Heated floor under the tile: the features of choice and operation

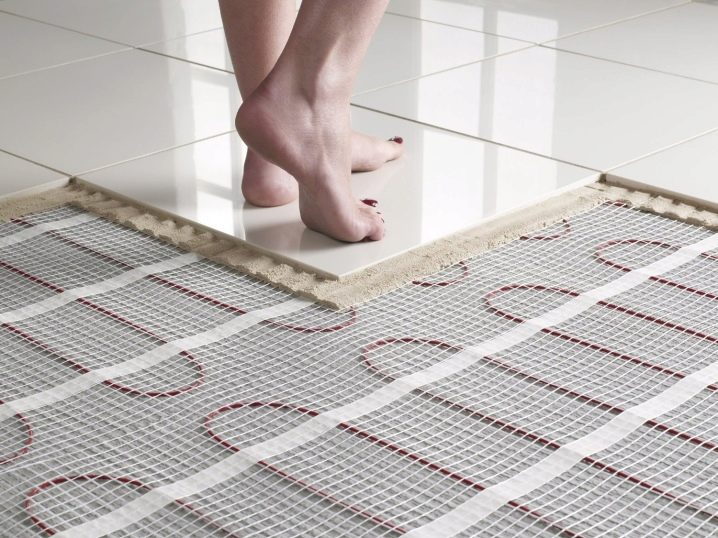

Heating systems for floor heating, offered by modern manufacturers, are distinguished by a variety of technological solutions. The ceramic tile is durable and differs in considerable wear resistance, it is very practical in service, but, nevertheless, it is very cold material. Therefore, it requires heating by means of a heated floor.

Special features

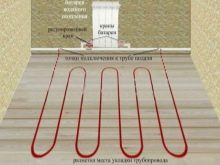

To date, there are two types of floor heating - water and electric. In general, the choice of method depends on the intended purpose of the room in which it is intended to mount such a floor, the estimated mechanical load on the sex base and the financial possibilities of the consumer.

It should be said that both types of floor heating from ceramic tiles have their advantages and disadvantages. So, the water heat-insulated floor consists of the pipes laid in the basis of a floor.

When installing it, it is necessary to create a certain angle of inclination of the water supply and its reverse circulation.

In addition, there is a need to install an additional water pump, which increases the circulation of the coolant in the system. For further tile laying on such a floor, it is necessary to fill it with a cement screed.

The advantage of such a system is a rather insignificant level of costs for its operation.

However, to install a warm water floor, the efficiency of which is directly related to the work of steam heating and booster water pumps, in high-rise buildings is not entirely appropriate.

In the event of failure of the heating system in the winter, the defrosting of the water floor together with the entire system and the inevitable breakthrough of its pipes inevitably occur. The result may be the need to dismantle the system thus destroyed and its complete replacement with a new one. Therefore, a warm water floor requires constant monitoring and requires systematic maintenance.

As for the floor electric heating systems, in recent years they have become traditional.

The principle of their operation is to generate heat by the heating elements of the system under the influence of an electric current. These elements can be electrical cables or infrared film heaters.

There is also a synthesized version in the form of electric water floors. At present, it is represented by two systems: XL Pipe and Unimat Aqua. They differ from each other in their design features, they have different principles of action, but both types of systems are installed in the screed.

Kinds

Electric cable floors are economical and safe to use. Technologically, the preparation of the base for cable laying is the most labor-intensive, since this operation requires a perfectly level base.

On top of the heating circuit should perform a tie and lay the tile.

The main disadvantage of such a system is its low resistance to surface pressure.

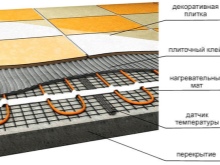

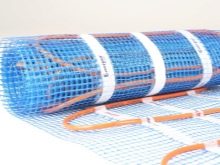

The easiest way of installation is to lay the tile directly on the electric heating elements. They can be mats from a cable or a rod floor with infrared heaters.

The practice of using rod mats indicates a lack of reliability of this type of electrically heated floor. Often there is a fragmentary heating of individual parts, and not the entire area of such a floor, or its complete failure.

The cause in most cases is the burnout of the joints between the heating rods and the current-carrying wires.

This, apparently, is the result of the not fully developed technology of manufacturing such systems. Their cost is quite high, and the installation of rod heaters under the tile floor can be fraught with the need to completely knock down ceramic tiles when heaters fail.

But the mats of another cable type, complete with a thermostat, proved to be excellent in work, because the process of their production and operation using long-established technologies in the European and American markets goes back several decades. Therefore, the installation of a heated floor, both in the form of a cable, and in the case of using a finished heating mat, can be considered a very reliable option.

The cost of this floor is much lower than infrared

The technology of installing mats under a tiled floor is similar to the use of carbon mats - they are spread on a flat base, cold cables are connected to the thermostat and ceramic tiles are installed on glue. At the same time, it is necessary that the thickness of the adhesive layer together with the tile be at least 2 cm.

If a resistive heated floor is being installed or if we are talking about a self-regulating cable system, it is necessary to create a tie for laying ceramic tile on it. This option is associated with the need to wait for complete drying and shrinkage of the screed for 28 days.

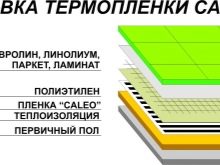

The infrared film heater is the second type of carbon-fiber underfloor heating after the rod mat. Being an emitter of thermal energy of the infrared range, it does not need to create a concrete screed for it.

The IR film has a very smooth surface and practically does not form adhesion with the cement mixture, but there are several special types of films that have perforations through. Such perforated infrared films are equally applied both on the screed and directly under the ceramics.

As for the technology of laying film of a conventional warm floor under a tile, it is performed without using a screed according to the so-called “dry” method, when sheet material such as plywood or sheets of chipboard, fiberboard and the like is placed on the film. On the basis of the thus-made and glue the tiles.

This is done because the polymer with carbonated paste in it in the screed layer undergoes destruction.

Such a floor consists of many layers in which a large amount of thermal energy is lost, as a result of which it cannot be considered the best option, and the price of a square meter of film is about 70-80 dollars. Therefore, it is more acceptable to install a perforated infrared heater of the film type because of the very high heat transfer from such a floor.

The floorings of the XL Pipe of the Korean manufacturer Daewoo Enertec are seven heating filaments placed in a hermetically sealed polyethylene pipe with antifreeze. Heating of such an element together with a coolant in it occurs almost instantly, with a uniform distribution of thermal radiation, unlike underfloor heating with water heating.

By changing the laying step of heating tubular cables, any level of heat transfer can be achieved, so XL Pipe floors can serve as a source of both primary and secondary heating.

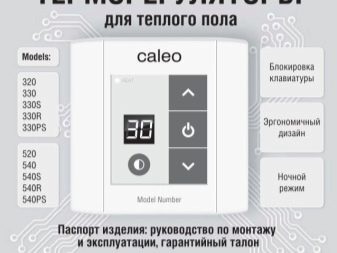

The well-known company Caleo produces another heating system with a completely different principle of operation called “Unimat Aqua”. It is also called the capillary heated floor due to the fact that the tubes of this system laid in the screed have a small diameter. Such a warm floor is powered from the network through a special control unit that simultaneously starts the system and heats and controls the temperature of the coolant.

This system has a power of 0.1 kW to 2.4 kW, so it is not able to generate significant amounts of heat, but it differs in ease of installation and connection literally to the outlet. Therefore, such a system can be recommended for installation in rooms such as bathrooms or baths, that is, where there is high humidity.

Concluding the description of the main types of heating systems for ceramic tiles, a few words should be said about their energy-saving properties.Energy savings in the operation of such a system depends on the choice of heating mat and its compliance with the heated surface. The considerable power of such a mat leads to a serious overspending of electricity.

Much also depends on the type of thermostat and the correct installation. On average, a comfortable temperature level in a heated room using a heated floor should be about 20 ° C or lower by two degrees, compared to the traditional method of central heating.

This is explained by the fact that when using traditional heating means the heat distribution is uneven. Directly above the floor, the air will always be colder with this method of heating, and under the ceiling, respectively, the temperature will be higher.

At the cost of heating the premises, the area of which may be about 100 square meters. m, provided good insulation of the house due to the installation of sealed windows during the heating season is quite comparable with the cost of central heating, consisting of a boiler with heaters.

An indispensable condition that must be met in this case should be the installation of thermostats in accordance with the technical conditions imposed on them.

The use of electric floor heating as a local heater can be carried out in two versions. If such a system is used for additional heating of the room, you should install mats of lesser capacity and, consequently, smaller size, and the parameters of the thermostat in this situation do not play a significant role.

If the warm floor is given the function of a full-fledged heating device under the condition of refusal from central heating, then it will be necessary to pay attention to the power characteristics of the mats, the quality of the heating cable and the management functions of the regulator.

In this case, the selection of cable mats must be carried out so that at the lowest power they would be able to maintain an optimal temperature level in a heated room.

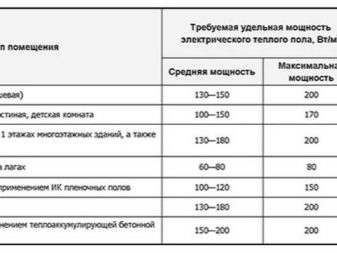

The choice of the parameters of the power of a warm electric floor is carried out at the rate of 100 W per 1 m2, if we are talking about additional heating of the premises, but if such an indicator is observed for the mats used, the temperature will take some time to reach the required comfortable level. With a rate of 150 W, the power of the heating mats per 1m2 can bebe used as an additional source of thermal energy in the room or serve as a complete heating system in the corridor.

With a power level of about 200 watts per 1m2, when used in bathrooms and other rooms with tile flooring, high temperatures are achieved by limiting the space for laying mats. Mats, characterized by high power, it is advisable to install in buildings where there are high ceilings, garages and premises for production purposes.

Safety standards for heating cables must comply with PN-IEC standards, which contain information on the minimum thickness of heating cables and specifications for recommended main types of them. The laying of the heating cable must be carried out in such a way that there is no need for its conservation and dismantling with knocking down the floor due to the detection of faults.

Do not purchase and install mats that have a power that exceeds the heating needs of a given room.

How best to choose?

The material for the heating system can serve as a tile of almost any kind, since all its varieties are good conductors of heat.It is, of course, necessary to distinguish floor tile types from its facade collections, although it is customary to call them “warm tile”.

These types of ceramic coatings consist of a high density decorative layer and a thermal insulation layer with a loose structure. A scope of such tile are external finishing works, therefore it is not intended for a covering of a heat-insulated floor by it.

The direct selection of a grade of ceramic coating depends on the type of room where it will be used. So, Pei I tiles, due to poor abrasion resistance and undesirable contact with outdoor shoes, are recommended for flooring in bathrooms. Similarly, Pei II tiles, but more expensive in price, are also used for rooms with limited movement, that is, for the same bathrooms.

Tile coating grade Pei III is placed in all rooms such as a kitchen or balcony, which can not be accessed from the street. The Pei IV and Pei V tiles are used in hallways and corridors, as well as in other public spaces due to resistance to abrasion, although they are distinguished by the highest price.

For the reasonthat the thickness of the ceramic tile coating varies depending on the technology, this indicator is not of fundamental importance and doesn’t affect the creation, so to say, of the hyperfine floor. But when choosing a material, attention should be paid to its porosity, which often manifests itself in thicker coatings.

The coating thickness of a high-quality floor should be chosen in such a way that it creates optimal conditions for the supply of heat to its surface.

The structure of ceramic tiles should be as dense as possible, without air bubbles that reduce the thermal conductivity of the coating.

Another criterion for choosing a tile is the difference in its glossy or matte surface. It mostly depends on personal preferences, but an economical choice should be made considering that scratches on the glossy surface are much more noticeable. There are also rough varieties of ceramic tiles for flooring.

Such varieties do not slip in the wetted state, so it is more expedient to use them in the bathroom or in the hallway under the door and in the space closest to it.

You should also make sure that all the material belongs to the same batch, as the production features can lead to decent deviations in color, and this is not recognized for marriage.

Depending on the room

Installation of a heated floor under the tile should be carried out after careful selection of tile covering for this purpose. In addition to the above varieties of tile coatings, various types of kermogranit may be a good option. This material looks very similar to ordinary tile, but it differs significantly from it in composition, technical characteristics and method of manufacture.

In comparison with tiles, porcelain tile is devoid of internal porosity, there are no internal voids and microcracks, for this reason it is characterized by higher strength, wear resistance and water resistance.

This material is resistant to household chemicals, alkalis, acids and temperature extremes. It is these properties that made porcelain tile a very useful material for covering the warm floor of the kitchen.

The use of kermogranitny tiles on the balcony or loggia may be due to the factthat when making it, the clay solution under pressure is fired in the molding tank, and then subjected to firing, the temperature of which significantly exceeds this figure during heat treatment of the tile

Although the cost of kermogranite is significantly higher than that of a tiled covering, its frost resistance and other qualities listed above make it quite an optimal option not only as a floor covering for a balcony or a glazed loggia and hallway, but also for outdoor installation for facing a porch and horizontal surfaces. To do this, apply grades of kermogranita, which resemble natural stone.

In addition to the latter types of stoneware coating, its varieties are coated with a coating of glaze. Porcelain stoneware glazed tiles with a variety of color and texture solutions are perfect for lining the warm floor in the toilet or bathroom.

In addition, due to the combination of its technical and operational characteristics, both types of tiled flooring can be successfully used as a flooring in a wooden house.

For technical specifications

The choice of floor heating system with tiled flooring should be made taking into account the technical characteristics of these systems and the conditions in which they will be installed and operated. The main advantages of warm electric floors are a fairly short heating time and the rapid achievement of the required maximum temperature for a heated room.

Uniform heat consumption, long service life and versatility, ease of installation and significantly lower installation costs of such floors, as well as the fact that an electric floor, unlike a water floor, heats up very quickly, are strong arguments for using an electric heating method tiled flooring. The installation of a water-heated floor is also associated with a significant increase in the thickness of such a floor.

Installation

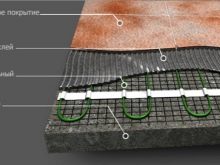

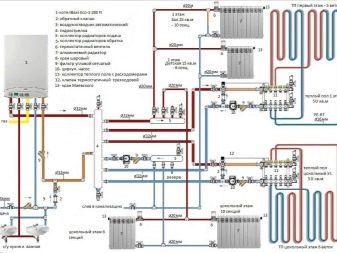

The installation of an electric floor heating for subsequent laying on heating cables of tiled or ceramic tiles by means of tile glue is carried out according to the technology according to which a cable heating system consisting of a cable and fixing tracks or ready-made mats, thermostat, temperature sensor and connecting wires is completed.

Depending on the kit of which manufacturer is used, its content may vary. If the set includes corrugated pipes, the number of which per 1 m2 depends on giving the floor the desired power rating, then in addition, you will also need double-sided tape and a heat insulator, for which the installation instructions for such systems recommend the use of foil-coated foam.

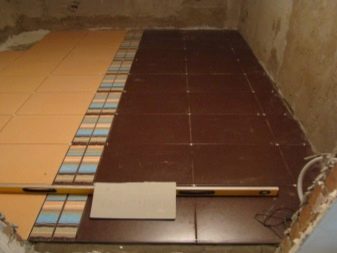

The preparation process consists in arranging a flat surface for laying the heating circuit, mainly by means of a screed for the purpose of economical glue consumption.

In addition, without screed, the elements of the heating structure are at a much greater risk of damage due to mechanical loads.

Upon completion of the preparation of the horizontal surface in compliance with all requirements, cleaning the floor from dirt and debris and priming its surface, proceed to installation.

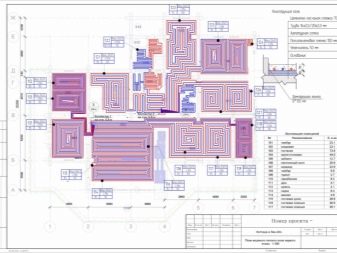

It should be noted that the area on which the heating elements are placed may not correspond to the total area of the room, as in order to avoid static loads from furniture,musical instruments or home appliances warm floor under them is not mounted. Therefore, the work must begin with a preliminary marking of the floor cloth.

According to the general requirements of the instructions for the installation of a warm electric floor, before laying the cable, it is necessary to place a foam or other insulator.

Its use prevents the dissipation of heat and eliminates unnecessary heating of the base. Such heat insulators are supplied in the form of rolls, and the joints between adjacent sections of the heat-insulating material are taped with adhesive tape in order to impart solidity to the structure while observing the one centimeter distance from the walls. If minimal heat losses are observed, then an insulator having a small thickness is chosen, and only the area occupied by the cable is covered. In a different situation, a more dense material is used, which is placed over the entire floor area.

If cable mats are chosen as a heating element, then it is sufficient to expand them according to the marking. To match the required geometry, the mounting grid with the cable pasted on it is cut in the right places.At the same time, it is necessary to observe spaces about 5 cm from the walls and not less than 10 cm from other heating household appliances.

If we are talking about a separate cable, then it should be distributed, fixed on the base and lead its end to the thermostat. The installation process should begin with the installation of the installation of the heating section to the place where the thermostat is located. The coupler together with the initial section of the section is fixed on the floor and from this place the layout is carried out with observance of a uniform, without crossing cable laying and maintaining a constant step of such laying throughout the entire heating area.

Do not allow adjacent coils of the cable to reach a distance of less than 8 cm.

The ends of the loops of the heating cable are fixed by means of a mounting tape to impart the integrity of the structure, after which the mounting ends are output to the thermostat.

The latter is connected to the electrical network according to the attached instructions. It is possible to connect a temperature sensor to a temperature controller, which is installed in a corrugated plug at the end in the middle of two cables to facilitate its replacement in case of a breakdown.For such a plug, an additional strobe is made keeping the bend angle between the floor and the wall with a radius of at least 5 cm.

The power supply to such a system, according to technical standards, must be supplied from a separate input, although this is not always respected. It is also necessary to take into account the indicator of the working section of the cable at the rate of 150 W power per square meter of floor. When the cable section 1.5 mm, it is used for 20 square meters. m heated area.

Installing tiles on glue begins after testing the system's performance.

Faults

When installing warm electric floors, strict adherence to the installation schemes developed by manufacturers is particularly important, which is a prerequisite for the uninterrupted operation of these heating systems and the safety of their consumers.

If all the necessary standards have been observed, but, nevertheless, the proper level of heating is not provided or it is completely absent, it is necessary to look for the cause of such a malfunction, which may be a lack of power supply, damage or incorrect operation of the control unit, breakage or damage to the heating unit. cable.

Finding such a break and understanding why the system heats up badly or refuses to serve at all without an appropriate tool is almost impossible; therefore, such diagnostics should be performed with a multimeter or indicator screwdriver.

Most often, the lack of power is observed in some part of the electrical circuit.

After it was assembled according to the above described method of laying, the “cold” ends of the power elements are connected to the collector, and then through the switchboard the system is closed to the thermostat. The latter is connected to the temperature sensor. The control box must be equipped with emergency switches.

If a system fails, then it is caused by a rupture in some part of it due to cable integrity problems, a wire burning out or other mechanical damage.

Using an indicator screwdriver is determined by the presence or absence of a phase in the open part of the cable. If power continues to flow, the indicator light comes on.

If the voltage does not come from the switchboard, then the cause of the malfunction is a gap somewhere in the wall,which is determined using an audio detector that acts like a metal detector and beeps a sound signal from a cable that is under voltage in a wall. When a gap is found, the room is de-energized, the plaster layer is removed, damaged wires are disconnected, and the system is tested for functionality.

If the floor does not heat up after that either, you should continue to ring the rest of the chain. Trivial oxidation of points at cable connections may be quite probable. This malfunction is eliminated by stripping the metallized sections of the cable cores.

If the ringing of the circuit reveals damage directly in the floor under the tile, then it is necessary to remove the layer of this coating along with the protective layer of the screed and proceed directly to the repair after de-energizing the system. At the same time, the exact place of the break is determined visually, because cable deflection will be observed in this place.

The ends of dangling cable cores are cleaned, connected with sleeves and compressed with a press jaw, and the joint is insulated with a heat shrink sleeve, which seals the joint after being treated with a hair dryer.At the end of the manipulations with the coupling, the repaired place is filled with concrete. Fill the new screed produced at the end of testing the system for health.

In case of malfunctions in the control unit, it is necessary to pay attention to the quality of the connection of its elements, correct fixing of the terminals of current-carrying wires, the temperature sensor and the like.

The main criterion for the normal operation of this unit is the same value of the voltage indicators at the outputs of the power cable and the presence of power when the thermostat is running. Therefore, it is necessary to measure the resistance of the thermostat itself and verify its value with that specified in the product data sheet.

To avoid all these troubles, you should carefully select the type of power cable and its power when installing the system of a warm electric floor, provided that the insulation is properly arranged. The length of the heating element must correspond to the dimensions of the heated room in order to avoid cutting the heating cable, as this negatively affects its strength.

It is forbidden to lay the power cable in the locations of massive household appliances, heavy musical instruments and furniture to avoid overheating.The cable can be laid only on the surface cleared of extraneous fragments. It should not be stepped on during installation.

A corrugated tube must be used to place the sensor. There should be no voids near the heating cable to avoid overheating. After installing the system, it is imperative to check the quality of all connections by measuring the resistance. Connect the heating system is possible only after the complete drying of the screed.

Manufacturers and reviews

To date, the market for warm electric floors is represented by a number of brands that occupy confident positions in the rating of their market segment and enjoy the well-deserved trust of consumers, judging by their reviews on the Internet. Here are a few brands, high-quality products which have gained popularity among all those who decided to equip a warm floor in their apartment, in the country or in the office:

Devi

The division of this company for the production of industrial electric heating appliances, founded in Denmark in 1942, was established in 2003. It is focused on the production of electric heating floor systems.The company's product range includes cable mats, represented by three models, two types of heating cables and four types of temperature controllers. The company's production is located in Denmark, France and Poland, its representative offices are open in 29 countries of the world, and products are supplied to 55 countries.

Heatluxury

Domestic manufacturer, focused more on the Russian market and consumers of several CIS countries, including Belarus, Ukraine, Kazakhstan and other countries of the community. Production of the group of companies bearing the name “Special Systems and Technologies” is concentrated in the Moscow region and can confidently claim one of the leading places on the European continent in the production of electrical equipment for underfloor heating, the assortment of which includes about 400 types of heating cables and components.

The products of Teplolux are capable of functioning even in rooms with high humidity, its life is set by the manufacturer for a period of up to 50 years with a guarantee of 20 years, and to protect the heating cable and its laying under the tile, the buyer is offered a proprietary blend from the manufacturer Teplolux Glims ".

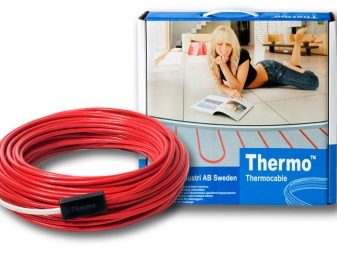

Thermo

The headquarters of the brand is located in Stockholm, and in Russia one of the enterprises of this company is located. The products of this company have been known among consumers in Russia and the CIS countries since 1991. The Thermo plant, as an equipment for an electrically heated floor, produces a heating cable, various modifications of which allow selecting the load level for different rooms and with a wide range of temperature conditions.

The company manufactures branded thermostats to optimize the consumption of electricity and the mode of operation of the equipment. In order to avoid overheating of the cables and to control the temperature, heat sensors are offered to the consumer.

The company's catalogs contain ready-made algorithms for counting the length of heating cables for rooms with different areas, and Thermomo supplied cable mats and heating cables can be installed not only inside residential and industrial premises, but also for heating porch steps, yard yards and other objects located in the open the air.

Electrolux

The history of this Swedish brand began in 1991, and after five years its products became widely known among European buyers,making the company one of the leaders in sales in the European market. In 2013, Electrolux warm floors became known in Russia.

The company offers its customers a wide range of products in the form of unique heating mats, cable sections, modern models of thermostats, as well as a number of professional options for electrical heating for pipelines, roof defrosters, gutters, and open areas.

Customer reviews include the company's products for the best type of underfloor heating.

In addition to the products of these manufacturers, in the domestic market one can find products of such well-known companies as Caleo, Spyheat, Warmstad and Unimat.

On how to do the installation of underfloor heating under the tile, see the following video.