Cross-linked polyethylene pipes: characteristics and features of operation

Modern developments in the production of materials allow us to expand the range of building products and products on the market. A similar trend concerns the manufacture of pipes for water supply. The most popular pipes today are made of cross-linked polyethylene.

Special features

Such material is obtained by polymerization. As a result of the processes occurring with ethylene molecules, they are combined with each other, due to which the density of raw materials and products produced from this type of polyethylene increases.

The specificity of the impact on the molecules of hydrogen and carbon, which are part of polyethylene, leads to the formation of new bonds at the molecular level.The process of formation of new compounds is called stitching. There are several options for working with the material, during which various substances are used. Based on this, the degree of crosslinking may also be different. Highlight the optimal value of crosslinking, ranging from 65 to 85%.

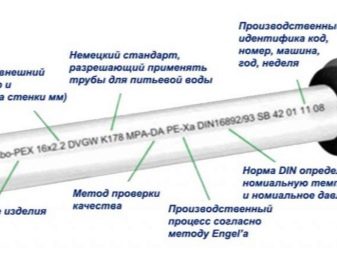

In addition to increasing the strength of raw materials due to the specifics of manufacturing, the resistance of the material to high temperatures increases, polyethylene becomes flexible and resistant to wear. The combination of these properties allows the material to take the original form after exposure to mechanical loads. Crosslinked polyethylene has a specific abbreviation - PEX. Accordingly, plumbing products from this raw material are called PEX-pipes.

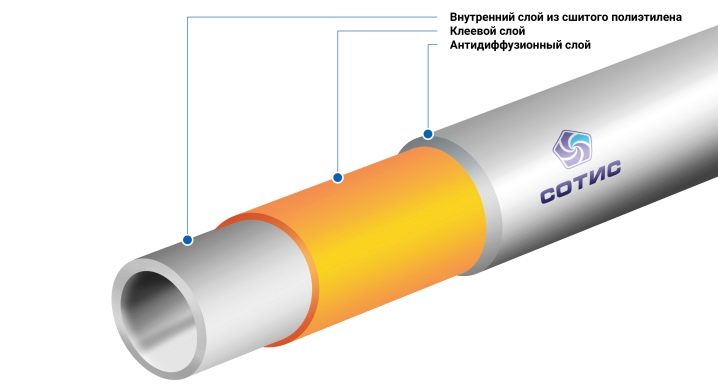

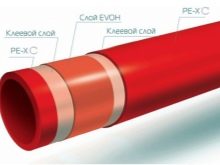

Products contain three layers:

- outside the pipe consists of an oxygen barrier;

- in the role of the inner layer is cross-linked polyethylene;

- fixing is carried out using an adhesive composition.

Some manufacturers produce products that consist of five layers. Another layer of glue and polyethylene is used as additional layers.

Pipes of cross-linked polyethylene are distinguished by high quality characteristics, which are several times higher than those of any polymer raw material.Such features allow them to be used as constituent elements not only of cold water supply, but also for arranging the system of heated floors and heating.

The main parameter, taking into account which, the selection of pipes takes place, is the method of material stitching. Since it depends on the number of connections, as well as the operational characteristics of the product. In addition, based on one or another option, a certain marking is assigned to the raw material stitching.

It is necessary to highlight the following methods of forming bonds in polyethylene:

- peroxide crosslinking - PEX-A;

- crosslinking using silane - PEX-B;

- radiation stitching - PEX-C;

- nitrogen - PEX-D.

During the manufacture of the material, the first method is to heat the raw material and introduce peroxides. The resulting level of density in this case has a maximum value of 70-75%. Technical characteristics of products produced using this method of stitching, make it possible to stand out among analogues. The only disadvantage of the product is the high cost, as well as the fact that during the use of PEX-pipes, the chemical substances are rather quickly washed out of the raw materials.

The release of PEX-B pipes includes two stages of work.First of all, organic silanides are introduced into the material, and then the products are hydrated. The density level of such stitching is 65%. Products have an affordable price, as well as high pressure. The disadvantages of such pipes, regardless of diameter and size, is their rigidity. This property prevents to bend a pipe if necessary.

The third group of products is made by exposing the material to electrons and gamma rays. The crosslinking rate in this case will be equal to 60%. In our country, such products are used very rarely, although the tubes have good molecular memory and flexibility.

PEX-D pipes are manufactured using nitrogen. They are distinguished by low quality indicators, and therefore are hardly used today.

Scope of application

The set of operational characteristics of pipes made of cross-linked polyethylene allows you to operate products in the following areas:

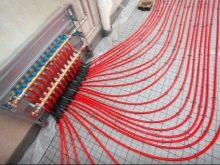

- laying of system of warm water floors;

- arrangement of heating communications;

- creation of cold and hot supply systems.

In industry, such products do not apply, since products having a large diameter will differ in high cost.

For warm floors such pipes are an ideal option, this is due to good thermal conductivity and minimal thermal expansion.

Products made of cross-linked polyethylene are recommended for supplying water of different temperatures due to their strength and resistance to external influences; moreover, flexible PEX-pipes are many times easier to install.

For arrangement of hot water supply systems based on the operational period and the maximum temperature of the liquid in the pipe, Products are classified as follows:

- products where the temperature does not exceed 60 С;

- for hot water with a temperature not exceeding 70 ° C;

- pipes for floor heating systems where low-temperature heating is used;

- to create high-temperature floor heating systems and heating structures.

Advantages and disadvantages

It is rather difficult to attribute pipes from cross-linked polyethylene to innovative products, but the available qualitative characteristics make it possible to distinguish a number of distinctive features of positive and negative character.

The advantages of the material should include some useful properties.

- Stability and preservation of characteristics even when exposed to high and low temperatures on raw materials. According to consumer reviews, the products are successfully operated at short-term temperatures down to -50 ° C or increasing to +120 ° C. In order for the material to begin to melt, the product must be heated to 150 ° C. from 0 С to +95 С.

- Resistance to pressure fluctuations inside. Products depending on the type can withstand from 4 to 10 atm.

- Good product flexibility.

- Resistance to wear due to the strength of raw materials.

- Long tube life. With proper installation and reasonable operation, products can effectively cope with the task for about half a century.

- The material is not susceptible to corrosion, the development of microorganisms, and is also resistant to contact with chemicals.

- The smoothness of the walls, in contrast to the walls of the corrugations, increases heat transfer, and also provides high hydraulic performance. Over time, these values remain at the same level, since no deposits of various kinds that interfere with the flow accumulate on the surface.

- Environmentally friendly material.Products are manufactured according to GOST and do not emit harmful substances.

- Elasticity of raw materials - in cases of freezing of liquid in the pipes, the product will not burst.

- Products perfectly restore their original shape after mechanical action, due to the molecular memory of the material.

- Cross-linked polyethylene absorbs noise well, which has a positive effect on comfort during the use of pipes.

- Minimum weight

- Simple installation, the pipes are very simple to connect and connect to the system.

The disadvantages of PEX pipes include the following characteristics:

- products do not tolerate exposure to sunlight;

- the anti-diffuse layer requires caution when transporting, it provides an oxygen barrier to the raw material, since contact with it will adversely affect the service life of the product;

- products are manufactured with a limited range of sizes, this applies to the diameter of PEX-pipes - most often the products have a diameter of 16 mm, 20 mm, 25 mm;

- liquid, which has a high level of mineralization, can contribute to the formation of deposits on the walls of pipes;

- fastening with an eyeliner of pipes from the sewed polyethylene, needs big efforts in comparison with water products from metalplastic.

Connection methods and installation

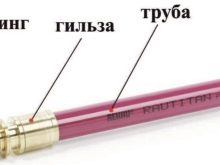

In addition to the acquisition of the pipes themselves, for the installation, you will need special connecting elements - fittings, as well as hand tools. In the course of the work it is very important not to deform the protective layer of the material. Competent and careful installation will extend the life of the pipe.

Therefore, some masters agree that the installation with their own hands should be carried out only with the appropriate experience, otherwise the work should be entrusted to professionals.

Extender and scissors are used to connect PEX-pipes. The compound is based on the molecular memory principle of the material. The scheme of works is as follows:

- the required pipe size is cut off;

- a ring-lock is put on the product;

- the extender head is pushed into the pipe and with rotational movements it stretches the pipe until the head completely penetrates into the interior of the product;

- after which the expander is removed, the pipe in an enlarged size is put on the fitting, and after a while it will take its original diameter, thereby securely gripping the nozzle.

Different types of fittings are used to connect pipes.

- Compression plastic products - they have a housing, a connecting and clamping ring, a clamping nut. The fitting is very easy to install on the pipe, it is enough to cut it at a right angle and put it on until it stops.

- Metal clamps - they are many times more durable than plastic ones, but they also have a higher cost. Fittings consist of the same parts and are put on the pipe in a similar manner. Products can be removed and reused.

- Press fittings consist of body and crimp coupling. Such elements provide the strongest fastening. In some cases, a crimping tool in the form of a press tong is used to work with them. Manual press is not always effective, therefore, when connecting a radiator or hot water supply, special equipment is used. And also it is necessary to involve in the installation of professional craftsmen.

- Pressure fittings - include the body and the press ring. Installation of such parts is simple, but also requires specialized equipment. This product is the most expensive compared to all the above elements.

It is strictly prohibited to glue, solder or weld pipes from cross-linked polyethylene.

Repair and service

Despite the fact that PEX pipes have proven to be products that are distinguished by a high level of reliability, they can still become unusable, as a result of which a number of restoration measures will be required.

Repair of pipes made of cross-linked polyethylene is reduced to dismantling a fragment of the water supply system that was damaged and replacing it with a new element. In the case when the spare pipe section is not available, and the work requires prompt action, there is a temporary method for eliminating the defect - coupling overlap. When choosing the second option, it is worth understanding that it can start to flow at any time.

If a leak occurs at the junction of the products, the question of replacing the fitting will arise. Such a breakdown may result from a displacement of the structure, or due to the poor quality of the seal.

If it is supposed to repair pipes from cross-linked polyethylene with a large diameter, then such work should be entrusted to professionals.

Maintenance of the plumbing system, which was provided with PEX-pipes, should be carried out regularly.If necessary, change the fittings, for which it is better to immediately purchase a set of elements for the whole structure.

Popular manufacturers

To reduce the risk of the need for a complete replacement of the pipeline within a short period of time after installation, the products for the systems should be purchased only from trusted manufacturers. Such companies provide a guarantee for their products, and also will not question their reputation and rating, realizing low-quality goods.

The following companies stand out in the domestic market for the manufacture and sale of PEX pipes.

- Rehau - German brand, offering high-quality products, represented by a large assortment of pipes made of cross-linked polyethylene, as well as a huge selection of various fittings for them. The products of this company belongs to the PEX-A group, products vary in color, as well as in the field of operation. The service life of pipes is about 50 years.

- Uponor (Germany) - the products of this company have a high level of flexibility and are universal, therefore it can be used for arranging pipelines of any type.

- "BIR-PEX" - offers Russian-made pipes of PEX-B class. Products are notable for low cost in combination with good quality characteristics. The release of products occurs on the English industrial equipment.

- Valtec - Italian brand that specializes in the manufacture of PEX-B pipes. Products are offered at an affordable price for the arrangement of underfloor heating systems, as well as hot and cold water supply, in addition, pipes can be used for radial heating.

- Rostherm Company offers the consumer PEX-B type universal pipes, as well as a wide range of fittings and various heating equipment.

In addition, products from Stout, Santex, and Sanline are in demand. Almost all manufacturers specify warranty periods for products that range from 20 to 50 years; however, when buying, it is worthwhile to carefully study the requirements that relate to the exploitation of the goods in order to protect themselves against breach of the conditions of warranty obligations.

See how to install KAN-therm Push pipes made of cross-linked polyethylene in the video below.