How to make a box of plasterboard on the ceiling?

The ceilings of other rooms are saturated with all sorts of communications: ventilation systems, exhaust hoods, plumbing pipes, electrical wiring, communication cables. All these elements look unattractive, there is a need to disguise them. The easiest way to disguise them is to make a plasterboard box on the ceiling. By means of a gypsum plasterboard (GCR) it is possible to construct structures of practically any dimensions and configurations. This design will perform a practical function, as well as decorate the interior.

Special features

The plasterboard box on the ceiling is a bright element of the room, it hides all sorts of problem areas, including electrical wiring and communications.A huge advantage is the ability to install additional lighting devices in the box, which is especially important for many rooms. In this design, you can put virtually any number of light bulbs and switches to be able to highlight a specific area of the room.

Kinds

It is possible to mount a one- and two-level plasterboard construction in any room. It can be decorative walls and partitions, non-standard ceilings, curvilinear structures, various decorative details. Consider in more detail each separately.

Ceiling structure

This category of structures is the most popular and running. On their basis, the formation of one-and two-level suspended ceilings. Creating a simple box, you safely hide the roughness and small flaws of the ceiling, cover the individual communications. The designs of two-level illuminated boxes make it possible to enjoy muted, even decorative lighting spreading from spot ceiling lights built into drywall.Only a good specialist is able to correctly perform such a difficult and labor-intensive work, although, having tried, you will be able to create such a structure yourself.

On the wall

The technique of making a plasterboard box on the wall is simpler than the ceiling design, but it requires basic skills for working with gypsum boards, maximum accuracy in calculations and scrupulousness during operation. A box made of plasterboards on the wall, besides leveling and thermally insulating the surface, solves other tasks: it creates non-standard shelves and niches, decorative components of the interior (for example, a plasterboard box for a television receiver).

Corner

An illustrative example of an angular design is a decorative fireplace box. The creation of such a design is carried out according to a special technology after detailed development. At the same time, the calculation of parameters, the amount of raw materials and a number of traditional architectural and construction moments are taken into account.

In the bathroom

Sanitary or sanitary box - a structure made of plasterboard in the form of a specialized department for laying sewer, water pressure pipes and ventilation systems.Often it is mounted in toilet rooms to create the appearance of built-in plumbing, when the toilet or sink is fragmentarily placed in the wall. Through these boxes in the bathroom mask instrumentation and taps, decorate the interior with new mezzanines, shelves. It is worth remembering that to create such structures in the bathroom or toilet, you must use a material that is resistant to high humidity.

Under the hood

The hood design is a simple construction of an exact rectangular configuration, which makes it possible to safely hide the ventilation duct or the grill. The design includes a skeleton of metal profiles and gypsum boards.

The assembled box under the hood can have:

- L-shaped configuration and adjacent to the corner of the wall;

- U-shaped and fixed on the ceiling;

- to be faced completely with gypsum boards and held onto specialized devices for hanging.

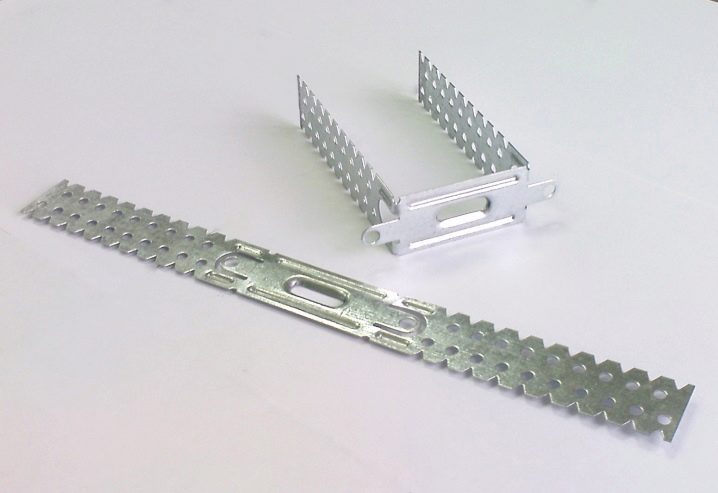

For heating radiator

The design under the battery has the simplest structure that even a beginner can assemble. This product is a conventional frame box based on a metal profile coated with zinc and pre-cut with drywall parts.The box for the radiator is mounted around the perimeter of the heating radiator, the fastening is made to the floor and the lower part of the window sill or to the surface of the wall, behind the battery. In the assembled structure, special slots are made to exit the flow of heated air. The decorative finish of the box will perfectly fit the design into the overall decor of the room.

How to calculate the material consumption?

Carrying out the calculation of the materials necessary for the work, one must take into account the type and type of drywall used, its metric area, and the purpose of the room. Usually sheets produce a standard length. Material can vary in thickness, width, weight. The optimum thickness for a suspended ceiling is 8-9.5 mm. Consider two ways to calculate the consumption of materials - graphical and mathematical.

Graphic technique

The calculation of the plasterboard box for the ceiling in this way involves creating a visual image on paper. This will make it possible to correctly place profiles, count them, correctly place the FCL so that the amount of waste is minimal.

The graphic project consists of several stages:

- Draw a plan of the ceiling, apply a grid on it with thin lines of 10 cm and lines of fatter - 1 m.

- Perform the GCR distribution, first of whole sheets, then fragments.

- Round up the resulting calculations for the integer. If it is difficult to imagine this process visually, it is worth spreading GCR on the floor of the room in which it is planned to create a hanging box.

- After that, you need to transfer the result in the form of a diagram on a sheet of paper. In the mind, you can perform the calculation as follows: divide the total footage into the square of one GCR (3 m2).

- Then you need to draw the lines of the location of the profiles. These calculations should be approached rationally, guided by the schematic drawing of the placement of drywall.

- Set the marks at the mounting points of the suspensions. If this amount is doubled, the required number of dowels will be released.

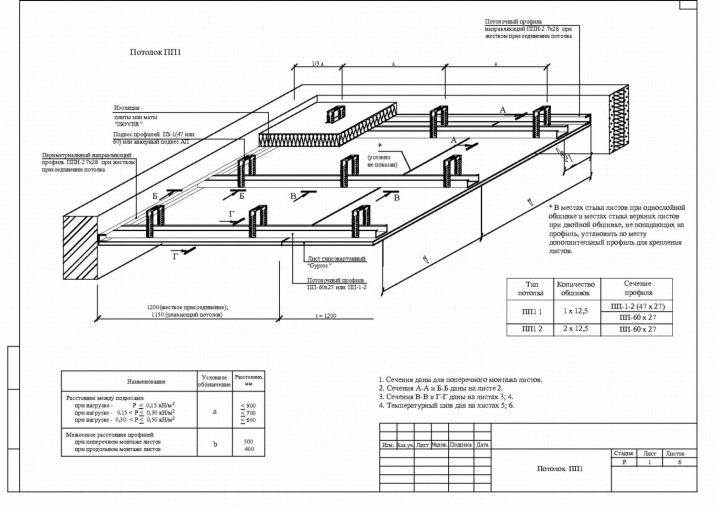

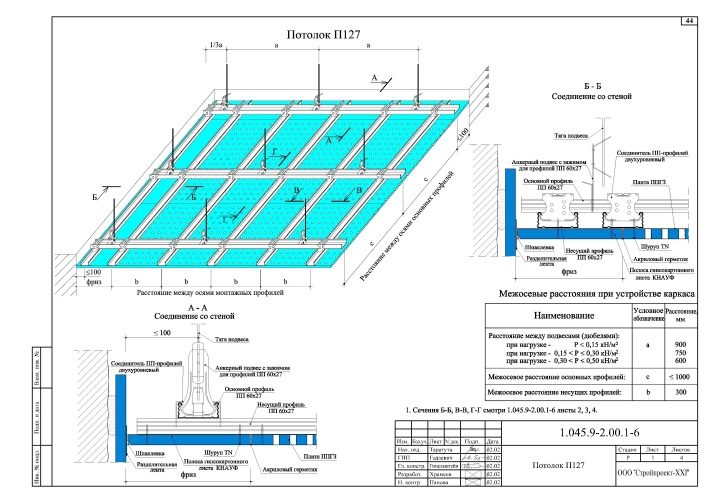

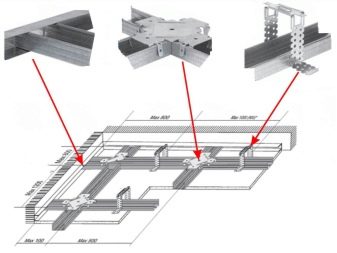

- Mark cross member from CD or PP profile. At the intersection of the lines of conjugation of metal profiles should be mounted "crabs" (four 18-mm screws for each).

The perimeter of the room is the cumulative length of the PN (or UD-27) profile. Calculate the perpendicular and longitudinal PP-60 metal profiles (or CD-60). The number of sections of the profiles is summarized, the number of joints taken away multiplied by 6 cm (width of the guide).All this should be divided into 3 or 4 m and rounded up.

Fixing guides is carried out with a gap of 25 cm. For 1 meter they will need 4 pieces. From this it follows that the entire perimeter must be divided by 4 and the added number 8 added (fixture for corners). This simple method of calculation will help to correctly determine the number of materials required for a suspended plasterboard box.

Mathematical method

If you know the floor space and the required list of materials, you can make the calculation of components in half an hour by means of mathematical calculations. Butt joints ГКЛ must necessarily be located on the surface of the profile, and not hang in the air. Based on this and the dimensions of the sheets of drywall, we calculate the distance between the metal profiles.

Calculation of drywall

To calculate the GCR, we calculate the ceiling footage and divide by 3 - this is the squaring of the gypsum plasterboard. Round up to a whole number (up).

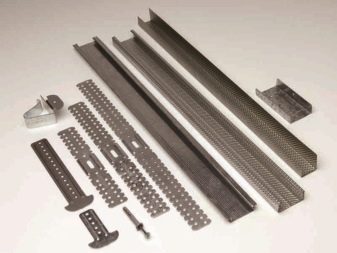

Calculate profiles

Guide metal profiles are easy to calculate: you need to keep in mind that the profile length is 3 to 4 meters. The number of profiles is calculated, starting from the perimeter of the room. Separately calculate how many will need 3-meter profiles, what 4-meter.UD or PN produce 3 and 4 meters. Elementary to mount them across the width of the room. If the step between them is 60 cm, dividing the length of the room by 60, we get the number of required profiles.

Jumpers

The jumpers are specialized connectors that contribute to the tight coupling of the two profiles with each other. The bridges with the profile form 60x60 cm squares. The distance between the profiles is 60 cm. For the calculation, take the CD-60 profile and subtract 3 cm from the bottom and from the top. For easy assembly, we remove another 0.5 cm. It remains 53.5 cm - the value of the basic lintel. Having established the number of jumper belts, multiply it by the length of the room. So find out what the footage profile will be required on the jumper.

Suspensions

This calculation is not particularly difficult, but you need to consider that mount suspensions every 0.5 meters. It turns out that each profile size of 4 meters will require 8 suspensions. Knowing the number of metal profiles, multiply by 8 and get the required number.

Number of screws and dowels

All fasteners must be purchased with a small reserve. The cost of such material is low. If it remains after installation, over time it can be useful in the household.For one "crab" you need 4 screws, 2 for each carrier and ceiling element, 4 for vertical hangers.

The number of suspensions is multiplied by 2, because 2 plugs-nails are used for 1 suspension. The guide part is installed in 300 mm increments, so we measure the perimeter, which must be divided by 300. Summarizing the numbers obtained by multiplying the suspensions and dividing the perimeter, we find the required number of dowels. Do not be dismissive of calculations: it depends on how much you spend on repairs, if you make it yourself.

Preparatory work

In order to avoid any complications during installation, one should not do without surface preparation before starting work. It is necessary to level the basis. To do this, cover it with several layers of plaster. Then apply a primer and paint the ceiling. This is done to prevent the formation of corrosion, which will significantly reduce the operating time of the installation.

If the work is done in a room with high humidity, experts advise treating the surface with an antiseptic, which protects the base from moisture.

When the paint is dry, the preparatory work continues. The next step is to apply the markup. To make it true, take into account the width and length of the profiles, the thickness of the sheets of drywall. After performing the markup, you can start the main work.

Installation

A step-by-step guide on how to mount a plasterboard box with your own hands on the ceiling will help you do the work yourself, without the help of specialists. It consists of several stages.

Markup

Draw with the help of a pencil line, controlling their evenness through the construction level. Lines for fixing guide metal profiles are drawn on walls and ceilings.

We prepare pipes

If pipes are placed on the ceiling, before packing them in a plasterboard structure, it is necessary to carry out work on priming and painting.

We drill holes

Along the contour where the guide profile will be localized, we drill holes for fasteners at the required distance. This will require a punch.

Fix the guides

First, it is necessary to fix those metal profiles that form the top of the future duct with dowels to the surface of the ceiling. Install UD profiles.Along the perimeter it is necessary to fasten guide profiles: this will be the base of the structure, therefore it is important to maintain the evenness of the horizontal position of the structure. Fixing of these elements is carried out by self-tapping screws.

Fix suspensions

They are easy to cut with scissors for metal (along the entire length of the box). To the lower segment of the suspensions using self-tapping screws fix the carrier CD profile. The main share of the load falls on these load-bearing profiles, it is necessary to monitor the accuracy of the work as closely as possible, and not even a small bias should be allowed.

We prepare the wiring

If you plan to install spotlights in the future, you need to lay the wires in advance and fix them directly to the ceiling surface.

Fix the transverse parts

They are fixed perpendicular to the wall, the step between them should not be less than 60 cm. The works on the construction of the frame under the box of gypsum boards are hung, you can proceed to the installation of plasterboard sheets.

Box trim

Prior to installation, cladding is heat-insulated, if designed. Plasterboard sheets cut to the size of the box.The butt joint of two adjacent sheets should be located on the same PP-profile. First sew the lower segment of the structure, and then the side. The material is fixed with self-tapping screws, the heads of which need to be embedded by 1–2 mm in order to simplify the putty.

Finish

Work on finishing shaped boxes, rectangular structures, as well as the soaring ceiling of gypsum boards begin with covering the entire surface with a primer. After it dries, it is the turn of the initial putty. Putting the putty is a responsible process. Incorrect finish will spoil the overall effect of the external appearance of the structure. For high-quality work, experts use two spatulas: auxiliary and working. Auxiliary putty putty, workers evenly distribute it over the surface.

Corner hinged box closed perforated anglefixed on the starting putty. It is necessary to press down the part to ensure a close connection to the box. After removing the corners, the joining seams are glued with a grid and filled with putty material. When the joints dry out, they putti the entire structure.When the putty dries, process the box with sandpaper to obtain a perfectly smooth surface.

If the first time the result did not suit you, you can put another layer of putty, then re-process it with sandpaper.

Useful tips

Drywall is a modern finishing material. It consists of a plaster mix and various additives, which are localized between 2 sheets of special paper. It can be made of any height, width, configuration, construction, similar to wood and even brick. Sheets of drywall can finish loggia, attic, attic.

Subtleties when using

Sheets of drywall are cut with an ordinary stationery knife with replaceable retractable blades. To do this, it is enough to cut a layer of paper and plaster into several mm. Great effort on the knife does not need to apply. After cutting the sheet breaks loosely. Do not seek to remove an improperly wrapped screw from drywall. It is better to twist it deeper so that it does not stick out above the surface and does not leave a hole.

Putty filling is better in small portions. Do not be lazy to knead by hand.You can do this by punching, trying to block the big turns. Putty, mixed at high speeds, seizes much faster, but loses much in quality.

After making a portion of putty, carefully wash the mixing container before the next batch. This eliminate the heterogeneity of the structure. When working with gypsum plasterboards, it is better not to use bars that are not treated with an antiseptic, if a wooden frame is being covered. To create crates of wood, as a rule, use bars 40 mm thick with a moisture saturation level of not more than 20%.

How to make a box of plasterboard on the ceiling, see the following video.