Features of underfloor heating

Under floor heating is possible using electricity or water. This is not to say that this or that option is perfect, both have strong and weak points. It is necessary to understand how the water-heated floor is arranged, how exactly it works, to make the right choice and design everything as competently as possible.

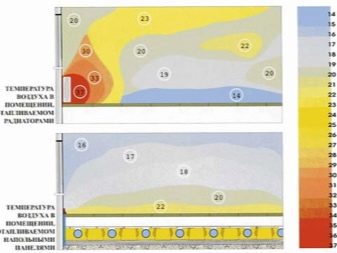

Special features

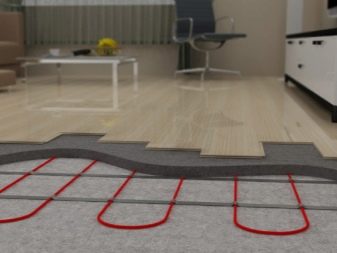

Water heating is more difficult to organize than electric, but it is much more convenient. The initial installation is quite expensive, but it pays off with relatively low maintenance costs, which will please the forward-thinking owners. The bottom line is that the floor covering hides a “layer cake” that contains pipes with a coolant moving along them. Since the total length of the pipeline is considerable, there can be many bends in it, a rare system in practice can do without pumps.

Given the low temperature of heating, water heated floor does not dry the air. If necessary, you can turn off some of the circuits, and still the concrete will retain its normal temperature for a long time. All designs are hidden inside the floor, they do not spoil the appearance of the room.

Without exception, all stages of installation must be completed before pouring, otherwise it will be very expensive, and sometimes impossible, to correct the flaws. In apartment buildings, it is very difficult to obtain permission to install a warm water floor, you will need to prove your case with the help of expensive expertise. In addition, increasing the load on beams and overlapping can be a big problem.

But it is up to you and you to decide whether the positive sides of a warm water floor overlap its disadvantages or not.

Types and principle of operation

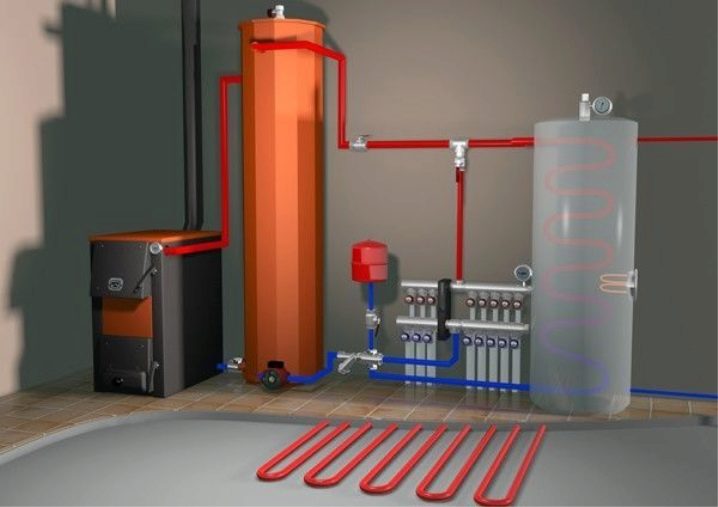

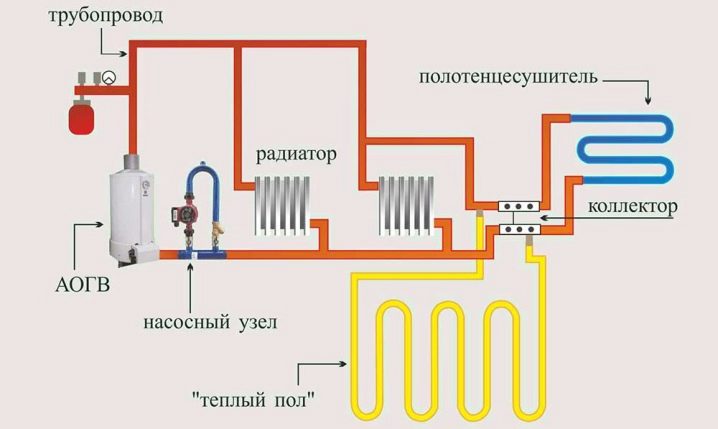

The heating of the heat carrier can technically be done in two ways: local boiler or central heating. The second option in urban apartments is unacceptable for legal reasons, and even in private homes is inappropriate, because the slightest interruption on the highway will deprive you of a warm floor for a long time.

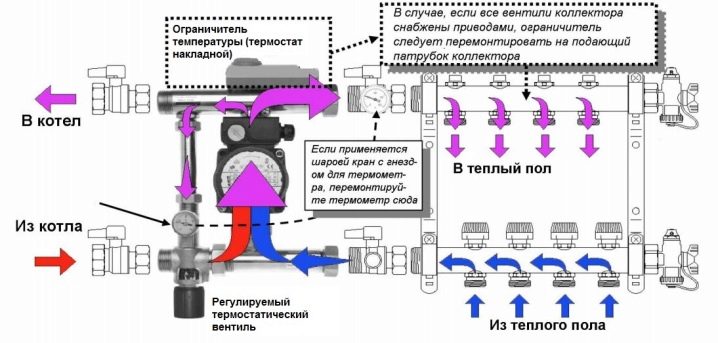

However, it does not matter which scheme to choose, because it is imperative to lower the temperature of the heating medium before it goes inside the heated floor. Virtually all boilers heat water to 65 degrees and above, and few people like to walk around the “hot frying pan”.

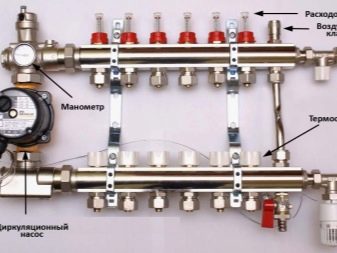

The method of cooling is simple - a hot liquid comes into the mixing unit before being supplied to the pipes, where it is mixed with water circulating through the return pipe. From the mixing unit the coolant flows into the collector, and only after that it goes through the pipes. The need for such a scheme disappears only when using condensation boilers that warm the water to the temperature required for a heated floor, and with a sufficiently high efficiency.

They are recommended to be installed together with similar heating systems.

In order for the self-leveling floor to be heated not only to a comfortable temperature, but also to a consistently maintained temperature, thermostats are required that are directly connected to the sensors. The required level of heating is set via the control panel, the control unit of the thermostat processes the messages of the meters.According to them and the program indicates the current parameters of the mixing node.

Even when the collector system has thermostats at the inputs, a separate thermostat for the water floor is very important.

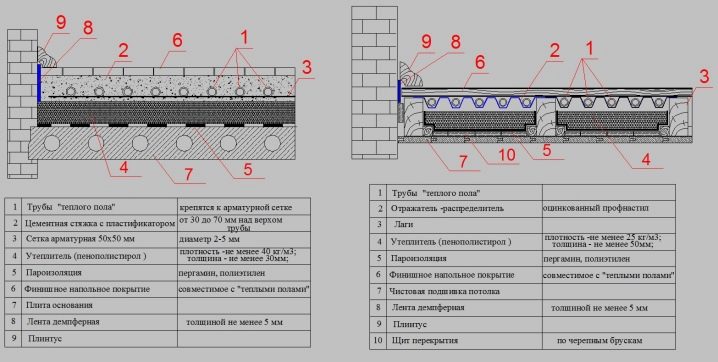

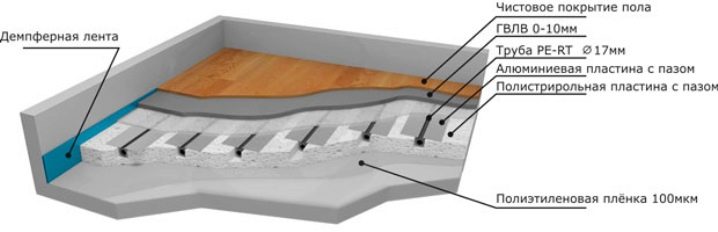

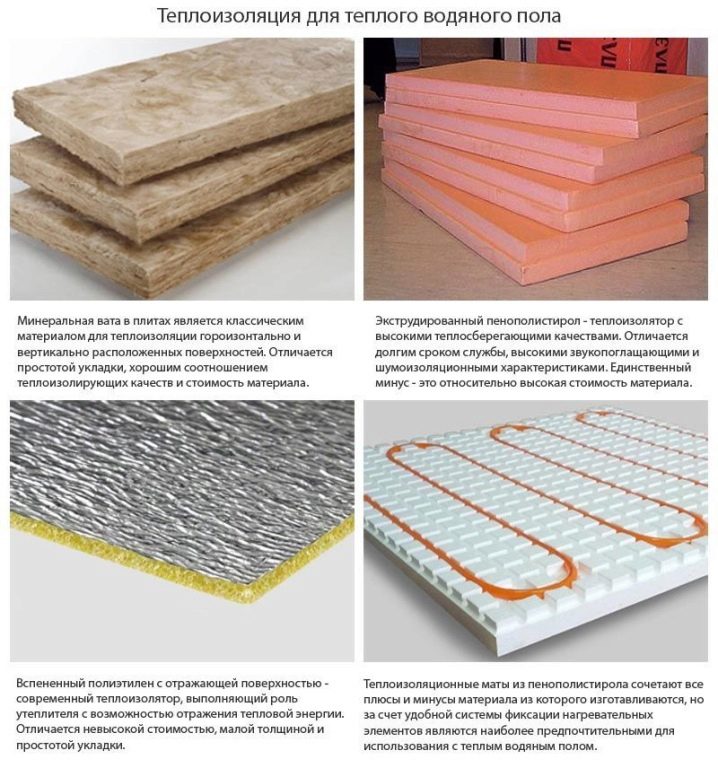

Water heated floors are always multi-layered structures that require thermal insulation of the base.

The bottom layer is heat-insulating, 3 cm is enough over heated rooms or offices, sometimes 2 cm is enough. When a room is placed above an unheated basement or immediately above a layer of earth, the minimum thermal protection is 5 cm.

In the arctic and subarctic regions, 10–15 cm heat insulation is absolutely necessary, as this is the only measure that allows for a normal level of comfort.

Drawing attention to the shortcomings of the water floor, designers are unsuccessfully looking for ways to improve it. But the most original solution, perhaps, is such an option as a hybrid of fluid and electrical systems.

It is represented by two different types. In the first of them, a cable divided into 7 cores is inserted into a polyethylene pipe filled with antifreeze. The pipes at the factory are sealed to complete tightness, put in the screed, and both ends of the cable lead to the mounting box connected to the regulating device.

The capillary type also implies laying thin tubes inside the screed and connecting them to the automation. The external system heats the fluid, forms the necessary pressure and at the same time monitors the constant heating. As a result, there are no wires inside the floor itself, which is much safer for users.

Regardless of how the fluid moves, there is necessarily a thermostatic valve in the system that initiates the mixing of water when the threshold level is exceeded. Before the circulation pump, a jumper is placed, which hides this valve (it can be both two-way and three-way). If the water has cooled to the minimum prescribed value, the supply of cooled liquid from the return flow immediately stops.

Then the coolant is in contact with the distribution comb, but not always - in insignificant areas where there is no need to organize two or more tubular loops, such a node is not used.

No less important than the order of circulation is how heated water is provided.

The classic option is considered one in which a boiler or a central pipeline is used for heating. Next, the coolant enters the pipe.Mixed type implies the already described hybrid of electric and water heating.

“Classic” can be easily created both in the construction process and in an already built house, compatible with any sources of hot water of proper quality. It is easily combined with all existing floor coverings, using such a system eliminates the need for complex installation schemes. But there are also weak points: there is a high risk to flood the neighbors from below, there is no possibility to install power regulators.

The combined version does not require the use of circulating pumps, the entire system is sold almost ready-made. All that is required for work is only a stable power supply. There is no need to fear that overheating will occur, the automation reliably prevents such situations. Fluids for work will need relatively little, the uniformity of heating the entire surface is guaranteed.

As for the substrate under a warm floor, polystyrene systems are superior to traditional concrete screed only in a few cases: when the ceilings are very low, when the main floor or floor is very weak, when there are difficulties with getting ready concrete or with its preparation on site.

Specifications

If you have not yet decided which floor will be used, you should prefer stone or ceramic tiles, which are distinguished by the optimal balance of warm-up time and heat preservation. But the laminate, linoleum can only be used is limited, if there is a marking on the possibility of flooring over the warm floor. This kind of coating will not throw toxic fumes and you will be reliably protected.

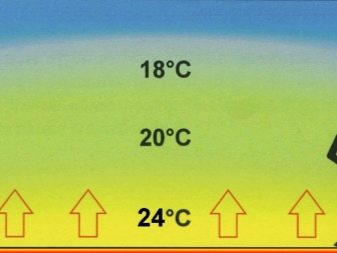

The optimum temperature of heating depends on two circumstances: the properties of the material and the characteristics of the specific room; if a carpet is placed on top, it can warm up to a maximum of 31 degrees.

The average temperature in the living room is 26 degrees, and where the humidity is particularly high, it is 5 degrees higher. In a non-residential area (bathroom) it is necessary to withstand heating up to 31 degrees. Parquet and laminated flooring should be heated to no more than 27 degrees, and rooms where children will constantly be - to 24.

Even directly above the floor heating pipes, the coating should not be heated to more than 35 degrees.

Obviously, the amount of heating is associated with such a parameter as the power of the system.The heat source (boiler) is selected with the expectation of full efficiency at the maximum planned load and with a power reserve of at least 15% above it. Then no critical situations will not be scary.

Maximum power 1 square. m of warm water floor, as well as the force of its heating, is closely connected with the main finishing material. When heating the base of the room will be the main source of heat, you will need to create a flow of energy of 160-180 W (in terms of 1 sq. M, not occupied by furniture and large household appliances).

First, calculate the level of heat loss in the room, and only then select the design of the heated floor and calculate its necessary parameters.

If on 1 square. m accounts for 80 watts of losses, then thermal insulation is extremely desirable, and if this figure is 100 watts or more, you cannot do without it.

Which is better to choose?

Speaking about the choice of a warm floor, it should be noted that in most cases water heating structures should not be installed in an apartment. Exactly under the ban fall those systems that are connected to central heating or hot water pipes.Violation of such a rule threatens to impose a fine, and an unauthorized connection will be detected at the first visit of plumbers. Sometimes even they will not need to enter, it is enough to establish the fact of unbalance of heating or hot water supply, the source of which is in a certain apartment.

Some regions of the Russian Federation establish softer rules, but even then the tenants will have to pay for the expertise, an act of which will prove that connecting a heated floor will not harm utility systems. An essential component of the heating complex will be an autonomous unit with pumps and mixers, guaranteeing a stable output pressure.

Very important: in the presence of a jet pump in apartment buildings, pipes made of metal and polypropylene should not be used.

Deciding to make a heating system in a wooden floor, you will need to abandon the screed. If you use it, it will destroy the very idea of a pure wooden flooring. Significant shortcomings in this are not exhausted - it is worth considering the considerable absorption of height, and the weight of the structure, and long-term drying, and low suitability for repair.A large mass of screeds is very bad in the frame house, because it deprives such a construction of the most important advantage - an easy and economical foundation.

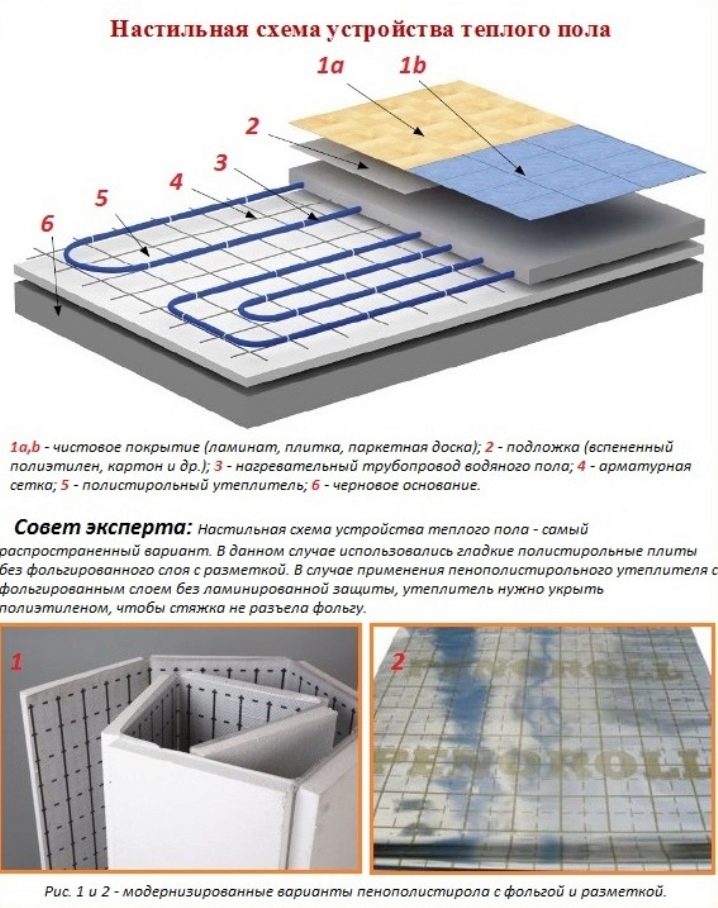

An excellent solution is the flooring complexes.

You can make them without resorting to “wet” work, the cost of installation is noticeably reduced, which will please any property owner and free up some of the funds for more necessary repairs. Flooring is divided into polystyrene and wood varieties. In the first case, we mean the popular dense foam with specially prepared grooves for parts of the pipeline. "Tree" is also called blocks based on chipboard or OSB. Considering the low heat transmission by such materials, their grooves are filled with metal plates with all the same grooves.

When pipes are installed, you can immediately lay a hard coating - board, parquet, laminate stripes. But keep in mind that soft floor materials are placed only on a rigid intermediate base, overlapping the pipes and additionally fixed. In principle, the glue can be placed directly on the plates of metal, but its composition must then be adapted for use in the “cake” of the heated floor.

On a concrete base, unfortunately, we cannot do without a screed.The schematic diagram of the device, in addition to it, includes the use of waterproofing and heat-saving layers, rebar grids, and a damper tape. When the floor is on the ground itself, it is recommended to use an extruded type of expanded polystyrene with a minimum thickness of 0.1 m; over a warm base it is permissible to reduce it to 30 mm. On the balcony and in other unheated premises, the required power of the underfloor heating should be increased by another 10%, then you will not need to excessively reinforce the layer of insulation.

In the bathroom, heating due to the warm floor will be self-sufficient - in most cases it is enough to completely eliminate the use of batteries, electric heaters and other systems.

How to connect?

An electric boiler is usually connected to a water-heated floor, not directly, but through an intermediary distribution unit. Its role is to increase the pressure in the system to the worker, to adjust the temperature, to ensure a uniform proportional flow of water into different circuits. Even if you have done all the other work yourself, we recommend entrusting the connection process to a specialist.Only he can choose the appropriate option and avoid fatal mistakes.

Immediately decide whether the management of the system will be limited by manual means or you will need automatic software control.

The connection of pipes to the collectors is achieved by means of a Euroconus clamping fitting. After all the circuits have been assembled, the compressor is turned on, which develops a pressure of at least 6 bar. It will allow to increase the internal pressure in all parts of the heating system to 4 bar and thereby detect the slightest signs of depressurization.

The pump, built into any modern boiler, confidently copes with pumping water through the warm floors of residential buildings, not exceeding 120 square meters. m by area. Only in the presence of a clearly larger area of the dwelling it is necessary to use additional pumping equipment, then it is placed in isolated collector cabinets. When it is required to mount two or more collector cabinets, the main route for pumping fluid is equipped with a splitter, and after all distribution nodes it is necessary to install narrowing adapters

Thanks to them, the water will evenly and smoothly get to all the most remote corners.

If the source of hot water is a central heating system, the equipment regulating devices for floor heating is not necessary. Anyway, according to safety rules, you are not entitled to change the intensity of the heat flow at your own discretion. On the other hand, they will remove the batteries from the room, which, even with the best possible appearance and careful designer playing, sometimes prevent them from realizing their design idea.

Once again we remind: the screed must first dry, and then the created warm floor can be connected and started up, not earlier.

For the formation of this layer, concrete of at least M-300 grade (aka B-22.5) is suitable, and the permissible crushed stone fractions are from 0.5 to 2 cm. The screed directly above the pipe should reach 30 mm thick (and this is only the minimum ), otherwise it is impossible to guarantee neither mechanical strength, nor uniform heat distribution over the entire surface. The mass of 1 m2 of concrete screed, the depth of which reaches 0.05 m, can be up to 1.25 c.

If the screed is thicker than 0.15 m or it becomes subjected to a significant load, this should be taken into account when calculating the thermal conditions. The thicker the protective layerthe higher its hardness, but at the same time the drying time is delayed, the system becomes less flexible, the thermal inertia increases.

Therefore, they usually try to provide a “middle ground”, to find a balance between opposite qualities.

To prevent the screed from being prematurely broken, shrink seams should be used. The existing technology prescribes to create them whenever the heated space exceeds 30 square meters. m or there is at least one wall longer than 800 cm. It is equally important to prevent thermal deformations when the length is 2 times longer than the width (or vice versa), when the structures themselves have expansion joints, as well as in rooms of a fancy configuration.

It is not enough one laying of a damper tape, therefore, where there is a seam, separate a reinforcing grid. The base of the expansion joints is exactly 1 cm, from above they must be treated with a sealant for greater stability. For your information, in rooms of an atypical configuration, a breakdown into the simplest forms - a rectangle or a square - is practiced. The boundaries of these segments are also covered with seams.

It is possible to lead the pipe through the expansion joint seam only by placing it in an external corrugated pipe, the size of which is 0.3 m before the obstacle and the same after it.It is undesirable to crush the contour with such seams. If the topcoat is tile, laying it on top of the expansion joint can cause problems.

Premature spalling is prevented by putting one of the parts onto the tile adhesive and holding the other with an elastic sealant.

To never face the cracking of a fresh screed, there are a few recommendations. In particular, it is advised not to use heat insulation lighter than 35 kg per cubic meter. The necessary plasticity is given to the tightening solution by adding more than one plasticizer, but also a fiber. It is necessary for the concrete to set gradually, 24 hours after pouring, the layer is covered with polyethylene and left for 7 days.

When choosing a plasticizer, make sure that it refers to the number of air-entraining compositions designed specifically for floor heating.

Prepare a solution of M-300 from M-400 need, taking to 1 part of the cement 1.9 parts of washed river sand and 3.7 parts of crushed stone of certain fractions. This ratio is by weight, and the volume proportion of sand and crushed stone is 17: 32 (for every 10 liters of dry cement).

An alternative scheme involves the use of granite screenings, easily replacing sand.24 kg of crushed stone fraction from 0.5 to 2 cm, 7-8 l of water, 400 g of hot water solution of superplasticizer SP1 are mandatory components. In addition to them, take 12 kg of cement and 36-48 kg of screening with a particle size of 0.5 mm.

Regardless of the recipe of production, good concrete does not emit water and does not stratify into fractions. If the work is done correctly, with a temperature of 20 degrees, the setting will begin after 240 minutes, and when it takes 12 hours, the heels of the shoes should not leave marks on the surface.

Accessories

Pipes are deservedly considered to be a very important part of components for a water heated floor. Metal-plastic constructions are recognized as the best option. Be sure to take branded products, a long time of which is confirmed by the experience of many people.

If the choice is stopped on polyethylene pipes, it is worth preferring Pex-a, Pert. Polypropylene is pretty good, but you should carefully evaluate the quality of its welding. Take only reinforced aluminum in the middle of the pipe.

Copper constructions are distinguished by increased reliability, but not everyone will be able to pay the costs of their purchase; if you really want a metal pipe, make a choice in favor of corrugated stainless steel.

Cross-linked polyethylene is difficult to bring into the desired shape; It is worth the material to warm up as it straightens. But this disadvantage has its own justification - there is no risk of solidification of the coolant and it will be possible to eliminate defects, and not to change the pipe in case of problems.

The copper pipe must be covered with a protective layer, otherwise the alkali will have a detrimental effect on it.

The electric boiler will be needed almost necessarily, this is the simplest and most practical way to apply a heated coolant to the warm floor. Approximate consumption of pipes is from 3 to 5 m per 1 sq. M. m of heated space (not the total area). The mixing unit becomes necessary when the boiler heats the coolant to significant temperatures, that is, it is always needed, except for options with condensation heating. It is also impossible to create a good system in which there would be no circulation pump and collector.

Collectors that can regulate the temperature value are required when the heated floor is located in several rooms at once. Thanks to this function, you can flexibly vary the heating of the floor covering,focusing on the purpose of the premises and the needs of people. So, children need a floor warmer, and where it is covered with tiles, it is necessary to strengthen the heating.

A mechanical thermostat interacting with a comb (or its electronic programmable analogues) just allows you to set the exact temperature for individual rooms and even for different parts of the same room.

For very large heating circuits, shield thermostats should be used; in other cases, ordinary wall variants provide sufficient efficiency.

Please note: do not confuse the temperature controllers that set the temperature of the air with those that monitor floor heating. The value of their testimony is different, but what is always the same - this is the return of commands to the servos that change the cross section on the lumen, thanks to which the intensity of the water flow also changes.

The working part of the servomotor is a thermal valve, which is able to push the valve back or close it. Heat distribution plates for dry floors are used in wooden structures. These aluminum blocks penetrate them and provide the optimal level of thermal conductivity in different parts of the floor.

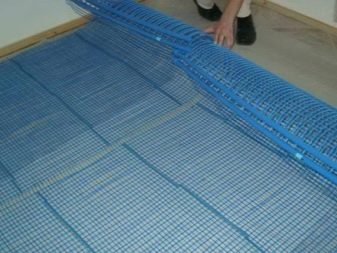

Now you need to understand the subtleties of the selection of individual elements.Reinforcing mesh is best suited with a small cell - 15 to 15 cm with a cross-section of rods 0.4-0.5 cm. When thermal insulation is made on the basis of special relief mats, reinforcement is not required at all.

Pipes attached to other structures are not recommended to buy unless the manufacturer provides a guarantee of 50 years of uninterrupted service and more. With modern technologies, it is not a problem to ensure such a long-term operation of the product, and the refusal to do so immediately betrays fans of easy money.

When choosing a copper pipe, look at whether the bend matches the configuration to your needs. It is possible to correct the discrepancy, but only on complex equipment and for a separate, very substantial fee.

The collector supplying pipes with hot water is located in a special cabinet or a specially prepared niche. On all output loops, except for shut-off valves, counters must be put, they are needed primarily for the timely detection of overruns of resources by one or another circuit. But both the collector and the valves will be powerless if there is no reliable, well-chosen boiler in the system.

The most practical are wall-hung boilers with closed combustion chambers; Connecting to such devices other infrastructure underfloor heating is not difficult.Steel devices are cheaper than cast-iron ones and much smaller than them, which is very important to consider even when selecting heating equipment for a cottage.

A rough estimate of the required power is most often made on the assumption that for every 10 square meters. m required 1 kW of energy emitted by the boiler. Even more or less accurate forecasts, not to mention the thermal calculations, should also take into account the climatic conditions of the area, the level of insulation of the house, its main material.

From the heating device to remove the flow of liquid by gravity and in the same way to direct it throughout the system will not work. Be sure to have to use pumps; for domestic needs, experts consider pumps that create a pressure of more than 6 meters to be unnecessary.

Please note that all these recommendations are only preliminary and cannot take into account the nuances of a particular dwelling, heating system, climate and microclimate. Therefore, drawing up a project and a list of equipment by professionals (with specification of specifications and requirements) allows you to save a lot of money and achieve an optimal result.

Installation and Management

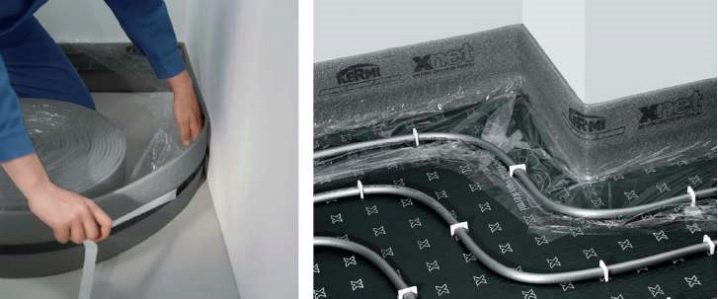

The device of a warm water floor requires rolling around the perimeter of the room damper tape or tape insulation.As it is usually used foam, polystyrene and other sheet insulation means from which the strip is cut with a width of exactly 0.1 m.

Such a restriction is needed to eliminate the occurrence of cracks and to reduce the amount of heat loss so that it less penetrates through the walls and the foundation.

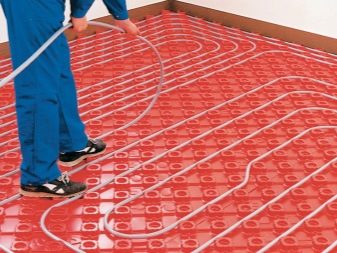

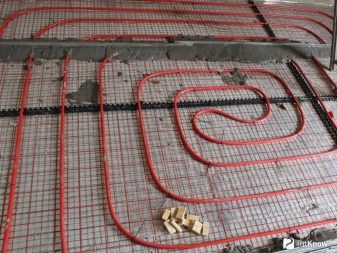

Pipes are placed on top of the insulation, which must be fixed, otherwise they will be unstable, deformations will occur. Often a grid of metal with a step of 0.5-1 dm is placed on the heat-insulating layer, since it is this distance that is most convenient for installation. Pipe rods are attached with steel wire or special plastic clamps. In another embodiment, fasteners are hammered into the floor, and then they will hold the pipe.

Finally, there are also special substrates of plates, equipped with protrusions to hold (fix) the pipeline. Such designs are produced by various companies. Color and geometry, the main material is different, but the principle of their work is identical. Sometimes used fastening tape, stuffed with an interval of 150-200 mm. These tapes are made in the production of “petals” that are bent in the direction, allowing to fix the pipe in the required position.

When laying and fixing are finished, it is time to prepare the mixture for pouring the screed.From conventional screeds, it will differ in the presence of components that dramatically increase thermal conductivity. Some developers, for maximum hardening of structures, suggest using reinforcing meshes on top of pipes, and only after installing them pour the solution. Then all installation manipulations will not damage the floor heating system.

Concrete less than 30 mm thick pouring does not make sense, such a coating immediately begins to "walk" when walking, be sure to form a band cooler and more heated.

When you fill the floor with a solution, pre-fill the pipes with coolant under normal working pressure. This will help to avoid problems in the daily operation of the system, the mismatch of the sizes of its parts.

The next step - finishing the floor, can be done on the 7th or on the 10th day, provided that the average air temperature was more than 17 degrees Celsius. Consider that full strength is gained by a coupler for 672 hours minimum even at room temperature and normal air humidity. All this time the inclusion of a heated floor or other heating it is unacceptable.

Regardless of how the tie is poured, the properties of the floor covering are taken into account: if it requires a perfectly flat substrate, use beacons. The height of the insulation installed around the perimeter should be higher than the finished floor; after drying the screed, the excess is removed with an ordinary knife.

To keep the heat-insulating layer securely, lining with factory marking is used for it, such material is made by many well-known companies.

If you look a little lower, at the base of a heated floor, you will find a previous insulation barrier that prevents fluid leakage. As it is widely used plastic films.

Never put aluminum foil and materials based on it on the screed. In less than 100 days, how it will turn into ordinary dust.

Only metallized coatings are required. Outwardly, it is difficult to distinguish them from a simple foil to a non-specialist, but the properties differ radically; these products in the layer of cement-sand mixture have been working stably for years.

Special attention should be paid to pipes of a water heat-insulated floor. The technology involves the laying of pipe coils without internal connections between them.When the length of the bay is insufficient, it is better to select an additional circuit than to try to organize the connection.

Important: the pipeline as the diameter grows allows you to create larger circuits, but when determining their length, take into account the thermal efficiency of the entire system.

Excessive amount of water leads to the fact that even the best automation does not allow you to adjust the degree of heating quickly enough. For domestic purposes, a pipe diameter of 1.6 to 2 cm is sufficient; then a balance between the main indicators is observed.

Metal pipe with a caliber of 16 mm can be folded into loops up to 100 m, however, it is more practical to reduce the “ceiling” by 20-40%. With a cross section of 2 cm, the theoretically achievable and practically suitable length of the contour is 140 and 120 m, respectively. You can generally orient oneself to these indicators when creating pipelines from other materials. For your information: each individual circuit is supposed to be supplied to a specially designated for it input or output of the collector node.

The damper tape can not only encircle the perimeter of the room, but also to delimit the contours from each other, to extinguish their mutual negative impact.It is recommended not to form contours that are very different in size without extreme necessity.

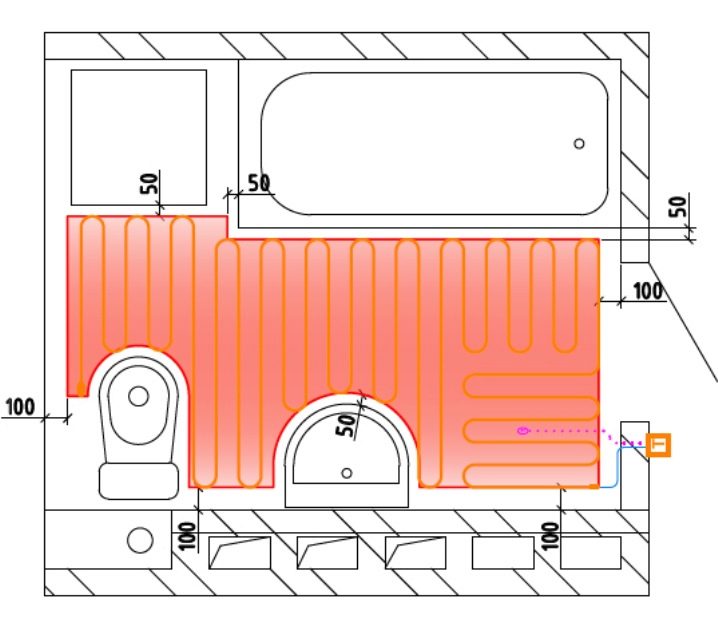

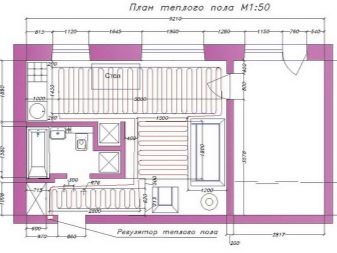

Most often, the design of the heating system is a "snake" and "snail"; It is difficult to say which of these solutions is better, because each has its own weak points.

Thus, a serpentine arrangement allows the use of a pipe of shorter length, however, such a saving turns into non-uniform heating of parts of the floor. The supply pipe is filled with a thoroughly heated coolant, and having reached half the total length, it will have time to cool down.

With skillful use, when the initial sector is placed at the window, at the door or near the cold wall, this disadvantage can even be turned into dignity.

"Snail" is calculated a little longer, but it rewards the homeowner with a uniformly warm floor; if the contours have to be made long, it is generally the only choice.

Regardless of the installation option, pay attention to its pitch (at least 100 and at most 300 mm). The kitchen, where there is enough heat, allows you to push the pipes up to 25 cm and even more. But tiled bathrooms require you to move the coils as much as possible and increase the heating, so the gap should not exceed 20 cm; The same is true for rooms set aside for children's games.

In each room, the coldest or blown parts are heated more actively, and the relatively warm ones require less energy consumption.

The semi-dry screed is equally compatible with the "snail" and the "snake" ;. Its indisputable advantage is the accelerated drying. Simply mix the reagent with the volume of water prescribed in the instructions, mix thoroughly and apply. Special additives make the appearing solution more plastic, reducing both the water consumption and the duration of "maturation". That is why the increased payment for these compositions is fully justified.

Regardless of the type of screed, the indentation of the pipe from the wall should be 150-200 mm; It will be very good if you make all the contours of individual pipes without resorting to welding. Each weld is a weak point in the construction, it is he who often causes additional problems. For your information: if you have to concentrate a lot of pipes somewhere, make their intersection, overheating the floor is easy to avoid - use external insulation over a section of a heated floor.

We draw your attention to the fact that laying of lines from metal-plastic often requires bending it, and this work must be done manually.An even bend at an angle on a small radius without cracking is obtained if you intercept the pipe with your hand several times in a row.

It is necessary to bend at a right angle with five or six interceptions: first, the thumbs rest against the surface, make a slight bend, then gently move the arms in its direction and repeat the manipulation. Never make a break where the pipe will sharply turn or connect to another.

Polypropylene to bend harder, as it will spring. Be sure to either heat the material, or weld it with a special type of fittings, or simply attach it to the grids, taking care of the least pronounced bend possible. Regardless of the material, the original end of the pipe is connected to the collector, and when the whole line around the room is laid, the return stroke of the pipeline is immediately connected.

Faults

Note that if a warm floor does not heat well, this does not necessarily mean that it has failed; This happens with illiterate design. Thermal calculations should be done by professionals, only they can take into account the whole mass of subtleties that affect the amount of heat loss and the internal course of heat fluxes.Self-assessment based on the volume is considered more accurate and close to reality than is based on the area of construction.

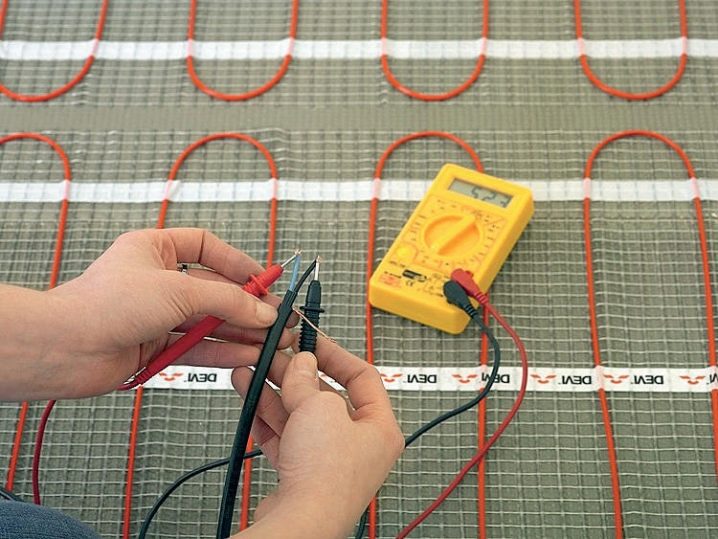

The most common problem is a violation of the integrity of a warm floor. It is easiest to prevent it by properly arranging hydraulic tests prior to pouring the tie or laying the topcoat (if there is no tie). It is necessary to fasten the hose to the drain pipe, the other end is connected to the sewer pipe, because a lot of water will be consumed during the test.

It is recommended to use a transparent hose to immediately notice when air bubbles appear.

The inlet of the collector serves to supply water through a shut-off ball valve; sometimes, in case of poor water supply, it is worthwhile to use an intermediate mechanical filter in order not to clog the system additionally. On any other conclusion of the collector, coupled with the contours of the floor mounted pressure pump. Where exactly to put it, determines the technical configuration of the system. The inspection begins with the fact that all air vent valves are unlocked, and each floor contour, except for one, is closed.

Feeding water, continuously assess the purity after draining, the amount of exhaust air. Even the most accurate construction often leaves behind oil stains, chips, which should not be tolerated. All this is not only detected during the test, but is also removed outside. Noticing that the water went as clean as at the inlet, that the air bubbles had disappeared, first close the outlet tap, then, after the final filling of the circuit, the inlet tap. So consistently work with all circuits to a single.

Testing with a pressure pump means opening all the circuits connected to the collector. The pressure pump is filled with clean water, after which its built-in supply valve is opened. The device turns on and pumps water at a pressure of 200% of the worker, that is, 6 atmospheres. The pressure gauge placed on the pump or on the manifold itself helps to control the compliance of the pressure with the specified value.

At elevated pressure, all pipes and their connections with each other are examined, while someone must continue to monitor the pressure gauge.

After giving the system a “breather”, the pressure is increased to the previous 6 bar, again all the contours and details are inspected.An additional pass is done in ½ hour; all places where outflow of water is detected are sealed immediately after relieving pressure. The absence of leaks is not a reason to calm down, the pressure should be raised again, and it has been holding for exactly 24 hours.

Provided that it does not fall by more than 25% and new places for water release will not appear, the heated floor can be recognized as suitable and ready for use.

Note that the individual brackets from pipes under pressure may break, and therefore all attachment points are additionally fixed with mortar. Of course, after the completion of work with a coupler or flooring, the pipes will be fixed and will not be able to “play” just like that, but the slightest flaws threaten too serious problems.

Suppose that during the installation everything was done correctly, but the water floor still does not heat or does not do enough. Such a problem may arise after a certain time after the construction is commissioned. It is very important to find the real causes and quickly eliminate them.

The weakness of the heating is often caused by poor quality insulation. It is not difficult to detect the appearance of such a problem; it is enough to regularly record the energy consumed and the temperature reached.To cope with the lack of insulation and significant heat loss without opening the entire structure and its subsequent restoration is impossible.

In order not to do this work in vain, it is recommended to double-check all calculations and drawings; if you made them yourself, show the professionals, and if you turned to the designers, use the advice of independent experts.

Suspecting that it is to blame for the deterioration of the heating, carefully examine the flooring and the plinth, especially the joints. Sometimes it is not possible to visually detect wet spots, and the final answer is provided only by thermal imaging. In the damaged area, carefully remove the floor covering, remove the screed fragment. The broken part of the pipe is removed, a new one is put in place; exactly how - is determined by the type of material. Of course, the flow of coolant stops, it is poured from the problem circuit, and after testing it is poured again.

Sometimes poor heating is caused by an uneven distribution of the coolant around the circuits (especially at different lengths). Since the rate of flow of water is the same, for a longer loop, it passes over an increased time and cools down more.The solution to this problem is the adjustment of the valves supplying the coolant to the individual circuits, with specific actuators being made more active. It will be necessary to wait some time until the warm floor warms up, since the exact time is determined by different circumstances.

To make it easier to control and tune the parameters of the system, try to choose a warm floor with the maximum degree of automation. This only at first seems like an expensive and impractical solution, but in fact it will help to avoid unnecessary openings of the floor, reconfiguration and repeated repairs.

If no checks help detect the real cause - and there is no leakage, and the installers did everything according to the rules, it remains to assume a failure in the electrical components. Most often, a circulating pump and a thermostat break down. Immediately check, using a multimeter, if they are supplied with current. Damage to the pump is convincingly demonstrated by the fact that it does not make noise.

For example, checking the thermostat showed nothing, then you need to measure the resistance of its individual terminals, the operability of the temperature sensors.Not finding a defect there, it is better to stop further searches and seek help from specialists, otherwise there is a risk of irreversible damage to something.

Manufacturers and reviews

It is impossible to give full guarantees that the floor will never fail, but for stable operation it is very important to choose a good responsible manufacturer of heating equipment.

- Products of the Swiss brand Rehau are deservedly in demand. Consumers say that it is very easy to mount them, compared to other structures, and that the heating of the floor covering is even. The company produces pipes for underfloor heating with a diameter of 1.01 to 3.2 cm. It is necessary to install heating structures using a special type of fasteners. Thus, the mats of the Varionova series effectively retain heat, dampen sound waves (which will delight residents of an apartment building). For the connection between each individual blocks using the folded technique. Favorable replacement for mats and panels are branded Raufix tires based on rigid polypropylene; their downside is complemented by special hooks that reliably grab any base of the floor.

Water heated floors from Rehau equipped with reliable harpoon-brackets, clips, insulating nails. Workflow management takes over the distribution manifold.

- Valtec products are also considered an affordable and reliable supplier of underfloor heating., but at the same time, some customers pay attention to the "capriciousness" of its equipment - with the error of installers there is a risk of swelling the floor. But the pipes on the basis of cross-linked polyethylene, easily resisting a significant temperature, delight many. According to the manufacturer, you can buy not only the heat supplying kits themselves, but also the control automatics and other devices that are ideally suited for solving the set tasks. Warm floors from Valtec are suitable for installation in situations of any complexity, the level of automation does not play a role (more precisely, its solutions are offered for any degree).

For 8 years now, the corporation considers heating equipment to be the leading offer and applies all the latest developments in this segment. The number of taps in the combs reaches 12, which allows to install underfloor heating even on a very large area.

- Kits under the brand Knauf are in no way inferior to competing optionsMoreover, the stability of work and the many years of successful action delight many. Information support (instructions, manuals) of the company at a decent level. Even installers who are not too versed in the matter will be able to do their job well, if they show responsibility and effort.

- In addition to the three leading brands, there are many other manufacturers that deserve attention. So, Danish concern Devi produces goods that rarely break - never in a regular 20 years of operation, this did not happen because of a manufacturing defect or poor quality. All major manufacturers of pipe products for underfloor heating make available to the client components and auxiliary materials. Even heat-insulating constructions initially come with already prepared markings.

To learn how to make a water-heated floor with your own hands, see the next video.