The subtleties of connecting the warm water floor in the house from the gas boiler with his own hands

For several years now, a heating system connected to a gas boiler has been very popular among heating systems. Installing this type of heating is not cheap, so many people install it with their own hands

Pros and cons of warm floors

Like any other system, warm floors have their pros and cons.

pros

One of the advantages is cost effectiveness, as well as network independence, if the system is connected to the boiler. On cold days, she will maintain the warmth in your home, thanks to the circulation of hot air will allow you to walk barefoot without fear for your health. Also, you can create the interior of your dreams, because you will not interfere with pipes, "crawling" on the walls,do not have to hide radiators under the tulle.

Minuses

The only significant drawback is the high cost of such a heating system. Unfortunately, not everyone can allow himself to install such an expensive structure in an apartment.

Types and characteristics of boilers

There are many options for connecting underfloor heating to boilers. They are divided into gas, electric, solid fuel, diesel, combined.

Electric

The electric boiler is the most expensive source of heating the coolant, but at the same time, the easiest to maintain. Water is heated by heating elements or by induction.

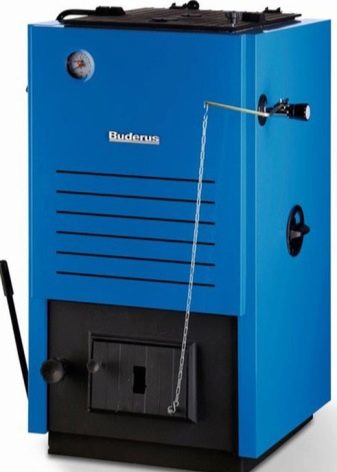

Solid fuel

Such models of boilers are considered the most economical in our time, because for their work you can use all the materials that burn. These include wood waste, coal or full-fledged firewood. It is profitable and convenient, from whatever side you look. Their only drawback is the need to control the filling of the firebox, although modern boiler designs allow the fire to burn for a long time without human presence.

Diesel

This design may seem to many even more profitable than a gas boiler, because the source of heat energy is burning diesel fuel. It is beneficial in that it is autonomous, uses natural gas. It can function for a long time itself, without human intervention.

Combined

This design is pleased with the opportunity to move from one type of fuel to another. She can have two fireboxes, and one. To change the types of fuel, it suffices to replace the burner. Such heating options are useful for homes where temporary fuel supply problems are possible.

Gas

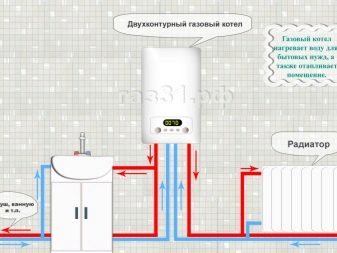

Of course, the most common type of boiler is gas. They are the most economical and practical, because gas has the lowest cost, and efficiency is the highest. Gas boiler produces heat due to the combustion of natural gas or its less popular form - propane. Such designs do not have special devices, however, new models have appeared, including a function called “warm floor”. Its inclusion leads to a decrease in power, which is not effective. Visually, the boiler looks like a small bedside table or a hanging closet.It is very convenient for connecting a warm water floor in the room.

There are different types of boilers that differ in many ways.

Outdoor

Such boilers are installed by the standard method. Modern designs are small in size, which is very good, because they do not take up much space. Can be used for heating houses of large and small areas. Also, unlike wall-mounted boilers, they do not create an extra load on the surface of the walls, which is important for frame buildings.

Wall mounted

Attached to the walls, which should be strong, because the weight of the boiler rather big. Used for heating not very large houses with an area of up to two hundred square meters. There are models designed for larger areas, but there will be a need for more powerful fasteners.

Also, boilers are double-circuit and single-circuit.

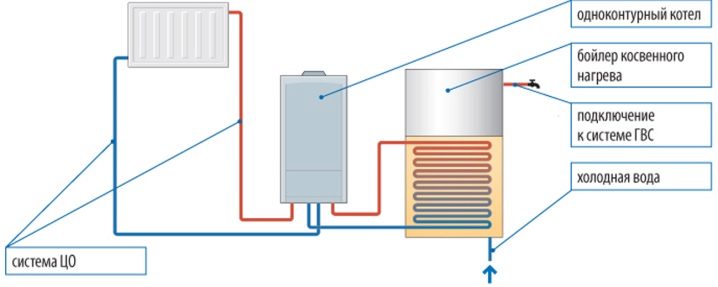

Single circuit

Serve only one heating line. They are considered the most economical because they use little fuel, that is, gas.

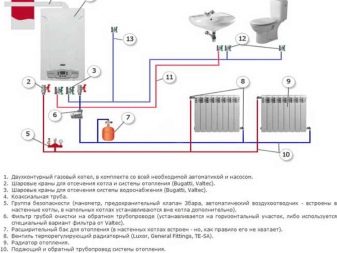

Double circuit

They serve both to power the heating system and to heat water, which can be used for the needs of the kitchen and bathroom.However, the water will not be as hot as from boilers or gas water heaters. The disadvantage is that the device will not work simultaneously in two modes. If you connect the DHW, the heating is automatically turned off.

Different heat transfer materials.

Steel

Steel is the cheapest and simplest material. It is short-lived: cracks quickly appear on it, because it is susceptible to corrosion. Modern developers are trying to eliminate these defects by applying different coatings.

Stainless steel

Unlike other boilers, they have many advantages. They combine the properties of iron and steel materials.

Cast iron

They have a corrosion-resistant coating, while the distinctive feature of any cast-iron material is brittleness, and boilers are no exception. Therefore, we must carefully monitor that the heating is uniform. This will not allow the boiler to crack.

Copper

Copper is used for wall models, because boilers made from this material have a small weight. Such materials are not subject to corrosion, have a small inertia, which makes it possible to quickly regulate the temperature.

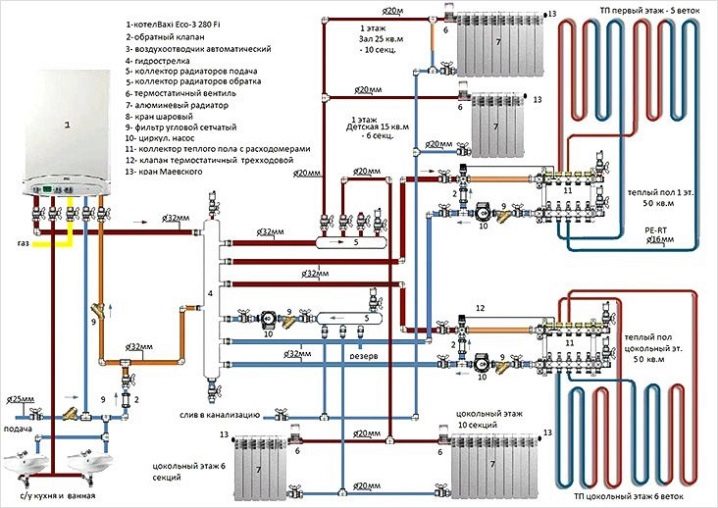

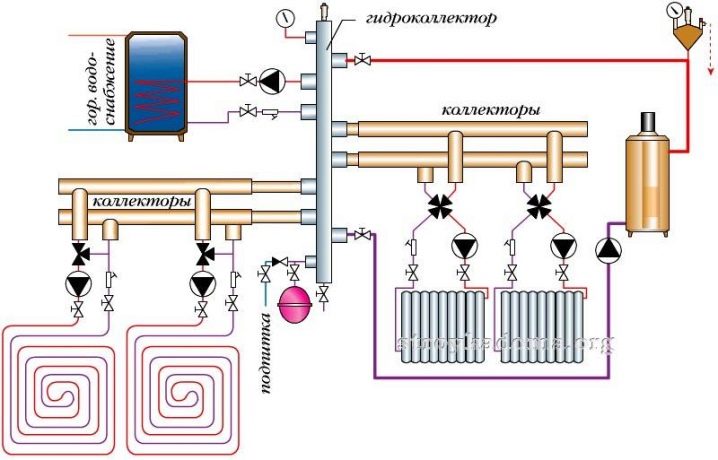

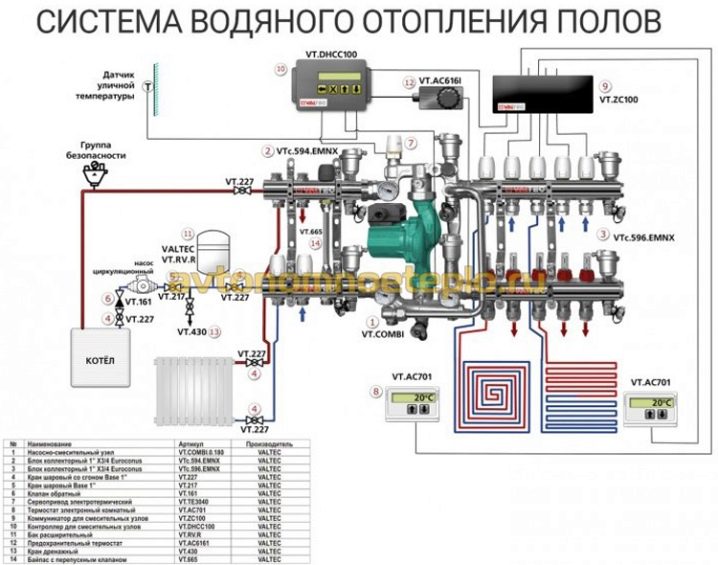

Wiring diagrams

There are three main schemes for creating the so-called underfloor heating: collector, one-pipe and two-pipe.

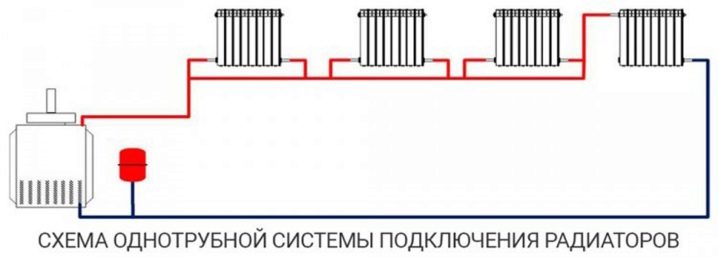

Single pipe

This includes connecting with a tie-in to one branch of the wiring between two batteries or between a radiator and a boiler. The only drawback is that in such a scheme it is impossible to adjust the temperature of the water. If you carry out a tie-in right behind the boiler, the floor will be very hot, and if after the last battery it will be very cold. In a system with radiator heating, you cannot even disconnect the circuit from the network.

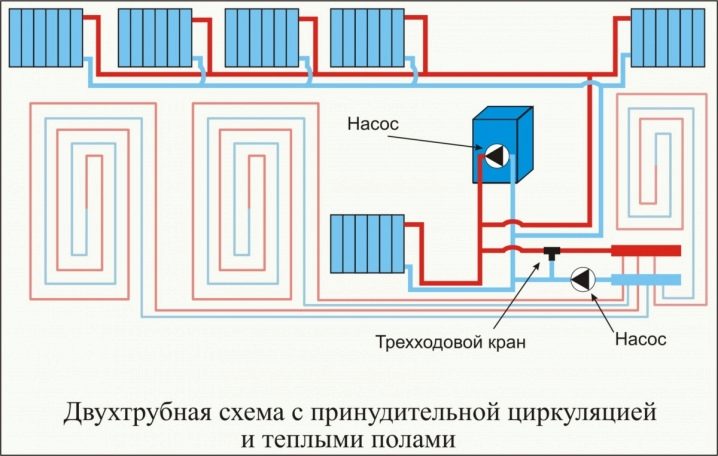

Twin tube

This connection scheme allows the insertion of the contour between the return and pressure branches of the wiring. This will give you the opportunity to regulate the volumes pumped through the floor contour, determine the energy consumption, control the heating temperature. Here there is a drawback: a tie-in of the stop and control valves in the place where the floor is located. This not only can ruin the look of the room, but also makes temperature control less accessible.

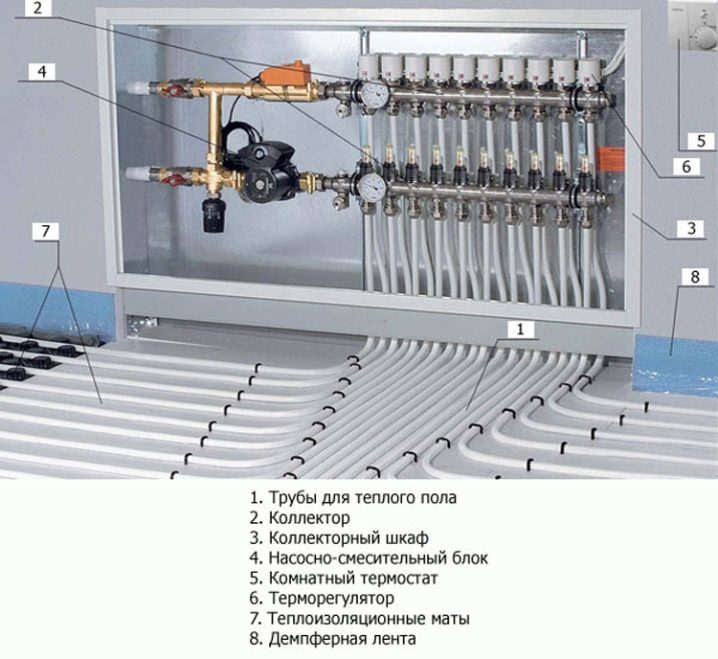

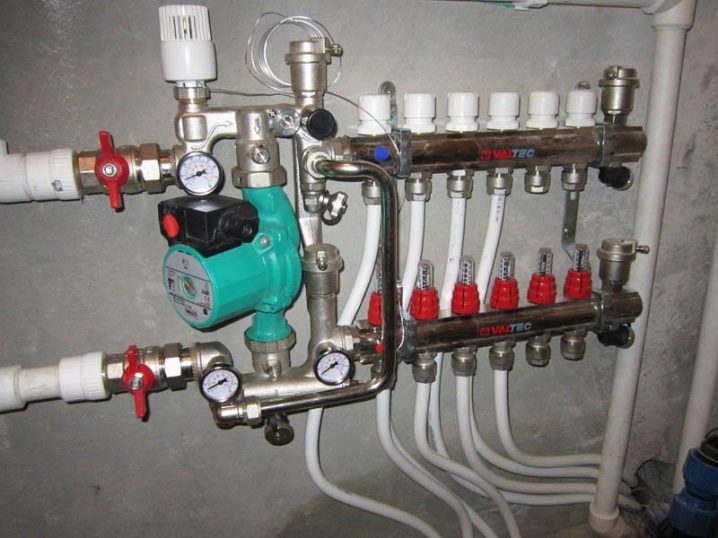

Collector

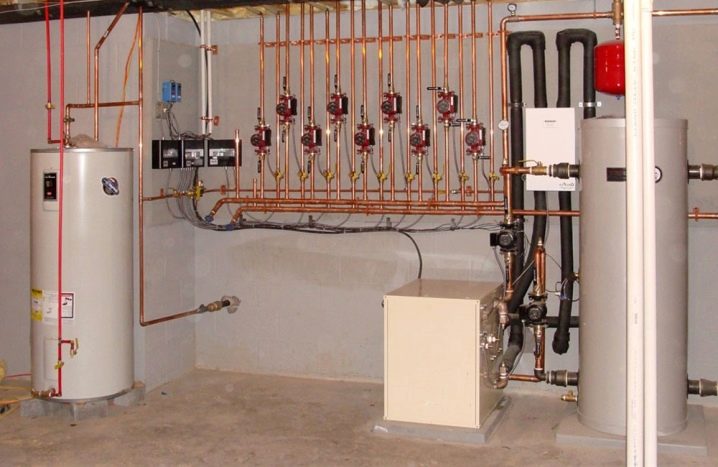

.In this scheme includes the flow of hot water into the collector. All lines connecting the boiler with different heaters are also connected to it.Before connecting a heated floor, it is necessary to install a collector cabinet located in an accessible place for supply and return pipes. Before this, stop valves are installed on the collectors. Thermometer can be installed to monitor the temperature., but it is better to buy a ready-made kit, which includes, besides the usual ones, also shut-off valves at all outlets for the installation of heat carriers. This will allow one circuit to be blocked for repair, while not shutting down the entire system.

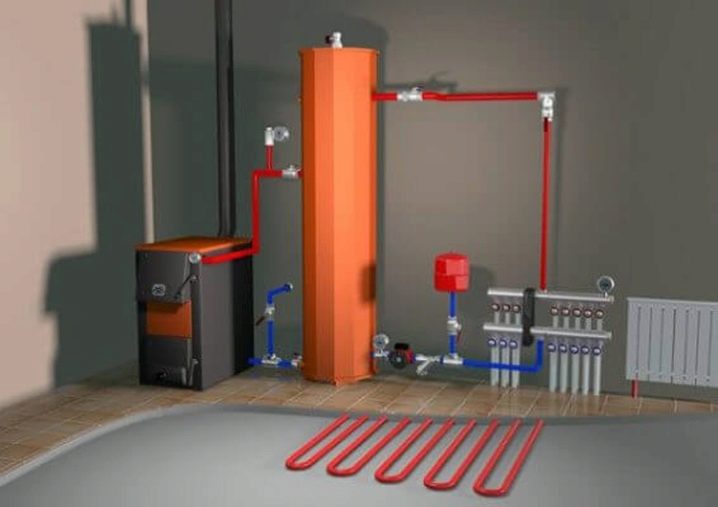

This scheme includes a circular pump, which will facilitate the circulation of water in the pipes. It is installed between the manifold, the supply pipe and the return pipe in front of the pipeline. Heating equipment using a heated floor is very effective for heating rooms. Now it is necessary to figure out what is a warm water floor.

This is a system that has spiral pipes 15-20 mm thick, located in a concrete screed or directly under the floor. The heat carrier, through which water circulates through pipes, transfers heat to the floor surface, and that, in turn, transfers heat to the inside of the room. Pipes are laid very tightly, which allows not to heat the boiler to extremely high temperatures. It will be enough 45-50 degrees.The lower the heat source, the better the room is heated.

Connection methods and installation features

Having considered what boilers are, it can be concluded that gas options are most suitable for connecting a warm water floor. Basically, the heating system is connected to the wall mounted gas boiler.

If you want to connect the heating system with your own hands, then you will need:

- roulette;

- level;

- keys;

- screwdrivers;

- perforator;

- pipe cutter and other tools that will help in the process.

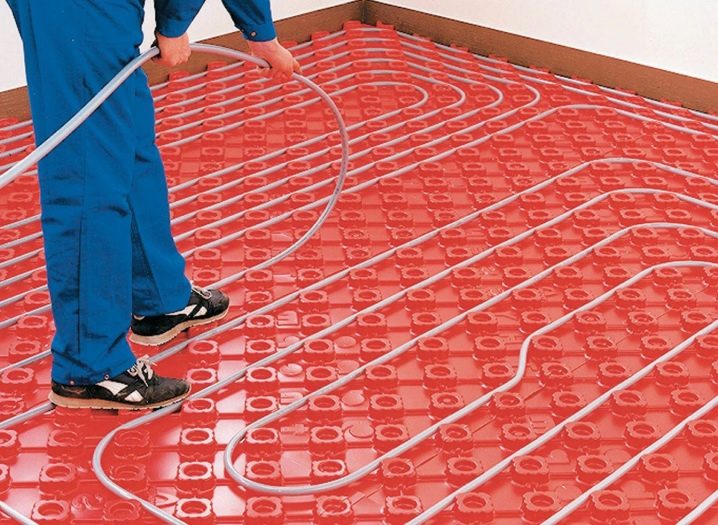

At installation of a warm water floor the most important is laying of the pipeline. Before this, the base must be leveled using screeds that protect the pipe with hot water from various damages. The composition includes a sand-cement mortar, after solidification of which a hard crust is formed, protecting the pipe. Also, the tube performs the function of a battery with a large dispersion area. For warming is best suitable expanded clay. Above you need to put a waterproofing film, as well as a reflector

Reflective material cuts the heating circuit from the floor slab and the space that is under it.It must be of high quality so that the heat goes to the floor and heats the air in the room, and not vice versa. The pipes are laid in the form of spirals directly on the reflector. Inset, in this case, comes from an existing network that is served by one boiler.

There are two options for mounting pipes:

- The first is using a reinforcing mesh to which the pipes are attached with wire.

- The second is with the help of fastening tapes and special clips, which can be purchased in specialized stores.

The length of the pipeline should not exceed 80-90 cm. A pipeline with a length of one meter or more is not suitable for the installation of this design. If this is not enough, you will have to add a new contour, while taking into account that they should be the same.

The next stage is to fix the pipeline to the supply manifold. Immediately after that you can lay the contour. It should be laid a whole piece to avoid leakage. The technology of installation of warm floors includes checking the entire system. This stage consists in the fact that hot water, under pressure, is fed into the pipeline. Check takes about two hours. If everything is in order, it is possible to lay the tie. Further installation of the boiler.To do this, you need permission from the gas and fire services.

Then you can connect all the pipes to the connections with nuts or couplings. Tying the boiler is done only with metal pipes. After install the expansion tank, which regulates the pressure in the circuit. Then follows the installation of the collector - two elements of the pipe, which are located one below the other. The number of nozzles must match the number of circuits. The connection of the lower and upper pipes is done by means of a bypass. A pressure gauge and air vent are installed on the upper section of the pipe, and a tap to drain water from the pipeline is installed on the lower section.

Pump for underfloor heating can be installed anywhereand the thermostat is at a point that is not exposed to drafts. After checking again whether the automation is properly connected, you can make the first connection of the water floor. For this purpose, all contours are filled with water, and air is released. It is necessary to check how taps and valves work, and whether the connections are tight. For this, several pressure control checks are done at intervals of one to two hours. During this time, it is allowed to reduce the pressure by only 20 kilopascals.If everything is in order, it means that you yourself have coped with such time-consuming work.

Important recommendations

Installing such a system at home, keep in mind the simple advice of experts. First of all, if you have never done the installation or repair of heating devices, then it is better to entrust this work to professionals. If you decide to perform this task yourself, then before starting the work, carry out a thorough calculation of the materials you need. So you will save the budget, and you will be sure that the installation process will not be disturbed due to the lack of some important element. Do not save on the quality of materials, because not only the heat of your home, but also safety depends on it. From all this we can conclude that even an inexperienced person will be able to build such a heating system, but it is necessary to thoroughly study the theory beforehand. Then you can move any mountains.

See the subtleties of mounting a warm water floor below.