Rules for choosing pipes for underfloor heating

Underfloor heating system impresses with its functionality and ease of use. Such systems are often used in premises of various purposes to heat a floor that is too cold and maintain a comfortable temperature in the room. But since the basis here is a rather complicated water heating system, for its installation it is necessary to choose the right accessories and components.

Correctly chosen pipes are a pledge of long service of a warm floor.

Special features

Starting the selection of pipes for floor heating, first of all, it is necessary to determine the operational features of the system.As a rule, the work of a heated floor is possible under the following conditions: the water pressure in the pipes should be 6 atmospheres, the temperature of water heating - up to 55 degrees. Most of these systems are fixed to the floor with a concrete screed, so that the floor load can reach 150 kilograms per square meter of surface.

Since the conditions for pipes are rather harsh, it is necessary to choose them from such materials that will not only carry the loads and the aggressive concrete environment around well, but also not be afraid of corrosion. Since the constant contact with water of different temperatures can spoil the material, which would entail sad consequences in the form of equipment failure and flooding of the space under the floor.

Since such pipes must withstand temperature jumps with ease, you should not use options that are initially assumed for cold and hot water systems, as they are less subject to temperature jumps when used for its intended purpose.

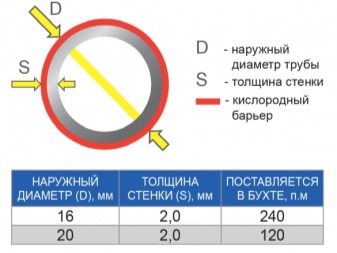

When choosing it is necessary to pay attention to the diameter of the contour of the pipe being mounted. So, the most common option has a diameter of 16-18 mm. That it is not only the most common, but also the most convenient in laying and reliable to use. In addition, it is precisely this volume that is sufficient to warm the floor and so that the height of the coating does not become much higher than its initial position.

The length of a pipe with a diameter of 16 mm is much shorter than a pipe with a large diameter. So, most often a product with a diameter of 16-18 mm has a length of 60 meters, but with a diameter of 25 mm, the maximum length is doubled and equals 120 meters. If the length is longer, this may lead to a quick failure and a decrease in efficiency.

In the case when the whole area of the room lacks one pipe, it is worthwhile to equip the second system for better work.

Service life and quality of work also depends on the material from which the pipes are made.

The most popular are the following:

- Polypropylene. This material has a high thermal conductivity, long service life and affordable cost. The downside of this material is its static nature,therefore, during installation, it is necessary to use various adapters to organize a flexible heating system around the perimeter of the floor.

- Stainless steel. This material is sufficiently plastic for organizing wiring around the perimeter of the room, in addition, it has high strength.

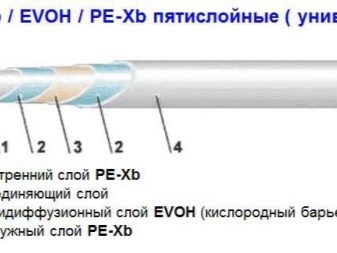

- Crosslinked polyethylene. It turns out in the processing of polyethylene special peroxides, which are fixed when exposed to x-rays. The result of complex manipulations are the so-called PEX-pipes. They are quite strong and durable, in addition, have excellent resistance to temperature shocks.

- Copper. Copper pipes have a high level of thermal conductivity and have one of the longest service lives. With proper installation and use, it can be about 50 years.

- Metal-plastic. One of the most popular options, as this material due to the aluminum interlayer is sufficiently heat conductive, has a significant service life, as well as an acceptable cost.

In addition to all the above aspects, for a long service life and high-quality heating, it is necessary to correctly install and run a floor heating system.

Species

High-quality floor heating system requires properly selected and fairly expensive materials and accessories. Cheap analogues quickly fail, and their replacement will cost several times more than the initial installation of high-quality components. First of all, it is necessary to understand the types of pipes used for the floor heating system, as well as to determine the nuances of their selection and installation. In addition, choosing the right type, it is necessary to determine the specific requirements that apply to heating systems.

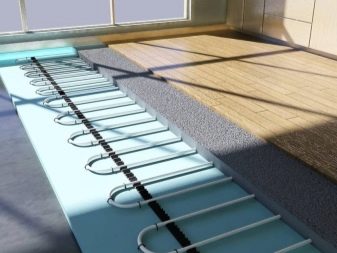

Basically, all pipes for underfloor heating, regardless of the material, pattern of installation and method of joints, are mounted using a concrete screed.

This allows you to get a monolithic strong warm floor with the highest quality fixed heat supply system. This requires high-quality materials, since the concrete does not allow for the maintenance and replacement of individual structural elements, and upon failure, you will have to completely remove everything and create the system again.

Most often, failure triggers the development of corrosive processes inside.Materials subject to corrosion accumulate growths inside the cavity, thereby blocking the passage of water and disabling the entire system. In addition, pipes selected for installation in the floor should not be afraid of sudden temperature fluctuations, since these changes may also lead to the failure of heating equipment.

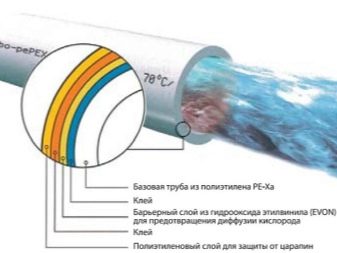

Modern models are also often equipped with special anti-oxygen devices, since the penetration of air into the tube cavity can also trigger the development of corrosion, as well as the rapid aging of system components.

Experts also advise not to use in any case the types of pipes that are used to create systems of cold and hot water. In addition to the fact that such options are not designed for such high loads and temperature drops, they are also very heavy, which will adversely affect the overlap.

In addition, choosing the right type of pipe is also important because the connection of such elements is always a weak spot, regardless of the method of their connection, so any, even the slightest accident, entails major consequences.And given the fact that in this case the pipes are filled with concrete screed, the leakage can not be seen at all, so it is very important to choose the most suitable and high-quality materials.

Ideally, all wiring of a heated floor should be made from a single pipe cut. Any joints - this is the potential danger of a breakthrough or blockage, which can also lead to the failure of the entire system. If the room is quite dimensional, it is better to take a few cuts and lay several contours. This option is preferable to laying pipes with joints and adhesions, and too long a design will create an overload on the pumping equipment, which also soon will cause a breakdown of the entire system.

However, the main and main criterion for the selection of pipes for floor heating is the material from which they are made.

Copper

Metal pipes are undesirable to use a warm floor in the system due to their weight and insufficient adhesion, however, iron structures can be made of various metals, so even among such options there are able to serve for quite a long time.These options, of course, include copper pipes.

Copper is an excellent conductor of heat., and also durable enough for use in the system. By the way, in Europe, copper pipe - the most common type, which is used to create a heated floor.

Copper has received such a distribution due to its thermal conductivity, in addition, it is not afraid of high temperatures, as well as its sudden drops. During operation, copper labor can withstand high atmospheric pressure (on average, about 27-279 atmospheres), which is the most suitable indicator for use in flooring.

Copper tubes do not require additional depreciation and accessories, plastic, so easy to fit, and also completely hypoallergenic and non-toxic, and therefore safe.

The characteristics of a copper floor heating system are the following: the temperature of the water inside usually reaches 30-50 degrees. Heating takes place with the help of a heat boiler; in addition, solar collectors or geothermal water can be used for the same purpose. The last option is most relevant for creating a flooring of this type in private homes.

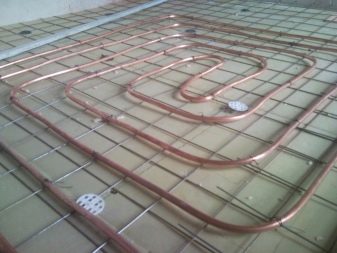

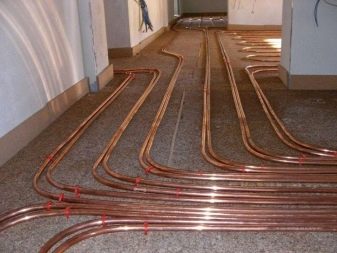

Laying copper pipes is usually carried out on the principle of the snake.The distribution of heat can occur unevenly, which can be both a plus and a minus. So, this method of laying will help to solve the problem with the most cold parts of the floor near windows and doors. In addition, you can choose a double method of laying, in which copper pipes are laid on the principle of combining hot and cold.

Copper pipes are quite plastictherefore laying by a snake or in the double way will not deliver work. They bend easily and do not require corner joints for turning. It is worth remembering that models of copper can be placed under absolutely any floor covering, be it laminate, cork, linoleum or parquet.

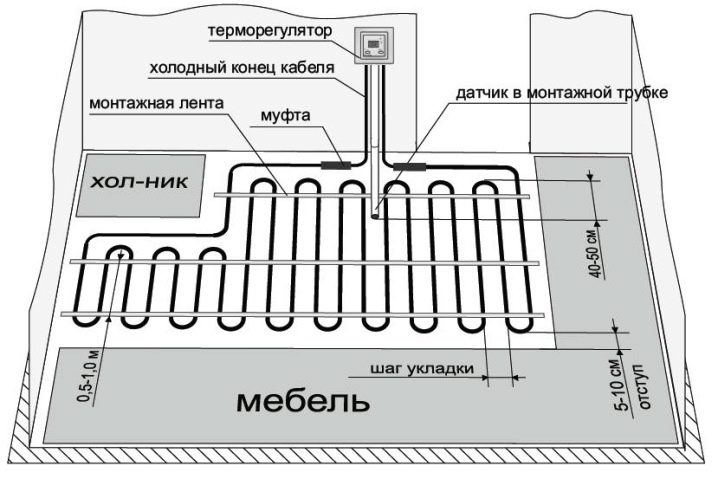

Before you install, you need to calculate the number of required wiring.

To do this, you need to make a drawing-diagram of the location of pipes in space and determine the type of placement. It is possible to minimize costs by eliminating heating elements in the area of the room where the furnishings will stand, therefore the placement of furniture and other items must also be drawn on the plan.

When the complete plan with the drawn method of pipe placement is ready, it is necessary to make calculations and determine the number of cuts of material and their length.

Copper pipe, as well as stainless steel, is protected from corrosion and internal deformation, in addition, today many manufacturers equip copper pipes with a layer of plastic, which is an additional protection against rust and delay of water masses inside.

Based on the above, a number of advantages and disadvantages of copper pipes for installing underfloor heating can be highlighted.

Pros:

- Long service life. Error-free correct installation, high-quality material and correct layout will ensure a long service life, efficient operation without repair and replacement of individual sections of the structure.

- High level of thermal conductivity. This material has one of the highest rates of heat transfer, so for cold apartments such pipes are an indispensable tool.

- Due to the softness and plasticity of the material, laying the desired pattern of copper pipes is not difficult, the absence of connections and joints will also provide a longer service life of the system.

- In addition, copper is famous for its resistance to temperature leaps. The temperature range that pipes of this material are able to withstand ranges from -40 to +115 degrees.

- In addition, phosphorus impurities are present in the copper alloy, which prevent corrosion and oxidation of the metal, which can also adversely affect the state of the structure.

- Copper has an attractive appearance and despite the fact that the pipes will be covered with a layer of concrete, for many it is a decisive factor for choosing.

- Contours made of copper do not emit any harmful substances, and therefore completely safe to use.

However, regardless of the large number of positive aspects, copper circuits have a number of disadvantages:

- The first and main drawback is the high cost.

Due to the quality and high wear resistance, the copper system for a warm field is quite expensive and its installation is not available to everyone.

- Rough water can lead to abrasion of the internal particles of the pipe, so these circuits must be equipped with special filters.

- Copper also extremely badly gets on with some alloys, therefore if creation of connections or transitions is necessary, it is necessary to use only bronze or brass.

Metal plastic

The most affordable type of pipe for underfloor heating can be called metal-plastic elements.This material is one of the newest on the market, but has already managed to win fans and gain fame as durable and high-quality raw materials. Metal-plastic contains a unique composition, it contains polymers and metal, which are in an ideal ratio to each other, this is what provides metal-plastic pipes with high performance characteristics.

Inside the pipe has a polymer basewhich perfectly protects against corrosion and scale that can clog the permeability and disable the entire system. Thanks to this interlayer, the service life of the stainless metal-plastic pipe is significantly increased.

The middle layer is an aluminum layer. Thanks to it, the circuit has sufficient thermal conductivity, and is also protected from sudden changes in temperature conditions of the system. The aluminum layer is also coated with a polymer shell, it protects against external influences, thereby prolonging the life of the product. The connection of all layers of the pipe occurs through a special adhesive mixture, which provides excellent adhesion of elements, as well as additional protection of internal components from external influences.Moreover, the durability of the structure increases.

However, today many manufacturers are striving to save on materials, which can lead to a quick breakdown, so the purchase of pipes for underfloor heating should be carried out only with reliable suppliers and with all the certificates and confirmed quality ratings of the selected products. In addition, you can conduct an independent quality check, for this it is worth everything to burn its edge on everything. The pipe created by all the rules should not be stratified during combustion.

In addition, the metal-plastic pipe can be corrugated, which provides additional plasticity of the structure.

Like any other material, metal-plastic has a number of its own special advantages and disadvantages.

Benefits:

- Flexibility. Due to its plasticity, metal-plastic allows you to create various twists and turns. Even an angle of 90 degrees is possible to create without the help of angles and special connections.

- High degree of protection against corrosion, mold, mildew, scale, which ensures a longer service life and proper performance of the declared functions.

- Resistance to temperature changes.The specificity of the material allows you to create a system that is almost immune to sudden changes in temperature, which also provides a longer life cycle of the circuit.

- In addition, metal-plastic prevents air from entering the circuit, which ensures complete tightness and preservation of the quality of the structure.

- During the installation, there is no need to use a welding machine, which eliminates the wear of the pipes at the interface.

- Long service life of equipment without breakdowns and restoration.

- Relatively low cost with high quality equipment.

As for the shortcomings, the following points can be noted:

- Metal-plastic is very susceptible to ultraviolet radiation and sunlight, but when using pipes of this type for a floor heating system, you can close your eyes to this disadvantage, because in any case a ceiling will be used to prevent contact with external stimuli.

- Also among the shortcomings can be noted the fear of mechanical damage and heat exposure, however, the correct qualitative overlap can eliminate this.

- For better performance and safety of use, a warm floor system on metal-plastic pipes must be pre-tested at a pressure one and a half times the working pressure.

Polymer

All types of polypropylene structures can be attributed to a number of polymer pipes for a heated floor system, as well as all sorts of options based on different degrees of processing of polyethylene.

Polypropylene material is one of the cheapest and most unreliable. options for the device of floor heating, they are more suitable for sewers and water systems. For the floor, it is better to use polypropylene pipes with a reinforced interlayer, only then the system will meet all the requirements of thermal conductivity and frame strength.

In addition, among the polypropylene pipes there are two large groups: single-layer and multilayer.

Among the single-layer options are:

- PPH. This variety is made of a special type of propylene; it is a good option in terms of strength and functionality, but its use for the floor is unacceptable. Most often such pipes are installed for water supply and ventilation systems.

- PPB Pipes with this marking have significantly greater strength, have a high degree of wear resistance to create a floor heating system in a private house.

- Ppr. A distinctive feature of this type is the ability to evenly distribute the load and internal pressure over the entire diameter of the pipe.

- The greatest efficiency and the best heat conduction among single-layer polypropylene variants is Pps. Also pipes differ in non-flammability and increased strength.

Reinforced pipes belong to multilayer.

They are also divided into several groups:

- Pipes with an interlayer from aluminum. Their production takes place as follows: the framework of the future pipe is made of polypropylene, then a thin reinforcing sheet is fixed on the outer surface of the pipeline. Such pipes are quite effective in use when creating a floor heating system. The most effective work occurs at a temperature of +95 degrees.

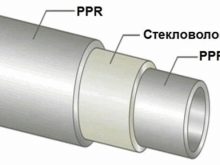

- Often in the system of underfloor heating are used multilayer options with reinforcement of fiberglass. Such pipes are light enough, both in the device and in operation, and they promise a good service life.

- Another layer option is composite.This material is formed by mixing aluminum chips and glass fiber particles. The layer of composite fits between two sheets of polypropylene.

Polymer tubes have many positive aspects.

These include:

- Long service life - quality options from proven manufacturers can last a total of 50 years.

- The polymers are not affected by corrosion and scale, their inner surface permanently retains its qualities.

- Such pipes are very convenient for apartments, because they have a low noise level.

- Any person without special training can make high-quality welding of pipes, it is enough just to use special tools and connective tissue.

- The cost of both the pipes themselves and all their accessories is low, so even if you need to create heating in the overall room or increase the contour pitch, the final price will be quite real.

You just need to calculate the required amount of material and purchase it from a reliable and trusted manufacturer or supplier.

- Low weight and durability make it easy to install the structure yourself.

- Polypropylene is environmentally friendly, during its operation there is no release of toxic fumes and other harmful substances.

As for the negative sides:

- For the device of such floor heating, it is necessary to additionally use multilayer polymer pipes with reinforcement, otherwise the system will quickly fail.

- The disadvantages include the sensitivity of propylene to high temperatures. Using too hot temperatures reduces the overall service life of any system on polypropylene pipes.

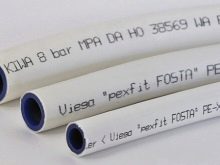

Pex

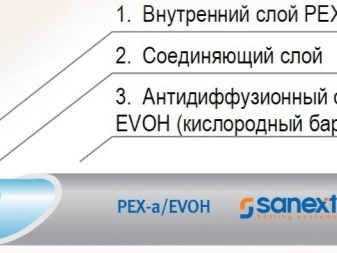

PEX is an option made of cross-linked polyethylene specifically for installation in underfloor heating systems. To connect and fasten this system, rigid fittings are used, as well as a plastic substrate at the base of the structure.

Cross-linked polyethylene has excellent thermal conductivity, long service life, strength and durability, in addition, this type of pipe has a feasible cost.

Depending on the density of the material there are several varieties of full-fledged pipes:

- Low density - LDPE;

- With average density - MDPE;

- With high density - HDPE.

In addition, PEX can be divided into versions according to the production technology:

- During peroxide crosslinking, PEX-a appears.

- In the process of irradiating polyethylene with electrodes - PEX-c.

- Humid environment and the presence of catalyst and silane in the production of PEX-b type pipes.

The most widespread installation is the PEX system, since it is this type of production that ensures the homogeneity of the material for the manufacture of high-quality PEX pipes. In addition, this option is the most plastic and is not afraid of temperature changes.

The flexibility of PEX tubes allows them to be bent at any angle to embody any layout plan, be it a snake or any other way of laying. In addition, due to the memory effect, you can change the picture; for this, it is worth blowing pipes with a hot hair dryer, which will immediately stretch and be able to be bent and laid out in a new pattern.

Which is better?

Due to its functionality, the underfloor heating system is increasingly used for heating premises for various purposes, and the selection of the right pipes for the heating system is the first and most difficult task.

Pipes to be used in a complex floor heating system must meet several basic characteristics.

If you do not take them into account, the installation of a heated floor will cause considerable difficulties, and the service life will be quite short, besides, the functions assigned to the device may not be fully implemented.

The choice of pipe is possible only after determining the power of the system itself, thanks to which it is possible to determine the most suitable diameter, which is advisable to use for the chosen construction.

What parameters need to pay attention to when choosing:

- Material. Naturally, the main parameter determining the choice will be the material, it will directly depend on the physical and mechanical condition of the pipeline, installation features, because installing a flexible corrugated pipe will require completely different accessories and tools than using metal-plastic.

- Diameter. The speed of movement of the coolant inside the device will depend on the diameter of the pipe, and the speed of heating the room when the system is turned on will depend on the speed of the coolant, respectively. In addition, the diameter will affect the intensity of resistance of the coolant inside the pipe, which will depend on the choice of pumping equipment.The most commonly used options are with a diameter of 16, 18, 20 and 25 mm.

- Temperature characteristics of the carrier. Each type of pipe has its maximum permissible heating value, therefore the type of pipes that are more suitable for the device will also vary depending on the coolant temperature.

- The pressure inside the pipes. As in the case of temperature regimes, each type of pipe has its own maximum allowable pressure inside. For example, for a private house it is quite possible to limit one-pipe system, the maximum pressure in which is up to 6 bar, and for an apartment building it is worth choosing pipes with a large indicator - up to 10 bar.

Most materials today meet all the stated requirements, so the choice will directly depend on the method of installation, as well as on the amount that the consumer has.

Of course, copper pipes are the best option, they have the longest service life among these materials, have a high thermal conductivity, but they are rarely used because they have a very high price, several times higher than the cost of other options.

The most popular are PEX pipes and metal-plastic.

PEX is a very good option for floor heating, they have sufficient thermal conductivity, flexible, therefore, easy to install.

Metal-plastic has a slightly higher thermal conductivity than PEXSince the pipes have a reinforced metal layer, and, as is known, it has an increased thermal conductivity. In addition, due to the aluminum layer increases the strength of the pipe, and hence the service life. However, the installation of such pipes requires the use of connecting elements that require a special method of fastening.

As for the most preferred firms, you should pay attention to the heating system and pipes company Uponor. The head office of the company is located in Finland, and the products are available in more than 100 countries. The full range of high-quality equipment from metal-plastic and polyethylene for underfloor heating can be found here. The diameter of the pipes sold is from 16 to 25 mm at a pressure of from 6 to 10 bar, depending on the material.

In addition, good quality at a reasonable price is offered by the Italian company Sanext - this is the production of high quality PEX pipes for heating systems.This manufacturer uses a special three-layer protection, which not only provides a longer service life, but also absorbs noise from the movement of water flow through the pipes.

Popular is also the German company Rehau. The pipes of this company are also equipped with special noise-absorbing interlayers, their diameter varies from 10 to 25 mm, the maximum use temperature is +95 degrees, and withstand pressure up to 10 bar, which is quite enough for arranging both a private house and an apartment in a high-rise building.

How to calculate the quantity?

The maximum length of pipes used in the system underfloor heating is 120 meters. This restriction is established because of the constant presence of water under pressure, which affects the integrity of the screed, therefore, excessively long and overall structures will fail more quickly than those that will not exceed the length value.

If the room is too large, it is worth using several circuits around the perimeter of the room.

In this situation, it is important to make a high-quality and durable connection of pipe sections.

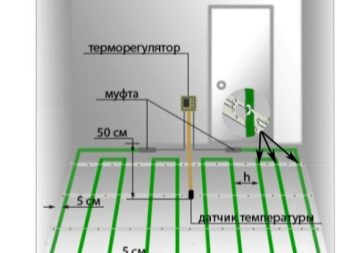

For proper installation, a certain distance betweenpipes, it should be about 10 centimeters at the edge, then it can increase each time by 5 centimeters, for example 15, 20, 25 centimeters and so on. However, it is not necessary to increase the distance to more than 30 centimeters, otherwise height differences will be felt on such a floor and it will be uncomfortable to walk on it.

To easily determine the required amount of materials, you can use a simple rule. It says that about 1 meter of material should be used for 1 m2. This calculation is relevant for the floor with a step between the components of the system equal to 20 centimeters.

For a more accurate calculation, the formula is applied: apply L = S / N * 1.1. In this case, L is the total amount of required footage for the entire space, S is the area of the room, N is the width of the distance between the pipes, 1.1 is the margin for turning the pipe.

In addition to these sizes, it is necessary to leave the stock of footage, the size of which will correspond to the distance from the collector to the floor.

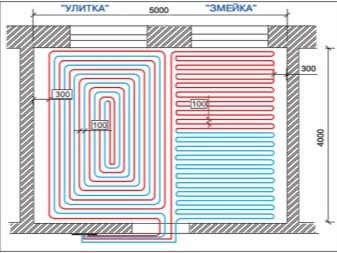

In addition to the area of the room, the length of the layout will affect the layout of its calculations during installation. There are 2 basic types of pipe laying indoors: a snake and a snail. Depending on the selected pattern, the required footage will also change.

Pick up the right amount of pipe - this is only part of the total calculation of the footage of the heating system. It is important to determine the meter contour for installation. In this case, the calculation will be influenced by the pipe diameter and the material from which the model chosen for installation will be made. So, if the selected option is made of metal-plastic and has a total diameter of 16, the length of the contour should not exceed 100 meters. It is better, of course, to focus on the length lying in the range from 75 to 80.

For PEX pipes with diameters of 18-20 centimeters, the length of the contour should be no more than 120 meters, and the most convenient option is a contour with a length of 90-100 meters.

In addition to the base of the pipes, it is necessary to pick up the loops and connecting corners if necessary. They are also calculated on the basis of the floor space, the layout of the layout and the material of the pipe itself.

How to lay?

When the difficult stage of selecting the manufacturer, the type of pipes has been completed and the required footage has been calculated, all the components have been purchased, you can proceed directly to the installation.

Installing a floor heating system includes several important steps.

The first stage is thermal insulation. At this stage, all the preparatory work is carried out, the floor is cleared, if necessary, old rotten floors are removed, a full cleaning of the space takes place.It is necessary to get rid of all the garbage, so that later it does not interfere with the installation. Installation is carried out only in a completely cleaned space without furniture and other furnishings.

Upon completion of cleaning, you can proceed to the laying of the thermal insulation layer. As a material for this can be an ordinary sheet foam. Its cost is minimal, and its carrying capacity makes it an effective tool in the fight against the penetration of cold air.

The foam is laid evenly around the perimeter of the room directly into the cleaned space, the so-called base. If desired, you can pre-primed surface. It is more convenient if the thickness of the foam sheet will not exceed 15 centimeters.

Having finished with polyfoam, it is possible to pass to the following stage - waterproofing.

As a material that performs the function of waterproofing, can act as a normal dense film. In the process of laying this layer, the polyethylene film is fixed along the perimeter directly to the walls in the area of the plinth, and the metal mesh is fastened from above. Thanks to this manipulation, the waterproofing layer will be more dense, and the film will not move around the foam in case of disconnection from the wall.

Then comes the most interesting and crucial stage - the pipe laying itself. By this time, the type and material, the method of connection to the main heater and the drawing on which the fixing will take place should be selected. And if, in addition to deciding the type of laying scheme, to have a drawn scheme according to the size of the space, the installation process can be significantly accelerated.

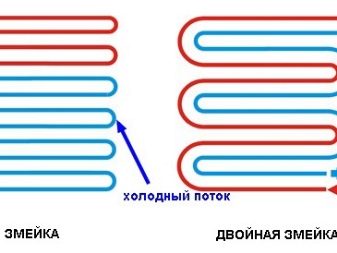

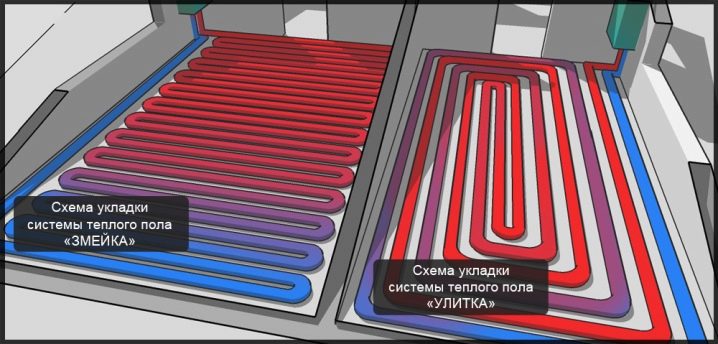

There are 2 main ways of laying pipes for underfloor heating: a snake and a snail. It is worth considering the differences and determining which scheme is more suitable for a particular type of room.

"Snake" is most often used for heating in small spaces. In addition, it can help out if, after laying the pipes, small empty areas remain to be filled with a snake. Pipes with this method of installation are located at a distance of 15-20 centimeters, since the bend with this method is equal to 180 degrees.

It is for this reason that it is necessary to be extremely careful not to break the fragile pipe.

Reducing the spacing between pipes is appropriate in the area of doors, windows and other colder areas of the room.In addition, you can use this method of laying as a "double snake" - two pipes repeat the pattern one after another in a symmetric display. This option will provide greater heat transfer. The total length of the contour here is 70 meters, otherwise there will be a decrease in the marginal efficiency of the heated floor.

The second method of laying - the "snail". It is considered the most acceptable and correct, because it is in this situation that the distribution of heat occurs as evenly as possible along the entire perimeter. It is better to keep the pipe pitch in the range from 10 to 25 centimeters, avoiding wider gaps, which will ensure differences in the height of the finished floor. The length of the contour with this type of layout can be increased to 120 meters.

Further, according to the chosen type of installation, the pipes themselves are laid directly, which are attached to the usual reinforcing mesh using special screeds.

When all the necessary length will be fixed around the perimeter, you can proceed to the next very important stage - pressure testing. This stage is a testing of the finished system. The crimping stage takes a total of 24 hours,it is precisely this time of the system operation in the normal mode is sufficient to identify possible mechanical damage to the pipes and promptly repair or replace them.

After this process is successfully completed, it is necessary to fill the entire surface of the floor with a solution of concrete. It should be noted that the pouring should occur under uniform pressure, and the layer at the exit should not exceed the mark of 7 centimeters.

Immediately after the concrete has completely dried, you can put any selected floor covering, however, it is recommended to stop the choice on linoleum or tile, since wooden coatings can quickly lose their attractive appearance due to temperature changes.

Reviews

Underfloor heating today is an extremely common phenomenon, so it is not surprising that on the Internet in various forums and manufacturers' sites you can see a lot of different reviews about pipes for floor heating and about this system as a whole.

Most users agree that a heated floor is necessary, especially in rooms with floor tiles or large windows.

Metal-plastic and PEX pipes are the most popular among users.they meet all the requirements in terms of price-quality, in addition, such pipes are convenient for self-installation, do not require special tools and special training. Many users in the reviews talk about their experience of self-installation of such a floor.

The volume of water in the pipes, however, does not suit everyone, there is noise and a constant fear of a breakthrough. In addition, wooden flooring deteriorates with a water-heated floor. The way out, based on user feedback, is the floor with an infrared conductor, which also moves through the pipes, providing heating.

In general, it can be said that those who have installed a high-quality warm floor do not regret their choice.

For more details on pipes for underfloor heating, see the following video.