Pump for underfloor heating: types and rules of choice

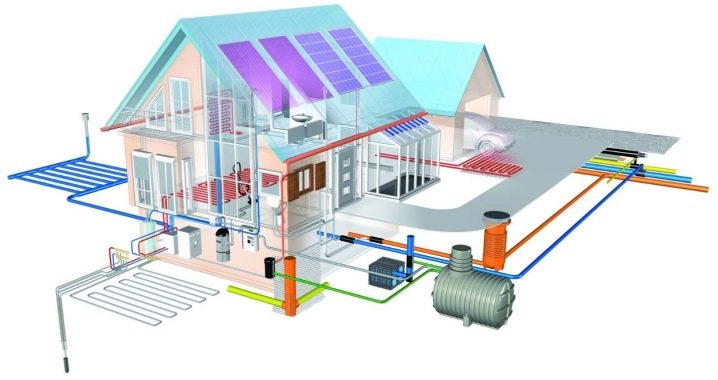

Warm floor has long ceased to be a unique phenomenon, today it is available to everyone, with the necessary literature and acquired knowledge, you can install it yourself without the involvement of specialists. This system is gaining popularity: it is now mounted not only in private homes, but also in apartments. Underfloor heating systems are profitable during operation, but expensive to install. Therefore it is necessary to select all the components correctly, one of which is a water pump.

The most important thing is to carry out a competent calculation and perform all installation work in accordance with the instructions.

Special features

In any heating system (especially in a floor heating system) there must be a pump.It is necessary for the circulation of fluid in the system. In its absence, there will be no exchange of warm and cold liquids. Intense heating will occur at the place of water heating, which in the future may lead to overheating of the heating elements, disabling all electrics, and boiling of water in the system.

Pumps for floor heating systems are not fundamentally different from other counterparts for radiator heating. Such units cannot be used for lifting water, they are not designed for this. They are designed to drive water into the system, preventing it from heating unevenly. Minor rises in the system are possible, the pump must be chosen, given this fact in advance.

Kinds

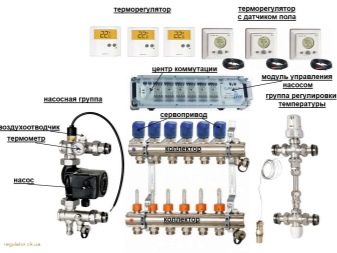

More often, all parts and appliances for floor heating are bought together with the entire floor heating system.

When choosing a pump, you need to pay attention to some parameters:

- productivity (it should pump three volumes of liquid of the whole system per hour);

- maximum pressure (it is calculated, taking into account the diameter of the pipes and their material);

- dimensions (the smaller the circulating pump, the easier it is to install it, but at the same time small analogs will not be able to produce a sufficiently large power);

- phase current (for a private house there will be enough a single-phase pump motor, for industrial premises - with a three-phase one).

There are two types of pumps:

- with a wet rotor;

- with a dry rotor.

The units of the first type do not have a huge capacity, but for a private house or cottage, this option fits perfectly. “Wet” rotor is called due to the fact that the impeller itself provides lubrication and cooling of the motor.

The main advantages of this type of rotor are:

- silent operation;

- low energy consumption;

- reliability;

- simple operation and ease of management.

Pumps with a dry rotor are often used in industrial premises. They require frequent maintenance in the form of cleaning and lubrication. While working quite noisy.

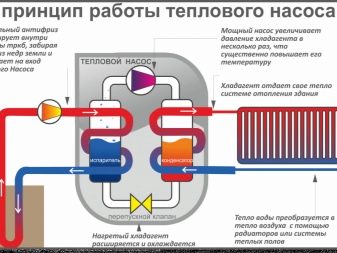

Principle of operation

The pump for a warm floor has a simple design. It is a product case and a rotor or motor attached to the case. The impeller is connected to the motor shaft. With the help of it is the circulation of fluid in the pipeline. The use of a separate unit is explained by the fact that it is necessary to create a working pressure in the system for a constant flow of warm water in the pipes.

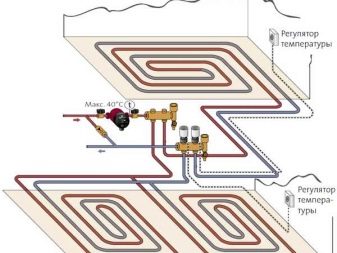

The additional pump is installed in the presence of a second circuit or a large area of pipe laying.

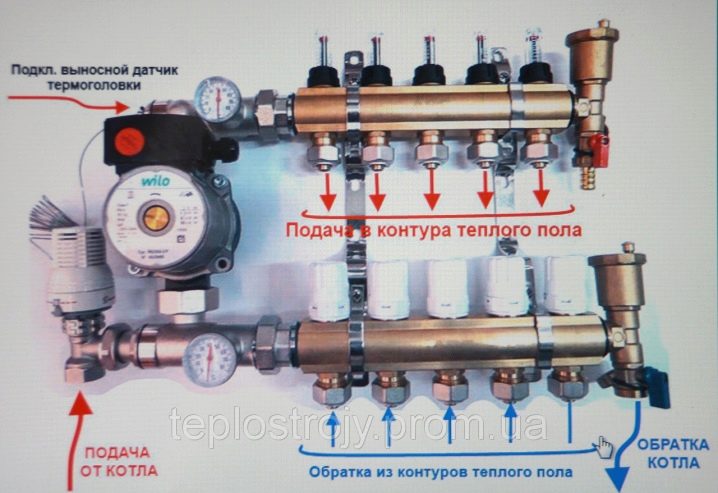

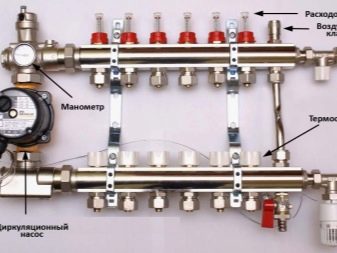

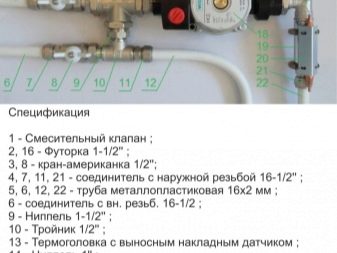

At installation it is necessary to remember that the shaft of the pump should be installed strictly horizontally. With a vertical shaft arrangement, the efficiency will be lower by 35-40%. The pump for proper operation should be installed before the heating element and in front of the collector. This allows the rotor to operate at lower temperatures, which increases the service life. Installation of the pump to the heating element allows to avoid airing (the pump will push the water, not allowing the air to remain in one place).

Before starting the system, make sure that there are no air plugs.

How to choose?

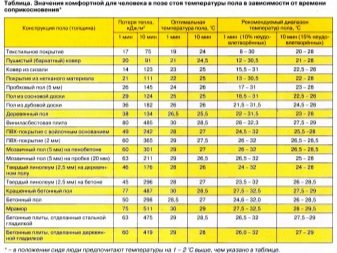

Choosing the right pump is the key to successful operation of the entire system. There are many parameters that must be considered when choosing all the details of the system. You need to know the technical parameters of the system, the area of the room where there will be a warm floor, as well as possible heat loss in the circuit itself. Once you know these characteristics, you need to make the selection of the desired pump.

The first (most important parameter) is the pump performance. It is calculated in cubic meters per hour of pump operation. It is necessary to calculate the minimum capacity, which will be sufficient for the operation and circulation of water in the system. The main rule is the fact that the pump must drive three times more water per hour than it does in the system itself.

It is desirable to add to the resulting performance of 10-20% in stock. This will increase the life of the entire system as a whole. So the pump itself will work easier, because the constant work at high speeds contributes to the rapid deterioration of internal elements. The gap in power is needed in order to increase the power of the system in winter and in the cold. When calculating the performance of the pump is taken into account and the area of the room. With a large area, you can install an additional (less powerful) mini pump so that the load on the main one is not high.

The second important parameter is head. To overcome the long distances, bends and kinks of pipes requires a unit with a large head. Often the concepts of "pressure" and "performance" are confused, although they are completely different.The flow rate of the fluid in the heating system depends on the size of the pressure. A pump with a high pressure will ensure a constant circulation of fluid even in the most remote parts of the system.

How to calculate power?

There is a universal formula for calculating the minimum power. It looks like this: G = Q X 0.86 / t, where:

- G - system capacity in l / h;

- Q - thermal energy (W);

- 0.86 - coefficient (Kcal / h);

- t is the amplitude of temperatures at the supply and in the return (C).

Similar calculations are more often performed by specialists, but if you have free time, you can do them yourself. With independent calculations, it is necessary to take into account all possible losses of power and heat. A standard pump for residential premises has the following indicators: with a capacity of 2.6-2.8 cubic meters per hour and a pressure of 5-6 m. There are features for calculating power for different types of connection diagrams.

With a parallel scheme, it is necessary to begin with the calculation of the costs for the branches and then summarize them. Then losses in all circuits are calculated. Then you can find out the flow in the mixing unit. Its value is influenced by the amplitude of the temperature and heat loss of the floor.With a serial connection scheme, the calculation of the recommended flow rate is performed. After the number of consumption determine the loss in power and head. Antifreeze viscosity is much higher than that of water. Therefore, it is necessary to change the calculations, take the pump with more power.

When choosing a pump and its capacity, be aware that you will pour into the system.

Manufacturers

In the market of pumps for heating systems, as in any segment of sales, there is a huge selection of companies and manufacturers that create the offer. Among the mass of varieties of goods presented for sale, there are companies with extensive experience, time-tested and having a lot of positive customer reviews.

German company Grundfos It has long taken its place in the segment of pumps for heating systems, both radiator and floor heating systems. These pumps have few complaints, they are different build quality and performance.

German company pumps Wilo also distinguished by durability. For the price, they are more affordable than Grundfos. The pumps of both companies almost do not differ, they have the same parameters in power and head. Both companies produce industrial pumps.They are a dual pump. Its principle of operation is the following: when there is a shortage of power of one pump, the second one turns on, so the operation of the pump and the whole system is normalized. If one of the pumps fails, the second pump will replace it until the broken one is replaced with a new one. Such a system is extremely convenient and does not create emergency situations.

These two firms are the flagships of the entire industry. The remaining companies are much less known or very expensive. And these two German firms are the best example of the combination of price and quality. Also often used Italian pumps, which are characterized by high power and long service life.

Successful examples and options

One of the best options in everyday life is the use of regulated varieties. This will help control the pressure in the system or individual circuits. One of the best options for installation recognized small, compact products. They do not take up much space and are easy to install. During installation, it is necessary to take into account the dimensions of the entire module, which includes the pump and all mixers with connections. This system should not be very dense (to avoid heating of all elements).

The choice of a pump for a heated floor is an important component of the successful operation of the entire heating system. Without it, the heating system can quickly become unusable or work incorrectly. To do this, you need to competently approach the case and perform several simple calculations. If they seem complicated, there is always the opportunity to consult a specialist to find the model correctly.

In the following video you will learn how to choose a circulating pump for a warm floor and install a collector.