Septic: types, use and production

The times when it was possible to simply use the street toilet in country houses and in country houses are long gone. Modern hygiene requirements have grown significantly, and now we need to strictly monitor the safety of household waste management. Good septic tanks help to solve the problem, but in order not to be mistaken with the choice, you need to carefully study their nuances.

Special features

Connecting to centralized sewer systems is far from possible. It is much more practical and reliable to remove sewage and domestic waste through a septic tank than using a commonplace cesspool. Speaking about the advantages and disadvantages of septic tanks, it should be noted that only one circumstance can cause certain inconveniences. This is the need to pay a certain amount of money, even in the case when the device is made by hand.

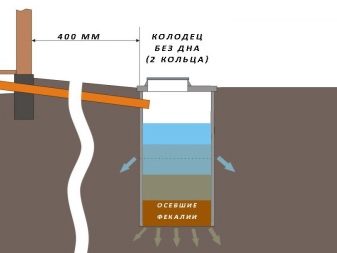

The principle of operation of the storage device is simple:

- in the capacity of the waste;

- as it is filled, a car with a pump and a tank for sewage is caused;

- for some time, the released container is again ready to receive waste.

As for the apparatus of the second type, it works in a fundamentally different way. The simple accumulation of pollution is replaced by their filtration, absorption and thorough disposal. The complexity of the design in this case is fully justified, since it allows you to most effectively solve the problem. When choosing products it is recommended to consider how many tenants are in the house or can visit it. Also important is such a circumstance as the type of plumbing equipment and the intensity of its work.

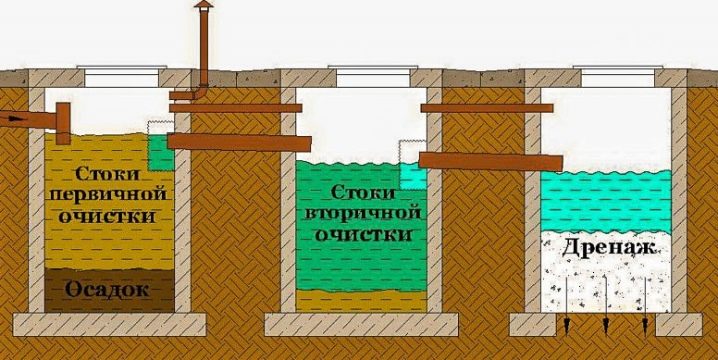

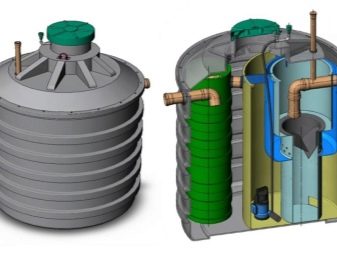

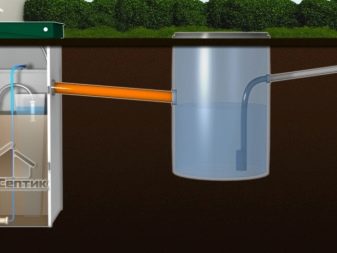

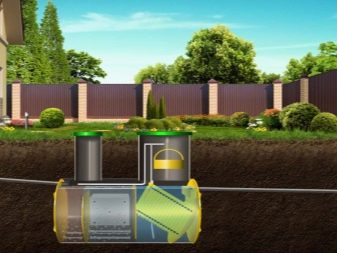

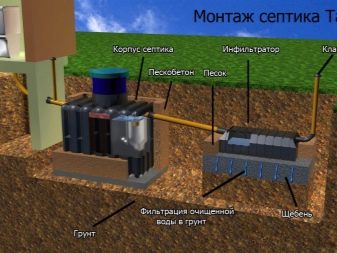

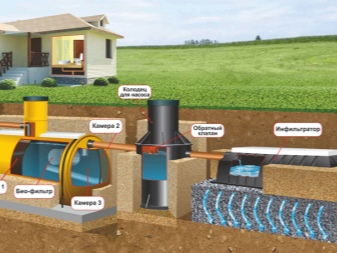

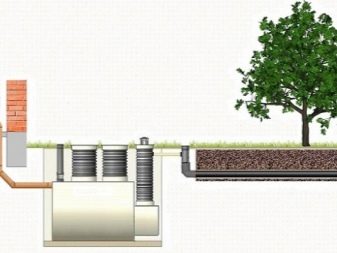

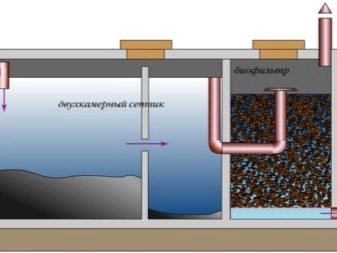

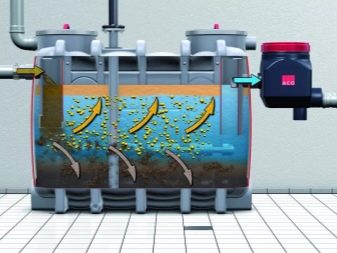

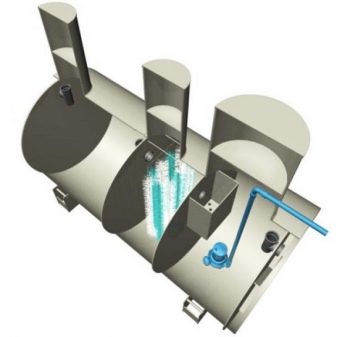

Regardless of the specific performance, you need to achieve a high level of sewage treatment, so that you can dump them into the ground without the threat of clogging. Typically, the flow of sewage entering through the sewer drain is sent to the source chamber, where it is divided into fractions. This leads to the fact that the largest solid particles settle to the bottom, and a relatively small suspension reaches the next chamber. Specially selected anaerobic microorganisms deal with them there. As a result of the biological effect, fermentation takes place, methane begins to be released.

Passages into the compartments of the septic tanks are covered with special devices (water gates). Thanks to this solution, the nuisance characteristic of simple cesspools and sumps is eliminated - the spread of a foul smell everywhere.

The third chamber also plays its role, in which the pollution that overcomes the first two stages is captured with a special filter design. Aerobic bacteria that live freely in an oxygen environment also assist the filter. The similar device is characteristic for any septic tank, whether it be the Russian or import product.

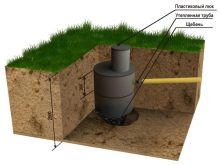

Fully finished copies after delivery to the site is lowered into a pre-shaped pit. Those drains that have managed to go through three stages of purification are completely safe in chemical and biological terms. You can safely redirect them to the filtration field and into the soil. The wastewater treatment plant complying with the norms of SNiP successfully operates even in the most severe climatic conditions. Severe frosts and storms are not terrible for him, and some versions do not depend on the power supply at all.

If for some reason factory products are not satisfied or there is a desire to save money, site owners can make a septic tank themselves.

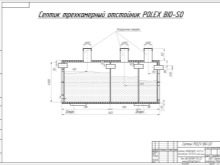

For this purpose, completely ready-made tanks are supplied, but with the difference that they will be assembled not by a team of specialists, but by the owners themselves. It is recommended to choose the strongest materials that successfully tolerate the aggressive effects of sewage. Before self-assembly of septic tanks should prepare the drawings to eliminate errors and flaws. To complete the task, there are sometimes enough 3-6 rings of concrete.

How to choose and do it yourself?

When working on an autonomous sewage system, there are no trifles, because even the slightest mistakes and omissions can lead to serious consequences.It is advisable to consider first the choice of the finished product, and then the design of his own hands. In either case, you need to take into account:

- how much waste accumulates per day;

- whether they live in the house all year round or only in the warm season;

- the amount of used plumbing;

- the presence of groundwater and their altitude, chemical properties;

- the amount that the owners can allocate for the purchase of sanitary equipment;

- soil characteristics at the site.

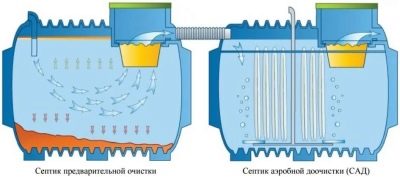

Evaluating the properties of any septic tank, whether homemade or industrial, it is better to begin their analysis with the performance of the device. This parameter is closely related to the number of working chambers and their dimensions. Minor wastewater streams can also be passed through single-chamber septic tanks with a preliminary cleaning unit. Household waste in this case will be cleaned quite effectively. But if the total flow is over 1 cu. m. in 24 hours, we need a more productive model.

In order not to make complex calculations, it is recommended to focus on a simple indicator: the seasonal dacha is easily serviced by single-chamber systems.

In terms of its performance, such a device often represents a simple drive, systematically cleaned with its own hands or when calling a sewage truck. For permanently used homes, such solutions are unacceptable. The active accumulation of waste provokes significant costs for the services of vacuum trucks. Increased efficiency is typical for biological cleaning complexes.

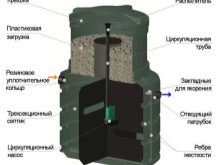

Anaerobic methods of sewage purification inevitably generate gases that are dangerous for people. Because you need to choose only kits with a fan riser. When choosing the right solution you need to find out also:

- which body material will be optimal;

- whether it is necessary to place the reservoir in the soil horizontally or vertically;

- how many cleaning chambers are required.

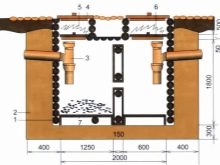

Simple installation of concrete settlers from blocks of typical dimensions or by pouring concrete into formwork is available to almost everyone. The use of prefabricated elements allows not to be afraid of problems with the quality of manufacturing parts, but it increases the cost of construction. For the transportation of rings of concrete need a powerful transport, and their installation is made by special lifting machines.Self-pouring is more economical, but it takes much more time. It will only be necessary to operate the settling tank after the cement mixture has completely set.

Reinforced concrete rings are difficult to seal, their suitability for repair remains in question. Such details are very bulky and heavy in their performance. But concrete products are more resistant than plastic to soil and groundwater pressure.

You should not choose a budget septic tank with metal tanks, because the savings will be illusory. It will be necessary to constantly treat the surface of the septic tank with anti-corrosion mixtures.

Metal blocks are preferred where it is required to create geometrically complex complexes of overflow pipes. For the installation of metal septic tanks used welding. Joints with plastic pipes are made using flange systems, complemented by rubber cuffs. The strength and considerable severity of steel hulls helps to avoid pushing them out with water circulating in the soil. In many cases, plastic septic tanks are used for a cottage or a simple private house.

Plastic elements can be mounted manually, and the tightness of the connections created with the cuffs is completely guaranteed. There is no need for complex protection from various substances.

After installation, plastic tanks are filled with water, this will help to equalize the pressure inside and outside.

For your information: the industry produces a number of products that are distinguished by increased rigidity. This allows you to bury septic tanks in a dry mode.

When choosing a device, it is worth paying attention to how the stock will be organized. The direction of fluid by gravity implies the need to lay pipes on an incline. Chambers of accumulative or filtration septic tanks are equipped with a stable waterproofing or are made of materials impermeable to water. Constructing a cleaning system with your own hands, you need to add overflow pipes to the septic tanks that transfer water to the filter section. Nozzles must be supplemented with continuously submerged vertical segments.

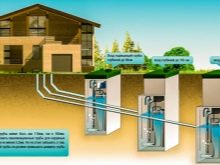

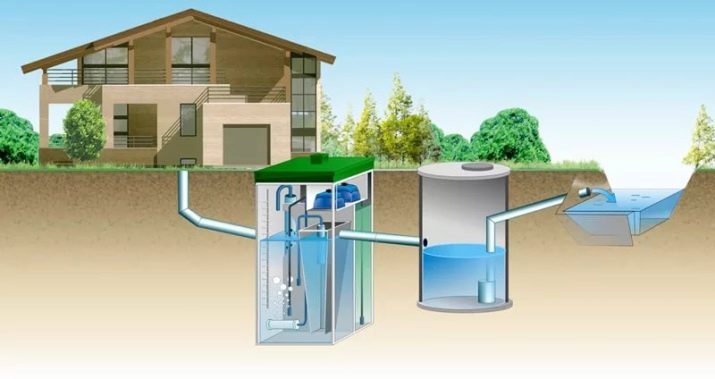

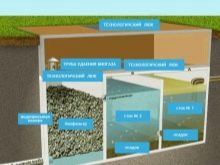

Both with independent production and with the purchase of a complete set, various methods of final soil cleaning can be used. Widespread received:

- filtration wells with a layer of drainage material at the bottom;

- tunnel infiltration devices;

- underground clearing "fields" where pipes with perforation are laid.

Choosing the right approach is not easy, because you have to take into account the necessary depth of sewage purification, the category of soils, the height of the location of soil waters and their chemical aggressiveness. When one of the chambers is set aside for aerobic microscopic cleaning, it is supplemented with aerators, so you have to take care of a stable power supply. An air pipe is laid between the parts of the septic tanks to compensate for the uneven pressure in them.

Regardless of the design, you will have to make hatches for inspection and cleaning of tanks.

Kinds

A septic tank for dachas with 2-3 tenants can be made on the cesspool; This is the most economical in terms of water consumption type. The capacity must be very durable, and the higher its capacity (within reasonable limits), the more practical the device.

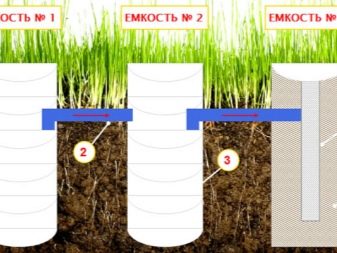

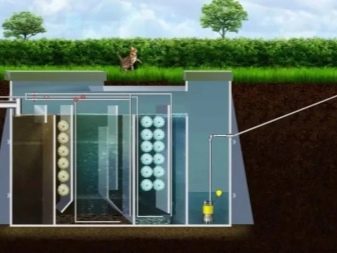

For permanent residence with a small amount of waste generated preferable overflow systems. Such equipment makes partial cleaning of waste, and it is necessary to empty the tank with the help of special equipment on average once every two or three years. The soil filter fields supplementing such septic tanks are made of rocks that are permeable to water.

The advantages of this solution are:

- ease of service manipulations;

- long intervals from one cleaning to another;

- increase the efficiency of waste utilization.

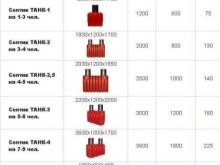

But septic tanks that have additional cleaning in the soil should not be used in clayey soil with insufficient permeability to liquids. In addition, this design is incompatible with high standing of the first horizon. For a private house in many cases use more powerful and sophisticated sewage treatment plants. Overall performance is determined by the number of cameras; There is no need to make calculations when choosing a device, the number of tenants served is written on the packages.

Autonomous cumulative (non-volatile) septic tank is always cheaper than dependent on the mains. The point is not only in operating costs, but also in the necessary basic components.The lack of connection to the power grid allows you to not equip the septic tank with pumps, compressor systems and fittings. But the valves and hoses will be used in a particular case.

It is worth considering that, if necessary, to recycle waste as deeply as possible (for use or as directed by sanitary authorities), energy-independent solutions will have to be abandoned completely.

The increased efficiency of devices connected to the electrical network turns into the need to constantly withstand strictly specified conditions.

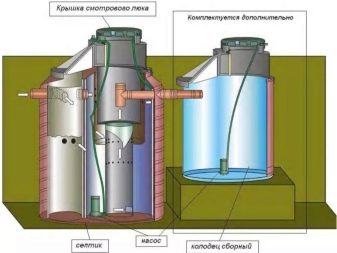

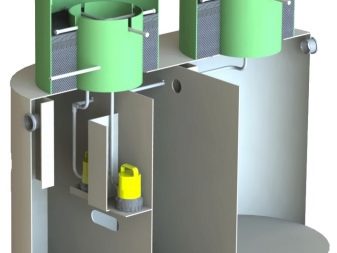

Volatile devices best mounted turnkey with the help of specialists. Sewerage for country houses may be common to several buildings. Discharge should be planned so that it is above the horizon of the soil water. The hatch of the simplest accumulative system rises 10-15 cm above the soil. In order to rarely call a machine for pumping, it is worth choosing a product with a capacity for a month and with a reserve of at least 1/5.

Non-volatile complexes are selected in such a way that the total capacity allows to absorb the volume of effluent in 72 hours and there is still a reserve volume of approximately 30-40%.The normal operation of overflow devices implies that the liquid fills a maximum of ¾ of the entire cavity of the tank. Active devices are in any case equipped with ventilation systems. In order for the system to work without odor, the discharge must be located at a height of 300-500 cm. The tanks are cleaned of accumulated sludge every few months.

Local cleansing stations help to minimize the intensity of bad odors.

Compared with simple septic tanks, such devices are more expensive, since waste treatment is performed not only by biological and mechanical methods. Be sure to use, in addition to infiltrators, also means of chemical processing. For non-permanent places such devices can not be used. But the level of remaining pollution is maximum 5% of the initial value.

Clarified water can be used for:

- irrigation of gardens, orchards and fields;

- filling the landscape reservoir;

- conducting construction and repair work.

When there is no need for such use of treated wastewater, they are allowed to be poured into natural water bodies and various ditches.Sewerage can last for several hours when there is a power outage, but no more. Therefore, it is necessary to supplement the sewage treatment plant with backup power systems, even if the power grids in a particular area work quite reliably.

In any case, the smaller the seams in a volatile or autonomous septic tank, the more efficient and stable it works.

Material

- Polyethylene structures do not have seams at all; therefore, cracking and the occurrence of leaks are excluded. Synthetic material does not rot and is not prone to corrosion. Multilayer polyethylene stably works even at frost of 30 degrees. No less quality are blocks of fiberglass. They are stronger than polyethylene and polyvinyl chloride, but the total fee for them is much higher. Plastic is used mainly for commercial objects or for several private houses at once. Many fiberglass constructions are able to meet the needs of up to 200 people at a time.

- Metal products (almost always steel) usually have two parts. The internal volume of the welded body contains an additional plastic tank.Even the best steel in itself is rarely used, because it can easily lose tightness, and if the outer layer is damaged, corrosion will quickly develop.

- Combined Devices (metal + plastic) can have up to four sectors for sequential cleaning of incoming wastewater.

- Depending on the decisions of the designers, the walls are made either inseparable with special holes or with overflow projections. Brick blocks popular in many respects because in their construction can be used waste material. In this case, a serious problem is the provision of tightness of the walls. The building stone initially has many gaps and gaps. To cover these openings, special sealants or penetrating mastics are usually used. Brick septic tanks are profitable for economic reasons, when working on them do not need complex machines or professional skills. Allowed laying in one brick. A more reliable solution is the choice of concrete structures, they are very durable. But there is a weak point - the need for complex equipment.

- For the manufacture of a septic tank is allowed to use both monolithic and prefabricated concrete. Monolithic elements must be poured into the formwork after the preparation of the pit.As with the use of bricks, you need to carefully evaluate the tightness of the joints.

Metal constructions are used less often because the negative qualities almost always outweigh the positive aspects.

Analyzing the properties of various solutions, most experts prefer plastic septic tanks.

Returning to fiberglass, one can also call its advantages such as:

- operational life up to 50 years;

- resistance to extreme cold and putrefactive processes;

- immunity to rodent attacks;

- the ability to pump out all waste in 60 minutes;

- the ability to use salvo discharges a significant amount of waste;

- protection from foreign objects;

- suitability for preservation for the winter without special training.

With regard to the use of other available materials, such steps are not approved by professionals. You can use them only in small cottages, which are visited only occasionally. Barrels, tires, old tanks and the like are used as storage devices of this kind. Superficial septic tank should be placed where a lot of soil water is concentrated, and at the very surface of the soil. If these problems are not present, it is recommended to use underground options.

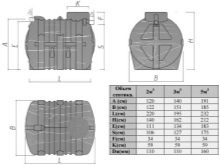

Dimensions

It is important to consider not only the properties of individual materials, but also the size of septic tanks. When calculating the dimensions, we must not forget that the volume is calculated as the total volume of all the component parts; it is calculated from the bottom to the input pipe. In the first compartment, the counting is carried out from the lowest point to the overflow device, in the final - to the place of discharge of the liquid into the drainage or filtration facilities. It should be borne in mind that in the initial chambers the average volume of solid accumulations reaches 1/5 of the height. Therefore, it is subtracted if they want to find out only the space where the fluid is located.

According to building codes, even for mini-septic tanks, the daily volume of water per user is 200 liters or 0.2 m3. The smallest storage is expected to operate without draining for 72 hours, this allows you to compensate for various incidents and problems. When designing or choosing a solution, it should be remembered that water can be discharged into the soil layers at least after 14 days. Only under this condition can anaerobic bacteria and a settling tank be able to completely neutralize liquid waste. Formally, it turns out that one person will have to put a tank with a capacity of 2.8 cubic meters. m

In practice, the situation is different; Rarely is the normative consumption of the standard volume of water achieved, sometimes it is half as much. This happens in rarely used homes or in budget-minded people. And the rise in the cost of water resources makes it increasingly important to save them. The problem is that when small septic tanks are detected, sanitary authorities can issue prescriptions for installing more powerful systems. And they will be completely right, even from a purely practical position!

The reason is simple - sewage contains many substances that are poorly processed or not absorbed by bacteria at all. Most often it is heavy fats, and therefore only the flow of large amounts of water allows for normal clarification. It is important not only to comply with hygienic requirements, but also to keep the equipment safe and sound. If the filtering elements and layers are overflowed with difficult decomposable substances, they will lose bandwidth. Immediately have to redo all the cumulative and filtering infrastructure.

On the other hand, you need to choose the volume of the camera, focusing on the capacity of the tanks of the sewage truck.Small cleaning tanks coming to the call can take no more than 3.75 cubic meters. m. of liquid. It is worth thinking about the depth at which a sludge pump can work; it does not exceed 3 m. These moments determine the linear parameters of the entrance chamber of the septic tank. In order for sedimentation and microbiological improvement to occur more efficiently, it is recommended to use, at any rate, dual-chamber complexes, at a minimum.

The standardized height of the rings is 90 cm, and with an internal diameter of 1000 mm their volume is 0.7 m3. If the diameter grows 1.5 times, the volume of the rings reaches already 1.59 m3, and two-meter structures have a volume of 2.83 cubic meters. m. As for the deepening of the drain pipe on the input to the septic tank, it can be quite different. Excessive lowering is undesirable, it is better to reinforce the layer of insulation. But there are other considerations, such as the need for a sufficiently strong retention of pipes.

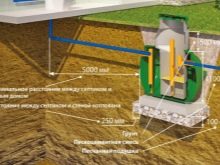

Removal of septic tanks from houses more than 10 m is impractical, and the minimum slope of the pipeline is 3%. Such an indicator makes it possible not to interfere with the freezing of pipes and reduce the risk of their filling with solid particles. The average depth of the waste pipe reaches 50 cm (together with a warming block).As a result, the depth of the overflow between the first and second compartments is 700 mm. Upper insulation is done with EPS plates of at least 5 cm thick.

Taking two meter rings, it will be possible to achieve a typical volume of 2.7 m3 with a pair of compartments. If you take concrete products and a half times the size, you will manage to get by with a single-chamber version. But as already mentioned, there should not be striving for simplicity. It should be borne in mind that each pipe inserted into the septic tank must be terminated with fittings directed downwards. Upside-up tees are also used (this helps reduce accumulation of garbage).

Colors

The color of the septic tank can be very different, but in any case it is worth avoiding screaming and annoying shades. Concrete blocks look good on their own. It is recommended to use blue, white or black tones - they allow you to provide an optimal appearance. Paint for any septic tank should be resistant to harmful wastewater, to damage by mobile soils. Any of the most durable and stable composition suitable for this task.

Manufacturers and reviews

Production of septic tanks from year to year improved.Modern technology can solve any task. Leading positions in various ratings are:

- "Topaz";

- "Mole";

- "Tank";

- "Triton";

- "Cedar";

- Ecoline.

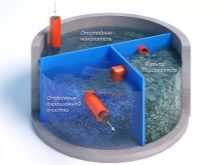

Version "Tank" designed with the integration of mechanical and biological methods for the clarification of domestic wastewater. The very first fragment of the septic tank is a settling tank, the initially purified liquid moves to the next chamber. There is an auxiliary sedimentation and suspended particles are precipitated. The third Tank unit contains beneficial microorganisms - this increases efficiency, but also increases the volume of the device.

The brand "Triton" has such competitive advantages as:

- low cost;

- the possibility (with the help of infiltrators) to leave only 2% of the dirt in the water;

- the acquisition of models with a variety of practical properties;

- complete elimination of unpleasant odors;

- strict compliance with sanitary standards;

- long period of operation in normal mode.

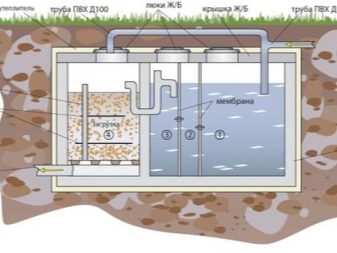

Problems may be associated with the absence of an infiltrator or aeration fields. If there is no such possibility, the efficiency of the septic tank is insufficient, and with a significant increase in the flow of sewage it will not cope. Design "Topaz" It has excellent economy, it works by aeration and the use of microorganisms. In normal mode, it is possible to clean the liquid by 98%. The developers took care of solid tightness and excellent anti-corrosion characteristics.

To install "Topaz", it is necessary to prepare the pit carefully. In a good groove there are necessarily special stiffeners, this allows you to guarantee a zero risk of deformation. The first compartment is able to separate solid matter from the effluent, only then the mixture is cleaned with oxygen. Purified water can be found the most widely used. But Topaz is highly dependent on electrical energy.

Firm "DSC" tried to make three-chamber products, where two segments become settling tanks, and the third is equipped with a biological filter. The decomposed and clarified impurities are transferred to the soil filter layer.

Company "Yunilos" The main attention was paid to improving the mechanical strength of their products, creating stiffening ribs on them and applying molecular welding. The device apparatus of this brand allows you to do without moving parts.A carefully designed wall with a thickness of 20 mm easily resists ground pressure. The effluent flows through the primary sedimentation tank, the aerobic installation and the secondary clarification tank. The release of water from pollutants by 95% allows it to be used for irrigation of agricultural plants. The disadvantages of the system are dependence on the power grid and instability in the cold. In addition, such blocks are very expensive.

Septic tanks Ecoline According to the manufacturer, they are the best choice for seasonal seasonal exploitation. With proper installation allowed their regular use. The system has only two cameras that do not have electrical components. The entrance camera is much larger than the output, which is responsible for the gravitational clarification. Additional cleaning is done in the soil.

Efficiency "Ecoline" does not allow all the same to consider their septic tanks the optimal solution. The fact is that the amount of remaining pollution is as much as 40%. In addition, it will not be possible to use such systems in places with elevated levels of soil water. Without enhanced cleaning by other means there is a high probability of infection.soil horizons by microorganisms. Equipment brand "Cedar" certainly requires cleaning with special equipment.

At the entrance, primary filtration is carried out, and the purified water from the sediment passes into the second block, where it is clarified deeper. Further the stream moves up and down, reaching the fixed microflora. The final compartment is responsible for the accumulation of waste.

Products "Mole" are recommended both for dachas, and for private houses. The advantages are self-assembly, high durability of the cases and no need for backfilling.

Finnish manufacturers Uponor and Green Rock deliver products of excellent quality and excellent reliability. The highest characteristics of genuine Scandinavian products, unlike fakes, do not allow them to be sold cheaply.

In the collection of Uponor there are three main subspecies.

- Products "Sako" differ in the partial defending of sewage and autonomy. Filtration area in the soil must be completed, otherwise the surrounding area will be a very unpleasant place.

- For the cottages, you can also put the goods series "Bio" (with enhanced chemical and microbiological water purification). Perfectionists will be pleased with the products of the Bio Bio category, which are very compact and easy to manage.

- Green Rock supplies only septic tanks with multi-stage cleaning. All the equipment of this brand combines the efforts of special reagents and microflora. This technique allows you to deploy a local sewage system from scratch, and significantly improve the existing one.

The “Bio” device requires periodically to dispose of used filtering units and special reagents, to replace them with fresh portions. Products of the Sako group do not resist cold well enough. In the most northern areas, it will be necessary either to install insulation or to choose equipment that is more stable for winter.

Finnish goods are made using seamless technology. It is much more reliable than the Russian approach, which involves the combination of prefabricated parts.

Successful examples and options

In addition to selecting the appropriate brands and models of septic tanks, you need to pay attention to the components that complement the cleaning system. The use of devices with a biofilter (colonies of anaerobic organisms) makes it possible to do without connecting to the electrical network. Microbes can get the energy they need by disintegrating organic matter without oxygen. Carbohydrates and various amino acids contained in sewage are split into low-molecular compounds that are safe for the natural environment. Anaerobic biological filter is performed as a plastic container, divided into fragments of a certain type.

The biological cleaner necessarily contains an inert material with a large specific area, which allows to combine the development of microbial colonies and additional mechanical filtration. Organic matter disintegrates when passing through the biofilter to the simplest soluble substances and sludge deposits. Il will have to be removed, but in many cases it is used as a fertilizer.

Typical fillers:

- expanded clay;

- brushes or nets made of plastic;

- granulated polymers strictly defined fraction.

Usually, the distribution of microbes in biological filters is made uniform over the surface, and if we replenish their stock in a timely manner, it will be possible to ensure stable operation throughout the year. Such filtering does not require any complex technical skills at work.Systems operate for a long time and odors do not penetrate. Security is fully guaranteed.

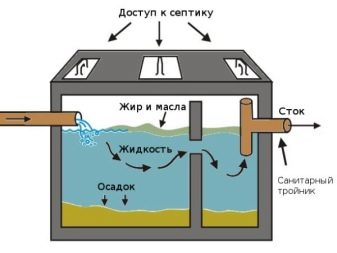

In addition to organic filtration, septic tanks are often equipped with a grease trap. In gravity drainage, fatty deposits become a serious danger, increase the likelihood of blockages and traffic jams. Fat traps must be mounted on production sites and in places where many people live. Private homeowners do not have such prescriptions, but it’s better to protect your system in advance before problems arise. The design and principle of operation are quite simple.

When water enters the inlets, it starts filling the first chamber. As this is filled, the fat particles rise to the top because they are lighter than water. Then the fat reaches the special tray, where it gradually accumulates. The fluid released from it moves to another compartment, which provides residual fat splitting. For this purpose, the most powerful and effective methods are used, and when the equipment finishes work, water flows into the sewer system.

The first sector is saturated with water-insoluble particles.That is why it will be necessary to remove, wash and clean the grease trap regularly. Industrial devices are easier to clean, there are special drainage pumps or stop valves in the bottom for this purpose. Placing a coarse delay filter in front of him helps reduce the chance of early contamination of the catch mechanism. Traps are most effectively used; if the fat is heated more than water, then it will dissolve in it and float up.

Waste separation is sometimes performed by a physicochemical method. The bottom line is the use of special reagents capable of binding single particles into large collections. Such agglomerates can be easier to get out of the fluid with mechanical filters. But even during the besieging cleaning in special chambers or settling tanks, preliminary chemical treatment helps to improve the result. The flotation method involves the use of special compressors that supply air bubbles in the cleaning chamber.

Fats, in contact with air bubbles, form special films. Bubbles go up. This technique helps best with a significant heating of drains, in which the fat is almost dissolved.The mechanical technique consists in the use of special membranes with finely dispersed cells. The pace of work is too small, the filter is rapidly becoming polluted with a powerful influx of fats.

But the overall efficiency of fat extraction will be very high. The solution is suitable for filtering wastewater regardless of their temperature and degree of dissolution. The coalition approach relies on the ability of fats to contract into certain structures and stand up. The emulsified fat in the filter chamber, exposed to gravity and surface tension, is collected on the surface. At this point, mechanical devices (manual or automatic) can assemble it.

There is another approach - the use of centrifuges. Differences in the molecular mass of water and fats cause unequal moment of inertia. Therefore, when rotating in a centrifuge, various substances are separated. The body of any grease trap is sealed, but it can always be disassembled. The device is connected to the nozzle inlet and outlet.

The lid is removable or opening, it allows you to:

- maintain the system;

- remove fat;

- evaluate the performance of the system.

The hulls are divided into at least two segments that allow you to take the drains, filter them and deliver clean liquid to the sewer. Regardless of the design decision, mechanical filtration, intake apparatus and liquid level indicator are used. Manual collection of accumulated pollution is practical for a private house, where you still do not need high performance.

Plastic grease traps are used when you need to dispose of a small amount of waste, and therefore for domestic purposes they are ideal. Perfect environmental safety and ease of maintenance make it possible to avoid problems.

Molding and molding of plastics give a wide range of various forms. Fastening is made to the pipe itself (in a compact design). For the most efficient operation, stand-alone devices are well suited; they are easy and comfortable to use. In addition, in self-contained units the capacity of the dirt compartment is larger. Fiberglass products are similar to simple plastic in their structural diversity.

Susceptibility to all major reagents found in everyday life and in drains,fiberglass is very small. At ease, the special composition is not reflected, but the rigidity to mechanical damage is very great. Stainless steel grease traps are considered the most robust and stable, effectively resist chemical and physical destroyers. Such equipment is mainly in demand in the industrial sector, because it tolerates strong heat. The disadvantage is that it is impossible to make a steel fat trap with a streamlined contour or with a non-standard configuration; The fee for metal devices is higher than for other options.

There is another question - whether to choose a two-chamber or single-chamber septic tank. No such device is able to work on its own, additional cleaning in the ground is required. These are the indications of building codes and regulations adopted in the Russian Federation. Septic tanks perform mechanical cleaning of sediment, ferment the precipitate itself, make it mineral composition suitable for fertilizing farmland. The water will be accurately cleaned in the necessary way that in one, that in several chambers.

But the treatment of sediment is a more delicate matter.In a single section, sedimentation of a suspension occurs non-uniformly, closer to the entrance this process is more intensive. When the septic tank is divided into several sectors, it allows you to collect the key mass of the substance in the very first compartment. Then the clogging of water in subsequent parts will be eliminated and the cleaning process will be simplified. In addition, the environmental characteristics of the final flow will be the best.

The more sections, the more gentle will be the mode of operation of the filter well, the fields of underground filtration and cleaning trenches.

It is almost impossible to clean the soil filtering complexes, it is necessary to spend big money on their updating. That is why the increase in the complexity of the septic tank has a positive effect on the convenience and comfort of consumers. It is important to consider that the equipment of a septic tank with microbiological cleaning forces to use only detergents safe for microorganisms. In addition, at temperatures of 4 degrees and below, the activity of microbes is zero, and therefore the cleaning efficiency drops sharply.

When choosing the point where the treatment plant will be delivered, a number of sanitary restrictions must be taken into account.

- You can not bring them to 5 m to the bases of residential buildings.The gap to the foundations of non-residential buildings and their ground structures is at least 1 m.

- The distance to the well or its replacement well, drilled in clay soil, is at least 20 m. If the ground is composed of sandy rocks, this gap increases to 50 m.

- A septic tank can be approached to the road by at most 5 m, and at least 100 cm should remain before any kind of fence.

It is very important to prepare a place so that there could drive a car with a pump. Alternatively, it is practiced to equip the tank with a fecal pump. Extracted sludge can be used as a garden and garden fertilizer. The capacity of 150-200 liters per each occupant allows you to confidently use the bathrooms and toilets, washing machines, and wash dishes.

The gap from the cover to the sewage mirror should be the same as the depth of soil freezing. The entire settlement volume must be placed below this mark. The higher the temperature, the better the impurities will be processed by microbes. The geometric shape of the septic tank does not matter much; it is not reflected in the level of work efficiency and the quality of wastewater treatment in it.But there is another consideration - round equipment saves construction materials.

When using a brick, the rounded construction will help to use 10-15% less blocks. Rounding allows you to better transfer the load that occurs when the ground moves. It is advisable to make monolithic two-chamber systems in the form of a square or a rectangle. Such forms make it easy to get formwork where you need to pour concrete. Flood elements can be made with your own hands, and this is only slightly more expensive than simple brick elements.

When wooden boards are placed on both sides, the pits need to be made 0.4 - 0.5 m wider than the size of the tank (along with the walls). If you plan to pour the solution into the gaps in the soil and formwork, digging the pit is made according to the external dimensions of the septic tank. When calculating the cost of work, you must consider the fee for the export of recoverable land. Plane gain is quite possible to do. But the bulk reinforcing frames will be completely redundant for the septic tank, they only complicate the installation and increase the cost of it.

How to make your own hands septic tank in the country, see below.