Features and installation of pipes made of cross-linked polyethylene for heating systems

The feeling of comfort in the house in all weather conditions outside the window is created thanks to the correct operation of the heating system. Its efficiency, quality and service life are directly dependent on the pipes. Today, the installation of the heating system is increasingly performed using pipes made of cross-linked polyethylene. The properties of this material allow him to surpass other options in many ways. However, when installing such pipes with your own hands, you need to know some of the nuances that will be discussed in this article.

Product Specifications

Pipes made of conventional polyethylene (PE) are widely used to create heating systems, water supply, sewerage.

There are several points to their main characteristics.

- The frost resistance allowing to use polyethylene designs at a temperature up to -20 degrees. This is a great advantage, since it makes it possible to carry out any work with pipes in the winter, including installing new equipment or repairing failed systems.

- Resistance to high temperature (up to 40 degrees).

- Flexibility that prevents pipes from deforming when bent.

- Plastic. Polyethylene products can expand or contract depending on temperature, without losing their shape.

In order to obtain higher strength pipes, a reliable and high temperature resistant material called cross-linked polyethylene (PEX) was created.

Its main feature is the maximum operating temperature - 90 degrees. Sometimes these pipes can withstand temperatures of 100-110 degrees, while maintaining normal operation for a certain time.

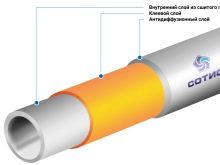

Another important feature of cross-linked polyethylene pipes is high oxygen permeability. When installing such products, you must be aware of this property and use aluminum foil or a special coating of polyvinyl ethylene to protect them.

Production methods

The technology of "stitching" of polyethylene in 1968 was invented by the Swedish chemist Thomas Engel. In 1972, one of the Swedish companies put it on the industrial stream. This technology and today leads the market.

The meaning of the process of "stitching" is to combine the molecules into a three-dimensional network as a result of cross-linking. In its course, polyethylene, the molecule of which contains atoms of hydrogen and carbon, loses a part of hydrogen. Therefore, free bonds appear to connect the molecular units with each other, as a result of which the molecules are tightly “stitched” together.

There are different ways to produce cross-linked polyethylene. The technical characteristics of the finished pipe depend on the method. The longest, but at the same time the most qualitative way, is the processing of polyethylene with peroxide. It gives the highest degree of crosslinking (85%). A pipe made of such material can easily withstand low and high temperatures, withstands the effects of chemicals, becomes resistant to shocks and other mechanical influences, and can restore its original shape.

Another method is the irradiation of a material with electrons in an electromagnetic field.Such stitching involves the irradiation of the finished product with electrons.

As a recommendation, we can note the fact that the values of pressure and temperature in the system should correspond to the threshold values of PEX pipes.

There is also a method of physical stitching, which uses x-rays. However, such structures are tough. They are not resistant to extreme cold and can not return to the previous form.

A common chemical method is silane crosslinking. It is more effective than physical. At the same time the polyethylene, optimum at the price and quality, suitable for use in life turns out.

Heat-resistant, strong material, pipes from which are perfectly suitable for the installation of heating systems of any type, hot and cold water supply systems, floor heating equipment is obtained as a result of each production method. One has only to choose the right characteristics, and also remember that the higher the degree of crosslinking, the higher the price of the material.

Merits

Pipes from the sewed polyethylene have a number of advantages, thanks to which they are most often used for the installation of heating systems.

- Resistance to high temperature (up to 95 degrees). Products made of cross-linked polyethylene are capable of expansion or contraction to certain sizes under the influence of low and high temperatures.

- Excellent mechanical strength due to good molecular memory of the material. It easily restores the original shape after deformation, unlike conventional polyethylene pipes.

- Corrosion Resistance. Products made of cross-linked polyethylene are not afraid of corrosion either inside or outside (unlike, for example, copper). This quality allows not to carry out the washing and cleaning of PEX pipes, which is periodically necessary for their metal “brothers” and has a rather high cost.

- Guarantee against the appearance of growths inside the pipes. Unlike steel pipes, which after some time become covered from inside by growths that slow down the flow rate, the internal walls of PEX pipes have a special Teflon coating and are not subject to the deposition of layers. Due to the smoothness of the internal walls in the heating system, there is always high hydraulics.

- Lightweight material. For example, 1 m of a pipe with a diameter of 16 mm weighs only 90 g.Therefore, they are convenient to transport and easy to install.

- Easy installation. PEX products can be mounted according to any scheme. They allow you to make loops and any number of bends. It does not require special welding equipment, as the pipes are connected without requiring soldering or gluing. Heating pipes are sold at 100 and 200 m, which makes it possible to install large parts of the system without using fittings.

- PEX products are ecologically safe and resistant to the reproduction inside them of harmful bacteria. The material belongs to the group of environmentally friendly, therefore it is widely used for drinking pipelines.

disadvantages

Despite the huge number of advantages, cross-linked polypropylene can not be called ideal.

It is necessary to take into account its shortcomings.

- Brass fittings used when connecting pipes made of cross-linked polyethylene for heating are subject to corrosion, so you have to pay close attention to the choice of materials for screed or plaster. It is better not to use materials that cause corrosion of the fitting, otherwise the quality of operation of the heating system will drop significantly.

- Tubes of cross-linked polyethylene "fear" of ultraviolet radiation.Therefore, they are more suitable for use in rooms, in closed systems and communications. To use such products outdoors, a special protective cover is required.

- The price of such pipes, in contrast to the cost of metal-plastic and ordinary polyethylene, is quite high.

Therefore, before purchasing pipes made of cross-linked polyethylene, it is necessary to carefully study all the technical characteristics of the heating and water supply system of the room in which they are to be installed.

Work process

If you need special knowledge and skills when mounting metal pipes, this is not required when installing cross-linked polyethylene pipes. For the quality of the work needed, only certain tools and a little effort.

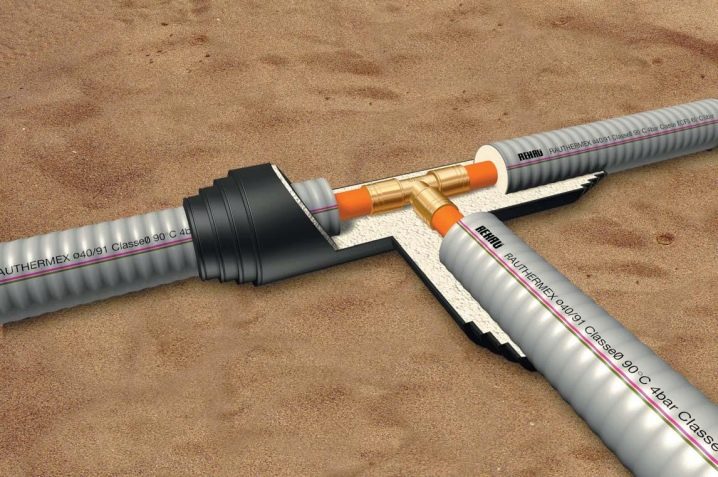

Pipes of cross-linked polyethylene are connected by fittings of various materials: polymers, brass, bronze. It is best to use polymer fittings (for example, Rehau), since they are high-quality, non-corrosive and last a long time.

In general terms, the installation process of PEX pipes is as follows:

- the end of the connecting structure is expanded with a flare tool, giving it a larger diameter;

- insert fittings there;

- using a press, the tension sleeve is pressed in, giving the greatest strength to the joint.

This technology makes pipe connections reliable and durable. The lifetime of such systems corresponds to the service life of the pipes themselves.

Reviews

Ease of installation, durability, reliability, environmental safety of structures made of cross-linked polyethylene are fully manifested in practice. Due to this, the products are widespread and popular with consumers. The material meets all the technical characteristics of modern premises and allows heating systems to work long and efficiently.

From the video below you can learn a lot of useful tips for connecting the heating on pipes of Rehau cross-linked polyethylene.