Manifold for underfloor heating: features of choice

Due to the fact that the climate in recent years is very unpredictable, many rush to install special heating systems that allow you to fully control the temperature in the room. Among such systems, the best performance characteristics show warm water floors with collector control.

Special features

Heating floors with water coolant can work in different designs. A simple and familiar system is underfloor heating, which provides heating with pipes directly attached to the heating equipment. These tubes are laid under the floor and quite acceptable heat the small rooms. But such devices are clearly limited technologically.Most often they lack the ability to control the temperature.

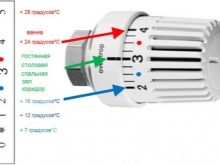

The whole system is connected to central heating.therefore, it is not difficult to guess that the temperature of the heating tubes will take on the same value as the temperature of the battery. Thus, the floor surface will heat up excessively. Perhaps it does not matter for the surface of the floor, but walking on such a coating will be very hot and uncomfortable. The normal temperature of the circulating composition inside the tubes is 35-45 ° С, and in the hot water supply pipes it is significantly higher.

To avoid overheating, you need to choose the option with a more complex heating system.

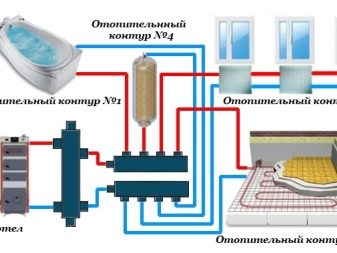

The main functional element of such systems is the collector. This device will keep the temperature at the required level. Thanks to its clever design, the distribution hub completely controls the flow directions. It provides smooth heating of the water circuit.

A feature of collector units is not only the ability to control the temperature. Its assembly also takes into account the safety of operation.Even a child can turn the whole system on or off. Collector systems are ideal as an autonomous heating of residential buildings. However, they may be unprofitable for heating bathrooms with direct connection to the riser.

What is it needed for?

A collector is a layout of parts that, when properly assembled, completely ensures a safe thermostatic process. Its design allows in the required dosages to mix and dispense liquid from parallel heating units. Due to the large diameter of the cavity and the insignificant flow rate of the coolant, the necessary temperature regime is created in the entire system. The flow of coolant comes from the boiler and is mixed with warm water heating pipes.

For correct mixing the collector system is equipped with a group of sensors. In general, they are focused on pressure and temperature.

This group of sensors includes:

- Water temperature sensor;

- Ambient temperature sensor;

- Pressure gauge inside the system.

They all measure the parameter to which they are tuned.The information received from the meters is sent to the valve control system, and the flow from the coolant is mixed using their capacity. For given conditions, they provide the intensity of heating of a warm floor. In turn, the pump unit assembled in the manifold kit, fully controls the pressure.

To understand the need for a collector installation, it is enough to know that a shower, radiators and a water floor require heat transfer media of different temperatures. And this cannot be achieved simply by connecting all the elements to the heating boiler. For this, a collector was created.

How to choose?

Typically, the choice of collector due to the dimensions and specific features of the room that you want to heat. Due to the fact that the working process has some difficulties, it is necessary to pay special attention to the materials of manufacture and the quality of the installation of the structure. Brass and stainless steel models are considered quality and durable. But you can also use polypropylene, if the operating temperature is low. Polypropylene is limited in use and therefore has the lowest cost.

Surely not all people dealt with collection plants. Therefore, it is necessary to know that in addition to the cost of construction, it is necessary to take into account some features. The number of taps for heating pipes is very important.

The number of these outputs is usually selected on the basis of a special calculation. However, the initial decision cannot be absolutely accurate, since the area of all rooms is not the same. Therefore, it may be that somewhere there will be an extra challenge or vice versa. It is recommended several times to recalculate or take everything with a margin.

Manufacturers usually offer two options for a water floor with collector heating:

- Equipment that provides only manual regulation of the process;

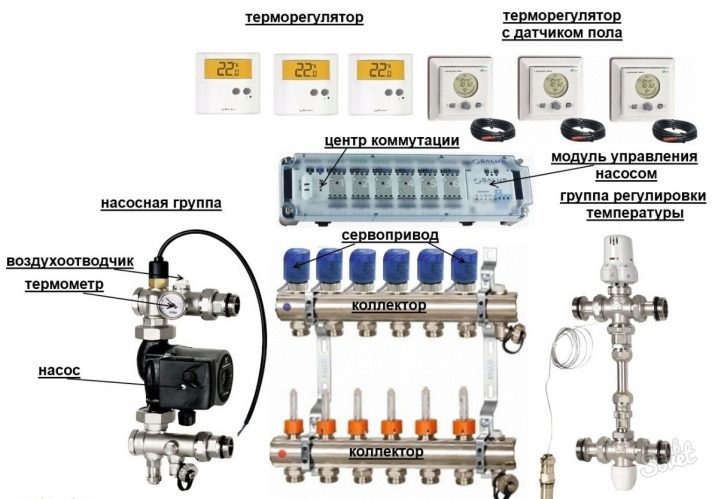

- A system that includes thermometers, pressure gauges, flow meters, pumps, valves, servos, and so on, which automatically maintains the work of a heated floor.

If all the outlines of the same length, and the heated floor system is not combined with radiator units, the equipment without automation is fine. In this case, the manipulation of the taps at the outlets, that is, the locking or release of flow from the coolant into the taps under the floor surface, is carried out only manually.In this case, the temperature is selected based on the personal feelings of the consumer.

In other cases, it is more convenient to use heating systems with all automatic control devices and with the possibility of installing a servo.

It should be noted that despite the high cost of automating the process, it will be able to reduce the cost of heating.

Kinds

Collector devices can be divided by the type of automated systems installed in them. Currently, manufacturers have been provided full automatic control of warm floors.

Depending on the built-in automation, temperature control of the room is carried out in different ways:

- Pump;

- Through the thermal head;

- The action of servos;

- Three-way valve;

- Weather-dependent controller;

- Group regulation.

Each of the methods has its own specifics, which means that the automation should be selected individually for each heated room.

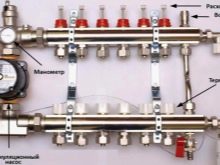

Pump control is a frequent and uncomplicated method to control the temperature of a heated floor. It will be most convenient if a large number of pumps are used in a heated room.The system is designed so that the pump unit is turned on or off by a command coming from a thermal sensor that transmits a temperature indicator of the air in the room. The method is not recommended if the entire heating system consists of a single circulation unit. Because the entire home heating process will stop when the sensor triggers.

Thermal head control - this system is not fully automated. The essence of this method of control is that the thermal head with an attached sensor becomes a device for measuring the temperature of water in the system. The installation of the thermal head is carried out on the mixing unit of the three-way valve. This valve opens or closes when the temperature in the system differs from the set point.

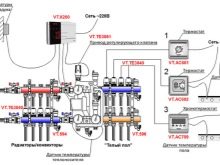

When controlled by servos, these elements are installed on the collector piping. They regulate the flow of coolant separately for each circuit. Regulation takes place on the basis of data obtained from a sensor measuring the temperature of a heated floor. The method is suitable if necessary to control the heating of the floor in separatepremises.

The control by means of a three-way valve consists in a certain dosing of the components of the mixture. It provides mixing of the colder and hot stream from the coolant in certain proportions. Control takes place via a room thermostat and servo-drive installation.

The weather-dependent method, as the name implies, adjusts the heating intensity according to the readings of sensors outside. The peculiarity is that the system calculates a dynamic indicator of changes in conditions on the street and sets the heating floor heating data in advance. The method is expensive, but allows you to save 25-30% of the cost of heating.

Group control is provided by a large number of mixers, this makes it possible to simultaneously control the parameters of the environment in the circuits of several rooms. The same method is carried out by connecting individual mixers, which allows you to control using only one unit. The method is suitable if you need to maintain a constant temperature at a time in a large number of rooms.

As a separate form, you can note homemade installation. Of course, all collector units - this is not the cheapest pleasure. Therefore, more and more people collect the entire system with their own hands. And self-made installations are gaining popularity, because their assembly is quite simple. But you still have to spend money on automation equipment.

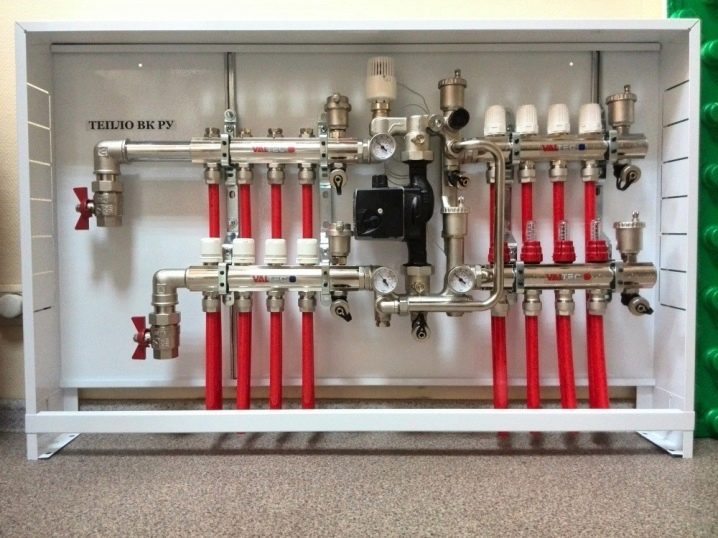

Regardless of the type of collector, you will have to think about where to put this heating system with all the equipment.

It is rather bulky and it’s good if you have a special place for it. However, if it is not there, then it is worth using cabinets, which are specially assembled for storing heating systems. Cabinets are a user-friendly metal structure in the form of a visually unobtrusive piece of furniture.

The structure of the mixing unit

On the market there is a huge number of different assemblies of mixing nodes of all kinds of complexity. All of them are distinguished by a set of automatic tools and some additional structural elements. They perform the same function in the underfloor heating system.

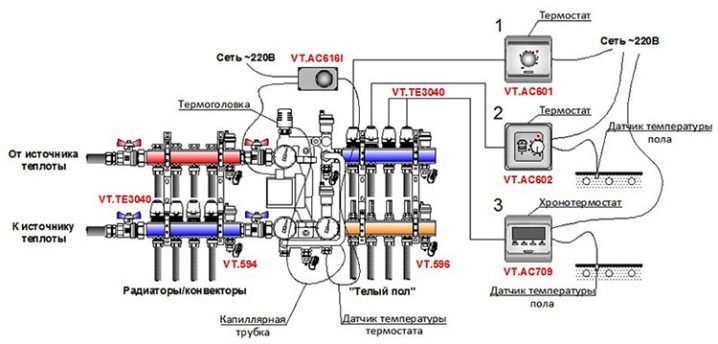

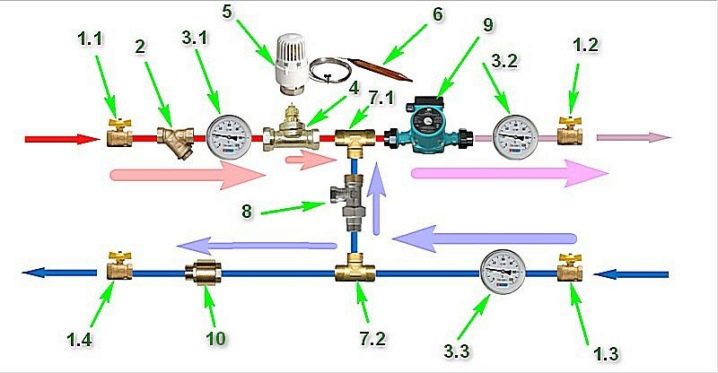

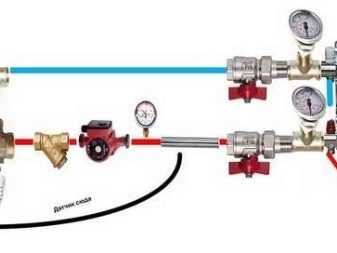

For a visual representation of the design, it is recommended to consider the components of the mixing assembly in the simplest scheme with a thermal valve:

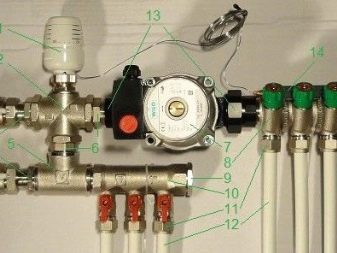

- Shut-off valve is a locking device that is not designed to regulate flow. It can only be in two positions: fully open and fully closed. Its task is to completely disable the pumping and mixing unit.

- The filter element is an optional part, but is recommended for use, as it can prolong the service life of the mixer system. It protects against mechanical impurities that can destabilize the operation of valves.

- A thermometer is a measuring instrument for monitoring a temperature parameter, which is carried out visually. Devices are a special need for commissioning or installation work floor heating.

- Two-way thermal valve - the main element of the dosage of warm and hot coolant flow.

- Thermal head with sensor - the controller for the thermal valve, which is installed on it with the help of special adapters. The control is based on the readings of the measuring sensor, which is attached where it is convenient for the user.

- Temperature sensor.

- Ordinary tees, between which is provided a bypass line.These lines will be the reverse flow of the coolant.

- Balancing valve - an element necessary for the correct operation of the mixing unit. With the help of this valve, the required values of head and capacity of circulation pumps built into the system are set.

- A circulation pump is a device that serves the entire heating system. One pump cannot take on circulation at once in several circuits of considerable length, therefore, it is necessary to install its own apparatus on each circuit.

- A check valve is the simplest safety device that does not allow the flow of water to inadvertently flow in the opposite direction.

The main functional component of the mixing units is the mixing valve. It plays a crucial role in the distribution flow process. Due to its functional features, the temperature of the desired value is ensured.

Mixers of any collectors work on one of the types of valves:

- Three-way;

- Two way.

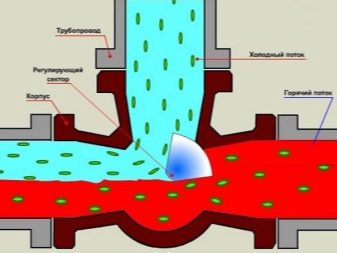

Three-way valves in the design of the collector provide mixing of hot liquid from the boiler and warm, going backwards from the heating circuits.The third place in the valve is assigned to the actuators, thermal head and other elements that control the system. This design is the most popular, but has several disadvantages.

The first disadvantage is that, at the signal of the thermo controller, the valve can fully open and let hot water through without any cooling. So the tubes will be under the influence of a temperature of about 90 degrees, the pressure in the system will also increase. At the same time there is a high probability of rupture of the tubes under the floor.

The second drawback is that the flow area of the three-way valve is large in size. Because of this, the slightest change in the position of the regulating element can dramatically change the temperature in the circuit under the floor. As a result, smooth temperature variation will be complicated.

And the second type of valve - two-way. The peculiarity of mixing constructions with such a valve is that the mixing goes on continuously. Warm floors will not be exposed to overheating. Also, due to the small value of the throughput section, the temperature change will occur stably and smoothly.But the mixer of this type also has a functional minus.

Mixing units with a two-way valve does not make sense to install in large areas (more than 200 m2).

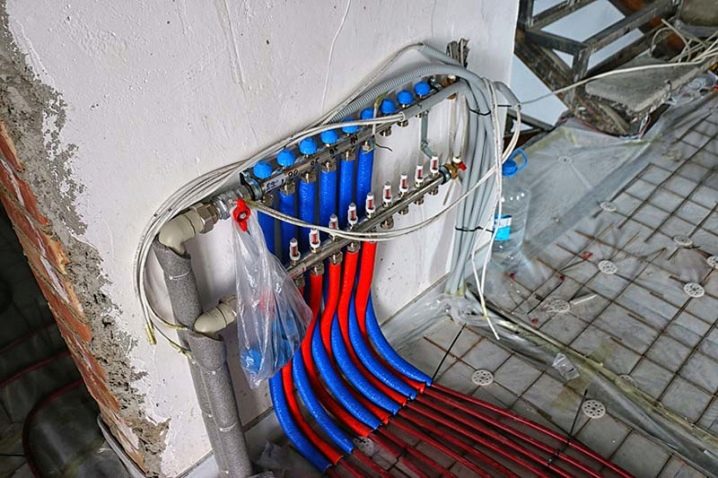

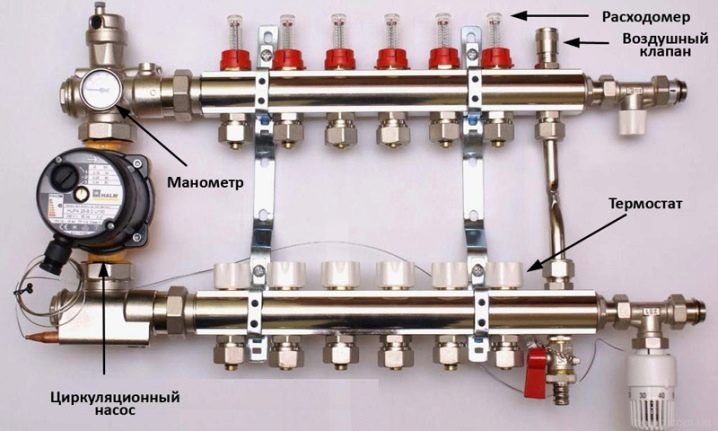

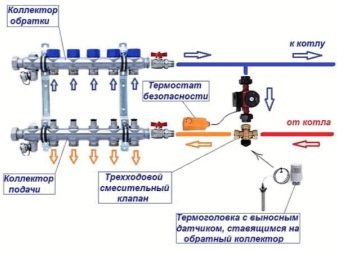

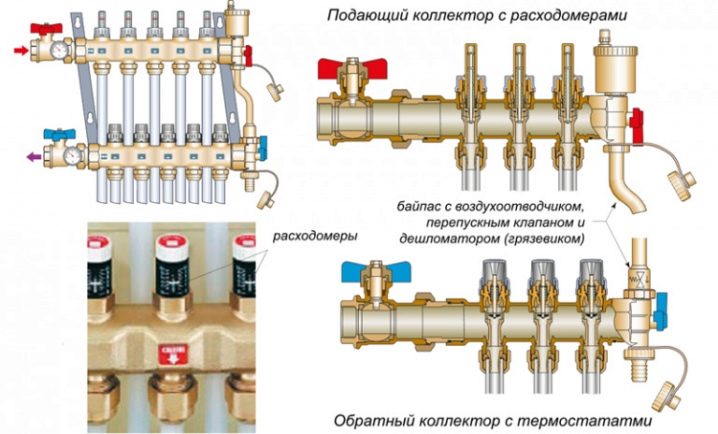

The structure of the "comb"

The collector harness looks like a comb, so it is sometimes called that. The node of the distribution comb is a piping coupling connections, complete with a set of taps to connect the heating circuits. If several circuits are connected to the comb, and the dimensions of the outlets of one circuit exceed the lengths of the tubes of the second, then flow meters must be installed and configured. Because without these elements, the flow will go only in the cavity with less hydraulic resistance. So one of the circuits will not be heated in the right amount.

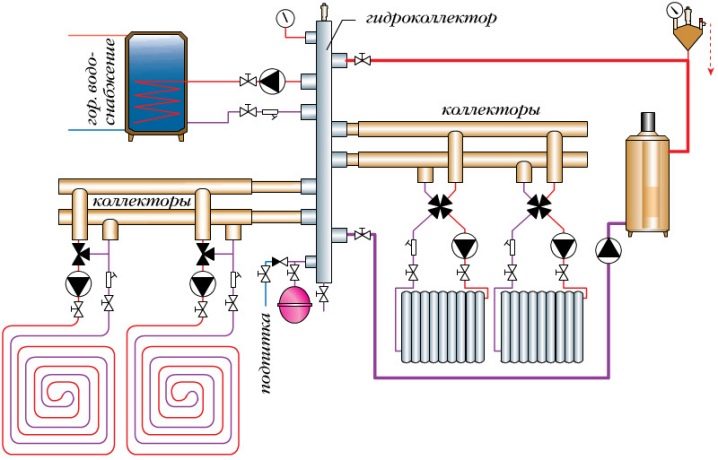

To make it easier to understand what the comb consists of, you need to carefully consider the image.

In spite of the fact that it is better to entrust the assembly and adjustment of the work of the comb to specialists, people often design it themselves. If you have experience with plumbing, then correctly assemble the comb according to the description will not be easy.To do this, you only need to solder pieces of polypropylene pipes and fittings, as well as gently attach them to plumbing tees.

The more you do with your own hands, the less material investments will be spent on this. Thus, the forthcoming expenses for the organization of heating reflected in the estimate will be much less.

System automation

As mentioned above, almost all the comfort of a heat-insulated floor heating system consists in automation equipment. The automation system is represented by a large variety of sensors and controllers that will control the heating on their own. Automatic systems with a collector differ from conventional heating radiators in a wide range of possibilities. Automated components every year are becoming more technological.

Here are the most common:

- Room thermostat - control unit of the heating of water floors. The control is carried out by only two positions of the thermostat: plus and minus. As soon as the set temperature is reached, the thermostat gives a command to close or open the circuit.It works in tandem with a control element, for example, a servo drive. It is advisable to buy this pair from the same manufacturer.

- Thermostat control usually placed in a distribution box, but it can also be connected to hidden wiring. This device has been used for a relatively long time, so its modifications are enough to satisfy the demands of consumers.

- Chronothermostat - programmable electrical appliance. We can say that it is a modification of the usual thermostat. Its principle of operation is that it allows you to control the temperature in the future. That is, the chronothermostat will automatically maintain the set temperature at the intervals you select.

- Flow meter - an indispensable element of the collector system, which is a device consisting of a polypropylene body and a glass flask with a float. It is installed on the return flow taps of the heat carrier, when it reaches the specified temperature, it narrows the flow area or completely covers it. Balancing the flow through the flow meter is controlled by a temperature sensor or manually.

All automatic systems have a significant cost.But they also allow you to save money due to the lack of energy overspending. After all, when everything is configured specifically at will, you won't pay anything extra.

Connection

If you decide to heat the house with a water floor with a collector system, then you need to know how to connect it. Connection is not difficult if you act according to the instructions.

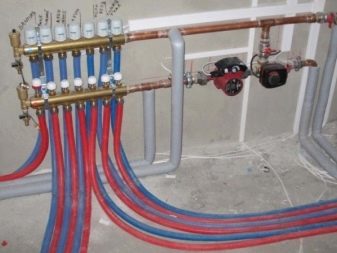

So, in the case of installing an uncombined version of the heating system, you need to choose the place where the unit will be located. Prepare a place near the wall, a special cupboard or niche. It must be remembered that the location should provide ease of maintenance of equipment. Check the availability of all spare parts, then you can proceed to the connection with the simplest scheme.

Install the unit so that the coolant inlet from the boiler is carried out from the bottom, and the reverse cooled flow goes from the top. There is another option, but this one is more popular.

Ball valves must be placed outside of the cabinet or installation site. This is done for ease of shutdown in case of unforeseen repair.

After the taps need to connect the circulation pump.

Next, you need to install a throughput valve with a temperature limiter and then connect the comb, lay the pipes under the floor surface, through which the flow from the heat carrier will flow.

Now it is necessary to connect the collector with the heating system. This is done using fittings. Usually they are included.

It remains only to let the warm flow into the system and check the tightness.

Manufacturers

When you get close to the installation of a collector heating system, the question of which manufacturer is of the highest quality will appear. At the moment, the championship in the ranking is taken by models from Italian companies. Italy is not in vain famous for its reverent attitude to work, so the quality of its products is kept at a high level.

A good example would be the Russian-Italian brand. Valtec. Valtec products are sold in an affordable price range and are very popular in Russia. The brand has a sufficient amount of time on the plumbing market and has managed to recommend itself well.

Most installations of warm water floors are created in China.Chinese goods have received the status of poor quality only because of their huge number. Undoubtedly need to pay attention to the young manufacturer of plumbing "Millennium"He may well compete with other companies. This manufacturer provides a wide range of products and constantly adds improvements to its heating systems.

One of the high-profile plumbing manufacturers is the company "Neptune". It interacts closely with customers and focuses on consumer demand. Neptune offers a wide variety of products.

It is important to remember that no matter which manufacturer chooses, the quality of installation and careful operation will always be the key to the durability of any equipment.

How to make yourself?

Earlier it was said that the collector can be made yourself. Yes, it makes sense if you need to save. However, the majority of improvised collectors are brazed from polypropylene pipes, which in turn complicates the installation of flow meters and thermometers. Therefore, a homemade design is suitable if the heating is single-circuit or dual-circuit, but no more.The design, which was created to feed only one circuit has significant dimensions, for a larger number it will increase.

To make a homemade collector, you will need:

- About two meters of plastic pipe with a diameter of 32 mm;

- Tee elements;

- Ball Valves;

- Direct balancing Vlapan;

- The ability to well solder polypropylene.

First you need to find out the depth of shrinkage of the pipe in the tee, and then solder them well together. Then you need to retreat from one edge of the fitting through the pipe a distance equal to the depth, and cut off the end. To the lower outlet tee need to solder the coupling. In the same way to make the required number of identical blocks and solder them with each other.

Now one end of the tube must be connected to the coupling for the ball valve, and the other should be soldered to the knee, in which the air vent will be installed. The resulting collector is ready for installation in the heating system.

If your heated house has more than one floor, then pre-assemble several collector systems. For correct operation of the heating, it is better to arrange a collector on each floor, because the exhaust of air that adversely affects the operation of the system is complicated by the number of floors.

Professional Tips

Any investment of significant funds is in doubt. And this is natural, because it is important that the costs are justified. Therefore, before buying, you need to fix your decision with the opinion of experts.

Knowledgeable people recommend that you necessarily calculate the number of circuits, so you can save on the possible simplicity of the collector system. It is not recommended to save on the quality of the equipment itself.

When assembling, install the valve on removable couplings in order to be able to clean the clogged valve, because the flow of water from the coolant in any case has mechanical impurities. In order to fix the assembly parts, use compressor fittings.

In detail about a collector for a heat-insulated floor and heating look in the following video.