Vinyl siding: pros and cons

Vinyl siding is the most popular category of materials for the implementation of the exterior. He recently appeared on the market and has already managed to win a wide audience of fans. Before buying this material, you should examine the pros and cons of the new product.

Special features

Vinyl siding has a special composition, 80% of which is occupied by polyvinyl chloride. It is this ingredient that gave the product its name. However, there are manufacturers on the market who reduce the amount of polyvinyl chloride to 70% in order to lower the cost of the material itself. This method has a negative impact on the technical characteristics of siding. But such products are also in demand, as some buyers are attracted by the low price.

If you do not want to save on the quality of the material for finishing, pay attention to the price category.There are options where the secondary raw materials are used in the amount of 5%, located only in the lower layers of the sheet. In this material, calcium carbonate is present in an amount of 15%, which fills the structure of the web.

The content of titanium dioxide reaches 10%, and this component is located in the upper layers of the material. This ingredient is responsible for the stability of the structure. And also the additive allows the material not to change the light, since titanium dioxide prevents the harmful effects of sunlight.

Other additives that are present in the composition of vinyl siding, are contained in lower doses and are aimed at increasing the mechanical strength. In the list of components there are different pigments that are responsible for the color solution of the material.

Advantages and disadvantages

Vinyl siding has many advantages. which should be read before buying.

- Long service life. The manufacturer of this material provides a guarantee on your product, which is several decades.

- Affordable cost. Vinyl siding is cheaper than metal counterparts.

- The main advantage of this siding is its versatility and attractive appearance. With the help of this material you can sheathe any object, no matter from what raw material it is made. The product will help to hide many of the drawbacks of the wall and make the room more attractive due to its beautiful colors.

- Front panels are resistant to mechanical stress and adverse climatic conditions. Positive characteristics are observed at temperatures from -50 to +50 degrees.

- PVC is not afraid of insect attacks. And also this product is not prone to the appearance of mold and mildew.

- Ease of installation work and low weight. At installation of this covering use of additional preparation and the ideal basis is not required.

- The safety of natural ventilation. The panels provide full air access to the wall.

- Fireproof. Due to the reagents that are present in the composition of the material, reduced siding toxicity. It does not burn, than can not boast a plastic analog. PVC begins to melt, but it does not support burning.

- Easy care.Such material does not require regular dyeing and specialized processing every year. The selected colors will delight your eye throughout the entire life cycle. To clean the facade of dirt is enough ordinary hose.

- PVC has insulating qualities.

- Many users choose this option of finishing, as the product is environmentally friendly.

- A wide selection of textures. You can choose a finish that qualitatively imitates wood, stone surface, wet plaster and other variations.

- Due to the locking mechanism you will be able to mount the panels yourself.

Despite numerous advantages, PVC has disadvantages.

- Panels cannot be repaired. If one of the sections is damaged, it must be replaced. In this situation, metal siding is better.

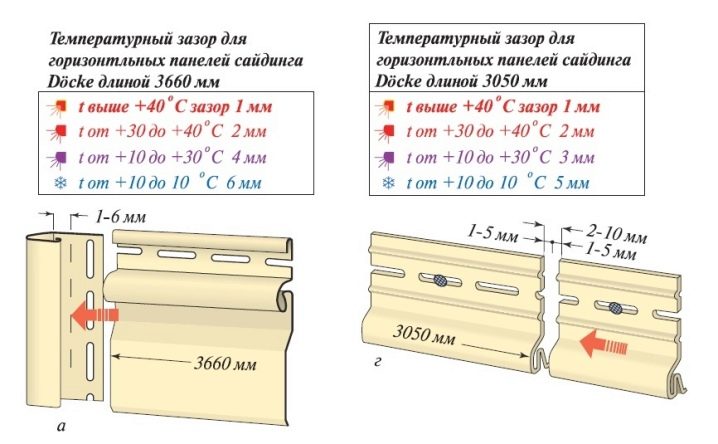

- When installing you will need to take into account the likelihood of compression and stretching of the panels with temperature drops.

- If you do not have the necessary skills that will be required to install the skin, it is best to seek the help of specialists.

After reviewing the pros and cons of PVC coating, you will be able to decide whether the installation of this type of plating is suitable for you or it is worth considering alternatives.

Specifications

In addition to a rich list of advantages, there are some requirements for the material, which it must necessarily meet. On the territory of the Russian Federation is not declared GOST for this material, there are only generalized parameters. As a basis for the designation of standards, ASTM recommendations are used - an American company that tests materials.

There are several characteristics according to the requirements of ASTM.

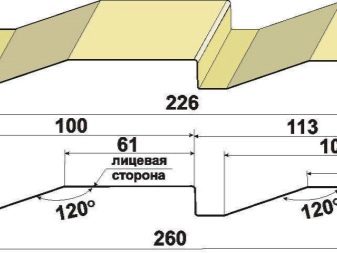

- Profiles should have a thickness of 0.9-1.2 mm. If you expect a long service life of the material, you should pay attention to the maximum thickness.

- The facade has the ability to maintain its pristine and original dimensions. The quality data are regulated by the standards ASTM D6864, DD3679, D7251.

- The material is resistant to acid. For testing, a solution of sulfuric acid was used, which affected the material for a long time.For two weeks, siding has shown the maximum indicators of resistance.

- Flammability of the material. The skin does not support burning.

- The boundaries of strength in relation to the effects of temperature are 88 degrees Celsius.

- The tensile strengths are 422 / kg / cm2.

Scope of application

Vinyl siding has a wide range of uses. It can be used for interior and exterior decoration of premises for any purpose.

Ground PVC

This material is used to work with the basement of the house. The product is realized in the form of short blocks, which are very thick when compared with standard sheets. Despite the increased dimensions, the basement panels weigh a little, which makes it possible not to carry out activities to strengthen the facade of the room.

PVC panels are sold in various variations; you can purchase material that imitates natural stone or brick of a decorative type.

PVC Wall

Such products are intended for finishing on a horizontal surface. Manufacturers are ready to offer their audience smooth panels or variations imitating wood.

There are several varieties of vinyl wall panels:

- single herringbone;

- double herringbone;

- triple herringbone;

- ship timber;

- block house.

Ship beam is widely demanded in the territory of the Russian Federation and in Europe, and the double herringbone is often used for finishing work in the territory of America and Canada.

But also because of its qualities, vinyl siding is used for covering buildings outside. The material has high performance characteristics, which allows it to gain great popularity.

Design

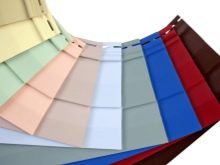

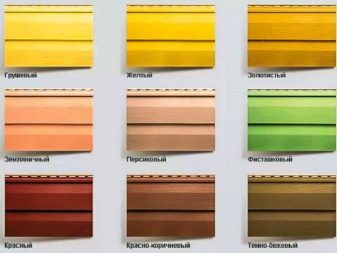

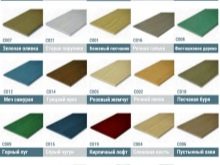

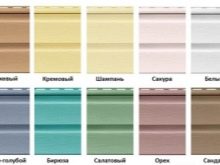

There are various shades of PVC siding on the market. For lovers of warm colors are presented: peach, olive, red and other colors. Many customers like this calm color scheme, but other original variants can be found on sale.

Popular lining of light oak, red-brown vertical siding, crimson. The choice is only for the buyer and depends on his ideas and preferences.

To simplify the selection, PVC siding is divided into several categories:

- white tone;

- colored;

- pastel.

The last option is considered the most popular, since such panels differ in affordable price and do not become boring after a few years.The low cost is caused by the small number of additives that are required to maintain shade and prevent it from burning out in the sun.

White and bright lining is often used to work with decorative components and edging. Such elements can advantageously emphasize the basic pastel tone.

Plinth siding is considered an exception. Imitation of bricks and other materials of natural character is used for the plating of the basement. The panel may have a beige, gray, sand or terracotta color. They are optimally combined with the walls of natural color to the design of the house looked logical and complete. Some buyers choose the facade cladding using brick imitation.

If you like block-house design, manufacturers are ready to offer natural motifs. On sale there are pistachio, cream, caramel and banana colors. Choosing the panel, make sure that they are combined with the roof of the house. When choosing the same colors, you risk to face the fact that the building will look dull.

How to choose the right color panels?

If you purchase PVC siding in a reputable company, the manager will offer you to use the service, which is to select shades.Do not rush to refuse such an offer, as the experts will be able to correctly select the appropriate option for your premises. With the help of a special computer program, you can pre-familiarize yourself with the exterior of your house after plating vinyl.

When choosing the desired color, remember that the shades displayed as a sample may differ from the finished facade. When implemented on a scale wall panels and roof, the colors increase their intensity.

It may seem to you that the chosen shade looks faded, but you should listen to a specialist who is familiar with the features of the panels and how they will look in business. Bright colors are used to highlight the individual architectural components. Pay attention to contrasting shades: delicate sand panels in combination with brown, pale pink paired with terracotta and other similar compositions.

It is necessary to take seriously the choice of colors for future trim of your house, since the panels will decorate it for decades, and you cannot change the color. Watch out forso that the chosen material is harmoniously combined with the surroundings and looks nice. Pick a color range that does not bother you after a few years.

To make the right choice, you should be familiar with the basic laws of combining shades. Among the win-win options include beige and brown palette, sand, terracotta, burgundy and yellow tones. For the more self-confident individuals, bolder combinations of orange, blue and lilac will suit.

DIY assembly

Installing vinyl siding can even be done by a newbie. To competently sheathe the facade of the building, you need to familiarize yourself with the procedure and features of the installation. The panels are ductile and ductile, so the risk of material damage is minimal. Step-by-step instructions, which are present in this article, will allow you to perform facing works correctly and eliminate common mistakes.

Facing is done using the necessary set of tools.

- Knife. Cutting vinyl siding should be done with a sharp knife. When working, mark the groove, then bend and fold the marked line several times. As a result, the material will break at the intended mark.

- Instead of a knife, you can use an electric jigsaw. This tool allows you to make the cut beautiful and speeds up the process of fitting in size.

- Perforator. This tool can be replaced with a drill. He creates quality holes that allow you to mount hardware or create new ones.

- Screwdriver designed to twist hardware.

- As in any construction work, you should prepare a laser construction level. You can use a simple level, but the first option is more comfortable.

- Construction Roulette. This tool allows you to calculate parameters.

If you decide to use a grinder for cutting panels, consider some features of operation. At high speeds you will encounter heating and melting of the cut. To exclude such a phenomenon, it is recommended to work at low power.

There are certain recommendations for installation.

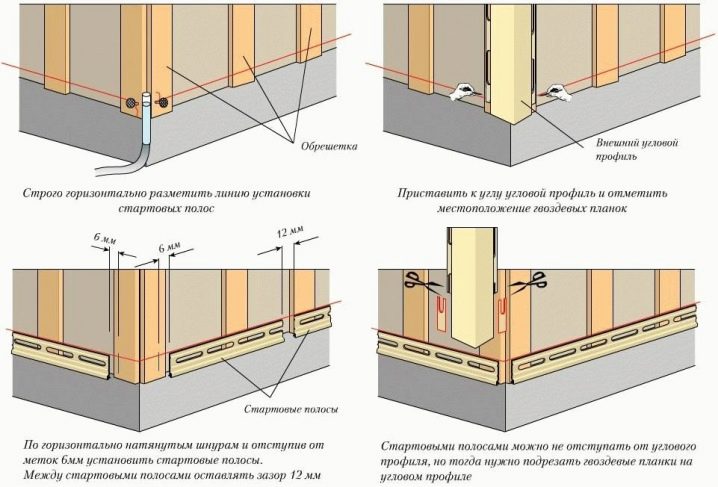

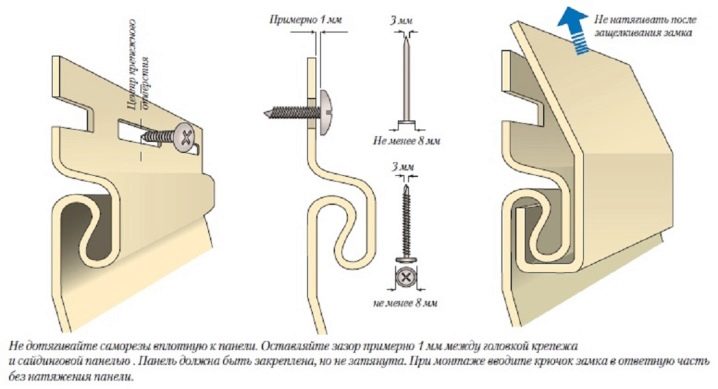

- When facing works should pay attention to the features of the material. The panels have a high coefficient in relation to the linear expansion. This indicator requires compliance with the requirement that a gap of 5-7 mm should be placed between the slats and rows.

- If the plating is made at negative temperatures, the minimum gap size should be 10 mm.

- The gap must be present between the working surface of the panel and fasteners.

Vinyl panels should rest for several hours on the street, after which you can proceed to installation work.

- Do not screw the siding through with screws. Such actions can lead to the fact that the sheet starts to crack. If you need to use these tools, ensure that the fixing is not in the place where the holes for the nails are punched, but create holes for the hardware, only after that fix the elements.

- Instead of screws allowed the use of nails and staples.

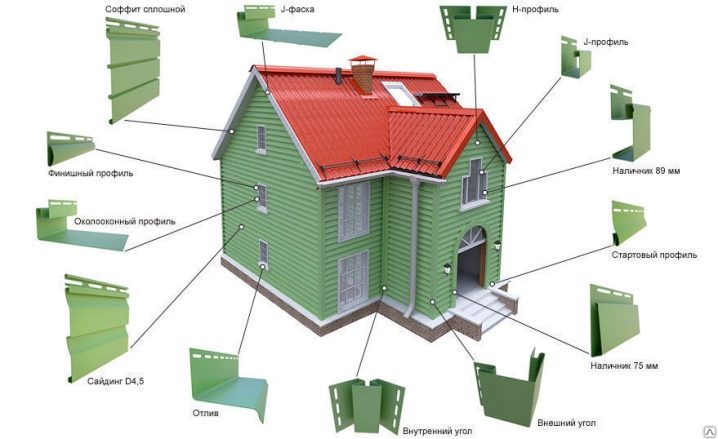

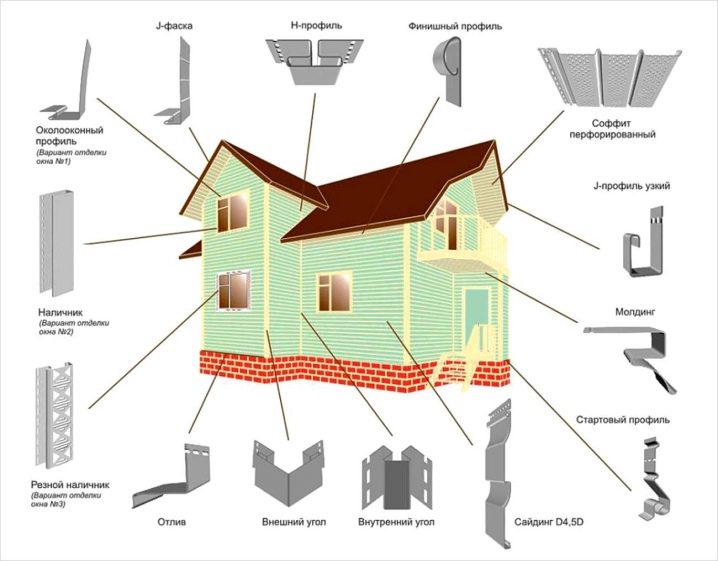

And you should also take care of the selection and calculation of the required components. Trademarks that offer vinyl siding to their customers are engaged in the implementation of all the components that will be required for installation. You can also purchase additional materials.

- Internal and external corners that will be required for covering buildings with a traditional length of 3 meters. To calculate the required amount of material, you will need to calculate the total measurements along the perimeter of the angles, which should be further divided into three.Eliminate the use of residues to make the exterior look attractive.

- The starting strips in length are 3.8 meters. The required value is calculated by subtracting the door openings from the perimeter of the indicators.

- J-profile will be needed to work with areas where attachment of attachments is observed.

- The bar that frames the windows has a length of 3 meters. The calculation is performed by adding the total perimeter of the window openings.

- Window drains are optional and are only required if necessary.

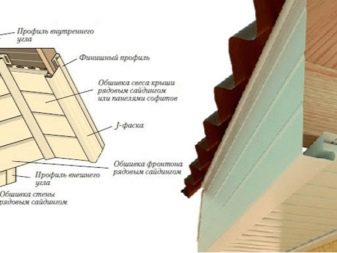

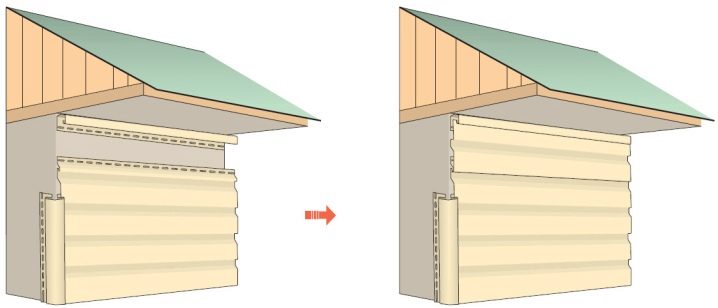

- The finishing bar is necessary to connect the eaves of the roof with the house itself.

- H-profile allows you to close the gaps at the joints that are between the panels. Installation of these elements is made vertically. Calculations are made by dividing the perimeter of the room by the length of the panels.

- Drain slats are mounted under the window opening.

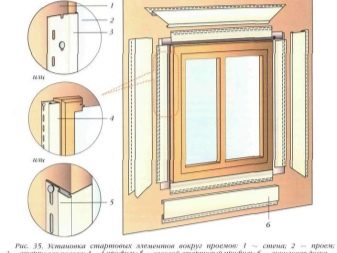

- Installing the casing is required for facing any opening that is flush with the walls.

- To make vinyl siding yourself, you need galvanized screws with a press washer. The length of the elements should be 25-30 cm.The quantity depends on the area of the wall. For one square meter required 20 pieces.

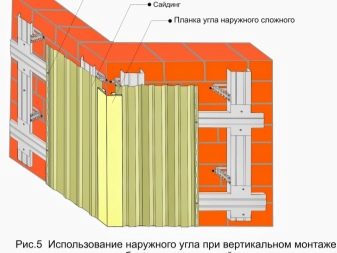

Installation of vinyl panels is accompanied by the following sequence:

- installation of the corner strip;

- fixing the starting bar;

- installation of the J-profile, which will act as a finishing material for the edges of the panels;

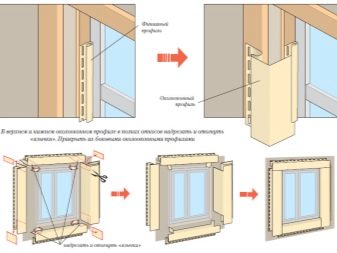

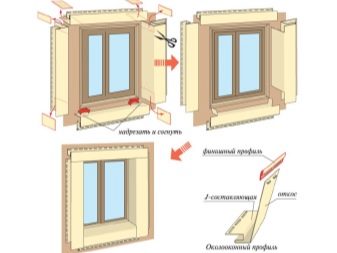

- trim window opening;

- facing work using vinyl itself;

- installation of the finishing bar.

Installation of the starting plate should be made around the perimeter of the building. You will need to carefully set this item. Attach the bar should be using screws. Follow the step when fastening 25 cm. Make sure that the screws are perpendicular to the surfaces. Screws need to be screwed exactly in the center of the oval hole to eliminate the curvature of the panels.

It is necessary to ensure that the screw is not included in the bar to the end. The gap between the head and panels should be about 1 mm. For more comfortable calculations, you can measure the gap with a coin. It is necessary to leave a gap of 5-7 mm in the center of the junction of the slats.

Window openings, which are located in the same plane with the walls, must be sheathed with the help of a wide casing, into which panels are subsequently brought up.If there are slopes in the windows, you can use a corner profile for decoration. First of all, it is recommended to sheathe the lower slope, and then proceed to work with the side sections, gradually moving to the center of the window opening.

When working with vinyl siding, you should ensure that each panel is included in the starting strips and can snap into place. Only after compliance with these rules, you can begin to fix the hardware. When attaching the panels, you should constantly perform reconciliation using the building level. For comfort during operation, you can use the rope.

The finish bar should be mounted under the roof. From this strip should be measured to the most extreme panel. The strips processed under the given parameters should take the form of an arc, and then go under the finishing panel.

Manufacturers

On the construction market there are many manufacturers of vinyl panels. If we talk about the domestic market, the plant's products are in demand for more than 10 years. "Terna Polymer". The manufacturer is known since 2001 and is engaged in the release of vinyl siding under the name Fineber.

The material is popular because it has many positive qualities.

- Production is aimed at the Russian climate, so the panels are highly resistant to humidity and temperature changes. The facade is able to withstand a temperature range from -50 to +50 degrees.

- In the production of siding used only high-quality polyvinyl chloride elements, in which there are additional ingredients aimed at color stability. The proportions of each component are calculated using computer programs.

- In the manufacture of applied coextrusion. This method is an economical and rational technology for the production of raw materials from two layers. A specific set of components has been added to each layer. For the outer surface, elements protecting against external influences and burnout are used. In the inner layer there are ingredients that determine the structural properties and quality of the facade. A similar technique is common in Canada and the United States.

- The products of this brand has a long service life, which is more than 25 years.

Among the foreign manufacturers in demand Canadian company Mitten inc, whose production facilities are located in Paris. Trademark Mitten has been manufacturing siding for over 50 years and offers high-quality products, thanks to which it has taken the world's leading positions in product sales.

Among the features of vinyl siding include the following properties:

- the manufacturer provides a warranty of 50 years on your material;

- panels are highly resistant shades;

- resistance to mechanical stress;

- high ductility, which allows installation even in cold weather.

And it is also worth noting the domestic manufacturer Grand line. Its production facilities are located on the territory of Voronezh, Kaluga, Nizhny Novgorod and Leningrad regions. The panels have unique characteristics, due to which they are in high demand.

Among the features include a number of properties.

- Resilience and flexibility. Performance is six times the performance of traditional siding. These qualities allow installation to be carried out even at low temperatures.

- Externally, the panels are similar to real wood.There are even knots on the material, which allow to imitate natural wood as much as possible. The covering possesses impregnation which consists of special dirt-repellent components.

- The arrangement of the locking mechanism provides increased resistance to the wind and makes it possible to carry out the installation in a short time.

- PVC siding is UV resistant. The term immunity reaches nine years, as evidenced by special tests that were conducted in Holland.

- The manufacturer provides a written guarantee on your product for a period of 50 years. The list of warranty obligations includes: strength indicators, long service life and uniform fading. In order for the product to fulfill all declared properties, it is necessary to comply with the requirements for transportation and installation.

- Vertical panels are available to buyers. They are used for covering individual elements on the surface of the facade. Many people use this siding to trim basements, decorative ledges, cornices or awnings. The length of the material is 3 meters, and the useful width reaches 1.5 meters.The color scheme consists of four tones, including: white, vanilla, lime and beige.

The Grand Line, just like Fineber, is ready to offer its audience a wide range of additional components, with the help of which it is possible to perform a comprehensive building lining. On sale there are: starting strips, finishing profile, trim and other components.

Reviews

Vinyl siding is very popular, so on the Internet you can find numerous reviews of the owners. Most buyers speak of this material as a quality product that looks good in business.

The Fineber brand has won numerous audiences, as evidenced by positive comments on this material. People who decide to purchase products of this manufacturer, report that the material is of good quality, rich and uniform color that does not fade with time.

Mitten attracts many consumers with its guarantee. Users report that the manufacturer guarantees a service life of 50 years, in which they are sure after a few years of use.Even after five years, siding does not change its appearance, maintains color saturation and does not fade from the constant exposure to sunlight.

Grand Line has a beautiful appearance, which qualitatively imitates the structure of the tree. With it, you can create a beautiful facade that will delight a long time. Buyers are positive about the ease of installation, which is provided by a locking mechanism. The material is not afraid of strong winds and is resistant to other weather conditions.

Tips and tricks

In the market there are many manufacturers who offer consumers vinyl siding. To make the right choice, you should familiarize yourself with the recommendations of specialists.

These tips and tricks will help you choose a quality product.

- Pay attention to the color of the siding. It should have a uniform color. The saturation of the shades on the outer and inner side may differ. In most cases, the inside has a lighter tone.

- The end cut should have the same thickness over the entire width of the material. If the figures are different, you are offered low-quality goods.

- Holes for attaching to the base should have smooth edges. Make sure they are the same.

- There should be no defects on the front. Refuse to buy if you notice cracks, scratches and peeling. The material must have a matte surface, since the gloss is considered a marriage. If there is a strong shine on the panel, it will warm up from exposure to sunlight, which will lead to further deformation.

- The thickness of the material should not be more than 1-1.2 mm, since thicker variants are not able to guarantee the same performance properties as other panels.

- Choose panels with anti-jerk locks. They are able to guarantee the strength of the structure.

- Check the ductility of the panels. To determine this property, you will need to bend the thin edge of the material, which is located near the edge. If it starts to break, give up the purchase.

- Packaging can also talk about the quality of the chosen products. Manufacturers who produce high-quality goods, monitor the safety of siding, therefore, provide high-quality packaging.

After purchasing vinyl panels, you may encounter a situation in which the material does not fit you in size. In this case, you need to cut the siding. Many people are faced with difficulties, because when cut, the end cuts are removed, which will be required to secure the material. You will need to create similar cuts again in the remaining area. You make it easier for yourself if you cut off the bottom of the siding.

How to care for vinyl siding?

Proper care allows you to extend the service life of vinyl siding.

Experts recommend to follow simple rules.

- Be wary of the damage that various insects can do.

- When installing, try to create high quality insulation to save on the heating process.

- Vinyl panels can not be painted. The panels initially have a certain shade that covers the front and inside of the material. The color does not exfoliate, and scratches are imperceptible on it. These properties do not imply measures for coloring during operation.

- After ten years of use, the panels may become paler.If you are faced with a similar situation, you just need to replace the defective area.

- Once a year you should clean the panels. Use a special machine for washing, or take the usual shlag and clean the siding with a jet of water.

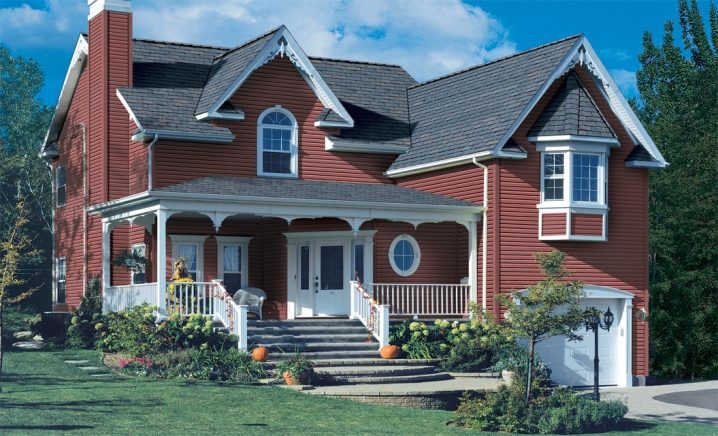

Beautiful examples

Designers are ready to offer a variety of options that allow you to transform your home and make it more attractive. To select the necessary design, you should build on your goals, wishes and the interior of the surrounding landscape.

The houses sheathed by a siding look attractively. The room, lined with light pink panels, looks gentle. Such a building will give the site a calm and peaceful atmosphere and never get bored.

Looks elegantly trimmed with pinned vinyl siding that mimics the ship's board. It is possible to combine two types of siding, using imitation masonry for finishing the basement. Such plating will show the good taste of the building owner and will stand out among other houses.

Some people choose shades of white, which give buildings some similarity to the English style.These rooms look elegant, gently and fit well into any design.

If you want to turn your home into a fabulous tower, pay attention to the siding, imitating round timber. Take care of a suitable landscape that will create the right atmosphere.

Looks good partial trim vinyl siding. You can emphasize individual elements using panels to create an original appearance.

In contrast colors you can get the original composition. Choose contrasting shades that look gorgeous in a pair. With this design you can highlight your room and attract the attention of others. Carefully carry out the selection of colors to the combination looked advantageous.

How to mount a vinyl siding with your own hands, you can see in this video.