ethnic motifs;

- abstract sketches;

- all sorts of curls in combination with large flowers;

- stone and brickwork;

- all sorts of plant compositions, tree branches and leaves.

Composition

The active ingredients of the polymer material, called a two-component, are epoxy resin, the necessary hardeners, solvents and plasticizers. In addition, the components of the lining are additional components to improve the practical and aesthetic characteristics, uniform distribution of the mixture on top of the subfloor or screed, as well as inorganic dyes.

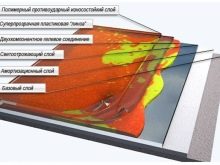

If the components of the epoxy floor are latex, polyurethane and casein, the composition becomes elastic and becomes more durable to weight effects. In addition to the main components that determine the operational properties, decorative blotches are often added to the mass, among which brilliant pearl and light-reflecting particles, glitter, flock, diamond or mineral chips and textile fibers (chips) are especially popular.

Adding decor often complicates the grinding process, although it gives the floor a unique look and often changes the texture,which can be:

- glossy;

- moderately glossy;

- semi-matt;

- matte finish.

How to calculate the quantity?

To find out the material consumption per 1 m2, it is worth counting the area of the planned treatment, multiplying the length by the width, and then correlating with the density of the solution. Approximately 1 liter fill lasts for 1 square. m floor with a minimum thickness of 1 mm. If the density of the material is greater, it is, for example, 1.3 kg / l, for processing a floor meter, you will need 1.3 kg of finished material.

In order to reduce the cost, trademarks can include in the composition of the material a supplement that weights the weight of the raw material, which increases the density of the finish to 1.75 kg / l. In this case, the consumption increases, which will be 1.75 kg per 1 sq. Km. m floor. To buy the right amount, it is important to always look at the density of the material indicated on the package.

Tips for choosing

The necessary filling of the floor is selected, in accordance with the purpose of a particular room, while it is undesirable to apply a thick layer to rid the floor of differences in height. Usually, self-leveling mixtures are used for leveling, which allow correction of the height difference level up to 8-10 cm.It is not necessary to fill the floor with epoxy coating: it will hit the pocket, can cause poor impact resistance, because the material itself is designed exclusively for thin layers of application.

It is worth considering: a thin poured floor based on epoxy resin is more expensive than classic compounds. Choose a material whose elongation at break is not less than 5% (up to 9% is permissible) with a density of the compound not exceeding 1.5 kg / l.

Coverage for a room full of equipment powered by electricity should be antistatic and, if necessary, able to block any static charges. Choosing a finish for the floor of the kitchen or bathroom, where moisture will inevitably fall on the surface, it is worth making a choice in favor of mixtures with anti-slip effect.

Quartz-filled varieties are good for hallways. If you need a perfect solid mixture, you should look at the epoxy-polyurethane material. Do not experiment with paints: leave water and latex varieties for other surfaces.

For the color of the floor covering meets the finish line. It is not necessary to fill the canvas floor in more than three or four layers. That is quite enough.If the epoxy floor is an accent floor, it is best to combine the finish with the tile. In other cases, it is allowed to combine the material on a one-color basis and a companion with a pattern.

Manufacturers and reviews

Epoxy sound-proof self-leveling floor receives a lot of rave reviews left on the Internet. Customers who have completed the installation of this material, note that this decoration looks extraordinary and modern. Such floors are easy to clean and do not accumulate pollution, being removed from the surface quickly enough. It is pleasant to walk on such a floor covering, it is durable and does not break if the furnishings fall to the surface.

To get acquainted with the products for lining the floor based on epoxy resin, you can refer to the products of trademarks, time-tested and having a lot of positive customer reviews:

- Silikal - polymer products of the German trade mark of industrial type with the widest scope of application, including materials with a smooth and rough surface, waterproofing, suitable for wet and dry rooms, characterized by a highly elastic composition.

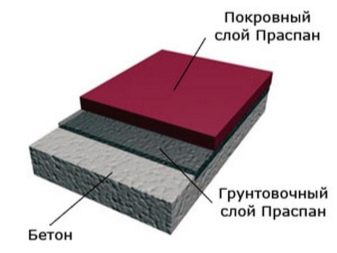

- "Praspan" - cladding with a uniquely low viscosity, which simplifies and accelerates the process of mounting the material on the concrete surface, a two-component, aroma-free cladding based on polyester resin and quartz filler, intended for commercial, warehouse, car repair and industrial premises.

- "Betolast" - water-epoxy self-leveling floor with semi-matt surface type, featuring excellent wear resistance and weather resistance, an ecological raw material with a vapor-permeable structure, not tinting in other shades, made on the basis of a suspension of dyes and mineral additives in a liquid epoxy resin.

- "Epolast" - a two-component epoxy self-leveling floor in 15 kg packages that does not have a strong odor and solvents, has high resistance to mechanical damage, resistance to ultraviolet radiation, which is a chemically resistant floor covering.

Ideas in the interior

Self-leveling floors made of polyester epoxy materials look stylish and fashionable in an apartment, country house, creative studio, exclusive salon.To appreciate their beauty and uniqueness, you can refer to examples of experienced designers who know how to arrange creative decoration harmoniously:

The interior of the bathroom can be decorated with a three-dimensional picture of the marine theme by mounting the floating floor: the blue background of the waves with white foam and the sandy shore look great against the background of wall panels with moldings and paintings with a yacht.

If you do not want to completely fill the entire area with epoxy floor, you can make a slight accent in the form of a mini-pool, framing it from all sides with ceramic tiles and supporting the walls in a similar shade.

Transparent surface casting with coin decoration looks interesting: using a variety of coins of different denominations and time periods, a small part of the area can be distinguished in this way.

Decorating the floor with a pattern of fresh greenery looks colorful and spring-like: this way you can decorate one part of a multi-level floor covering by maintaining the color of the photo printing through a lighter shade of wall covering.

The decorative polymer coating based on epoxy resin in the form of a stylized carpet looks stylish: due to the muted soft colors of the pattern,It harmoniously fits into the design idea, zoning the space into separate functional areas.

The interior of the kitchen can be supported by a picture of autumn foliage: such a pattern is very practical, there will be no noticeable random chips and cracks on it, it will be easy to wash it, and the floor surface will not differ from the zones of maximum permeability.

How to make an epoxy floor of natural stone, see the following video.