How to choose a sensor for floor heating?

Heating of the room can be organized in several ways. Today, warm flooring is a popular option. These systems involve the incorporation of heating elements inside the screed.

An important factor for the proper functioning of this design is its temperature, which must be constantly monitored. Therefore, before installing these structures, you should clarify how to choose a floor heating sensor. He works in the complex thermostat, which allows for more accurate control methods.

Special features

One of the most important tasks of the underfloor heating system is to control the temperature of the coolant. If this is not done, severe overheating can affect not only finishing materials,but also to create uncomfortable conditions for a person when walking on the surface. Solve this problem with the help of a sensor capable of detecting changes in temperature.

This design is quite simple and consists of several basic elements:

- Thermal Resistance. This device is an element capable of delivering different amperage at a certain heating. To eliminate external influence on this device, it is often hidden in a small glass flask.

- Cable. It is connected to thermal resistance and transmits an electrical signal to a thermostat, which, on its basis, already performs some actions. In most cases, copper wires are used for such purposes. Their length in some cases can reach 50 m. But experts recommend using as small a piece as possible, as this will reduce signal loss and also minimize financial costs.

The main advantage of the sensor is the possibility of constant temperature control inside the flooring. This, in turn, can significantly reduce the cost of electrical energy by organizing the correct operation of the floor heating system.

If the sensor is installed inside the screed, then if it breaks, repair will be quite time-consuming. Therefore, experts recommend installing it in such a way that at any time you can access this device.

The temperature of the heated floor should be maintained at 30-35 degrees. This value can be monitored using a special thermal sensor. These constructions measure the heating force with the minimum error that allows to obtain practically real values.

Depending on the location, the sensors can be divided into several types:

- Submersible. Thermal head is located inside a special corrugated tube under the floor surface. The distance between the heating element and the sensor is selected individually. This is the main tool, without which none of these systems function.

- Outdoor Remote sensors are used to check the air temperature. They are optional. They are used only for creating comfortable conditions in residential premises. They can be embedded directly into the thermostat or connected to it with a cable.

Internal sensors can be divided into 2 subtypes:

- Devices for soft coatings. Used together with laminate or parquet. Their feature is the presence of a plastic case and a protective cylinder.

- Sensors for solid coated. They are recommended to be used when laying ceramic tiles or natural stone on the floor is planned. Here, the protective sheath is already made of materials that can withstand mechanical loads, as well as resist the aggressive environment of concrete.

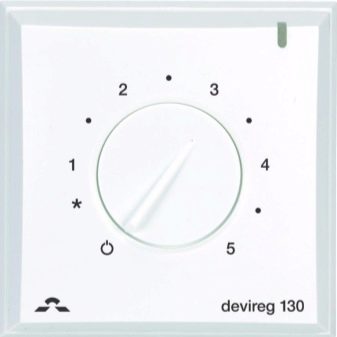

Temperature sensors are always working together with the thermostat. This mechanism analyzes temperature changes and, if necessary, turns the heating on or off. Depending on the method of work, such constructions are divided into the following subspecies:

- Mechanical. All changes are controlled by a curved plate. When a signal is applied, the design simply closes and opens the contact, applying current to the heating system.

The simplest modifications that allow only to maintain the temperature at the same level.

- Digital. These thermostats are a lot like the previous type.They are supplemented with a push-button or touch interface that allows you to accurately set the temperature.

- Programmable. This type of device is the most difficult. Using such devices, you can not only set the temperature, but also indicate its values, depending on the time of day, day of the week or month. Thus, it is possible to achieve that the floor warms up during the day better, and only a little heating is used at night.

With the help of these thermostats, you can reduce the consumption of electrical energy by 30-50%.

What you should pay attention to?

The temperature sensor itself does not carry any benefit. Therefore, when choosing it is important to consider several thermostat parameters:

- Device power. This parameter should be synchronized with the technical characteristics of the electrical network. If there are inconsistencies, it is desirable to fix them with the help of special mechanisms.

- Thermal sensor parameters. Here the main characteristic is the minimum range of temperatures that it can perceive. This is important for quality control of underfloor heating.

Installation and adjustment

Modern modifications of sensors are sold complete with temperature controllers. The principle of their work is quite simple, but without it there is no opportunity to optimize the climatic conditions inside the room. The installation manual for such structures consists of the following steps:

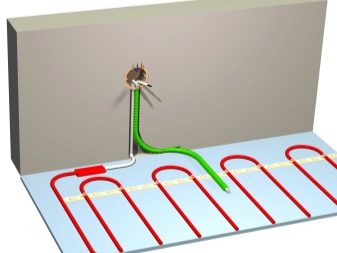

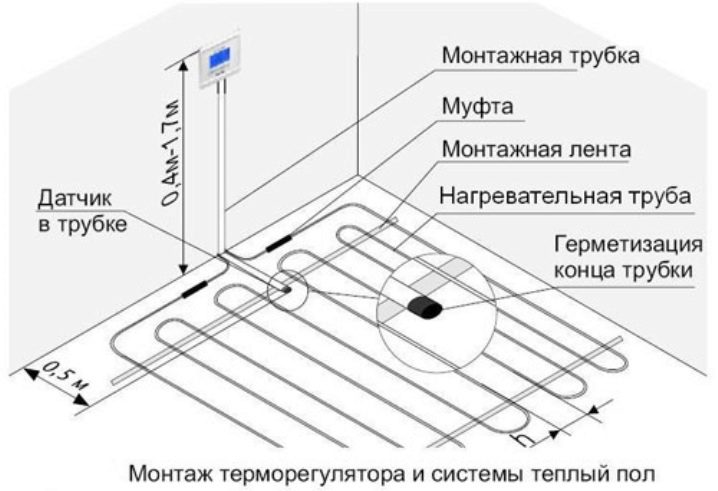

- The formation of channels under the pipe. The grooves are made after the concrete on the floor has completely hardened. The channel is laid in such a way that the sensor is located between two heating elements. Please note that it should not close to an electrical cable or pipe.

The length of the wire from the sensor to the thermostat should also be minimal and not exceed a few meters. Putting the strokes is necessary so that they have smooth corners.

- Cable laying. The sensor is placed in a plastic corrugation, the end of which is necessarily sealed with tape or cork. This is to prevent cement from entering the channel. Corrugated, if necessary, can be attached to the floor with a special adhesive tape.

Some experts recommend smoothing the junction of the cable and the sensor head with electrical tape.This will allow you to easily pull out the wire in case you need to replace or inspect it.

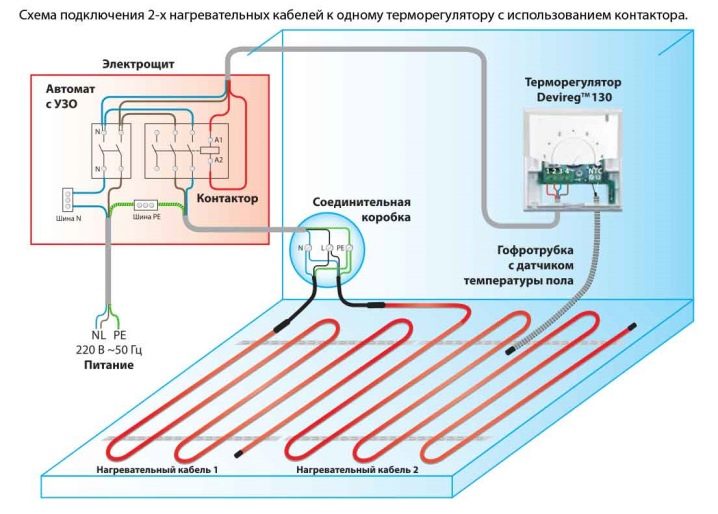

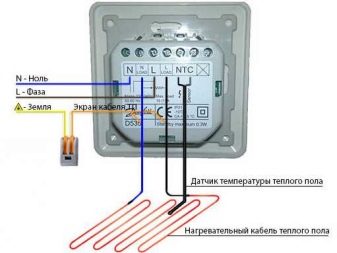

- Connection This process involves connecting the sensor to the thermostat. To do this, two wires from the device are connected to the terminals on the thermostat. Often, each manufacturer marks the outputs under the sensor, so it is almost impossible to make a mistake here.

After completing the mounting of this device, you should connect the thermostat to the network. There are already several options that depend on the heating cable underfloor heating. To put such a system should be strictly with the recommendations of the manufacturer to eliminate all faults.

Setting the thermostat involves checking the operation of all mechanisms. To do this, initially set the minimum heating mode, and then transfer the system to maximum speed. A click should be heard at this point. Checking or tuning programmable models is much easier.

Often, if the sensor is broken, an error message may appear on the screen. If the system is working properly, and the floor is not heated to a specific temperature, then first of all it is advisable to check the temperature sensors.They may fail or simply be too close to the heating elements. This, in turn, causes the system to shut down quickly.

Manufacturers

The quality of a temperature sensor depends not only on its technical characteristics, but also on its brand. Today in the market there are several manufacturers, among which are the following:

- Tech. Modern thermostats capable of working both stationary and remotely. The company presents models that are controlled via Wi-Fi networks. In this case, you can find devices that work not only with electric, but also with gas boilers.

- Herz. Under this brand produced a lot of modifications. A special place should be given to mechanical and electronic models. They can be adapted to almost any type of floor heating.

Some modifications are complemented by built-in thermal sensors, which eliminates their additional installation.

- Spyheat. Thermostats of this type are operated with external sensors. To prevent the system from malfunctioning, they are supplemented with a blockage in case of an external thermal sensor breakdown.The mode of variable temperature can vary from 0 to +50 degrees.

- Legrand. The products of this company are practical and versatile. With these thermostats, energy savings of up to 30% can be obtained, depending on the environment of use.

Thermostats are complemented by infrared, remote, or built-in temperature sensors. They can be located both on the floor surface and inside it. The use of several meters allows to obtain very accurate indicators.

- Floureon. The company represents several types of thermostats. They are capable of operating at a network capacity of not more than 3.6 kW. The systems are also complemented by several types of temperature sensors that can be programmed in a specific temperature range. Among the advantages of high-quality displays and a lot of functionality.

Thermal sensors are an important component of a floor heating system. Their choice should be approached carefully and demanding. This will allow you to get the optimal ratio of comfort and durability.

See below for how to install and connect a floor heating temperature sensor.