Coupler under a heat-insulated floor: types and ways of filling

In recent years, heated floors have become very popular, which are gradually replacing traditional heating systems. The market offers a wide range of such options, each of which deserves separate attention. But whatever the option of a warm floor you choose, you first need to determine the organization of the screed, as this is one of the most important stages of the installation of heating.

Special features

First of all, the screed is made to level the floor so that the floor can be laid easily and without problems. And if you want the heating to be uniform, as well as the heating elements serve for many years, you need to do high-quality filling using good-quality materials.

You will need to choose one of the screed options, based on the characteristics of the room and other criteria.In such matters, it is necessary to consult with the professionals or provide this work to them so that they can fulfill the task qualitatively.

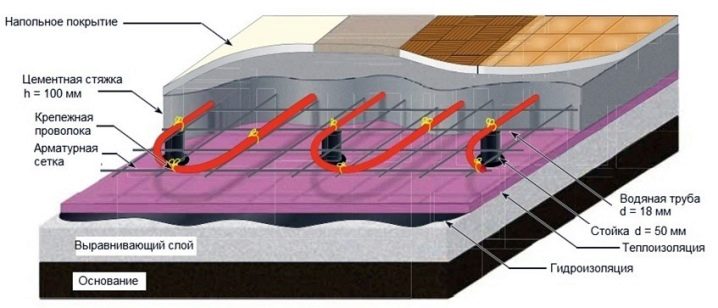

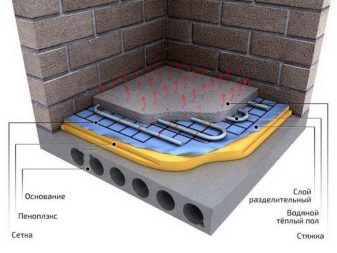

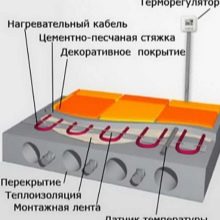

It should be noted that the construction of a heated floor consists of four layers, each of which performs a specific task:

- The bottom one is a rough tie, which should solve the problem of uneven floor surface. If you have a floor slab installed, this layer will not have to be done, since the coating is free from defects.

- A heat insulator is applied to the roughing coupler, the role of which can be performed by cork substrate or penoflon. They will not warm the foundation, and this is an important point.

- For this layer follows the laying of a water pipe, mats or cable, it all depends on the type of floor heating you intend to install.

- And the final stage will be the organization of the concrete screed.

It is necessary to pay special attention to the screed, because it performs not only a thermal function, but must also withstand heavy physical loads. This means that you need to take care of the strength of the floor. To do this, experts eliminate any defects in the coating, detect cracks and close them up.

If you do not repair the floor, the elements will overheat, resulting in system failure. If you properly perform the tie, the structure will be strong and reliable, and the heating system will not become deformed.

Workflow organization

You can solve the problem yourself if you carefully study all the details and follow the instructions step by step. The first thing you need to decide on the option of intermediate flooring, as they are different and are suitable for certain premises. To one of the most relevant can be attributed wet roughing screed.

Regarding the thickness of the coating, it all depends on the volume of the room, which must be properly related to the amount of mortar you will use.

It takes a long time to dry the wet solution. But this option is in great demand because of its economy.

The best is considered a semi-dry roughing screed, which is preferred by many experts. This intermediate floor covering is formed from a mixture of concrete, water and sand. Such a lining would be the best choice under the warm floor, besides it is easy to lay laminate, ceramic tile and even parquet on it.

There is also a dry draft screed, in which, of course, water is not used.For its manufacture special mixtures are used, distributed over the floor surface. After that, you must use dense sheets of plywood or concrete blocks to cover the area. An important role here is played by insulating materials, on top of which a laminate or tile is already being installed.

If you do not want to distribute the mixture over the surface and want to save time on this, it is recommended to pour a self-leveling roughing mixture. This is a finished bulk mass, which is transferred to the floor, and itself is distributed evenly. For apartments, this method of filling is best suited.

The height of the flooring is adjusted individually for your needs. You can consult with a qualified specialist, ask him questions and get useful recommendations for a specific room.

To achieve a low level of the floor, use a small amount of mortar.

Types of screed

Semi-dry

To install a warm floor, you need to understand what type of tie you choose, and whether it will be poured under the tile or laminate.Skilled builders who have a lot of experience in this field often use exactly semi-dry, because it allows you to get any thickness of coating. By the way, this indicator plays an important role, so it should not be missed.

If you make the thickness small, it can lead to a change and sometimes breakage of the heating elements. As for the high screed, it eliminates the effect of water or electric floor. It is important to use high-quality building materials in order to achieve the desired result, and to be sure that the coating will last for many years without causing any problems.

For the manufacture of semi-dry screeds themselves must choose a certain type of sand and concrete. They must be designed by the manufacturer for rough flooring, which is installed in a residential area. Thanks to this screed, you can make either an electric or a water-heated floor. Such a "ground" is not afraid of temperature fluctuations and can withstand heavy loads, which is an important advantage.

The composition should not be plastic, like cement mortar, rather, it should resemble wet sand.For the distribution of the material used shovel or trowels, through which you can do everything evenly and evenly. Full drying of the semi-dry screed occurs after twenty-four hours. Try not to touch the “ground” and wait before laying tile or laminate on it. Continue to work after two days to make sure the room is completely ready.

For electric floor heating

There are no regulatory documents to which the work must comply, but in order to achieve a quality result, it is recommended to follow certain rules. The first thing you need to pay attention to the thickness of the screed, both under and over the heating cable.

Then the method of installation is selected, the solution is prepared correctly and pouring takes place. If you follow the recommendations, the surface will not crack, the heat will be evenly distributed, and the strength will remain for many years.

How to determine the thickness of the layer?

The main task is to make the surface flat before laying the cable. Specialists who are engaged in installation of the screed, do not make it thinner than three centimeters.It is believed that this is the minimum value that guarantees a quality result. However, if leveling mixtures are used, it can be limited to two centimeters.

The following factors affect the thickness:

- foundation for casting, which is at least ten centimeters, it all depends on the surface irregularities that need to be fixed;

- the material from which the mixture is prepared.

If we talk about the installation of an electric floor, then about the screed experts express a different opinion. We cannot do without the recommendations of the manufacturer of the product, since it indicates the main indicators and constitutes the operating instructions for all products.

Features of Knauf products

Today, many manufacturers offer dry and ready-mix to create a tie under the warm floor. One of the most famous and popular options is products from the company Knauf. The composition of the mixtures includes multi-component compositions, which not only provide an even, durable and durable coating, but also guarantee excellent heat and sound insulation of the finished floor.

All products meet the highest quality standards, and this is confirmed by the numerous customer reviews that have used Knauf blends when installing underfloor heating in their home or office.

Reinforcement

During work, each specialist wants to be sure that at each stage a qualitative result is achieved, and no defects will be observed. And for this it is important to check whether cracks do not appear, since they cause the occurrence of cold zones, so heat is unevenly distributed. To prevent this, it is necessary to provide reinforcement screed.

There are several ways to reinforce. For the manufacture of the solution is used fiber, which is an additive. It contains polypropylene. The mixture is increased several times, which has a beneficial effect on its strength characteristics. The screed will be more resistant to damage, protected from cracks and subsidence.

Reinforcing mesh, which is often indicated as a mandatory element in the performance of work, is in great demand.

Fill rules

Before starting work on installing underfloor heating in your home or office, you need to decide on the type of screed. For residential premises it is better to use a dry or semi-dry screed. Moreover, it is much easier to do it, unlike cement. In addition, you do not need to wait until the floor is completely dry, and you can soon exploit the room, as well as continue to repair and interior design.

Filling is necessary in order that installation of a heat-insulated floor passed qualitatively and elements correctly distributed heating. Therefore, this task should be taken seriously, and choose the appropriate type of screed, which will ensure evenness of the coating.

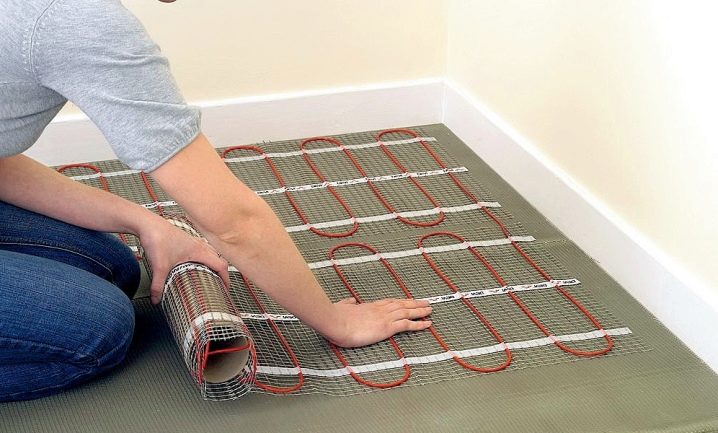

To achieve the desired result, you must follow a certain technology. It all starts with the preparatory work, you need to expand the cable, because it will be mounted. Experts can not do without beacons, which must be set to the surface turned out as smooth as possible.

The elements are placed at a distance that should not exceed 0.8 m. The lighthouses line up along the edge of the room, the fishing line is stretched between them, under which the remaining elements are exposed. If you follow all instructions, the result will not disappoint you!

The lighthouses are fixed with a special solution, after which the pouring of the screed begins.

The work must be performed in stages:

- The first layer is applied in two to three centimeters. A day later, the second is poured, and the final is beaten along the beacons.

- The important point is the observance of boundaries, so that the excess solution does not go beyond the edges, otherwise holes will form on the surface.

- It will take several days to dry the mixture, but it is necessary to close the windows so that direct sunlight does not fall on it. The screed is covered with a film, and watered several times with the same time difference for five, sometimes seven days.

If you study everything carefully, choose the right materials and mixture, strictly follow the instructions and follow all the recommendations of specialists, you will achieve the desired result and be satisfied with the effect. After installing a quality screed, you can do the mounting of the heating system or laying tile, laminate or parquet.

Thus, an optimal climate will be created in the room, and thanks to the work well-done, the heat will spread along the floor evenly. Easy repair and quality results!

How to make the perfect composition of the screed for underfloor heating, see the following video.